CONTENT

Welcome Message by Rector of Sebelas Maret University...2

Welcome Message Founding Chairman of 3rd ICRMCE ...3

Committees ...4

Invited Speakers ...7

Program Schedule ...10

Parallel Sessions...12

Abstracts ...21

Material and Structure ...21

Geotechnic ...30

Management ...34

Earthquake ...38

Water Resources...42

WELCOME MESSAGE

By Rector of Sebelas Maret University

Assalamu alaikum wr.wb.

Distinguished guest, Mr. Atiyanto Bustono, from the Ministry of Public Work and Housing Republic Indonesia, the invited speakers, speakers, guests, participants, sponsor and partners. Welcome to Solo and to this 3rdInternational Conference on Rehabilitation and Maintenance in Civil Engineering.

As National Reputable University, we have a strong vision to be the World Class University by 2019. Universitas Sebelas Maret is happy to conduct international academic events, involving experts from many countries in all over the world. One of them is this international conference. Smart Rehabilitation and Maintenance in Civil Engineering for Sustainable Construction has been chosen as the topic for the 3rdInternational Conference on Rehabilitation and Maintenance of Civil Engineering.

It is our great pleasure to see that this conference is an effective means to link the civil engineers from all over the world, especially those with a commitment to advance sustainable development and environmentally friendly buildings and infrastructures. It has been the meeting place to establish long-lasting collaboration among the researchers and the engineers. It has provided an opportunity for the professionals and researchers to learn and share the latest development and research in civil engineering.

Therefore, I fully support this important event and would like to express my deepest gratitude to all the speakers for their contribution and participation. I would like also to thank all of the participants, who have shown their interests and concerns to this conference and the committee for their hard work and perseverance.

On behalf of Universitas Sebelas Maret and the Organizing Committee, I officially open this International Conference on Smart Rehabilitation and Maintenance in Civil Engineering for Sustainable Construction.

Thank you,

Wassalamu alaikum Wr.Wb.

Solo Indonesia, November 19, 2015

Prof. Dr. Ravik Karsidi, MS

By Chairman of the Committee

Assalamu alaikum wr.wb.The honorable Rector of Sebelas Maret University Prof. Dr. Ravik Karsidi, the Vice Rectors, the Chairman of Agencies, the Dean of Faculties at Sebelas Maret University.

Dear keynote speakers Mr. Atiyanto Bustono, invited speakers and all speakers, guests and participants of the 3rd International Conference on Rehabilitation and Maintenance in Civil Engineering (ICRMCE). This year s conference is held in Solo City, Indonesia on 19-21 November 2015. Welcome to Solo, the spirit of Java

Having long preparation after our 2nd ICRMCE at the year of 2012, eventually the day has come. The theme of this 3rdICRMCE isSmart Rehabilitation and Maintenance in Civil Engineering for Sustainable Construction. Civil engineers, researchers, educators, students and related industries from all over the world are expected to work hand-in-hand to build a sustainable future for our next generation. We do hope that this conference will be a meaningful event for sharing ideas and expertise and strengthening our network. As we announced world wide through many conference gates, more than 80 already submitted by the experts around the word. However, trough tight reviewed there will be around 60 papers will be presented at this conference followed by publication in the proceeding by Transtech Publication, Switzerland.

We are honored to have Mr. Atiyanto Bustono on behalf of the Directorate General of Highway Agency of the Ministry of Public Works and Housing Republic of Indonesia, Mr Setiabudi, Prof. Buntara Sthenly Gan, Dr. Damian Palin, Prof. Masyhur Irsyam, and Dr.Hendra Jitno as invited speakers as well as Dr Han Ay Lie and Dr. Sholihin As ad who will be the chairlady and chairman of our plenary session. We also want to extend our great appreciation to more than 40 scholars around the world who have helped us to review the papers, special appreciation will be delivered to you at our Conference Dinner tonight, where all the guest are expected to join.

