FARAH HULLIANDINI

FORMULATION AND CHARACTERIZATION OF ANALOGUE RICE

MADE OF SWEET POTATO (

Ipomoea batatas

),

SAGO STARCH (

Metroxylon sp.)

, AND MAIZE FLOUR (

Zea mays

)

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY

BOGOR AGRICULTURAL UNIVERSITY

BOGOR

STATEMENT OF MANUSCRIPT,

LITERATURE REVIEW, AND SOURCES OF INFORMATION*

Hereby I declare that manuscript entitled Formulation and Characterization of Analogue Rice made of Sweet Potato (Ipomoea batatas), Sago Starch (Metroxylon sp), and Maize Flour (Zea mays) is my authentic scientific work supervised by advisor commissionary and has not been proposed to other higher education institution. Review based on published or not published literature has been written in the manuscript and references.

Therefore, I give my manuscript copyright to Bogor Agricultural University (IPB).

Bogor, May 2014

Farah Hulliandini

ABSTRACT

Abstract. Rice as the main carbohydrate source in Indonesia has created an

Manuscript

as one of requirements to achieve degree of Sarjana Teknologi Pertanian

at

Food Science and Technology major

FORMULATION AND CHARACTERIZATION OF ANALOGUE RICE

MADE OF SWEET POTATO (

Ipomoea batatas

), SAGO STARCH

(

Metroxylon sp.)

, AND MAIZE FLOUR (

Zea mays

)

FARAH HULLIANDINI

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY

BOGOR AGRICULTURAL UNIVERSITY

BOGOR

Manuscript Title : Formulation and Characterization of Analogue Rice made of Sweet Potato (Ipomoea batatas), Sago Starch

(Metroxylon sp), and Maize Flour (Zea mays)

Name : Farah Hulliandini

NIM : F24090115

Approved by,

Dr. Eko Hari Purnomo, M.Sc Prof. Dr. Slamet Budijanto, M.Agr

Advisor 1 Advisor 2

Acknowledge by,

Dr. Feri Kusnandar, M.Sc

Head of Food Science and Technology Department

Praise to Allah for the mercy, graciousness, and guidance throughout the research and manuscript completion. Chosen theme for this research was analogue rice, entitled Formulation and Characterization of Analogue Rice made of Sweet Potato, Sago Starch, and Maize Flour.

The author would like to appreciate and say thank you to Dr. Eko Hari Purnomo and Prof. Slamet Budijanto as advisors also Dr. Nancy for their valuable and inspiring advice and support, Mr. Zaenal, Mr. Ujang, Mr. Sadar, Mr. Ade, Mrs. Iin, Mr. Yahya, and Mrs. Antin who helped collecting primary data. Aldith, Trina, Fefi, Vincenia, Richard, and Kho Di Dza as same advisor colleagues. Author very appreciate Dani who revised the research proposal and Kak Sarwar who revised this final manuscript in a very detailed way, Dr. Endah Agustina and Ms. Alfa Chasanah from Tri-U who thought to nail a presentation in a good way.

Family and colleagues have given author support in this four years time and ahead. Papa, Mama, Sarah, and Shafa who always there and indulge me through any kind of non-academic activities. Author appreciates all good friends in IPB, there are Sarida who went through ups and downs together during thesis writing, Afi who cheers us to keep moving forward, Icha who gave a second home all this time, and Kyo who always there with so many precious little supports she could give. Partners in business, Fuad and Sarida, gave experiences and memories that one could ever give, the author really appreciate all the time spent together. Also Wenny, Libby, and Suci who gave memories as great housemates. Last but not least, colleagues who were fighting together as the very last 2009 student to graduate: Ayash, Lina, Anan, Olga, Mutiara, Sobich, Desi, Usaid, and Devi.

Hope this scientific work beneficial for analogue rice and food science development.

Bogor, May 2014

TABLE OF CONTENTS

TABLE LIST vi

FIGURE LIST vi

INTRODUCTION 2

Background 2

Objectives 2

RESEARCH METHODOLOGY 2

Materials 2

Instruments 3

Method 3

Method of Analysis 3

Sensory analysis 3

Chemical analysis 3

Color analysis 3

Bulk density analysis 4

Average grain mass analysis 4

Hydration properties analysis 4

Texture analysis 4

RESULT AND DISCUSSION 4

Analogue rice formulation 4

Average grain mass analysis 7

Bulk density analysis 7

Color analysis 8

Hydration properties analysis 8

Texture analysis 10

CONCLUSIONS AND RECOMMENDATIONS 11

Conclusions 11

Recommendations 11

REFERENCES 11

TABLE LIST

Table 1 Formulation of analogue rice based using different forms of

sweet potato 3

Table 2 Formulation of analogue rice based on weight ratio 3 Table 3 Formulation of analogue rice using hydrocolloid 3 Table 4 Chemical composition of analogue rice from sweet potato, sago

starch, and maize flour 9

Table 5 Mineral composition of boiled sweet potato and polished rice 9 Table 6 Analogue rice color using Chromameter CR 300 12 Table 7 First falling down, constant rate point, moisture loss, and

moisture content of cooked analogue rice and cooked polished rice 13 Table 8 Texture analysis for cooked analogue rice with/ without

hydrocolloid 13

FIGURE LIST

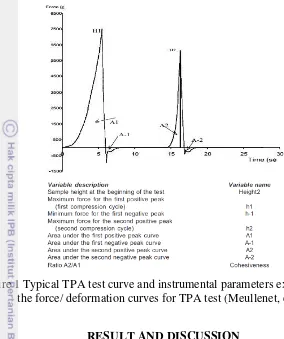

Figure 1 Typical TPA test curve and instrumental parameters extracted from the force/ deformation curves for TPA test (Meullenet, et al,

2000) 6

Figure 2 Analogue rice produced using different forms of sweet potato 7 Figure 3 Hedonic result of analogue rice produced using different forms

of sweet potato 7

Figure 4 Analogue rice obtained formulation from different ratio of sweet potato, sago starch, and maize flour (left to right: formula 1,

formula 2, formula 3, and formula 4) 8

INTRODUCTION

Background

Food diversification in Indonesia is not developing well because of the eating culture which basically relies on rice. This fact can be clearly seen not as staple food yet. Food scientists have been trying to create a product that can be one of the diversification attempts which does not oppose the eating culture.

