PRODUCT DEVELOPMENT AND BUSINESS MODEL PLAN

OF ANALOGUE RICE

ALDITH NATAKUSUMA

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY FACULTY OF AGRICULTURAL TECHNOLOGY

BOGOR AGRICULTURAL UNIVERSITY BOGOR

STATEMENT ON BACHELOR THESIS AND

SOURCES OF INFORMATION AND COPYRIGHT

DELEGATION*

I hereby state that all statements inside my bachelor thesis under the title :

Product Development and Business Model Plan of Analogue Rice is solely my own initiative or my own research under the supervision of the advisory committee, unless it is clearly stated. This bachelor thesis has never been presented to any institution or university to obtain certain achievement or degree in similar program. References of all data and information have been clearly stated and can be varified.

I hereby assign the copyright of my writings to the Bogor Agricultural University.

Bogor, 26 May 2014

ABSTRACT

ALDITH NATAKUSUMA. Product Development and Business Model Plan of Analogue Rice. Supervised by SLAMET BUDIJANTO

Analogue rice is an artificial rice made from other carbohydrate sources beside rice. Main purpose of this research was to formulate and plan business model for analogue rice industry. Analogue rice on this research was mainly made from sago starch with another complements, such as white corn flour, yellow corn flour, and cassava. Analogue rice produced was tested using hedonic test and found that cassava analogue rice was the best one to be developed industrially. Business model for analogue rice used business canvas, which parameters are customers relation, key partnership, key activities, key resources, value propositions, cost structure, revenue streams, channels, and customer segments. Business feasibility study showed that B/C of analogue rice was 1.0563; NPV Rp1 061 036 059; IRR 16.53%; payback period 8.82 years; and BEP was 510.17 kg output/day). It can be concluded that analogue rice industry was feasible economically.

Bachelor Thesis

Submitted as a fulfillment to obtain Food Science and Technology Bachelor Degree

in the Undergraduate program of Department of Food Science and Technology

PRODUCT DEVELOPMENT AND BUSINESS MODEL PLAN

OF ANALOGUE RICE

ALDITH NATAKUSUMA

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY FACULTY OF AGRICULTURAL TECHNOLOGY

BOGOR AGRICULTURAL UNIVERSITY BOGOR

Thesis Title : Product Development and Business Model Plan of Analogue Rice Name : Aldith Natakusuma

NIM : F24090089

Approved by

Prof Dr Ir Slamet Budijanto, MAgr Advisor

Acknowledged

Dr Ir Feri Kusnandar, Msc Head Departement

FOREWORD

Praise and gratitude author prayed to Jesus Christ Almighty over all His grace so that this scientific work is successfully completed. Author would like to thank his family, especially his parents and sister for their unending love, support, and encouragement. Author owe his deepest gratitude to his advisor, Prof. Dr. Ir. Slamet Budijanto, M.Agr, for all support, advice, patience, and guidance during the research. Special thanks to Mrs. Tintin Sarianti, and Mr. Faleh Setia Budi as examiners. Writer also thanked Larry Page and Sergey Brin who invented search engine which helped writer to finish this thesis. Writer also thanked to Gibran, Alay, Adly, Uset, Bayu, Wal, Ardy Brian (Acin), Ncen, Kyo, Farah, Satrya, Lina Adju, Yantel, Jodi, Sobich, Brian, Daniel, Agatha, Ryan Stevan, Kak Leo, Mba Fida, IAAS Family, Trina, and all of my friends who always support whatever I did.