Our gratitude goes to Balai Pendidikan dan Pelatihan VII, Ministry of Public Works and Housing Republic of Indonesia, who has financially helped the committee to run this conference successfully. We would also thank our sponsors and partners who have contributed to this conference. Among others are PT Wijaya Karya Jakarta, The Construction Service Development Agency (LPJK), Techno Construction Magazines, the industry associations and the universities partner.

On behalf of the Organizing Committee and the Steering Committee I wish you all a blessed and productive time in our 3rdICRMCE.

Wassalamu alaikum Wr.Wb.

Solo Indonesia, November 19, 2015 Ary Setyawan, Ph.D.

COMMITTEES

Organizing Committee

Chairman Ir. Ary Setyawan, MSc (Eng), PhD

Member Yusep Muslih Purwana, ST., MT., PhD

Prof. S.A Kristiawan, ST., MSc (Eng)., PhD Dr. Techn. Ir. Sholihin As ad, MT

Budi Yuliyanto, ST., MSc., PhD Amirotul MHM, ST., MSc Edy Purwanto, ST.,MT Dr. Dewi Handayani, ST., MT Dr. Niken Silmi Surjandari, ST., MT Ir. Noegroho Djarwanti, MT Setiono, ST., MSc

Dr. Ir. Rr Rintis Hadiani, MT Ir. Djoko Sarwono, MT Fajar Sri Handayani, ST., MT Widi Hartono, ST., MT Ir. Sunarmasto, MT

Scientific Committee

1. Prof. T. F. Fwa, Director Centre of Transportation Research, NUS, Singapore.

2. Prof. Dr. Ing. Dr. h.c. mult. Franz Nestmann, Ordinarius, Institute for Water and River Basin Management, Karlsruhe Institute of Technology, Germany 3. Dr. Ing. Edgar Bohner, VTT Technical Research Centre of Finland, Onkalo,

Finland

6. Prof. Ir. Indra Surya B. M, MSc., PhD, Sepuluh Nopember Institute of Technology (ITS), Indonesia

7. Prof. Ir. Tavio, MT., PhD Sepuluh Nopember Institute of Technology (ITS), Indonesia

8. Prof. Dr. Ing. Ir. Ahmad Munawar, M.Sc., Gadjah Mada University (UGM), Indonesia

9. Prof. Ir. Iswandi Imran,MASc., PhD, Bandung Institute of Technology (ITB), Indonesia

10. Prof. Ir. I Nyoman Arya Thanaya,ME., PhD, Udayana University (UNUD), Indonesia

11. Prof. Ir. Masyhur Irsyam, MSE., PhD, Bandung Institute of Technology (ITB), Indonesia

12. Dr. Ir. Bambang Riyanto, DEA, Diponegoro University (UNDIP), Indonesia 13. Dr. Ir. Han Ay Lie, MEng, Diponegoro University (UNDIP), Indonesia 14. Ir. M. Agung Wibowo, MM., M.Sc., PhD, Diponegoro University (UNDIP),

Indonesia

15. Dr. Ir. Sri Tudjono, MS, Diponegoro University (UNDIP), Indonesia

16. Dr. Ir. Lily Montarcih Limantara, M.Sc, University of Brawijaya(UB), Indonesia

17. Prof. Dr. Ir. Wimpie Agung N. Aspar, Agency for the Assessment and Application of Technology, BPPT, Indonesia

18. Dr. Ir. Ade Lisantono, M.Eng, Atmajaya Catholic University, Yogyakarta , Indonesia

19. Anastasia Yunika, M.Eng, Atmajaya Catholic University, Yogyakarta , Indonesia

20. Dr. Ing Andreas Triwiyono, Gadjah Mada University (UGM), Indonesia 21. Dr. Gito Sugianto, Soedirman University, Indonesia

22. Agus Setyo Muntohar, ST, M.Eng.Sc., PhD. Muhammadiyah Yogyakarta University, Indonesia

24. Dr. Ing. Jack Wijayakusuma, Pelita Harapan University (UPH), Indonesia 25. Prof. Suripin, Diponegoro University (UNDIP), Indonesia