Analogue rice is one of the diversification attempts that can be considered and consumed as staple food. Analogue rice has to be made of non-rice and non-wheat ingredients using cooking extrusion (Budijanto et al, 2011 and Kharunia, 2012). Cooking extrusion involves relatively high temperatures a ove o tained y pre-conditioning and/ or heat transfer through steam-heated barrel. It results in fully or partially pre-cooked simulated rice kernels (Mishra et al, 2012).

Indonesia has a large variation in carbohydrate sources. Tuber as one of the carbohydrate sources has not been widely explored yet as the main ingredient for analogue rice. Prasetia (2009) had studied sweet potato rice made of Heat Moisture Treatment modified sweet potato starch. Using sago pearl method, therefore resulting capsule-like form and having 1-2 months shelf life in PE packaging and 4-5 months in PP packaging.

Thus, this research is to improve the characteristics of sweet potato rice using cooking extrusion process. Sweet potato rice needs some optimization on the form of sweet potato added to the formula and gelling agent hydrocolloid addition to improve the texture and hydration properties. Gelling agent type of hydrocolloid is chosen because the swollen particulate forms of gelled hydrocolloids are particularly useful as they combine macroscopic structure formation with an ability to flow and often have an attractive soft solid texture (Milani and Maleki, 2012).

Objectives

RESEARCH METHODOLOGY

Materials

The main ingredients used were healthy “SQ-27” variety of sweet potato roots (cream colored skin and flesh), maize flour, sago starch, water, glyceryl monostearate, alginate, carrageenan, and konjac.

Instruments

Instruments used in this research were analytic scale, mixer, twin screw cooking extruder, oven, rice cooker, and TA.XT2 Texture Analyzer.

Method Sweet potato flour production

Fresh sweet potato roots was sorted, then cleansed from soil, peeled, and any damaged parts of the root should be trimmed off. Sweet potato washed and sliced into uniform pieces about five mm and soaked 0.3% sodium bisulfate for one hour to decrease browning reaction (Widowati, 2009). Sweet potato chips dried in ca inet dryer at 6 ◦ for two hours, then dried sweet potato milled into flour at 40 mesh.

Mashed sweet potato production

Fresh sweet potato roots was sorted, then cleansed from soil, peeled, and any damaged parts of the root should be trimmed off. Sweet potato washed and sliced into four parts. With boiling water underneath, sweet potato steamed for an hour then mashed in food processor until it formed a homogenous mashed sweet potato.

Sweet potato pulp production

Fresh sweet potato roots was sorted, then cleansed from soil, peeled, and any damaged parts of the root should be trimmed off. After washed, a rasper was used to destruct sweet potato roots and formed a sweet potato pulp.

Analogue rice formulation

The best formula was determined using hedonic test. Then, the best formula with addition of hydrocolloid analyzed by its color, bulk density, grain mass, hydration rate, and texture profile.

Hedonic test

The rice was prepared using 1:1 water to rice ratio in a rice cooker. Panelists were instructed to evaluate uncooked rice and warm cooked rice. The number of respondents in this experiment was 30 untrained panelists. A 7-point hedonic scale was used to assess panelists’ liking of overall, color, odor, and taste specifically.

Chemical analysis

Moisture content (AOAC 2007 925.09B)

In cooled and weighed aluminium dish, previously heated to 130 C, ground analogue rice weighed approximately 2 g. Dish and analogue rice dried overnight in air oven, then transferred to desiccator, and weighed soon Table 1 Formulation of analogue rice based using different forms of

Table 2 Formulation of analogue rice based on weight ratio

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Table 3 Formulation of analogue rice using hydrocolloid Sweet

potato

Sago starch

Maize

after reaching room temperature. Flour residue reported as total solids and loss in weight as moisture (indirect method).

Ash content (AOAC 2007 923.03)

Ground analogue rice weighed 2 g into ashing dish that has been ignited, cooled in desiccator, and weighed after reaching room temperature. Sample and dish ignited in furnace at C to constant weight. Final weight reported as ash content (direct method).

Fat content (AOAC 2007 920.39C)

Into folded paper, 2 g of ground analogue rice weighed, and dried in oven at C. Then folded paper and cotton stopper inserted in glass funnel, and funnel connected to condenser and flask. Hexane solvent decanted as much as possible into flask then extracted for six hours. Aside solvent inside flask, then sample and flask dried in oven 105 C, cooled in desiccator and weighed.

Protein content (AOAC 1984 14.067)

In Kjeldahl flask, 0.1 g of ground analogue rice placed with 1 g K2SO4, 40 mL HgO, and 2 mL H2SO4. Flask placed on preheated burner and briskly boiled until solvent clears. Cooled clear solvent transferred to distillation apparatus. Kjeldahl flask rinsed six times using 2 mL distilled water, then the distilled water decanted to distillation apparatus. NaOH 60% - Na2SO3.5H2O at 8 mL added and distilled. Erlenmeyer with H3BO3 5 mL and indicator (red metilen 0.2%: blue metilen 0.2% = 2:1) as much as four droplets placed under condenser. After 15 mL of distillate obtained, titration with HCl 0.02 N until distillate changed color from green to grey.