TABLE OF CONTENT

TABLE OF CONTENT ix

TABLES LIST x

FIGURES LIST x

Introduction 1

Background 1

Research Purpose 2

Methods 2

Product Development 2

Determining Optimum Temperature 2

Determining the Best Formula 3

Generating Business Model 4

Result and Discussion 5

Determining Optimum Temperature and Best Formula 5

Proximate and Density Analysis 7

Business Model 7

Technical Aspect 7

Business Entity and License 10

Business Model Identification 11

Customer segments 11

Value Propositions 11

Channels 11

Customer Relationships 11

Revenue Streams 12

Key Resources 12

Key Activities 12

Key Partnerships 12

Cost Structure 12

Conclusion 14

Recommendation 15

Literature 15

TABLES LIST

1. Analogue rice formulation 2

2. Optimum temperature of each formula 5

3. Proximate and density analysis of cassava analogue rice 7

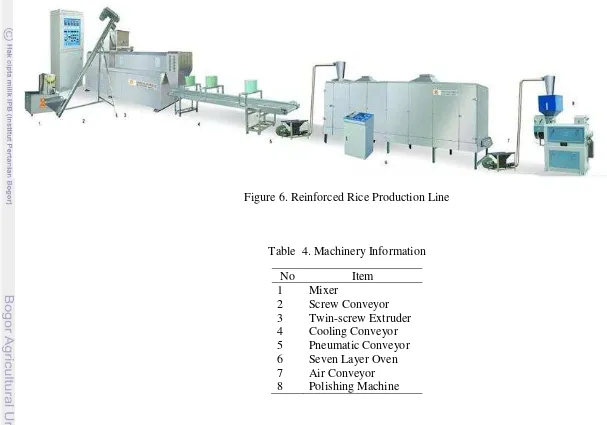

4. Machinery Information 9

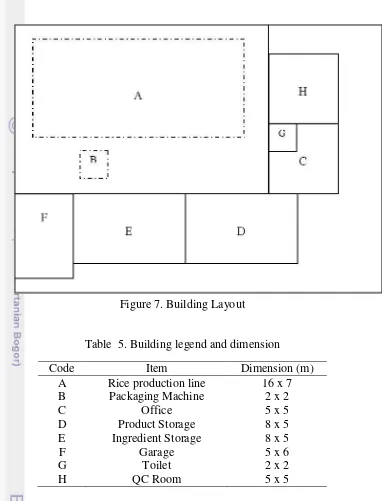

5. Building legend and dimension 10

6. Investment cost 13

7. Cost of production for 1 year 14

8. Financial aspects of analogue rice 14

FIGURES LIST

1. Flow chart of analogue rice production 3

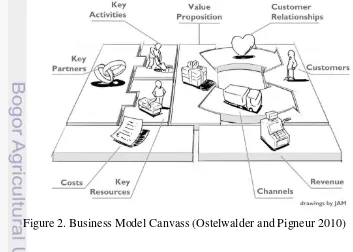

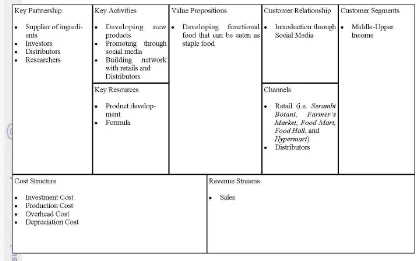

2. Business Model Canvass (Animated) 4

3. Result of Analogue Rice 5

4. Hedonic Rate Score of Uncooked Analogue Rice 6

5. Hedonic Rate Score of Cooked Analogue Rice 7

6. Reinforced Rice Production Line 9

7. Building Layout 10

8. Business Model Canvas 13

APPENDICES LIST

1. List of documents needed to apply for PT license 18 2. List of documents gained after PT registration 18

3. List of documents needed to apply for IUI 18

4. Reinforced Rice Production Line (200 kg/hr) 19

5. Packaging Machine Specification 20

6. Assumptions 21

7. Investment cost 22

8. Overhead cost 24

9. Variable cost 24

10. Depreciation cost 25

11. Profit/Loss 27

12. Reinvestment 29

13. Salvage Value 30

14. Business feasibility 31

Introduction Background

Ministry of Agriculture recently conducted strategic plan to solve food safety and security issue. One of the critical issue was to reduce rice consumption in Indonesia and promote food diversity consumption. Several researches and acts have been conducted to overcome food safety and security issue, such as promoted indigenous food and ministerial regulation regarding food diversity. Ministry of agriculture also supported funding for UKM (Small and Medium Enterprises) in Indonesia to run diversity of food consumption program (Ministry of Agriculture, 2010). Changing people practice in consuming something is not easy. It is easier to turn carbohydrate sources in Indonesia into rice by applying science and technology. Rice consumption in Indonesia is massive since it is Indonesians’ staple food, while on the other hand this country is rich of other carbohydrate sources. Several resources which are very potential to be consumed nationally as main source of carbohydrate are sago starch, white corn flour, yellow corn flour, and cassava. Sago plantation in Indonesia is the biggest in the world totaled 1.12 million hectares, equal to 51.3% of total sago plantation in the world (Suswono 2010). As a potential carbohydrate source, sago has not been consumed nationally as much as rice. Sago has been consuming commonly at rural area at Papua and Maluku (Ariani 2010).

Besides sago, Indonesia also produced 18.5 million tons of yellow corn and 25.5 million tons of cassava (Statistics Indonesia 2013). There is white corn variety which is being developed by Ministry of Agriculture as food. Several area in Indonesia already consumed white corn as main carbohydrate intake such as NTT and Gorontalo (Ministry of Agriculture 2013). These carbohydrate sources have not been utilized optimally as daily carbohydrate intake on national scale, because Indonesians used to eat rice every time they eat. Besides availability, sago has low glycemic index 28(Haliza in Alfons 2011) which is lower than rice, ranged between 34-74(Indrasari et al. 2013). One of the most promising solution to support food diversification is converting sago starch into analogue rice which is very promising to support government plan on food diversity issue.

Analogue rice is rice imitation, made from another flours besides rice (Budijanto et al. 2011). Several researches regarding analogue rice have been done. Research about artificial rice (Kurachi 1995), rice substitute based on soybean (Kato 2006), sorghum-based analogue rice (Budijanto and Yuliyanti 2012). Analogue rice can be processed through several methods, but one of the most promising one to develop it as commercial product is hot extrusion (Mishra

et al. 2012). Hot extrusion can be done by using double screw extruder or single

screw extruder.

Problem Formulation

formula. The business model was constructed for the best formula after it had been chosen.

Research Purpose

To formulate analogue rice based on selected carbohydrate sources (Sago, white corn, yellow corn, and cassava) and plan business model for the best formula of analogue rice.

Methods

Method for this research was differentiated into two parts; product development and business model plan.

Product Development

Product formulation was done to obtain the best formula for generating business model and done in several steps. First was determining best temperature for each formulations, second was sensory evaluation, and the last was nutrition and density analysis for the best formula.

Determining Optimum Temperature

There were 3 potential formulations to be developed as analogue rice, showed on table 1.

Table 1. Analogue rice formulation Formulation of sago starch + other carbohydrate +cassava fiber

Temperature used for processing each formula was different because carbohydrates have its own gelatinization temperature. Gelatinization temperature of sago starch was varied between 69.4 – 70.10 C (Ahmad et al 1999). Gelatinization temperature of white corn starch was, 62-740C (Aini and Hariyadi 2010), yellow corn starch on extruder was 950C (Kokic et al. 2013), and gelatinization temperature of cassava was 68-710C (Uchendu et al. 2013).

Determining the Best Formula

Best formula was determined by sensory evaluation. Analogue rice was tested using hedonic rate test by 30 untrained panelists (BSN 2006). The attributes that tested on the uncooked rice were only color, form, and overall. Meanwhile on the cooked rice, the attributes tested were color, odor, form, texture, taste, and overall. Scoring was scaled between 1 (dislike most) to 7 (like most). Data was tested using univariate all two way analysis using one way Analysis of Variance (ANOVA). If there was a real difference on 95% scale, Duncan’s Multiple Test

was done as the advanced test. Water content of best formula also tested to determine as product specification.

Generating Business Model

Market for analogue rice was promising, especially if targeted niche market. Food diversification program is hard yet possible. Targeting niche market who really needs this product is the first step to start food diversification program in Indonesia. One of the most potential market is diabetics. As a diabetics, they still need carbohydrate source, but the glycemic index must be kept as low as possible. Cassava has low GI 41(Anonim, 2014) and sago 28 (Haliza in Alfons 2011), which considered as a food with low glycemic index. In this research,

cassava analogue rice has a very potency to be developed as ‘rice’ for diabetics.