26. Prof. Yoyong Arfiandi, Atmajaya Catholic University, Yogyakarta , Indonesia

27. Prof. Dr. Ir, Sobriyah, MS, Sebelas Maret University, Indonesia

28. Prof. S. A Kristiawan, ST, M.Sc (Eng), PhD., Sebelas Maret University, Indonesia

29. Kusno A. S., ST, PhD., Sebelas Maret University, Indonesia

30. Dr. (techn). Ir. Sholihin As ad, MT., Sebelas Maret University, Indonesia 31. Yusep Muslih P, ST, MT, PhD., Sebelas Maret University, Indonesia 32. Dr. Eng.Ir. Syafi i, MT, Sebelas Maret University, Indonesia

33. Ir. Ary Setyawan, MSc (Eng), PhD., Sebelas Maret University, Indonesia 34. Dr. Dewi Handayani, ST, MT, Sebelas Maret University, Indonesia 35. Dr. Ir. AP Rahmadi, MSCE, Sebelas Maret University, Indonesia 36. Budi Yulianto, ST, MSc, PhD, Sebelas Maret University, Indonesia 37. Dr. Ir. Mamok Suprapto, M.Eng, Sebelas Maret University, Indonesia 38. Dr. Niken Silmi Surjandari, ST, MT, Sebelas Maret University, Indonesia 39. Dr. Ir. Rr Rintis Hadiani, MT, Sebelas Maret University, Indonesia 40. Dr. Cahyono Ikhsan, Sebelas Maret University, Indonesia

41. Dr. Ir. Arif Budiarto, MT, Sebelas Maret University, Indonesia 42. Dr. Senot Sangadji, ST, MT, Sebelas Maret University, Indonesia 43. Dr. F Pungky Pramesti, ST, MT, Sebelas Maret University, Indonesia 44. Tuti Agustin, MEng, Sebelas Maret University, Indonesia

45. Dr. Winny Astuti, Sebelas Maret University, Indonesia

Advisors :

Dean Faculty of Engineering, Sebelas Maret University

Head of Civil Engineering Department, Sebelas Maret University Head of Post Graduate Program in Civil Eng. UNS

ed iaartne r

The Programme of the 3

rdInternational Conference on Rehabilitation

and Maintenance in Civil Engineering (3

rdICRMCE)

Solo, 19-21 November 2015

The Sahid Jaya Hotel

Jl. Gajah Mada No.82, Banjarsari, Kota Surakarta, Jawa Tengah 57132, Indonesia

Date/Day Time Activities Venues

9

thNov 2015

Thursday

07.30-9.00 Registration

Pedan Room 09.00-10.15

Opening Ceremony

Indonesia Raya, Hymne UNS Welcoming speech

(Chair of the Organizing Committee of the 3rd

ICRMCE Ary Setiawan) Opening Speech

(Rector the University of Sebelas Maret Prof. Ravik Karsidi)

Keynote Speech : Atiyanto Bustono (Directore General of Highway Ministry of Public Works and Public Housing the Republic of Indonesia)

Voca Erudita Singing Performance: Gundul-gundul pacul

Kopi Dangdut Photo session Announcement

10.15-10.30 Refreshment / morning break 10.30-11.45 Plenary session

Voca Erudita Singing Performance (1 song) Chairman : Han Ay Lie

10.30 -10.50 Invited Speaker 1.