Physical analysis Color

Color was measured using Chromameter CR 300 Minolta. Data can be presented by absolute score or by-difference score using standard. Calibration was conducted by putting measuring head on to the white plate.

Bulk density

A uniform size rice sample poured into measurement glass until reached 10 mL volume. Sample weighed and calculated as follows:

Average grain weight

Intact rice as much as 1000 grains weighed using analytical scale. The weight result divided by 1000 then the average of rice acknowledged.

Rate of moisture loss

Analogue rice was added to the boiled distilled water in ratio 1:1. After being cooked in 10 minutes, 50 grams of cooked rice sample in petri dish was weighed every 30 minutes for five hours to analyze the analogue rice moisture loss, which would be stated as the rate of moisture loss per time. To calculate dry weight of cooked analogue rice, approximately 2 g of cooked analogue rice was weighed, in duplicate, and dried at C for 24 hours using drying oven. Cooked rice moisture content was calculated as the percentage of moisture weight of cooked rice sample (wb).

Texture

Figure 1 Typical TPA test curve and instrumental parameters extracted from the force/ deformation curves for TPA test (Meullenet, et al, 2000)

RESULT AND DISCUSSION

Analogue rice formulation

There were three steps of analogue rice formulation. The first step of formulation was to determine which form of sweet potato should be added to analogue rice formulation (flour, mashed, or pulp). Sweet potato form is important in producing analogue rice. Sweet potato processing such as steaming and drying affect its color and carbohydrate structure consequently has impact on the appearance of analogue rice. Second step of formulation was to choose the best formula using different weight ratio of sweet potato, sago starch, and maize flour. And third step of formulation was addition of hydrocolloid to increase moisture content of analogue rice.

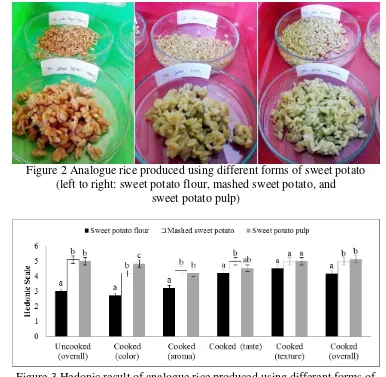

Figure 2 Analogue rice produced using different forms of sweet potato (left to right: sweet potato flour, mashed sweet potato, and

sweet potato pulp)

Figure 3 Hedonic result of analogue rice produced using different forms of sweet potato

Uncooked analogue rice produced using mashed sweet potato and sweet potato pulp were more favorable than sweet potato flour based on overall parameter. Five parameters in cooked analogue rice were showing variation of results. Color of analogue rice using sweet potato pulp was preferable than two other analogue rice, while aroma, taste, and texture showing no differences among the three analogue rices. Cooked analogue rice based on overall parameter showed that mashed sweet potato and sweet potato pulp used in analogue rice production had higher score than sweet potato flour.

Based on hedonic result, analogue rice produced using mashed sweet potato and sweet potato pulp were superior than sweet potato flour. Economy and energy factors were considered to determine the best form between mashed sweet potato and sweet potato pulp. Sweet potato pulp used less energy and consequently lower cost to produce analogue rice. Based on those considerations, sweet potato pulp chosen as the best form for analogue rice production.

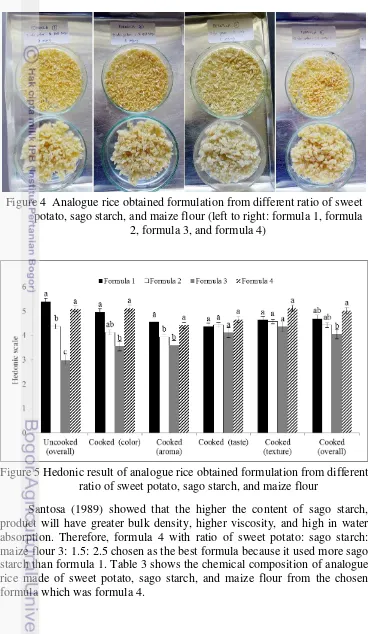

hedonic test was used to compare four formulas, with ratio of sweet potato: sago starch: maize flour were 3: 3: 1 (formula 1); 3: 2: 2 (formula 2); 3: 1: 3 (formula 3); and 3: 1.5: 2.5 (formula 4). The result in Figure 3 showed that formula 1 and 4 were more preferred formulas as indicated by its color, aroma, and overall score.

Figure 4 Analogue rice obtained formulation from different ratio of sweet potato, sago starch, and maize flour (left to right: formula 1, formula

2, formula 3, and formula 4)

Figure 5 Hedonic result of analogue rice obtained formulation from different ratio of sweet potato, sago starch, and maize flour

Table 4 Chemical composition of analogue rice from sweet potato, sago starch, and maize flour

Fat and protein content of sweet potato analogue rice is lower than polished rice. However, ash content in sweet potato analogue rice is higher than polished rice. As shown in Table 5, combination of sweet potato, sago starch, and maize may cause analogue rice high in thiamin, riboflavin, niacin, K, P, Fe, and Ca 2-3 times than polished rice. But usage of tap water in sweet potato processing might cause a positive error in ash content of analogue rice.

