KEY SUCCESS FACTORS AND ACHIEVEMENT OF KNOWLEDGE AND TECHNOLOGY TRANSFER IN SMEs

(A Study on Introduction of Lupin Beans Tempe Production for Tempe Producers)

ABSTRACT

Tempe is a typical and traditional food in Indonesia, also well known as product that is made with simple production technology and unstandardized. The application of technology innovation is a must to produce a high quality and hygienic tempe. The preliminary study showed there were pretty much tempe producers categorized as laggards. They will adopt a new production technology after seeing the tangible results of others. However, the study also found that there were numbers of tempe producers which can be called as innovators and early adopters. Accelerating the adoption of a new innovation in small businesses is important to enhance the competitiveness of tempe producers. Therefore, this study aimed to explore the key success factors of knowledge transfer (knowledge sharing) to accelerate the adoption of new innovations on the tempe producers. Research carried out on a number of producers especially innovators and early adopters.The results of the study show the key success factors of knowledge and technology transferred were influenced by several factors such as characteristics of technology agent, characteristics of environment, characteristics of media, characteristics of target groups, and characteristics of knowledge to be transferred.

Keywords : Adoption of technology, Transfer of knowledge, Tempe producers

INTRODUCTION

Business success is highly dependent on the ability of businesses to apply a

variety of appropriate technologies that can improve business efficiency and in

turn can improve the competitiveness of enterprises. The use of simple and

traditional technology is believed to be one of the obstacles that make a small

such as limited capital, lack of expertise and skills of human resources, and

management problems (Hanani, 2003 in Sumarno, 2010).

Indonesia as the largest tempe producer country in the world, the issue of

improving the quality and efficiency of tempe production is important to note.

Research conducted by Hidayat, Sukardi and Humanities (2004) showed that

tempe processing technology in Indonesia was highly varied and most producers

still use the conventional way, so there was no standard that could be used

nationally. This is one cause that tempe product has not been able to expand the

reach of marketing as well as being a supplier to the food processing industry

made of tempe.

Julianto and Wahyudi (2010) found that small businessmen often have

difficulty in adopting new technologies because they do not have sufficient

resources capabilities and have difficulties in managing rapid evolving technology

changes. With those limitations, small businesses need to establish a culture of

learning to improve the capability of adopting new innovations that lead to

increased competitiveness. Small businesses will be able to take advantage of

new innovations in order to improve competitiveness if they have the capability

and competence to be able to take advantage of what has been learned.

Therefore, the knowledge transfer process is important in increasing the capacity

to absorb the information and adopt new technological innovations.

The last few years precisely since 2010 a kind of bean named Lupin has

been introduced to the tempe producers in Indonesia as an alternative to soy

beans which cost is uncertain. Lupin is a grain legume that has been used for a

long time as a food ingredient in Western Australia. Lupin bean was introduced

to Indonesia because it has benefits and high nutritional value and to be a raw

material for making Tempe and Tofu which has a cheaper price than the price of

soybeans imported from America (www.detikfinance.com, 9th of April 2010).

the Western Australia government to the tempe producers in Indonesia who are

incorporated in KOPTI (Indonesia Tofu in Tempe Cooperative).

Studies on knowledge and technology transfer have found a number of

factors that can be the key to the success of technology transfer such as the

feasibility of human resources who receive the transfer, the existence of

supporting media, the form of knowledge/technology transfer, recipient’s

characteristics, environmental characteristics, and characteristics of the agent

that perform the transfer (Bozeman, 2000; Emery, 2002; Gouza, 2006). The

above explanation shows that the successful use of technology by small

industries cannot be separated from the knowledge and technology transfer

process. With a thinking pattern as it has been described above, it appears some

of the following research issues: (1) What are the key factors of successful new

knowledge/ technologies transfer in Tempe producers, and (2) To what extent do

new knowledge/ technology transfer are achieved by the tempe producers?