Title: Friction Type seismic Isolation Device of Steel Pile Foundation in Shaking Table Tests and its Numerical Simulations

By Prof. Buntara Sthenly Gan

10.50 -11.10

Invited Speaker 2

9

16

22

23

Parallel session 1 (the 1

stday)

Thursday, 19

thNovember 2015

Time Presentation Paper Number

Group A : Material and Structure 13.00-14.40 Venue: Sukoharjo Room 1

Chairman : Prof. S.A Kristiawan, ST., MSc (Eng)., PhD 13.00-13.20 Design of Structural Health Monitoring UsingWireless Sensor Network Case Study Pasupati Bridge

Annisa Dian Kumalasari; Suhartono Tjondronegoro

Strengthening and Retrofitting Strategy for Masonry

13.20-13.40 (New Build Construction in Indonesia) 13

Gede Adi Susila; Parthasarati Mandal; Thomas Swailes

13.40-14.00 Durability of Class C High Volume Fly Ash Concreteincorporated with Lime Water as Mixing Water

Mochamad Solikin

14.00-14.20 Concrete under Flexural LoadingSisal Fiber as Steel Bar Replacement of Lightweight

Murtiadi Suryawanand Akmaluddin

14.20-14.40 Steel Fiber Reinforced Concrete to Improve theCharacteristics of Fire-Resistant Concrete

Yenny Nurchasanah, Mohamed Alfitouri Masoud and Mochammad Solikin

Time Presentation Paper Number

Group B : Material and Structure 13.00-14.40

13.00-13.20

Venue: Sukoharjo Room 2

Chairman : Dr. Senot Sangadji, ST, MT

Strength Models of Axial Capacity of FRP-Confined

Circular Concrete Columns 24

IdaBagusRaiWidiarsaand INyomanSutarja

Experimental Investigation on the Flexural

13.20-13.40 Performance of Brick Masonry Wall Retrofitted 40

using PP-Band Meshes under Cyclic Loading

Andreas Triwiyono, Frederica Neo, Johan Ardianto, GumbertMayldaPratamaandAndreasSugijopranoto

13.40-14.00 Experimental Investigation Of Trapezoidal ProfileSheeting Under Varying Shear Spans

A.Siva,S.Swaminathan, K.Prasanth and R.Senthil

30

Experimental Study On Shear Capacity Of Rc Beams

14.00-14.20 Strengthened With Carbon Fiber Reinforced Polymer

Mandated By ACI 440 31

Sri Tudjono, Himawan Indarto and Monica Devi

Determination of Damage Location in Reinforced

14.20-14.40 Concrete Beams Using Mode Shape Curvature

Square (MSCS) Method 43

y

6) Structural Condition Assessment of

Steel-Framed Maintenance Plant in Muara Badak, Balikpapan, East Kalimantan

Strength Models of Axial Capacity of FRP-Confined Circular Concrete

Columns

Ida Bagus Rai Widiarsa

1,a* and I Nyoman Sutarja

2,b1,2Department of Civil Engineering, University of Udayana, Bali, Indonesia

a

*email: [email protected]

bemail: [email protected]

Keywords: strength model, axial capacity, FRP-confined, circular, concrete column.

Abstract. Several numbers of strength models of FRP-confined circular concrete columns have been published by several researchers. In this study, strength models were proposed based on experimental data. Nine existing FRP-confined strength models of column confinement were reviewed in this study and two forms of strength models of FRP-confined circular concrete columns were proposed. The models were proposed based on different number of experimental data collected from literature. Based on the number of experimental data, i.e. 64-, 106-, 156- and 192-, the strength models were developed. The performance of the existing and the proposed strength models were evaluated and compared. The evaluation results showed that the strength models proposed based on 192-data had the best performance among other models proposed with smaller number of data. It was also shown that the proposed strength models had better performance than the existing strength models.

Introduction

Strengthening of reinforced concrete structures has become very important and has been accepted in the world of construction along with that many structures of civil buildings suffered damage (deterioration). The strengthening method is more advantageous to be done when compared to the method of replacing or rebuilding of the structures. There are several conditions that make reinforced concrete structures require strengthening or retrofitting for example cracks, corrosion, damages due to earthquake loads, the imperfection of the design, and increment of service load. For concrete column structures, strengthening by wrapping columns with certain materials (method of jacketing) has become a popular method, where it especially has been done using fiber reinforced polymer (FRP). FRP has several advantages in mechanical properties such as high strength, high stiffness and durability, low density, corrosion resistance, low thermal coefficient and high strength to weight ratio [1]. FRP types that commonly used as structural strengthening materials are Glass, Carbon, Aramid and Kevlar fiber.