Sweet potato analogue rice has lower moisture content than polished rice. Lower moisture content of cooked rice increases its hardness. The increase in cooked rice moisture content during cooking was accompanied with an increase in total solid leach in cooking water and play a significant role in determining cooked rice stickiness (Saleh, et al, 2012). Suwansri et al. (2011) reported that both stickiness and hardness were important determinants of overall acceptance of rice. Therefore, addition of hydrocolloid to sweet potato analogue rice was done as an attempt to increase moisture content and texture of analogue rice.

Composition (% w/w) Sweet potato analogue rice Polished rice*

Moisture 10.26 ± 0.76 11.22 ± 0.11

Ash 0.83 ± 0.07 0.56 ± 0.00

Fat 0.83 ± 0.01 1.46 ± 0.10

Protein 4.60 ± 0.39 7.40 ± 0.00

Carbohydrate 82.61 89.56

a

Based on dry material * Ohtsubo (2005)

Table 5 Mineral composition of boiled sweet potato and polished rice Mineral

Hydrocolloid usage in cereal technologies depends on their properties to increase viscosity, water holding capacity, hydration rate, and effect of temperature on hydration. Although being used at a very low concentration, approximately less than 1 % of formula, hydrocolloid has considerable effect on texture and sensorial properties in food products (Mikus, et al, 2011).

To obtain the best hydrocolloid usage in analogue rice production, a 0.1% of hydrocolloid (alginate, konjac, carrageenan) concentration were added to analogue rice mixture and extruded. The treatments are as follow: 1) analogue rice + alginate 0.1%, 2) analogue rice + konjac 0.1%, 3) analogue rice + carrageenan 0.1%, 4) analogue rice without hydrocolloid, and 5) polished rice. Furthermore, grain mass, bulk density, color, hydration rate, and texture were analyzed to conclude the hydrocolloid usage.

In the food industry, there are several kinds of hydrocolloids used to change the structural organization and rheological properties of starchy food. The hydrocolloid edible films are classified into two categories taking into account the nature of their components: proteins, polysaccharides or alginates. The hydrocolloids are divided based on the principal function, such as gelling agent, thickener, emulsifier, and antimicrobials. Alginate, konjac, and carrageenan are classified as gelling agent hydrocolloid type. (Milani and Maleki, 2012).

Alginates are alginate acids, which come from “ rown seaweeds” Phaeophyceae species. Alginates form thermostable gels in the presence of calcium ions (Mikus, et al, 2011). Carrageenan have similar synergetic effect is known also for kappa-carrageenan and carob. In the mixture with lecithin it softens, improves volume, and structure of baked product (Mikus, et al, 2011). While konjac gum is a carbohydrate gum processed and refined from amorphophallus rerieri stem tuber. It is applied widely in the area of food, package, drilling, coating, bio-medicine and make-up because of its favorable properties of thickening, blending, setting, gelling, film-forming, lubricating and biodegradable proprieties and its medical and health function (Wang et al., 2008).

Physical properties Average grain weight

Figure 6 Average grain weight of analogue and polished rice

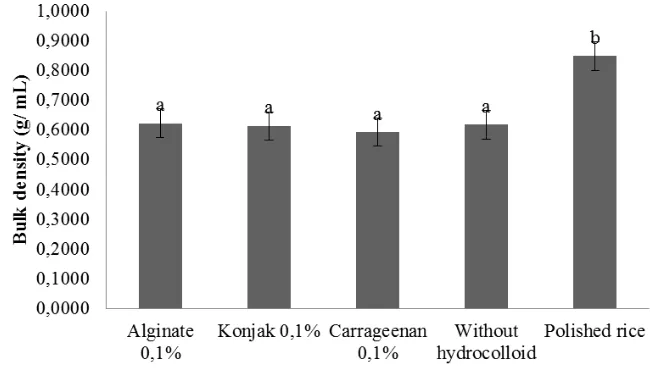

Bulk density

Bulk density is defined as a mass density of the sample per volume unit. Bulk density has an inversely proportion of mass and volume. Therefore, when the bulk density number is greater, the volume proportion is smaller. As shown in Figure 7, analogue rice formulation with or without hydrocolloid were significantly lower than polished rice. If the bulk density is higher, then correspondingly water uptake (determined as increase in weight of rice samples after cooking) will also be high (Rajeev et al, 2013).

Figure 7 Bulk density of analogue and polished rice

Color

Table 6 Analogue rice color using Chromameter CR 300

Analogue rice without hydrocolloid was the brightest among four samples, with L score 58.94. Also with high a score and b score, analogue rice without hydrocolloid seem to has a slightly red color (+3.40) and bright yellow (+29.33).

Hydration rate

Figure 8 shows decreased of weight and rate of moisture loss every 30 minutes. Highlighted parameters were first falling down point, constant rate period, and moisture loss. First falling down (FFD) showed the rate of moisture loss in the first 30 minute. The major decrease was caused by the huge difference of RH between rice cooker and room condition, then moisture in boiled rice tended to have desorption isotherm phase, which also were caused by external pressure (Jangam and Mujumdar, 2010).

Figure 8 Rate of moisture loss in analogue and polished rice

L a b

Table 7 First falling down, constant rate point, moisture loss, and moisture content of cooked analogue rice and cooked polished rice

The range of the first falling down was 0.0022 – 0.0032 g H2O/minute, with the highest falling down in polished rice which contained more moisture than other samples. At certain time, sample would reach a holding capacity of analogue rice. The table also showed that analogue rice has a lower moisture content compared to polished rice. This condition makes analogue rice get dry easily in room temperature.