LITERATURE REVIEW

Knowledge and Technology Transfer

Knowledge transfer is the process or the way that the researchers conduct

the proof deployment of a theory or disseminate new knowledge (Profetto,

2004). Meanwhile, the transfer of knowledge and technology by Sung and

Gibson (2001) are defined as a communication process of knowledge and

technology between individuals and between organizations that have a high

degree of difficulty because it requires collaboration between two or more

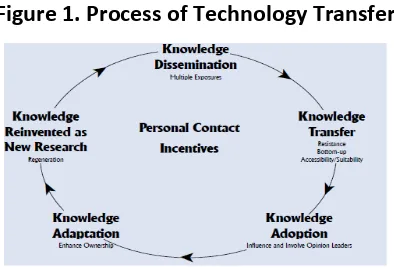

individuals or functional units of different cultures. The process of technology

transfer cannot be separated from the process of knowledge transfer as can be

Figure 1. Process of Technology Transfer

Source: Roger, et al (2012)

Knowledge is the basis of technology creation which in turn the knowledge of the

technology will need to be transferred to encourage the adoption and

implementation of technology. Devine et al (1987) suggested three general

models to explain the process of technology transfer, namely (1) Appropriability

Model, emphasizing the importance of the research quality and competitive

market competition; (2) Dissemination Model that focuses on the deployment of

innovation among individuals; and (3) Knowledge Utilization Model that

emphasizes the importance of interpersonal communication as well as the

barriers and drivers of the transfer process of the organization aspects.

Knowledge Utilization Model is used by many researchers to understand

the knowledge and technology transfer process as a whole. Associated with

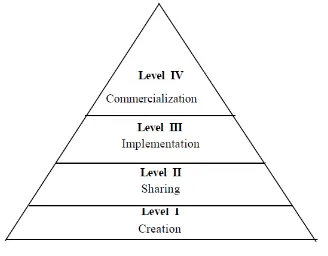

knowledge utilization models, Smilor and Gibson (1991) suggested four stages in

Figure 2. Stages of Knowledge and Technology Transfer Process

Source: Gibson and Smilor (1991)

The creation of knowledge and technology is the initial stage of the knowledge

and technology transfer process. Furthermore, the knowledge and technology is

spread or distributed (knowledge and technology sharing) to the user. Stage two

is said to be successful if the spread of knowledge and technology is acceptable

and well understood by the user. The third phase, an implementation phase, is

the application of knowledge and technologies that are created at the individual

or organization who became a role model. The final stage of the knowledge and

technology transfer process is commercialization that is the dissemination of

knowledge and technology on a large scale.

Indriartiningtias and Wirajmadja (2012) developed a model of the

knowledge and technology transfer for small industries based on a review of

various endogenous and exogenous variables in the knowledge and technology

transfer process in small industry, as shown in the picture below.

Source: Indriartiningtias and Wirajmadja (2012)

The successful knowledge and technology transfer in small and micro enterprises

(SMEs) depends on five elements, those are characteristics of the technology

agent, media characteristics, knowledge characteristics, environmental

characteristics, and characteristics of the target (SMEs). The mechanism of

knowledge and technology transfer in the media characteristics can be divided

into broad categories (Nokes, 2009). The first mechanism is the analogical

transfer, this transfer mechanism is composed of three main activities: 1) to

mimic the existing knowledge, 2) to map the current conditions and problems

encountered, and 3) to utilize conditions and problems mapping and formulate

relevant solutions in the applicative context. The second type of knowledge and

technology transfer mechanisms is called knowledge compilation. In knowledge

compilation, knowledge transfer actors try to find the solutions to problems by

formulating a procedure based on pre-existing knowledge. The third type of Characteristics of

Knowledge/ technology Type of knowledge Complexity Ambiguity advantages

Characteristics of

media

Transfer mechanism Information system Transfer form

Characteristics of

agent of technology

Resources Leaderships Objectives Reliability

Experiences

Transfer of knowledge and technology Characteristics of

Environment Social/Personal relationships Culture

Capital Government Higher Institution

knowledge and technology transfer mechanism is called constraint violation, this

mechanism is also a kind of procedural transfer but involves a cognitive process

of the actors in formulating a knowledge. In violation constraint mechanism

there are to evaluate and revise activities in order to enhance the knowledge to

improve performance.