Some experimental tests on concrete columns with circular cross section have been conducted by several researchers [2,3,4,5,6]. The results of such studies showed that strengthening concrete columns with FRP increased the strength and performance of the columns.

Methodology

This study was conducted by reviewing and analyzing some existing strength models of confined circular concrete columns. Several researchers have published strength models to determine the axial compressive capacity of circular concrete columns confined with FRP sheets, such as Newman and Newman [13], Fardis and Khalili [7], Mirmiran and Shahawy [14], Miyauchi et al. [8], Toutanji [9], Lam and Teng [10], Lam and Teng [11], and Matthys et al. [12]. The strength models were formulated based on the testing results having various parameters and different number of specimens.

The majority of the available existing models to determine the compressive strength of FRP-confined circular concrete columns are based on the confinement model derived by Richart et al. [15] using Eq. (1).

where, fcc' and fco' are the compressive strength of confined and unconfined concrete, respectively;

1

k is the coefficient of confinement effectiveness, and f is the lateral confining pressure. The l

lateral confining pressure provided by the FRP jacket is expressed in Eq. 2 as:

d t f

fl =2 f f (2) where, f is the rupture tensile strength of FRP; f t is the thickness of FRP; and d is the diameter f

of the confined concrete.

Lateral confining pressure of FRP jacket on the circular concrete section can be illustrated as in Fig. 1.

Fig. 1. Confining pressure of FRP jacket

Some of the existing strength models for FRP-confined circular concrete where had been published in the literatures were reviewed and analyzed in this study, including:

- Model of Fardis and Khalili [7]

- Model of Mirmiran and Shahawy [14]

'

where, fl,a is the actual confining pressure and can be calculated as:

d average value of strain efficiency factor (εh,rup εf ) of 0.63 was obtained for a different type of FRP, where εf is the ultimate tensile strain of FRP from coupon tests.

- Model of Matthys et al. [12]

and some other models had the following form:

where α is the coefficient of the lateral confinement ratio.

In formulating Eqs. (12) and (13) which is determining the values of k1 and α, analysis using

optimization methods was done. Optimization was done by using a statistical indicator i.e. the criteria of Sum of squares error (SSE), which was formulated as follows [16]:

(

) (

)

The analysis to formulate the strength models was done based on different number of experimental data. The data were grouped according to the research development or based on the year of publication. The data were summarized as follows and in detailed were shown in Table 1.

- 1994 to 1999 : 64 data - 1994 to 2001 : 106 data - 1994 to 2007 : 156 data - 1994 to 2012 : 192 data

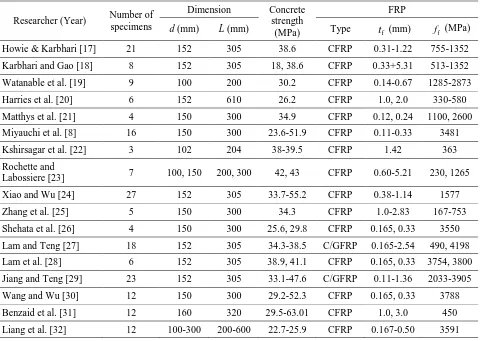

Table 1. Database of Experimental Results of FRP-Confined Circular Concrete Columns

Results and Discussion

Strength Models Proposed Using Different Number of Experimental Results

Analysis to determine the value k1 of the Eq. 12 was performed by means of optimization

process to obtain the smallest value of SSE. Optimization was done for each number of testing data

and the results were shown in Fig. 2.

Fig. 2. Performance of strength models in a form of Eq. 12 with different number of testing data

It can be seen from Fig. 2 that the larger the number of experimental data resulted in a greater value of SSE. The model based on 64 testing data had the smallest value of SSE which was about

4.90. Meanwhile, the greatest value of SSE was obtained from the strength model proposed based on

192 testing data which was about 12.63.