Texture analysis

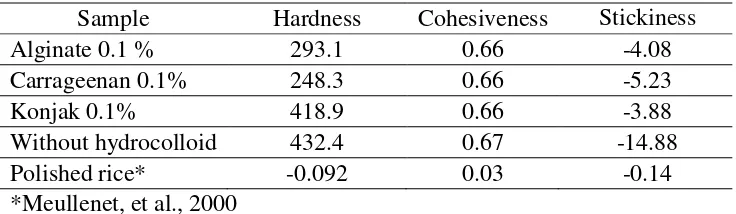

Hardness is related to the strength of the cooked rice structure under compression (Lau, et al., 2012). Based on Table 8, addition of 0.1% konjac did not differ with analogue rice without hydrocolloid. But 0.1% carrageenan and alginate did lower the hardness of analogue rice, with carrageenan addition has the lowest hardness 248.33.

Sample First falling down

Sample Hardness Cohesiveness Stickiness

Alginate 0.1 % 293.1 0.66 -4.08

Carrageenan 0.1% 248.3 0.66 -5.23

Konjak 0.1% 418.9 0.66 -3.88

Without hydrocolloid 432.4 0.67 -14.88

Polished rice* -0.092 0.03 -0.14

Cohesiveness is a measure of the degree of difficulty in breaking down the sample's internal structure (Sanderson, 1990). Since most of the cooked rice matrix was not broken during the first compression cohesiveness near to 1 (0.66-0.67), more energy was required to break the remaining cooked rice matrix during the second compression so that the cooked rice may be perceived as being tough when chewed.

Moreover, addition of hydrocolloid increased the stickiness of analogue rice. It is shown by large gap between analogue rice without hydrocolloid (-14.88), while analogue rice with carrageenan had -5.23, alginate -4.08, and konjac -3.88. Both hardness and stickiness of analogue rice with/ without hydrocolloid still far from polished rice, with hardness -0.092 and stickiness -0.14.

CONCLUSIONS AND RECOMMENDATION

Conclusions

Analogue rice made of sweet potato, sago starch, and maize flour has been formulated and characterized using hedonic test and physicochemical analysis. This analogue rice excellences are using low-processed sweet potato roots as one of the main ingredient, which consume less energy and consequently lower production cost, and high in thiamin, riboflavin, niacin, K, P, Fe, and Ca 2-3 times than polished rice from the combination of sweet potato, sago starch, and maize flour. The formulation as follows sweet potato pulp: sago starch: maize flour with weight ratio 3: 1.5: 2.5. Using cooking and twin screw extruder at , the analogue rice would contain 82.61% of carbohydrate, 0.83 ± 0.01% of fat, 4.60 ± 0.16% of protein, 10.26 ± 0.76% of moisture, and 0.83 ± 0.02% of ash. Addition of 0.1% gelling agent hydrocolloid improve the analogue rice texture quality, with carrageenan 0.1% decreased the hardness (184.1) also konjac 0.1% increased the stickiness (-11), however did not improve the hydration properties of analogue rice.

Recommendation

REFERENCES

AOAC [Association of Official Analytical Chemist. 2007. Official Method of Analytical of the Association of Official Analytical Chemist. Washington DC: AOAC.

Bourne, M. C. 1982.Food texture and viscosity: concept and measurement (pp. 44±117). New York: Academic Press (Chapter 3).

Budijanto S., et al. 2011. Develop chain transform of local cereal value to strengthen national food security [Strategic Research Program Report]. Bogor: Faculty of Engineering and Technology, Bogor Agricultural University.

CSA. 2012. Indonesia Statistic. Central Statistical Agency, Jakarta.

Hutching, J.B. 1999. Food Color and Appearance. Aspen publisher Inc., Maryland.

Indonesia Ministry of Agriculture. 2012. Macro Statistic: Agriculture Sector Volume 4 No 2 2012. Agricultural Data and Information System Center, Indonesia Ministry of Agriculture.

Jangam, S.V. and Mujumdar A.S. 2010. Basic Concepts and Definitions, in Drying of Foods, Vegetables and Fruits – Volume 1. Jangam SV, Law CL, Mujumdar AS, editor. ISBN – 978-981-08-6759-1. Singapore page 1-30.

Kharisma, T. 2013. White Analogue Rice Formulation from Sago Starch (Metroxylon sago R.), Cassava (Manihot esculenta Crantz), and Coconut Pulp (Cocos nucifera L.) [Essay]. Faculty of Engineering and Technology, Bogor Agricultural University.

Kharunia, A. 2012. Sorghum-based Analogue Rice Formulation [Essay]. Faculty of Engineering and Technology, Bogor Agricultural University.

Lau, M.H., Tang J., Paulson A.T. 2000. Texture profile and turbidity of gellan/gelatin mixed gels. Food Research International 33, 665±671. McCance, R.A and Eggum, B.O. 1978. The composition of foods. Her

Majesty’s stationery offic. London.

Meullenet, J.F., Loire, S., and Suwansri, S. 2001. Prediction if Consumer Acceptance of Cooked Jasmine Rice Texture Profile Analysis and Stress Relaxation Tests. B.R. Wells Rice Research Series 2000, AAES Research Series 485, 296- 300.

Milani, J. and Maleki, G. 2012. Hydrocolloids in Food Industry, Food Industrial Processes – Methods and Equipment, Dr. Benjamin Valdez (Ed.), ISBN: 978-953-307-905-9, InTech, Available from: http://www.intechopen.com/books/food-industrial-processes-methods-and-equipment/hydrocolloids-in-foodindustry

Mikus, Ľ., Valik, Ľ., Dodok, L. 2 . Usage of hydrocolloids in cereal technology. Acta univ. agric. et silvic. Mendel. Brun., 2011, LIX, No. 5, pp. 325–334.