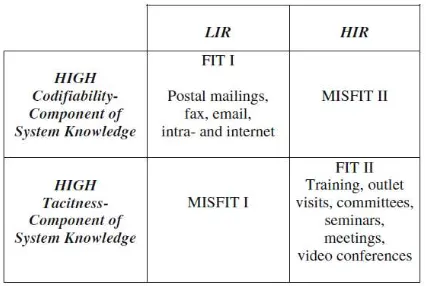

Appropriate information systems and transfer media forms in the

knowledge transfer process is associated with a form knowledge that is

transferred in the process. Referring to the knowledge-based view and

information richness (IR) theory, it is required an adjustment between

information systems and the transfer media forms with the degree of tacitness

of knowledge (Windsperger and Gorovaia, 2010). Alternative information

systems and transfer media form that are appropriate for the transferred

[image:7.595.220.433.462.605.2]knowledge is presented in the following figure.

Figure 4. The relationship between system and transfer media form with the knowledge form

Source: (Windsperger and Gorovaia, 2010)

The more explicit the transferred knowledge form and more easily coded, the

more easily the post media, mail media, email media, and internet media can be

and hard to be coded than training media, meetings media and seminars media

are more appropriate.

STUDY METHODS

This research is an applied research that used the approach of research and

development as well as an action research approach. This research was

conducted in the municipality of Salatiga, Central Java Province, with a

population of small entrepreneurs engaged in tempe industry. The choice of

location was based on the social and economic condition of small tempe

businesses that can describe the situation of research. Another consideration

was to support the efforts of Central Java Primkopti in creating new technologies

to support tempe production more efficient and more hygienic.

The population of this study were tempe producers in the municipality of

Salatiga and Primkopti officers in Central Java and Central Jakarta. Tempe

producers as respondents or informants in this study were producers who are

included in Early adopters and Innovators categories who met the following

criteria: 1) join or attend Primkopti meetings regarding the use of lupin beans as

a form of new technology, and 2) has been trying to process lupin beans into

tempe products and other processed food products. The data were obtained

with the approach of focus group discussions (FGDs) and in-depth interviews.

STUDY RESULTS AND DISCUSSION

Key Success Factors of Knowledge/Technology Transfer Process on SMES Agent’s Characteristics

Overview of the knowledge and technology transfer process from the agent

point will be explored from the factor of resources, agency leadership,

organization reliability, direction clarity and the experience of transferred

knowledge/technology. Lupin beans Introduction to the tempe producers in

Organization). Lupin was first introduced to Indonesia in 2009 in Jakarta, which

then proceed to other areas such as Central Java, East Java and Bali. The direct

involvement of the Australian government shows the seriousness of the agency

to make the successful knowledge transfer program to Lupin tempe producers in

Indonesia. From an organizational perspective, it appears that the presence of an

agent organization is quite convincing.

In performing the approach to the users in Indonesia, the agent always

designates the party who has the authority. For the knowledge transfer process

on Lupin to the Primkopti in Jakarta, the parties involved, among others, Minister

of Food and Agriculture of Western Australia (Mr Terry Redman), Mr. Martin

Newbery (Regional Diretor of WATO) and Mr. Bralen from the Australian

embassy in Indonesia. Representatives from the agencies went down the field

directly. They have a participative leadership style that can be seen from a

number of efforts made by Lupin party to obtain input from businessmen in

Indonesia, through a number of activities through FGD and gathering activities.