Technical and legal aspect should be done before business model is developed. Technical aspects consist of location, ingredients, production area, technology, production process, and building layout. Legal aspect consist of business entity, business license, and building permits (Nurmalina et al. 2010). Business model is a new concept to plan a business which is different with business plan. On business plan, there are unchecked hypotheses and hard to be changed. There are also hypotheses on business model, but they are easily

changed. Hypotheses were written on a ‘canvas’ and if there is unmatched

hypothesis , both business owner and investor can easily adjust it. Therefore, analogue rice business would use business canvas to generate its business model (Osterwalder and Pigneur 2010). Components for business canvass are customer segments, value propositions, channels, customer relationships, revenue streams, key resources, key activities, key partnership, and cost structure. Cost structure consists of investment cost, production cost, and overhead cost. Business canvass points out the important things and explains the whole business in one picture as shown in figure 2.

To determine economic feasibility, parameters used were Net Present Value (NPV), Internal Rate Return (IRR), Payback Period, Break Event Point (BEP), and Net Benefit Cost Ratio (Net B/C) (Nurmalina et al. 2010). IRR is a rate of return used in capital budgeting to measure and compare the profitability of investments. NPV is a time series of cash flows, both incoming and outgoing, is defined as the sum of the present values (PVs) of the individual cash flows of the same entity. Net B/C ratio shows how much profit generate per capital expenditure. Payback period is the time needed get back the initial investment. BEP is the point of balance between making either a profit or a loss (Nurmalina et al. 2010).

Result and Discussion

Determining Optimum Temperature and Best Formula

Determining optimum temperature is depended on gelatinization temperature of starches used which varied widely depending on starch sources. If the temperature was too low, analogue rice would be crumbly and turned into paste when cooked. If the temperature was too high, analogue rice would be colored blackish or too dark. After several trials, optimum temperature for each formulation is shown on Table 2 and rice produced, both uncooked and cooked is showed on Figure 2.

Top: uncooked analogue rice; a=yellow corn, b=white corn, c=cassava Bottom: cooked analogue rice; d=yellow corn, b=white corn, c=cassava

Figure 3. Result of Analogue Rice

Table 2. Optimum temperature of each formula

F1 = yellow corn analogue rice, F2= cassava analogue rice, F3= white corn analogue rice.

Formula Temperature

T1 T2 T3

F1 95 95 85

F2 85 85 75

Best formula was tested using hedonic rate test by 30 panelists for both uncooked and cooked analogue rice. Figure 3 showed sensory acceptance for uncooked rice. Shape of all uncooked rice was not significantly different among samples. Color of the uncooked rice showed that yellow corn analogue rice had the lowest score in average, significantly different with white corn analogue rice and cassava analogue rice. Overall acceptance of uncooked yellow corn analogue rice was the lowest and significantly different with others. These condition for both color and overall of uncooked analogue rice can be explained by natural

rice’s color. Naturally, rice’s color is white, meanwhile yellow corn analogue rice

colored in yellow. This condition might lead yellow corn analogue rice has the lowest color and overall acceptance among other formulas.

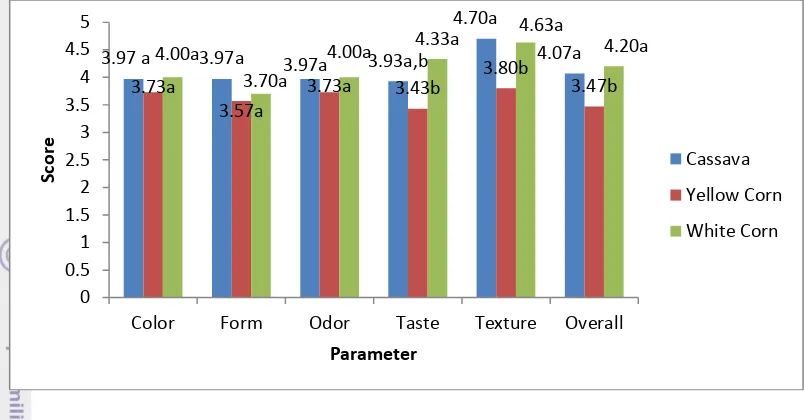

Figure 4. Hedonic Rate Score of Uncooked Analogue Rice a= not significantly different, b=significantly different

Cooked analogue rice hedonic rate test was based on color, form. odor, taste, texture, and overall. There was no significant difference for odor, form, and color among samples. They were significantly different on taste, texture, and overall. Taste score of yellow corn analogue rice was the lowest and different significantly with white corn analogue rice and not different significantly with cassava analogue rice. Texture of yellow corn analogue rice was different significantly with white corn analogue rice and cassava analogue rice. Overall acceptance showed that yellow corn analogue rice different significantly with white corn analogue rice and cassava analogue rice. Results of hedonic rate test can be seen on figure 4 for each parameter.

a= not significantly different, b=significantly different Figure 5. Hedonic Rate Score of Cooked Analogue Rice

Proximate and Density Analysis

Best formula, cassava analogue rice was analyzed to identify its nutrient content and density and shown on Table 3. Density of rice was used to determine size of packaging. Each pack will be contained 5 kg or analogue rice. Packaging material used is polyethylene (PE) and sized 30 x 45 cm. Water content was used as the specification of product to keep it save from spoilage. This product has lower water content than standard rice that set by Bulog, 14% (Bulog 2014).

Table 3. Proximate and density analysis of cassava analogue rice

Parameter Amount product in the establishing stage, a 1 ton production of analogue rice per month is very possible to establish and sell this product for diabetics.

Technical Aspect

The factory of analogue rice will be located in Sentul industrial area (Bogor, Indonesia). Building a factory inside industrial area has some beneficial effect

3.97 a 3.97a 3.97a 3.93a,b

Color Form Odor Taste Texture Overall

such as no need of environmental analysis effect, waste water treatment plant, and building permit (IMB). Ingredients used to produce this analogue rice are cassava starch, sago starch, cassava fiber, GMS, jelly powder, palm oil, and water. There is a difference between the real production and preliminary research ingredient. It is cassava. For economical reason and continuous supply, cassava starch is preferred to fresh cassava. Source of each ingredients is shown in appendix 15. To produce 1 ton of analogue rice per day, ingredients needed are cassava fiber 50 kg, sago starch 800 kg, cassava starch 150 kg, GMS 20 kg, palm oil 20 liter, water 0.5 m3, and jelly powder 1 kg. In this location, electricity, communication, and water piping already existed and developed for industrial function. Total cost to produce analogue rice in a year can be seen on appendix 9.

There will be 6 rooms within the industry site; production room, office room, ingredients storage, product storage, garage, and toilet. Each room size is shown on Table 4 and building layout is shown in Figure 4. Total building area is 376 m2 and land area is 26 m x 19 m (494 m2).