Ohtsubo, K., Suzuki, K., Yasui, Y., and Kasumi, T. 2005. Bio-Functional Component in the Processed Pre-Germinated Brown Rice by a Twin Screw Ekstruder. Journal of Food Compositions and Analisys 18: 303-316.

Prasetia, H. A. 2009. Quality Improvement of Sweet Potato Rice using Heat Moisture Treatment (HMT) Modified Sweet Potato Starch [Thesis]. Faculty of Engineering and Technology, Bogor Agricultural University.

Rajeev, B, R. Thomas, Wan-Nadiah, W.A. 2013. Physiochemical properties, proximate composition, and cooking qualities of locally grown and imported rice varieties marketed in Penag, Malaysia. Intl Food Rsch J 20(3): 1345-1351 (2013).

Saleh, M. and Meullenet, J. F. 2012. Contour presentation of long grain rice degee of milling and instrumental texture during cooking. Intl Food Rsch J 20(3): 1337-1344 (2013).

Sanderson, G. R. 1990. Gellan gum. In P. Harris, Food gels (pp. 201±232). New York: Elsevier Science Publishing Co., Inc.

Sanusi, A. 2006. Instant Sago Formulation as High Calorie Meal [Essay]. Faculty of Engineering and Technology, Bogor Agricultural University.

Song, Rukun, Huang, Min, Bin, Li, and Bin, Zhou. 2012. The effect of three gums on the retrogradation of Indica rice starch. Nutrients 2012, 4, 425-435.

Suwansri, S., J-F. Meullenet, J-A. Hankins, and K. Griffins. 2001. Preference mapping of Jasmine rice for U.S. Asian consumers. In: R.J. Norman and J-F. Meullenet (eds.). B.R. Wells Rice Research Studies 2000. University of Arkansas Agricultural Experiment Station Research Series 485:312-321.

Wang, Yuan-lan, Li, Zhong-hai, and Wei, Yu. 2008. Rheology and influence factor of low-concentration Konjac gum solutions. J. Cent. South Univ. Technol. (2008) 15(s1): 6− 9.

Widara, S. S. 2012. Study of Analogue Rice Production made of various carbohydrate sources using Cooking Extrusion Technology [Thesis]. Faculty of Engineering and Technology, Bogor Agricultural University.

Woolfe, J.A. 1989. Nutritional aspects of sweet potato roots and leaves. Improvement of Sweet Potato (Ipomoea batatas) in Asia. CIP. Lima, Peru. p. 6 − 2.

APENDICES

Apendix 1 Hedonic result of analogue rice produced using different forms of sweet potato

Panelists Uncooked rice

Panelists

Cooked analogue rice

Apendix 2 Hedonic result of analogue rice obtained formulation from different ratio of sweet potato, sago starch, and maize flour

Panelists Uncooked analogue rice

Formula 1 Formula 2 Formula 3

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Formula 2 3 2 2 0.02

Cooked analogue rice

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Formula 2 3 2 2 0.02

Cooked analogue rice

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Formula 2 3 2 2 0.02

Cooked analogue rice

Panelists Overall Rice preferences

Formula 1 Formula 2 Formula 3

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Formula 2 3 2 2 0.02

Panelists Uncooked rice

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Formula 2 3 2 2 0.02

Panelists

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Formula 2 3 2 2 0.02

Panelists

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Formula 2 3 2 2 0.02

Panelists

Sweet potato Sago starch Maize flour GMS

Formula 1 3 1 3 0.02

Formula 2 3 2 2 0.02

Apendix 4 Hedonic test statistical analysis of analogue rice produced using different forms of sweet potato (formula 1, formula 2, and formula 3)

Overall preferences of uncooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Overall Source Type III Sum

of Squares df Mean Square F Sig.

Model 1871.489a 32 58.484 31.847 .000

Panelist 65.156 29 2.247 1.223 .253

Sample 81.489 2 40.744 22.187 .000

Error 106.511 58 1.836

Total 1978.000 90

a. R Squared = ,946 (Adjusted R Squared = ,916)

Overall

Duncana,,b

Sample N

Subset

1 2

Sweet potato flour 30 3.03

Sweet potato pulp 30 5.00

Mashed sweet potato 30 5.10

Sig. 1.000 .776

Means for groups in homogeneous subsets are displayed. Based on observed means.

Color preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Color

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1499.089a 32 46.847 46.122 .000

Panelist 53.289 29 1.838 1.809 .028

Sample 69.089 2 34.544 34.010 .000

Error 58.911 58 1.016

Total 1558.000 90

a. R Squared = ,962 (Adjusted R Squared = ,941)

Color

Duncana,,b

Sample N

Subset

1 2 3

Sweet potato flour 30 2.73

Mashed sweet potato 30 4.17

Sweet potato pulp 30 4.83

Sig. 1.000 1.000 1.000

Means for groups in homogeneous subsets are displayed. Based on observed means.

Aroma preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Aroma

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1535.689a 32 47.990 42.618 .000

Panelist 112.056 29 3.864 3.431 .000

Sample 23.356 2 11.678 10.371 .000

Error 65.311 58 1.126

Total 1601.000 90

a. R Squared = ,959 (Adjusted R Squared = ,937)

Aroma

Duncana,,b

Sample N

Subset

1 2

Sweet potato flour 30 3.23

Sweet potato pulp 30 4.20

Mashed sweet potato 30 4.40

Sig. 1.000 .468

Means for groups in homogeneous subsets are displayed. Based on observed means.