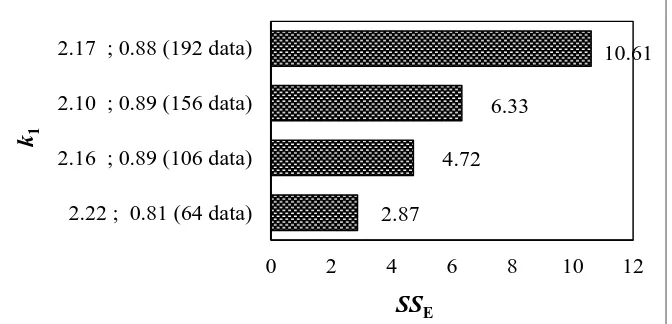

Furthermore, analysis to determine the value k1 and α of the Eq. 13 was performed by similar

method to obtain the smallest value of SSE. Optimization was also done for each number of

experimental data and the results were shown in Fig. 3.

Fig. 3. Performance of strength models in a form of Eq. 13 with different number of testing data

Similar condition as in Fig. 2 was observed from Fig. 3 as well. The larger the number of testing data resulted in a greater value of SSE. The model based on 64 testing data had the smallest value of

SSE which was about 2.87. Meanwhile, the greatest value of SSE was obtained from the strength

model proposed based on 192 testing data which was about 10.61. Until this stage, no optimum

4.90 5.71

7.26

12.63

0 2 4 6 8 10 12 14

2.22 (64 data) 2.2 (106 data) 2.12 (156 data) 2.22 (192 data)

SSE k1

2.87 4.72

6.33

10.61

0 2 4 6 8 10 12

2.22 ; 0.81 (64 data) 2.16 ; 0.89 (106 data) 2.10 ; 0.89 (156 data) 2.17 ; 0.88 (192 data)

Verification of the Proposed Strength Models

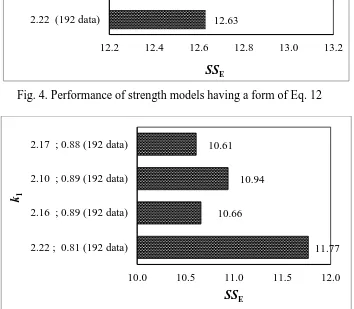

In order to define the proposed strength model which gives the best performance, i.e. the smallest value of SSE, all strength models with corresponding coefficients k1 and α were evaluated

using 192 data of experimental results. The result of the evaluation showed that the strength model proposed using 192 experimental data had the best performance with the values of SSE of 12.63 and

10.61, respectively for models having the form of Eqs. 12 and 13. The evaluation results are completely shown in Figs. 4 and 5.

Fig. 4. Performance of strength models having a form of Eq. 12

Fig. 5. Performance of strength models having a form of Eq. 13

Based on the aforementioned evaluation results, the following equations were proposed as the strength models to determine the axial compressive capacity of FRP-confined circular concrete columns:

12.2 12.4 12.6 12.8 13.0 13.2

2.22 (192 data)