Various activities carried out by the agency to introduce Lupin beans in

Indonesia from 2009-2014 showed a clear direction, planning and objectives. The

description of the various activities carried out by the agent on knowledge and

technology transfer process of Lupin tempe production from 2009 until 2014 are

as follows:

Table 1. Activities carried out by the Agent (Lupin Producer) Year Activities carried out by the agent (Lupin producer)

2009 Lupin beans are introduced to Jakarta Primkopti, at that time these beans are still in the form of unpeeled lupin bean peas

March 2010

Involving LIPI in collaboration with Curtin University in Australia, sponsored by Grain Foods CRC ltd. Australia, examines the quality and suitability of Lupin beans instead of soybeans to produce tempe and generate recommendations to use those beans as a raw material for lupin tempe production

June 2010

production from Lupin beans to tempe producers in Jakarta and surrounding areas. Socialization was performed at Ritz Carlton Hotel Jakarta

Sept 2010

A test of the Lupin Tempe product quality by consultants from LIPI. Tested Lupin Tempe were the production of tempe producers as Central Jakarta Primkopti members which produce a total of 100 pieces

January 2011

Provide free samples of Lupin skinless peanuts as much as one container to the number of producers to make Lupin tempe. At this stage there was an product sale experiment to a number of areas in Jabodetabek

May 2011

Perform lupin tempe production promotion for basic pizza ingredients in Sanur Bali Hotels by involving chefs from WA named Theo Kalogeracos August

2012

Together with IPB held a National seminar with the theme: "Price Volatility of Soybean and It's Solutions" at IPB International Conference Centre

2012 Lupin party executed a Meeting at Sheraton Hotel Surabaya by inviting representatives of 5 Primkopti producers and PT Inja as Lupin importers

2012 Mr. H. Slamet Hanafie and Mr. Suyoto as the Central Jakarta Primkopti board members visited Western Australia at the invitation of Lupin party.

2013 Lupin Party with facilitation from Central Jakarta Primkopti is unceasingly introduce lupin to the tempe producers in Salatiga, Purwodadi, Surabaya and Bali

2014 Seeing slow market response to Lupin tempe, and even tended to decline, producers (agents) perform a variety of efforts to improve Lupin tempe production process

Source: Interview with Jakarta Primkopti, 2014

In terms of available resources, the agent is able to ensure that the

availability of Lupin will be met in a long term. It is based on the fact that the

land planting areas in Western Australia are still open and has great potential for

the cultivation of Lupin beans to ensure the availability of long-term supply. In

addition to the planting area, Lupin producers in Australia also have skilled

workers and skillful farmers. Besides, the agent will always try to convince their

commitment to provide the qualified Lupin beans materials and tailored to the

needs of the market. It was shown from the Lupin producers who enhance

efforts from the original crusted Lupin beans - it adds the cost and time of tempe

processing -, into Lupin beans that have been pealed off so that it can be treated

with a more efficient production process. To convince Indonesia in supporting

resources, the Executive Board of Central Jakarta Primkopti and the secretary

(Mr. H.Slamet Hanafie and Mr. Suyoto) were invited to visit Australia in 2013 to

Western Australia planned to meet 70% of domestic soybean import needs is

some 1.2 million tons of Lupin beans to Indonesia (The West Australian News,

November 10th 2010).

Media Characteristics

The discussion of the media characteristics in this case would include the

transfer mechanism, the system information and transfer forms. Knowledge

transfer mechanism for Lupin bean product was performed with a sample of the

physical form of the Australian Lupin beans to be shown directly to the tempe

producers. Based on interviews with the Executive Board of Central Jakarta

Primkopti it was obtained information that lupin beans were introduced in 2009

in the form of crusted Lupin beans. Because crusted Lupin beans posed

inefficiency in the tempe production process, then in 2011 the Lupin producer

party Lupin managed to make a peeled Lupin beans.