Figure 6. Reinforced Rice Production Line

Table 4. Machinery Information

No Item

1 Mixer

2 Screw Conveyor 3 Twin-screw Extruder 4 Cooling Conveyor 5 Pneumatic Conveyor 6 Seven Layer Oven 7 Air Conveyor 8 Polishing Machine

Figure 7. Building Layout

Table 5. Building legend and dimension

Code Item Dimension (m)

A Rice production line 16 x 7

B Packaging Machine 2 x 2

C Office 5 x 5

D Product Storage 8 x 5

E Ingredient Storage 8 x 5

F Garage 5 x 6

G Toilet 2 x 2

H QC Room 5 x 5

Business Entity and License

Starting production, BPOM registration is a must, where HACCP and Halal are voluntary. GMP (Good Manufacturing Practice) will be needed for BPOM certification. GMP created by company itself will be audited by BPOM auditor as prerequisite for BPOM certification. BPOM certification is compulsory for medium food industry to ensure food safety and quality to customers (BPOM, 2013).

Business Model Identification

Business model on this research was explained using business model canvass. Main fields explained on business model canvass were customers, offers, infrastructure, and cost structure. Contents of business canvass itself was customer segments, value propositions, channels, customer relationships, revenue streams, key resources, key activities, key partnership, and cost structure (Osterwalder and Pigneur, 2010). possible, especially diabetics are forbidding to eat rice, and cassava analogue rice can fulfill their desire to eat rice. This product, in the future, is going to be

developed as a ‘vehicle’ for functional ingredients. Middle-upper segment concern more about food for health. They are mostly willing to pay extra price for food that combine appetite and health effects.

Value Propositions

Value proposition is the reason why this company differ from others. Value proposition for analogue rice is functional food that can be eaten as staple food. First step of functional properties if this product is its low GI so that diabetics can eat this product. in the future, this product is very promising to be

developed as ‘vehicle’ for other functional ingredients.

Channels

Communication, distribution, and sales channels are the ways of company to interact with potential customers. Distribution channel for analogue rice can be divided into two segments. They are direct and indirect selling. Direct selling targeting high-end supermarket like Serambi Botani, Farmer’s Market, Food

Mart, Food Hall, and Hypermart are very promising as selling place. Indirect

selling is done by partnering with distributors. Relationship with distributors must be built to ensure this product is available everywhere in Indonesia.

Customer Relationships

Revenue Streams

Main revenue of this company is product sales. Revenue streams for analogue rice comes from selling the product. Within one year, estimated product sales is 261 ton and sold at Rp 12,600/kg. So that, within 1 year, this company can generate revenue Rp 3,288,600,000.

Key Resources

Key resources allow an enterprise to create and offer value propositions, reach markets, maintain relationship with customer, and generate revenue. Key resources can be physical, intellectual, human, and financial. Key resources for this business are product development and formula of each product. Formula of each product is must be kept secretly to ensure investors that no other companies will be able to produce the same product illegally. In the future, addition of functional ingredients are very promising to develop this product as functional food.

Key Activities

As an enterprise, a lot activities should be done to ensure that business is running well. Among those activities, there will be key activities which play important roles to grow and run the business in the future. As a new enterprise which sells new product, analogue rice, building network with local and national retails is very important. Promotion in social media is needed to introduce this product to customers. Product development is also important to reduce its production cost and formulate new products with functional ingredients.

Key Partnerships

Partnerships are becoming a cornerstone for many business models. Companies create alliances to optimize and maximize their business model. Key partners for this enterprise will be suppliers of ingredients, distributors, investors, and researchers. Suppliers of ingredients are ensuring production availability. The suppliers selected were based on availability, economic efficiency, and portfolio of the suppliers. Produced products need strong wide distribution chain. This enterprise will not focus on distribution, so that distributors are needed. Advantage of developing partnership with distributors is: they already have distribution channel widely. Researchers are needed to synchronize between product development, functional ingredients, and how to put these ingredients into analogue rice. Partners for analogue rice production is can be seen in appendix 15. Cost Structure

Figure 8. Business Model Canvas (Osterwalder and Pigneur, 2010)

Initial investment needed to build cassava analogue rice factory is for building, equipments, and licenses. Main equipment for producing analogue rice is reinforced rice production line which is ordered from Jinan Saibainuo Technology Development Co., Ltd, China. Sentul industrial area is selected and cost for building is obtained from direct correspondent with architect. Summary for investment cost is shown on table 5, and detailed investment cost is shown on appendix 10.

Table 6. Investment cost

Item Total

Equipments Rp1 086 237 000

Building Rp1 730 400 000

Licenses Rp26 680 000

Others Rp53 957 000

Total Rp2 897 274 000

The cost for analogue rice production is divided into three parts, variable cost, overhead cost, and depreciation cost. On the variable cost, cassava fiber, sago starch, cassava starch, GMS, packaging, palm oil, and jelly powder are obtained from distributors and producers directly.

Table 7. Cost of production for 1 year

Component Cost

Overhead Cost Rp482 927 602 Variable Cost Rp2 073 449 250 Depreciation Cost Rp137 007 000 Total Cost Rp2 693 383 852

Total output was not same with input because there will be defect. From production line, total yield is assumed 65% due to drying and loss. Therefore, from 1.541 ton of ingredient, total output is 1000 kg for each day production. Constructing business feasibility need some assumptions, so that analogue rice can be determined its economical feasibility. Main assumptions used were: In one year (261 working days) there will be 261 ton of analogue rice produced. Price of production for each kg is Rp 10 319.48. Price of production is obtained from total cost (Table 6) divided by total analogue rice produced per year. Economical age of this business was 10 years. Total workers are 7 people, where 4 people responsible for production, 1 manager, 1 QC staff, and 1 purchasing staff. Detailed information about the assumptions used is shown on appendix 6. Financial aspects observed for business feasibility are IRR, NPV, and B/C ratio. These number were obtained from appendices 7-14.