10.0 10.5 11.0 11.5 12.0

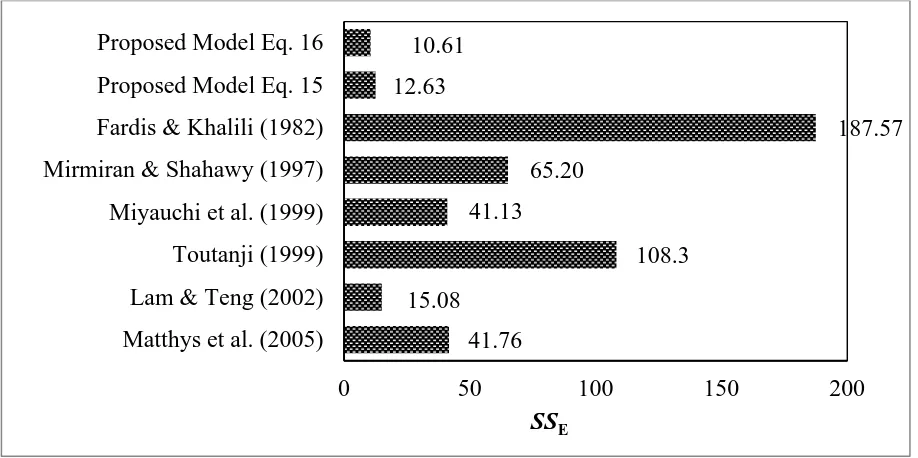

When compared with the existing strength models and analysed using 192 experimental data, again the strength models proposed in this study showed the best performance, as shown in Fig. 6.

Fig. 6. Performance comparison between proposed and existing strength models

Conclusions

Strength models of FRP-confined circular concrete columns under axial compressive loads were proposed in this study based on different number of experimental data. The analysis results showed that the value of confinement effectiveness k1 varies between 2.10 to 2.22 and the value of

coefficient of lateral confining ratio α varies between 0.81 to 0.89. The strength models that proposed in this study using 192 experimental data had the best performance. The analysis also shows the proposed strength models have better performance than those of the existing strength models.

References

[1] Pendhari. “Continuous bounded controller for active control of structures”. Computers and Structures, Vol. 84 (2008), 798-807.

[2] Li, J. and Hadi, M. N. S. “Behaviour of Externally Confined High Strength Concrete Columns Under Eccentric Loading.” Composite Structures, 62 (2003), 145-153.

[3] Hadi, M. N. S. “Behaviour of FRP Wrapped Normal Strength Concrete Columns Under Eccentric Loading.” Composite Structures, 72 (2006), 503–511.

[4] Hadi, M. N. S. “Behaviour of FRP Strengthened Concrete Columns Under Eccentric Compression Loading.” Composite Structures, 77 (2007a), 92–96.

[5] Hadi, M. N. S. “The Behaviour of FRP Wrapped HSC Columns Under Different Eccentric Loads.” Composite Structures, 78 (2007b), 560–566.

[6] Bisby, L. and Ranger, M. “Axial-Flexural Interaction In Circular FRP-Confined Reinforced 41.76

15.08

108.3 41.13

65.20

187.57 12.63

10.61

0 50 100 150 200

Matthys et al. (2005) Lam & Teng (2002) Toutanji (1999) Miyauchi et al. (1999) Mirmiran & Shahawy (1997) Fardis & Khalili (1982) Proposed Model Eq. 15 Proposed Model Eq. 16

[7] Fardis, M. N. And Khalili, H. H. “FRP-encased concrete as a structural material.” Magazine of Concrete Research, 34(121), 1982, 191-202.

[8] Miyauchi, K., Inoue, S., Kuroda, T., and Kobayashi, A. “Strengthening Effects of Concrete Column with Carbon Fiber Sheet." Transactions of the Japan Concrete Institute, 21 (1999), 143-150.

[9] Toutanji, H. A. “Stress-Strain Characteristics of Concrete Columns Externally Confined with Advanced Fiber Composite Sheets.” ACI Materials Journal, 96(3), 1999, 397-404.

[10] Lam L. and Teng, J. G. “Strength Model for Fiber-Reinforced Plastic-Confined Concrete.” Journal of Structural Engineering, ASCE, 128(5), 2002, 612-623.

[11] Lam, L. and Teng, J. G. “Design-Oriented Stress-Strain Model for FRP-Confined Concrete.” Construction and Building Materials, 17 (2003), 471-489.

[12] Matthys, S., Toutanji, H., Audenaert, K., and Taerwe, L. “Axial Load Behavior of Large-Scale Columns Confined with Fiber-Reinforced Polymer Composites." ACI Structural Journal, 102(2), 2005, 258-267.