At first the Lupin producers have had prior knowledge of the Lupin

processing procedure to be lupin tempe that further be disseminated to the

producers, which were as follows 1) lupin bean grains soaked in water has a pH

of 4.5 for 12 to 20 hours at room temperature with a ratio of 3 liters water for 1

kg of lupin beans; 2) Once drained, lupin beans are put in boiling water for 2-10

minutes; 3) Drain and then packaged with yeast (www.lupinfoods.com.au/

Indonesian-information-for-tempe-producers/). However, the initial procedure

of Lupin tempe did not produce as expected in various regions. The Lupin tempe

products were slimy and if they were made into fried tempe, they will be hard.

This is due to Lupin beans contain a lot of gluten, besides the way of successful

tempe making is highly dependent on water conditions and local air

temperature.

This fact then encouraged the producers to use other transfer mechanisms

that was giving free samples to a number of manufacturers in a number of areas

tempe from Lupin with a view to obtain a production process in accordance with

the conditions of each region. From interviews and FGDs it was revealed that

there were continuous evaluation and revision activities based on the cognitive

aspects of the each step results of the transferred knowledge to enhance the

performance of the resulting products. The mechanism of knowledge and

technology transfer related to the use Lupin beans as a substitute soybean raw

material in tempe production process that occur among tempe producer SMES

of Primkopti members could be categorized as constraint violation. Referring to

Nokes (2009), the constraint violation is a procedural type of transfer but

involves a cognitive process of the actors in formulating knowledge. In violation

constraint mechanism there are evaluating and revising activities in order to

enhance the knowledge to improve performance.

Information systems in knowledge transfer process that was occurred

among tempe producer SMES of Primkopti members was initiated by the board

of Central Jakarta Primkopti in cooperation with the Australian lupin bean

producers. The form of knowledge transfer media was selected through the

meeting, Mr Haji Slamet visited several Primkopti in areas such as Malang,

Purwodadi, Salatiga, and Bali to share lupin bean processing procedures

knowledge to be tempe products. Training media was also selected in the

knowledge and technology transfer process that took place amid the tempe

producers of Primkopti members. For example, Mrs. Nurchayati at Salatiga who

was considered successful in producing tempe and tempe crackers made from

lupin bean was required to train the tempe producers in Bali. In addition to

meeting media and training media, mass media and internet media had also

become an alternative form of selected media in the knowledge and technology

transfer process of the tempe producers as Primkopti members. TEMPO is one of

the mass media ever review on the utilization of lupin bean by the tempe

producers in Malang (www.tempo.co/read/news/2014 / 01/26/090 548 396 /

available a special web on lupin beans which was managed by the Australian

producer party (www.lupinfoods.com.au/), which presents the various ways and

information on lupin beans processing.

This study found that the development of knowledge transfer process in

Jakarta tempe producers was stagnant because the information flow was only

occurred at the board level so that the knowledge creation was less developed.

Different with the tempe producers in Salatiga who had more successful

knowledge transfer process due to the two-way flow of information between the

board and the members where the members played an active role in knowledge

transfer activities, participate actively in evaluating and revising to create new

knowledge, as well as the sharing of knowledge among members and the board

through regular meetings.

Referring to the knowledge-based view and information richness (IR)

theory it is required an adjustment between information systems and the

transfer of media forms with the degree of tacitness of knowledge (Windsperger

and Gorovaia, 2010). More explicit transferred knowledge form and more easily

coded knowledge will make the mail media, email media, and internet media can

be used. On the other hand, if the transferred knowledge form is tacit

knowledge, and hard to be coded, the training media, meeting media and

seminars are more appropriate. Thus it appears that the knowledge / technology

transfer process of Lupin beans have utilized the correct media.