There were assumptions used to calculate financial aspects of analogue rice and they were shown on appendix 6. Based on calculation, this company could generate net profit Rp520 814 129 per year. Indicators of feasible business are: IRR > Discount rate; NPV (+), and B/C ratio is >1. IRR >Discount rate means that this business has 0 NPV when discount rate is 16.53% (more that Discount rate itself, 10.25%). NPV (+) means that this business could generate profit on its financial age. Benefit/cost ratio >1 means every 1 resources spent, it could generate profit because the output is bigger than the resource itself. BEP is the minimum production needed to balance the financial condition of this company. Financial aspects of analogue rice is shown on table 8.

Table 8. Financial aspects of analogue rice

Parameter Value

NPV Rp1 061 036 059

Benefit/Cost Ratio 1.0563

IRR 16.53%

Payback period (Year) 8.82

BEP (kg output/day) 510.17

Conclusion

analogue rice was T1 = 850C, T2 = 850C, T3 = 750C. Uncooked cassava analogue rice overall acceptance and color were significantly different from yellow corn analogue rice and not significantly different with white corn analogue rice. Texture and overall parameter of cassava analogue rice were significantly different with yellow corn analogue rice and not significantly different from white corn analogue rice. Business feasibility of cassava analogue rice was fulfill each parameters where IRR was 16.53% (more than discount rate) ; Rp1 061 036 059 (+); and B/C ratio was 1.0563 (>1). Payback period of analogue rice industry was 8.82 years, and its break event point is 510.17 kg of output per day. It can be concluded that analogue rice business is feasible economically.

Recommendation

Business canvass of cassava analogue rice can be tested after investors were found. For the first time, this business can focus on introduction to customers, especially middle-upper segment. In the future, analogue rice is also

promising to be developed as a ‘vehicle’ for specific consumer, i.e. diabetic and

anti-cancer. In vitro experiment also needed to obtain the real GI of cassava analogue rice in this research. Further research is needed to develop this product and also market research should be conducted.

Literature

Alfons, JB, Rivaie AA. 2011. Sagu Mendukukng Ketahanan Pangan dalam Menghadapi Dampak Perubahan Iklim. Perspektif. 10(2) 81-91.

Anonim. 2014. Raw Cassava [internet]. [reffered 15 April 2014] Available at http://nutritiondata.self.com/facts/vegetables-and-vegetable-products/2389/2. Ahmad, Fasihuddin B., Peter A. Williams, Jealn-Louis Doublier, Sylvie Durand,

Alain Buleon. 1999. Physico-Chemical Characterisation of Sago Starch. J. carbohydrate Polymers 38: 361-370.

Aini, Nur and Purwiyatno hariyadi. Gelatinization Properties of White Maize Starch from Three Varieties of Corn Subject to Oxidized and Acetylated-oxidized Modification. J. International Food Research Journal 17: 961-968. [AOAC] Association of Analytical Communities. 2007. Official Method of

Analysis. Washington DC (US).

[BCA] Bank Central Asia. 2014. Prime Lending Rate [internet]. [reffered 10 March 2014] Available at http://www.bca.co.id/id/biaya-limit/sbdk/sbdk_landing.jsp.

[BAPEPAM] Financial Institutions Supervisory Agency. 2013. Undang – Undang Republik Indonesia Nomor 40 Tahun 2007 tentang Perseroan Terbatas [internet]. [reffered 20 January 2014]. Available at http://aria.bapepam.go.id/reksadana/files/regulasi/UU%2040%202007%20Pers eroan%20Terbatas.pdf

[BPOM] The National Agency of Drug and Food Control. 2013. BPOM e-registration [internet]. [reffered 15 January 2014]. Available at Source: http://e-reg.pom.go.id/#

[BPS] Statistics Indonesia . 2013. Food Crops Production [internet]. [reffered 12 january 2014]. Available at http://www.bps.go.id/eng/tnmn_pgn.php?kat=3

[BSN] National Standardization Agency of Indonesia. 2006. SNI 01-2346-2006 : petunjuk pengujian organoleptik dan atau sensori.

[Bulog] Badan Usaha Logistik. 2014. Alur Pengadaan [Internet]. [reffered 14 April 2014]. Available at http://www.bulog.co.id/alurada_v2.php.

Ariani, Mewa. 2010. Diversifikasi Konsumsi Pangan Poko Mendukung Swasembada Beras. Proceeding. Pekan Serealia Nasional 2010.

Budijanto S, Yuliyanti. 2012. Studi persiapan tepung sorgum (Sorghum bicolor L. Moench) dan aplikasinya pada pembuatan beras analog. J Tekno Pert 13(3): 177-186.

Budijanto S, et al. 2011. Pengembang rantai nilai serelalia lokal (indegenous sereal) untuk memperkokoh ketahanan pangan nasional. [Report of Strategic Research Program]. Bogor: Faculty of Agricultural Engineering, Bogor Agricultural University

Directorate General of Taxes. 2013. Hak dan Kewajiban Wajib Pajak [internet].

[reffered 12 March 2014]. Available at

http://www.pajak.go.id/sites/default/files/HKWP-Bab2_0.pdf

Indrasari, Siti Dewi et al. 2013. Nilai Indeks Glikemik Beras Beberapa Varietas Padi. Penelitian Pertanian Tanaman Pangan Vol. 27 no. 3 2008.

Kato K, founder. April 6th 2006. Soy-based rice substitute. United States Patent ID 11233906.

Kokic, Bojana M., Jovanka D. Levic, Maria Chrenkova, Zuzana Fermelova, Maria Placikova, Matus Rajsky, Rade D. Jovanovic. 2013. Influence of Thermal Treatments on Starch Gelatinization and in Vitro Organic Matter Digestibility of Corn. J. Journal of Food and Feed Research 40 (2) 93-99

Kurachi H, founder; Japan Corn Starch co.,Ltd. 4th April 1995. Process of making enriched artificial rice. United States Patent ID 5403606.

Ministry of Agriculture. 2010. Revisi Rencana Strategis Badan Ketahanan Pangan Tahun 2010-2014 [internet]. [reffered 21 January 2014]. Available at http://bkp.deptan.go.id/tinymcpuk/gambar/file/Renstra_BKP.pdf

Ministry of Agriculture. 2013. Jagung Putih untuk Diversifikasi Pangan. Ministry of Agriculture.

Mishra A, Hari NM, Pavuluri SR. 2012. Preparation of Analogue rices Using Extrusion Technology. J. Journal of Food Science Technology 47:1789-1797. Nurmalina R, Titin Sarianti , Arif Karyadi . 2011. Studi Kelayakan Bisnis. Bogor:

Departemen Agribisnis FEM-IPB.