Taste preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Taste

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1987.689a 32 62.115 56.020 .000

Panelist 91.956 29 3.171 2.860 .000

Sample 9.689 2 4.844 4.369 .017

Error 64.311 58 1.109

Total 2052.000 90

a. R Squared = ,969 (Adjusted R Squared = ,951)

Taste

Duncana,,b

Sample N

Subset

1 2

Sweet potato flour 30 4.20

Sweet potato pulp 30 4.53 4.53

Mashed sweet potato 30 5.00

Sig. .225 .091

Means for groups in homogeneous subsets are displayed. Based on observed means.

Texture preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Texture

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 2191.356a 32 68.480 50.504 .000

Panelist 93.822 29 3.235 2.386 .002

Sample 4.689 2 2.344 1.729 .186

Error 78.644 58 1.356

Total 2270.000 90

a. R Squared = ,965 (Adjusted R Squared = ,946)

Texture

Duncana,,b

Sample N

Subset 1

Sweet potato flour 30 4.50

Mashed sweet potato 30 4.97

Sweet potato pulp 30 5.00

Sig. .121

Means for groups in homogeneous subsets are displayed. Based on observed means.

Overall preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Overall

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 2105.733a 32 65.804 80.322 .000

Panelist 59.458 29 2.050 2.503 .001

Sample 15.650 2 7.825 9.551 .000

Error 47.517 58 .819

Total 2153.250 90

a. R Squared = ,978 (Adjusted R Squared = ,966)

Overall

Duncana,,b

Sample N

Subset

1 2

Sweet potato flour 30 4.17

Mashed sweet potato 30 4.97

Sweet potato pulp 30 5.12

Sig. 1.000 .524

Means for groups in homogeneous subsets are displayed. Based on observed means.

Apendix 5 Hedonic test statistical analysis of analogue rice obtained formulation from different ratio of sweet potato, sago starch, and maize flour

Overall preferences of uncooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Overall

Source

Type III Sum of

Squares df Mean Square F Sig.

Model 1979.822a 32 61.869 58.656 .000

Sample 118.156 2 59.078 56.009 .000

Panelist 74.989 29 2.586 2.452 .002

Error 61.178 58 1.055

Total 2041.000 90

a. R Squared = ,970 (Adjusted R Squared = ,953)

Overall

Duncana,,b

Sample N

Subset

1 2 3

Formula 3 30 3.00

Formula 2 30 4.57

Formula 1 30 5.80

Sig. 1.000 1.000 1.000

Means for groups in homogeneous subsets are displayed. Based on observed means.

Color preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Color

Source

Type III Sum of

Squares df Mean Square F Sig.

Model 1722.333a 32 53.823 25.871 .000

Panelist 82.767 29 2.854 1.372 .152

Sample 26.667 2 13.333 6.409 .003

Error 120.667 58 2.080

Total 1843.000 90

a. R Squared = ,935 (Adjusted R Squared = ,898)

Color

Duncana,,b

Sample N

Subset

1 2

Formula 3 30 3.57

Formula 2 30 4.23 4.23

Formula 1 30 4.90

Sig. .079 .079

Means for groups in homogeneous subsets are displayed. Based on observed means.

Aroma preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Aroma

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1687.089a 32 52.722 43.122 .000

Sample 20.422 2 10.211 8.352 .001

Panelist 95.822 29 3.304 2.703 .001

Error 70.911 58 1.223

Total 1758.000 90

a. R Squared = ,960 (Adjusted R Squared = ,937)

Aroma

Duncana,,b

Sample N

Subset

1 2

Formula 3 30 3.60

Formula 2 30 4.17

Formula 1 30 4.77

Sig. .052 1.000

Means for groups in homogeneous subsets are displayed. Based on observed means.

Taste preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Taste

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1808.067a 32 56.502 29.277 .000

Sample 2.067 2 1.033 .535 .588

Panelist 116.000 29 4.000 2.073 .009

Error 111.933 58 1.930

Total 1920.000 90

a. R Squared = ,942 (Adjusted R Squared = ,910)

Taste

Duncana,,b

Sample N

Subset 1

Formula 3 30 4.13

Formula 1 30 4.37

Formula 2 30 4.50

Sig. .341

Means for groups in homogeneous subsets are displayed. Based on observed means.

Texture preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Texture

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1920.733a 32 60.023 49.545 .000

Panelist 97.167 29 3.351 2.766 .000

Sample 1.067 2 .533 .440 .646

Error 70.267 58 1.211

Total 1991.000 90

a. R Squared = ,965 (Adjusted R Squared = ,945)

Texture

Duncana,,b

Sampel N

Subset 1

Formula 3 30 4.37

Formula 2 30 4.50

Formula 1 30 4.63

Sig. .382

Means for groups in homogeneous subsets are displayed. Based on observed means.

Overall preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Overall

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1837.067a 32 57.408 49.014 .000

Panelist 60.767 29 2.095 1.789 .030

Sample 7.400 2 3.700 3.159 .050

Error 67.933 58 1.171

Total 1905.000 90

a. R Squared = ,964 (Adjusted R Squared = ,945)

Overall

Duncana,,b

Sample N

Subset

1 2

Formula 3 30 4.07

Formula 2 30 4.47 4.47

Formula 1 30 4.77

Sig. .158 .287

Means for groups in homogeneous subsets are displayed. Based on observed means.

Apendix 6 Hedonic test statistical analysis of analogue rice produced using different forms of sweet potato (formula 1, formula 2, and formula 4)

Overall preferences of uncooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Overall

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 2131.600a 32 66.613 93.322 .000

Panelist 72.100 29 2.486 3.483 .000

Sample 14.600 2 7.300 10.227 .000

Error 41.400 58 .714

Total 2173.000 90

a. R Squared = ,981 (Adjusted R Squared = ,970)

Overall

Duncana,,b

Sample N

Subset

1 2

Formula 2 30 4.20

Formula 1 30 5.00

Formula 4 30 5.10

Sig. 1.000 .648

Means for groups in homogeneous subsets are displayed. Based on observed means.