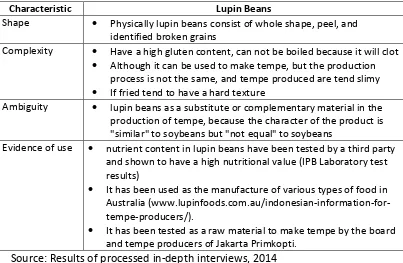

Knowledge characteristics

Knowledge Characteristics include the forms, complexity, ambiguity, and

evidence of the use. For the lupin tempe production, knowledge which occur is

divided into knowledge of lupin beans and knowledge about the process of

making lupin tempe. Knowledge of lupin beans are lupin beans characteristic in

the physical form (whole, peeled, and broken grains), the type of crop, nutrient

knowledge on lupin bean from the lupin beans producers, while the tempe

producers in Salatiga acquired knowledge about lupin bean from the producers

and Jakarta Primkopti boards who have acquired knowledge transfer about Lupin

beans first. These condition indicated that knowledge of the lupin bean is an

explicit knowledge, because it can be formulated. Characteristics of knowledge

for lupin bean obtained by the Jakarta and Salatiga Primkopti were described in

[image:14.595.111.514.295.558.2]the following table.

Table 2. Knowledge Characteristics Lupin of Products

Characteristic Lupin Beans

Shape Physically lupin beans consist of whole shape, peel, and

identified broken grains

Complexity Have a high gluten content, can not be boiled because it will clot

Although it can be used to make tempe, but the production process is not the same, and tempe produced are tend slimy

If fried tend to have a hard texture

Ambiguity lupin beans as a substitute or complementary material in the

production of tempe, because the character of the product is "similar" to soybeans but "not equal" to soybeans

Evidence of use nutrient content in lupin beans have been tested by a third party and shown to have a high nutritional value (IPB Laboratory test results)

It has been used as the manufacture of various types of food in Australia (www.lupinfoods.com.au/indonesian-information-for-tempe-producers/).

It has been tested as a raw material to make tempe by the board and tempe producers of Jakarta Primkopti.

Source: Results of processed in-depth interviews, 2014

Knowledge of lupin tempe making process, using the basic knowledge of

making soybean tempe that has been owned by the tempe producers. Stages of

making tempe in general are the same through the process of soaking, washing,

boiling, and the provision of yeast. Knowledge of the common steps are stored in

the minds of tempe producers, but can be formulated. The details of each

manufacturing process are not easily formulated as experience and

confidentiality of the product to be able to compete are the parts of the

tacit that can be converted into explicit. Therefore, the knowledge characteristics

about the Lupin tempe making process showed some characteristic differences

between tempe producers in Jakarta Primkopti and tempe producers in Salatiga

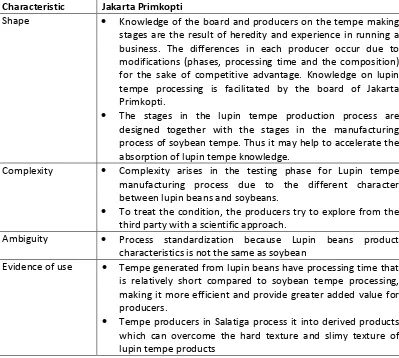

[image:15.595.111.510.231.589.2]Primkopti as shown in the following table

Table 3. Knowledge Characteristics on the Lupin Tempe Making Process Characteristic Jakarta Primkopti

Shape Knowledge of the board and producers on the tempe making

stages are the result of heredity and experience in running a business. The differences in each producer occur due to modifications (phases, processing time and the composition) for the sake of competitive advantage. Knowledge on lupin tempe processing is facilitated by the board of Jakarta Primkopti.

The stages in the lupin tempe production process are designed together with the stages in the manufacturing process of soybean tempe. Thus it may help to accelerate the absorption of lupin tempe knowledge.

Complexity Complexity arises in the testing phase for Lupin tempe

manufacturing process due to the different character between lupin beans and soybeans.

To treat the condition, the producers try to explore from the third party with a scientific approach.

Ambiguity Process standardization because Lupin beans product

characteristics is not the same as soybean

Evidence of use Tempe generated from lupin beans have processing time that is relatively short compared to soybean tempe processing, making it more efficient and provide greater added value for producers.