[One Window Service]. 2013. Layanan Mendapatkan Izin Usaha [Internet].

[reffered 15 January 2014]. Available at

http://www.satulayanan.net/layanan/mendapatkan-izin-usaha-industri/prosedur-pembuatan.

[Novo Nordisk]. 2013. The Blue Print of Change Programme [Internet]. [reffered

14 April 2014] Available at

Osterwalder, Alexander and Yves Pigneur. 2010. Business Model Generation. USA: John Wiley & Sons, Inc.

Suswono. 2010. Percepatan Diversifikasi Pangan. Proceeding. Seminar Nasional Lokakarya Sagu. Bogor, October 14 2010.

Uchendu, Nene O., Eze, O.O. Sabinus, Okechukwu Ugwu, Enechi O.C, Slysvester M.C. Udeh. 2013. Characterization of ifferent Varieties of Cassava Starch for Industrial Utilization. J. International Journal of Research and Reviews in Pharmacy and Applied Science 3 (3) 370-386.

APPENDICES

Appendix 1. List of documents needed to apply for PT license Item

Copy of ID card of founders (minimum 2 people) Copy of CEO's NPWP

Photo of CEO 3x4 2 pcs (colored) Name of Company

http://aria.bapepam.go.id/reksadana/files/regulasi/UU%2040%202007%20Persero an%20Terbatas.pdf

Appendix 2. List of documents gained after PT registration Item

Endorsment certificate issued by ministry of law SIUP

TDP BNRI

http://aria.bapepam.go.id/reksadana/files/regulasi/UU%2040%202007%20Persero an%20Terbatas.pdf

Appendix 3. List of documents needed to apply for IUI Item

Application form for IUI

Appendix 4. Reinforced Rice Production Line (200 kg/hr)

Component Detail Picture

Appendix 5. Packaging Machine Specification

Type : WP – AW5

Filling System : Digital Weighing System Volume : 1,00-5,000 gr

Accuracy : +0.5-2%

Packing Speed : 500 – 700 bags/hour

Electric Power : 3,500 watt, 220/380 V, 50 Hz

Appendix 6. Assumptions

Assumption 1. Each day, total material processes 1,541 kg. 2. Product lost is 35.11% due to drying and defect.

3. On the first year, product sales is 80% of total production due to trial and error.

4. Discount rate is 10.25% (Bank Central Asia, 2014). 5. Ingredients price is stagnant year to year.

6. Selling price of analogue rice is Rp 63.000/ pack. 7. The weight of each pack analogue rice is 5 kg. 8. Labor cost is Rp 2,500,000 per month.

9. Manager cost is Rp 3,500,000 per month

10.Tax is 12.5% of profit (Directorate General of Taxes, 2014). 11.1 USD = Rp 12,500.

12.Selling price of analogue rice is stagnant.

13.Number of analogue rice production per year is stagnant. 14.Payback period is based on NPV.

15.There is reinvestment on every year for trademark license and on the sixth year, there is another reinvestment.

Appendix 7. Investment cost

Item Quantity Unit Price/unit Total

Equipments

Reinforced rice production line 1 set $38 500.00 Rp481 250 000

Conveyor belt 3 set $800.00 Rp30 000 000

Warehouse Storage Steel Trolley 2 unit $41 Rp1 025 000

Freight production line + Conveyor Belt 67.5 m3 $50.00 Rp42 187 500 Insurance (5% of total cargo price) 1 unit $1 965.00 Rp24 562 500 Import tax and Local transportation 1 unit Rp120 000 000 Rp120 000 000