Color preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Color

Source

Type III Sum

of Squares Df Mean Square F Sig.

Model 2130.867a 32 66.590 50.072 .000

Panelist 92.267 29 3.182 2.392 .002

Sample 22.200 2 11.100 8.347 .001

Error 77.133 58 1.330

Total 2208.000 90

a. R Squared = ,965 (Adjusted R Squared = ,946)

Color

Duncana,,b

Sample N

Subset

1 2

Formula 2 30 4.03

Formula 1 30 5.03

Formula 4 30 5.13

Sig. 1.000 .738

Means for groups in homogeneous subsets are displayed. Based on observed means.

Aroma preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Aroma

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1707.622a 32 53.363 69.744 .000

Panelist 127.822 29 4.408 5.761 .000

Sample 8.956 2 4.478 5.852 .005

Error 44.378 58 .765

Total 1752.000 90

a. R Squared = ,975 (Adjusted R Squared = ,961)

Aroma

Duncana,,b

Sample N

Subset

1 2

Formula 2 30 3.73

Formula 1 30 4.37

Formula 4 30 4.43

Sig. 1.000 .769

Means for groups in homogeneous subsets are displayed. Based on observed means.

Taste preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Taste

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 1914.622a 32 59.832 59.445 .000

Panelist 108.456 29 3.740 3.716 .000

Sample 1.622 2 .811 .806 .452

Error 58.378 58 1.007

Total 1973.000 90

a. R Squared = ,970 (Adjusted R Squared = ,954)

Taste

Duncana,,b

Sample N

Subset 1

Formula 1 30 4.37

Formula 2 30 4.40

Formula 4 30 4.67

Sig. .281

Means for groups in homogeneous subsets are displayed. Based on observed means.

Texture preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Texture

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 2185.689a 32 68.303 82.001 .000

Panelist 88.489 29 3.051 3.663 .000

Sample 4.356 2 2.178 2.615 .082

Error 48.311 58 .833

Total 2234.000 90

a. R Squared = ,978 (Adjusted R Squared = ,966)

Texture

Duncana,,b

Sample N

Subset 1

Formula 1 30 4.67

Formula 2 30 4.67

Formula 4 30 5.13

Sig. .065

Means for groups in homogeneous subsets are displayed. Based on observed means.

Overall preferences of cooked analogue rice

Tests of Between-Subjects Effects

Dependent Variable: Overall

Source

Type III Sum

of Squares df Mean Square F Sig.

Model 2043.489a 32 63.859 76.350 .000

Panelist 58.622 29 2.021 2.417 .002

Sample 6.156 2 3.078 3.680 .031

Error 48.511 58 .836

Total 2092.000 90

a. R Squared = ,977 (Adjusted R Squared = ,964)

Overall

Duncana,,b

Sample N

Subset

1 2

Formula 2 30 4.40

Formula 1 30 4.63 4.63

Formula 4 30 5.03

Sig. .327 .096

Means for groups in homogeneous subsets are displayed. Based on observed means.

Apendix 7 Chemical composition of analogue rice from sweet potato, sago starch, and maize flour

Moisture content

U W dish W sample W dried sample

+ dish % MC Mean SD

1 5,0481 3,0783 7,7893 10,95 10,795 0,22

4,8484 2,1712 6,7885 10,64

2 4,3065 2,2408 6,3281 9,78 9,72 0,08

4,6908 2,1626 6,6446 9,66

Mineral content

U W dish W sample W dried sample +

dish % MC Mean SD

1 21,8232 2,9109 21,8494 0,90 0,88 0,02

20,3976 2,7571 20,4214 0,86

2 16,5751 2,2861 16,5931 0,79 0,77 0,02

21,2948 2,2613 21,3117 0,75

Fat content

U W sample W flask W flask +

sample % FC Mean SD

1 2,7325 97,2261 97,2477 0,82 0,84 0,02

3,0124 105,7075 105,7334 0,86

2 2,0128 106,3060 106,3228 0,83 0,82 0,01

2,1984 107,1387 107,1568 0,82

Protein content

U W sample VOL. HCL % PC Mean SD

1 0,1030 3,6 4,99 4,88 0,16

0,1081 3,6 4,76

2 0,1011 2,4 4,31 4,32 0,01

Apendix 10 TPA test for sensory textural parameter of analogue rice

Regression Coefficient

Sample Hardness L1 A1 L2 A2 A2/

A1

Sticki -ness Alginate

0.1 % 293.1 1.84 1.84

0.22-1.84 61.33 0.66 -4.08

Carra-geenan 0.1%

248.3 1.66 67.38

0.15-1.66 44.15 0.66 -5.23 Konjak

0.1% 418.9 1.41 93.08

0.16-1.41 61.33 0.66 -3.80 Without

hydro-colloid

432.4 1.50 110.72

CURRICULUM VITAE

Writer named Farah Hulliandini was born in Hull, England at February 12th, 1992 as the first child from Sonatha Halim Yusuf and RR Yura Widyaningrum. Writer educational background was Al-Azhar 1 Kebayoran Baru Senior High School, then accepted to IPB through SNMPTN in 2009 and enlisted as an undergraduate student of Food Science and Technology department.

Writer actively participated in various organizations such as International Association of Students in Agriculture and Related Sciences (IAAS LC IPB) as secretary of external affair division 2010, Agria Swara IPB student choir mem er, also food and nutrition magazine “Emulsi” at 2013 as head of layouter.