Tempe producers in Salatiga process it into derived products which can overcome the hard texture and slimy texture of lupin tempe products

Source: Results of processed in-depth interviews, 2014

Based on the opinions and trials of the producers to use lupin bean as a

basis for making tempe showed that knowledge of the lupin product and lupin

bean tempe-making process were easy to understand for both producers in

Jakarta Primkopti and Salatiga Primkopti. Knowledge ambiguity arised after the

process test of lupin bean tempe production. At the beginning, the knowledge

making tempe. But after the test was performed and the persistence of the

problems associated with lupin bean tempe products (slimy and hard if fried) and

the existence of price instability of lupin beans, then there was a shift from

substitution into complementary products in the tempe production. If the

problem of lupin bean tempe products which are slimy and sticky can be

overcome, then the producers will consider to use lupin beans as raw material

substitutes for soy beans, but if the problem can not be solved, the most

probable way is to use them as complementary goods in tempe production.

SMES characteristics

SMES Characteristics in the knowledge and technology transfer process

include the ability and availability of human resources, SMES motivation and

SMES absorption. In terms of availability of human resources in the regions those

were Central Jakarta and Salatiga it could be said that there were a lot of tempe

producers. Based on the data members summary, Central Jakarta Primkopti had

504 members in 2010 (Central Jakarta Primkopti Member List, 2010). While in

2012 there were 424 tempe producers as the members of Handayani Salatiga

Primkopti (Salatiga Primkopti Member List, 2012). Related to the ability and

absorption capacity of MSE to the knowledge and new technology which were

represented by the rate of MSE producers adoption, Suharti et al (2013) found

that more than 50% tempe producers in Salatiga Primkopti members were

categorized as innovators, early adopters and early majority. Based on these

findings it can be presumed that Salatiga tempe producers have the ability and

good absorption in the knowledge and technology transfer process. This

suspicion is strengthened by the findings that there were fairly high number of

tempe producers (30 people) who tested lupin bean processing as raw tempe

material (FGD Attendance List, 2014).

Related to the MSE motivation, this aspect becomes one of determining

Central Jakarta and Salatiga. Tempe producer SMES in Central Jakarta had large

production and marketing capacity, in the average a tempe producer needs 55 kg

per day (Central Jakarta Primkopti Member List, 2010) and based on the

information from Mr Haji Slamet, daily production quantity of the producers

always sold out. The stability of the marketing aspect of the tempe producers in

Central Jakarta made them reluctant to try something new and uncertain, such

as Lupin as substitute raw material for soybean in tempe production. Therefore it

can be concluded that tempe producer SMES motivation in the knowledge and

technology transfer process is low and they can be categorized as a group of late

majority adopters and laggards.

Salatiga tempe producer SMES have lower production capacity and

marketing capacity where in the average soybean demand is 16 kg per day for

individuals. This causes producers have high enough motivation to learn

something new that can increase the capacity of their operations and their ability

to compete. This could be seen through their enthusiasm in the FGD process

whereby a producer who had not been successful in processing the lupin bean

was actively listen and ask questions. For example, Mr. Amat Rohim, one of the

producers who has tried lupin beans but stopped halfway because the products

did not match the expectations and desires of the market. Mr. Amat Rohim

enthusiastically asked Mr. and Mrs. Nurchayati Basori as the producer who has

been successful in treating lupin beans about the process and the treatment that

they performed so that the resulting products were as they expected. The high

motivation of the tempe producers in Salatiga was increasingly apparent with a

variety of innovative efforts of Lupin derivative they developed after the results

of tempe Lupin were less acceptable by the market. A number of Lupin tempe

derivative products generated by the tempe producers in Salatiga Primkopti

include Lupin tempe chips (Basori Mr. and Mrs. Nurchayati), Lupin beans instant

have great potential to be developed and contribute added value much greater

to the tempe producers than to sell in the form of raw tempe.