Freight Packaging Machine 1 unit Rp4 000 000 Rp4 000 000

Digital scale 3 kg 1 unit Rp999 000 Rp999 000

Digital scale 50 kg 1 unit Rp1 700 000 Rp1 700 000

Measuring Cylinder Pyrex 1 liter 10 unit Rp454 000 Rp4 540 000

Small Saucepan 2 liter 10 unit Rp235 000 Rp2 350 000

Rice Storage 1 unit Rp3 000 000 Rp3 000 000

Packaging machine 1 set Rp165 000 000 Rp165 000 000

Stainless Steel Pot Capacity 50 liter 10 unit Rp579 500 Rp5 795 000

Hyno truck 110 SL 1 unit Rp186 300 000 Rp186 300 000

Samsung AC split 3/4 pk 1 unit Rp4 659 000 Rp4 659 000

Computer 1 set Rp5 000 000 Rp5 000 000

HP Deskjet 1050 All-in-One 1 unit Rp619 000 Rp619 000

Office Desk + Table 1 set Rp1 000 000 Rp1 000 000

Fax Machine Panasonic KX-FT981 1 unit Rp1 050 000 Rp1 050 000

Digital Scale 100 gram 1 unit Rp700 000 Rp700 000

Sub Total Rp1 086 237 000

Building

Land 494 m2 Rp1 600 000 Rp790 400 000

Building 376 m2 Rp2 500 000 Rp940 000 000

Sub Total Rp1 730 400 000

Licenses

Trademark License 1 unit Rp600 000 Rp600 000

BPOM Registration 1 unit Rp3 000 000 Rp3 000 000

BPOM Analytical 4 unit Rp1 820 000 Rp7 280 000

GMP registration 1 unit Rp5 000 000 Rp5 000 000

PT License 1 unit Rp10 800 000 Rp10 800 000

Sub Total Rp26 680 000

Others

Wall hung basin kris wht jd0018 1 unit Rp525 000 Rp525 000

Basin tap kris CHR 19001KS-E5 1 unit Rp439 000 Rp439 000

Toilet kris siphon one piece wht 1 unit Rp925 000 Rp925 000

Exhaust fan KDK 40 AAS 6 unit Rp553 000 Rp3 318 000

Installment Cost 3 person $1 300 Rp48 750 000

Sub Total Rp53 957 000

Total Rp2 897 274 000

Appendix 8. Overhead cost

Component Quantity Unit Price/unit Total/year

Electricity 801.76 kWh/day Rp972 Rp194 827 602

Labor 6 People/month Rp2 500 000 Rp180 000 000

Manager 1 People/month Rp35 000 000 Rp35 000 000

Solar 200 litre/month Rp5 500 Rp13 200 000

Telephone and internet 1 unit/month Rp250 000 Rp3 000 000

Stationary 1 set/month Rp50 000 Rp600 000

Marketing and Promotion 1 unit Rp50 000 000 Rp50 000 000

Water 30 m3/month 17500 Rp6 300 000

Total Rp482 927 602

Appendix 9. Variable cost

Item Quantity Unit Price/unit Total/year

Cassava fiber 13050 kg Rp 1 250 Rp 16 312 500

Sago starch 208800 kg Rp 7 600 Rp 1 586 880 000

Cassava starch 39150 kg Rp 5 000 Rp 195 750 000

GMS 5220 kg Rp 30 500 Rp 159 210 000

Palm oil 5220 liter Rp 10 000 Rp 52 200 000

Water 130.5 m3 Rp 17 500 Rp 2 283 750

Packaging 52200 pack Rp 750 Rp 39 150 000

Jelly Powder 261 kg Rp 83 000 Rp 21 663 000

25

Appendix 10. Depreciation cost

Item Quantity Unit Price/unit Total

Economical Age (year)

Depreciation Cost/Year Production Room

Reinforced rice production line 1 set $38 500.00 Rp481 250 000 10 Rp48 125 000

Conveyor belt 3 set $800.00 Rp30 000 000 10 Rp3 000 000

Warehouse Storage Steel Trolley 2 unit $41 Rp1 025 000 5 Rp205 000

Digital scale 3 kg 1 unit Rp999 000 Rp999 000 5 Rp199 800

Digital scale 50 kg 1 unit Rp1 700 000 Rp1 700 000 5 Rp340 000

Measuring Cylinder Pyrex 1 liter 10 unit Rp454 000 Rp4 540 000 2 Rp2 270 000

Small Saucepan 2 liter 10 unit Rp235 000 Rp2 350 000 5 Rp470 000

Rice Storage 1 unit Rp3 000 000 Rp3 000 000 5 Rp600 000

Packaging machine 1 set Rp165 000 000 Rp165 000 000 10 Rp16 500 000

Stainless Steel Pot Capacity 50

liter 10 unit Rp579 500 Rp5 795 000 5 Rp1 159 000

Oven 1 unit Rp500 000 Rp500 000 5 Rp100 000

Digital Scale 100 gram 1 unit Rp700 000 Rp700 000 5 Rp140 000

Sub Total Rp73 108 800

Toilet

Wall hung basin kris wht jd0018 1 unit Rp525 000 Rp525 000 10 Rp52 500

Basin tap kris CHR 19001KS-E5 1 unit Rp439 000 Rp439 000 10 Rp43 900

Toilet kris siphon one piece wht 1 unit Rp925 000 Rp925 000 10 Rp92 500

Storages

Exhaust fan KDK 40 AAS 6 unit Rp553 000 Rp3 318 000 5 Rp663 600

Sub Total Rp663 600

Office

Samsung AC split 3/4 pk 1 unit Rp4 659 000 Rp4 659 000 10 Rp465 900

Computer 1 set Rp5 000 000 Rp5 000 000 5 Rp1 000 000

HP Deskjet 1050 All-in-One 1 unit Rp619 000 Rp619 000 5 Rp123 800

Office Desk + Table 1 set Rp1 000 000 Rp1 000 000 5 Rp200 000

Fax Machine Panasonic

KX-FT981 1 unit Rp1 050 000 Rp1 050 000 5 Rp210 000

Sub Total Rp1 999 700

Licenses

Trademark License 1 unit Rp600 000 Rp600 000 1 Rp600 000

BPOM Registration 1 unit Rp3 000 000 Rp3 000 000 5 Rp600 000

BPOM Analytical 4 unit Rp1 820 000 Rp7 280 000 5 Rp1 456 000

PT License 1 unit Rp10 800 000 Rp10 800 000 5 Rp2 160 000

Sub Total Rp4 816 000

Garage

Hyno 110 SL 1 unit Rp186 300 000 Rp186 300 000 10 Rp18 630 000

Sub Total Rp18 630 000

Others

Building 376 m2 Rp2 500 000 Rp940 000 000 25 Rp37 600 000

Sub Total Rp37 600 000

Appendix 11. Profit/Loss

Year

Component 1 2 3 4 5

Inflow

Sales Rp2 630 880 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000

Total Inflow Rp2 630 880 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000

Outflow

Overhead Cost Rp482 927 602 Rp482 927 602 Rp482 927 602 Rp482 927 602 Rp482 927 602 Variable Cost Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Depreciation Cost Rp137 007 000 Rp137 007 000 Rp137 007 000 Rp137 007 000 Rp137 007 000

Total Outflow Rp2 693 383 852 Rp2 693 383 852 Rp2 693 383 852 Rp2 693 383 852 Rp2 693 383 852

EBT -Rp62 503 852 Rp595 216 148 Rp595 216 148 Rp595 216 148 Rp595 216 148

Tax -Rp7 812 982 Rp74 402 018 Rp74 402 018 Rp74 402 018 Rp74 402 018

Net Profit -Rp54 690 871 Rp520 814 129 Rp520 814 129 Rp520 814 129 Rp520 814 129

Year

Component 6 7 8 9 10

Inflow

Sales Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000

Total Inflow Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000

Outflow

Overhead Cost Rp482 927 602 Rp482 927 602 Rp482 927 602 Rp482 927 602 Rp482 927 602 Variable Cost Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Depreciation

Cost Rp137 007 000 Rp137 007 000 Rp137 007 000 Rp137 007 000 Rp137 007 000

Total Outflow Rp2 693 383 852 Rp2 693 383 852 Rp2 693 383 852 Rp2 693 383 852 Rp2 693 383 852

EBT Rp595 216 148 Rp595 216 148 Rp595 216 148 Rp595 216 148 Rp595 216 148

Tax Rp74 402 018 Rp74 402 018 Rp74 402 018 Rp74 402 018 Rp74 402 018

Appendix 12. Reinvestment Item

Economical Age (year)