[13] Newman, K. and Newman, J. B. “Failure Theories and Design Criteria for Plain Concrete.” Proceeding of International Civil Engineering Materials Conference On Structure, Solid Mechanics and Engineering Design (Southampton, 1969). Wiley Interscience, New York, (1972), Part 2, 963-995.

[14] Mirmiran, A. and Shahawy, M. “Behavior of Concrete Columns Confined by Fiber Composites." Journal of Structural Engineering, ASCE, 123(5), 1997, 583-590.

[15] Richart, F. E., Brandtzaeg, A. and Brown, R. L. “A Study of the Failure of Concrete Under Combined Compressive Stresses.” Bulletin No. 185, Engineering Experiment Station, Univ. of Illinois, Urbana, 1928.

[16] Montgomery, D. C. and Runger, G. C. Applied Statistics and Probability for Engineers. John Wiley & Sons, Inc., New York, 2003.

[17] Howie, I. and Karbhari, V. M. “Effect of materials architecture on strengthening efficiency of composite wraps for deteriorating columns in the North_East.“ Proceeding of the 3rd Materials Engineering Conference, Material Engineering Division, ASCE, 1994, 199-206.

[18] Karbhari, V. M. and Gao, Y. “Composite Jacketed Concrete Under Uniaxial Compression – Verification of Simple Design Equations.“ Journal of Materials in Civil Engineering, ASCE, 9(4), 1997, 185-193.

[19] Watanable, K., Nakamura, H., Honda, T., Toyoshima, M., Iso, M., Fujimaki, T., Kaneto, M. And Shirai, N. “Confinement effect of FRP sheet on strength and ductility of concrete cylinders under uniaxial compression.“ Proceeding of the 3rd International Symposium, Japan Concrete Institute, Sapporo, Japan, 1, 1997, 233-240.

[20] Harries, K. A., Kestner, J., Pessiki, S., Sause, R. and Ricles, J. “Axial behavior of reinforced concrete columns retrofit with FRPC jackets.“ Proceeding of the 2nd International Conference on Composites in Infrastructures (ICCI), Tucson, Arizona, 1998, 411-425.

[23] Rochette, P. and Labossiere, P. “Axial Testing of Rectangular Column Models Confined with Composites.“ Journal of Composites for Construction, ASCE, 4(3), 2000, 129-136.

[24] Xiao, Y. and Wu, H. “Compressive Behavior of Concrete Confined by Carbon Fiber Composite Jackets.“ Journal of Materials in Civil Engineering, ASCE, 12(2), 2000, 139-146.

[25] Zhang, S., Ye, L. and Mai, Y. W. “A Study on Polymer Composite Strengthening Systems for Concrete Columns.“ Applied Composite Materials, 7, 2000, 125-138.

[26] Shehata, I. A. E. M., Carneiro, L. A. V. and Shehata, L. C. D. “Strength of short concrete columns confined with CFRP sheets.“ Materials and Structures, 35, 2002, 50-58.

[27] Lam, L. and Teng, J. G. “Ultimate Condition of Fiber Reinforced Polymer-Confined Concrete.“ Journal of Composites for Construction, ASCE, 8(6), 2004, 539-548.

[28] Lam, L., Teng, J. G., Cheung, C. H. and Xiao, Y. “FRP-confined concrete under axial cyclic compression.“ Cement & Concrete Composites, 28, 2006, 949-958.

[29] Jiang, T. and Teng, J. G. “Analysis-oriented stress-strain models for FRP-confined concrete.“ Engineering Structures, 29, 2007, 2968-2986.

[30] Wang, L. M. and Wu, Y.F. “Effect of corner radius on the performance of CFRP-confined square concrete columns: Test.“ Engineering Structures, 30, 2008, 493-505.

[31] Benzaid, R., Mesbah, H. And Chikh, N. E. “FRP-confined Concrete Cylinders: Axial Compression Experiments and Strength Model.“ Journal of Reinforced Plastics and Composites, 29(16), 2010, 2469-2488.