Reinvestment (Year 5) Equipments

Reinforced rice production line 10 -

Conveyor belt 10 -

Warehouse Storage Steel Trolley 5 Rp 1 025 000

Digital scale 3 kg 5 Rp 999 000

Digital scale 50 kg 5 Rp 1 700 000

Measuring Cylinder Pyrex 1 liter 5 Rp 4 540 000

Small Saucepan 2 liter 5 Rp 2 350 000

Rice Storage 5 Rp 600 000

Packaging machine 10 -

Stainless Steel Pot Capacity 50 liter 5 Rp 5 795 000

Hyno truck 110 SL 10 -

Samsung AC split 3/4 pk 10 -

Computer 5 Rp 5 000 000

HP Deskjet 1050 All-in-One 5 Rp 619 000

Office Desk + Table 5 Rp 1 000 000

Fax Machine Panasonic KX-FT981 5 Rp 1 050 000

Sub Total Rp 24 678 000

Licenses

BPOM Registration 5 Rp 3 000 000

PT License 5 Rp 10 800 000

Trademark License 1 Rp 600 000

BPOM Analytical 5 Rp 7 280 000

Sub Total Rp 21 680 000

Others

Wall hung basin kris wht jd0018 10 -

Basin tap kris CHR 19001KS-E5 10 -

Toilet kris siphon one piece wht 10 -

Exhaust fan KDK 40 AAS 10 -

Total Rp 46 358 000

Appendix 13. Salvage Value

Item Economical Age (year) Depreciation Cost/Year Salvage Value

Land - - Rp 790 400 000

Building 25 Rp 35 100 000 Rp 564 000 000

Total Rp 1 354 400 000

Appendix 14. Business feasibility

Year

Component 0 1 2 3 4 5

Inflow

1. Sales Rp0 Rp2 630 880 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 2. Salvage Value

Total Inflow Rp0 Rp2 630 880 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000

Outflow

1. Overhead Cost Rp482 927 602 Rp482 927 602 Rp482 927 602 Rp482 927 602 Rp482 927 602 2. Production Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250

3. Investment Rp2 897 274 000 Rp600 000 Rp600 000 Rp600 000 Rp600 000 Rp600 000

4. Tax -Rp7 812 982 Rp74 402 018 Rp74 402 018 Rp74 402 018 Rp74 402 018

Total Outflow Rp2 897 274 000 Rp2 549 163 871 Rp2 631 378 871 Rp2 631 378 871 Rp2 631 378 871 Rp2 631 378 871

Net Benefit -Rp2 897 274 000 Rp81 716 129 Rp657 221 129 Rp657 221 129 Rp657 221 129 Rp657 221 129

Discount Rate 10.25% 10.25% 10.25% 10.25% 10.25% 10.25%

Discount Factor 1 0.907029478 0.822702475 0.746215397 0.676839362 0.613913254

PV Net Benefit -Rp2 897 274 000 Rp74 118 938 Rp540 697 450 Rp490 428 526 Rp444 833 130 Rp403 476 762

Contd.

Year

Component 6 7 8 9 10

Inflow

1. Sales Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000

2. Salvage Value Rp1 354 400 000

Total Inflow Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp3 288 600 000 Rp4 643 000 000

Outflow

1. Overhead Cost Rp482 927 602 Rp482 927 602 Rp482 927 602 Rp482 927 602 Rp482 927 602 2. Production Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250 Rp2 073 449 250

3. Investment Rp46 358 000 Rp600 000 Rp600 000 Rp600 000 Rp600 000

4. Tax Rp74 402 018 Rp74 402 018 Rp74 402 018 Rp74 402 018 Rp74 402 018

Total Outflow Rp2 677 136 871 Rp2 631 378 871 Rp2 631 378 871 Rp2 631 378 871 Rp2 631 378 871

Net Benefit Rp611 463 129 Rp657 221 129 Rp657 221 129 Rp657 221 129 Rp2 011 621 129

Discount Rate 10.25% 10.25% 10.25% 10.25% 10.25%

Discount Factor 0.556837418 0.505067953 0.458111522 0.415520655 0.376889483

PV Net Benefit Rp340 485 550 Rp331 941 330 Rp301 080 572 Rp273 088 954 Rp758 158 847

NPV Rp1 061 036 059

Benefit/Cost Ratio 1.0563

IRR 16.53%

Payback period (Year) 8.82

BEP (kg output/day) 510.17

Appendix 15. Source of Information

Component Source

Investment Equipments

Reinforced rice production line Jinan Saibainuo Technology Development Co., Ltd. Conveyor belt Jinan Saibainuo Technology Development Co., Ltd. Warehouse Storage Steel Trolley Dalian Huameilong Metal Products Co., Ltd.

Freight production line + Conveyor Belt Seabay International Freight Forwarding Ltd. Insurance (5% of total cargo price) Seven Seas World Wide Insurance

Import tax and Local transportation Doohan88 Freight Packaging Machine Winapack

Digital scale 3 kg Bhinneka.com

Digital scale 50 kg Bhinneka.com

Measuring Cylinder Pyrex 1 liter Bhinneka.com

Small Saucepan 2 liter Alatdapur.com

Rice Storage Tirta Stainless Tank

Packaging machine Winapack

Stainless Steel Pot Capacity 50 liter Blibli.com

Hyno truck 110 SL Hino.co.id

Samsung AC split 3/4 pk Ace Hardware

Computer Infoharga.com

HP Deskjet 1050 All-in-One Infoharga.com

Office Desk + Table Simpati Furniture

Fax Machine Panasonic KX-FT981 Toko Telepon Building

PT License Tama Solusi

Others

Wall hung basin kris wht jd0018 Ace Hardware Basin tap kris CHR 19001KS-E5 Ace Hardware Toilet kris siphon one piece wht Ace Hardware Exhaust fan KDK 40 AAS Jualelektronik.com

Fixed Cost

Electricity PLN Bogor

Solar Pertamina Telephone and internet Estimated Price

Stationary Estimated Price

Marketing and Promotion Estimated Price Variable Cost

Cassava fiber Indo Agro Cassava

Sago starch PT Mina Sago Lestari

Cassava starch Agromaret.com

GMS Guangzhou Cardlo Biotech Co., Ltd.

Palm oil Giant

Water PDAM Tirta Pakuan

Packaging Karung beras.com

BIOGRAPHY

Aldith Natakusuma was born in Bogor on August 27th 1990, as the first son and has one sister, Ardelia Natakusuma. He was graduated from Regina Pacis High School in 2009, Mardi Waluya Secondary School in 2006 and Kesatuan Elementary School in 2003. Writer was enrolled in Food Science and Technology Department, IPB by UTM

(Ujian Talenta Mandiri).