Environmental characteristics

Various attempts have been made by Lupin party in the context of establish

relationships/social /personal relationship with the various parties who are

respected within the tempe producers in Indonesia. To introduce Lupin beans in

Indonesia, especially in Jakarta, they performed it in cooperation with the

Central Jakarta Primkopti as the founder and pioneer of the Kopti establishment

in Indonesia. Through this centre Kopti, the Lupin party also expected that the

approach to the government will be easier. Furthermore, for the knowledge and

technology transfer about Lupin to other tempe producers such as in Salatiga

municipality, then the Lupin party rely on Jakarta Primkopti as an arm of the

Lupin. Form interview with Mr. Haji Slamet as the committee chairman of Jakarta

Primkopti it can be concluded that there is a close and well established social

relationships between the Jakarta Primkopti and Primkopti in the regions. It is

believed to be one of the factors that makes the dissemination and transfer of

knowledge regarding Lupin beans can be well received in a number of areas

including Salatiga Primkopti.

In addition, WATO / Lupin party also took a systematic and planned

approach and involved universities such as Curtin University in Australia and the

Institute of Agriculture (IPB) and LIPI research institutes in Indonesia to test the

feasibility of the nutritional value of Lupin bean as a substitute for soybean in

tempe production. This effort was enough to convince the Primkopti and tempe

producers about the benefit and nutritional value of Lupin beans. It was as

recognized by a resource person from Salatiga (Pak Amat Rohim) as follows:

The role of the government is very important in relation to the availability

of lupin beans as substitute for soybean. One of the things that will be a plus

value for the producers to adopt lupin tempe is when Lupin bean price could be

cheaper than the soybean price. Therefore, there should be free import duty for

Lupin beans as the determinant of the Lupin bean price. Various attempts have

been made by the Lupin party together with Jakarta Primkopti to smooth the

Lupin import process by import duty exemption, but until now it has not been

realized and is still in process.

In addition to the various environmental aspects above which has been

accommodated well by the Lupin producers, another important factor to note is

also the cultural and social aspects of the market. As we know, tempe is a kind of

populist food in Indonesia, and for the tempe consumers in Indonesian, tempe is

identical to soybean. So many efforts to substitute soy beans with other raw

materials for tempe production need to consider the cultural aspects and

perceptions of consumers in Indonesia. In fact after Lupin beans were introduced

nearly five years since 2009, Lupin tempe was not widely known in Indonesian

market. This is presumably very closely related to the Indonesian environment

which has values and unique culture with regard to the perception of a

traditional food.

Market or consumer acceptance becomes one of the most important

aspects found in this study. The production of Lupin tempe which is harder and

has slimy texture compared to soybean tempe makes this product difficult to be

accepted by tempe lovers in Indonesia. In the mind of consumers, Lupin tempe

which has physical shape similar to soybean tempe is also expected to have the

same taste with soybean tempe. Different with "benguk" tempe and "koro"

tempe that are acceptable in Indonesian society because of the different shape

and texture compared to soybean tempe, so that consumers can receive a

"distinctive flavor" which is different from the tempe made from soybeans. Less

producers in Jakarta to continue producing Lupin tempe. Similarly, Salatiga

Primkopti tempe producers, nor produce Lupin tempe for sale to consumers in

the form of raw tempe, but it is processed again into derivative products such as

Lupin chips, Lupin pie and others that can be accepted by the market.

Achievement of Knowledge and Technology Transfer Phase in Tempe SMES

Gibson and Smilor (1991) suggested that there were four stages in the

knowledge and technology transfer process; those were the stage of creation,

sharing, implementation and commercialization. The knowledge / technology

transfer in the case of Lupin also pass through several stages. What is interesting

is that the study found Creation stage in the process of knowledge transfer of

Lupin beans was long enough. First, socialization of lupin bean as raw materials

to the tempe producers. Further the knowledge development faced an

internalization process for the initial knowledge in lupin beans creation process.

This condition is very attractive because to find out the lupin tempe making

process, the agent did not really have enough knowledge on tempe making

process. Thus, the knowledge discovery development was carried out by the

producer. The results of trials to soybean producers continued in the process of

sharing knowledge held by producers, manufacturers, nutritionists, customer

trials, and higher education institutions for the scientific approach to the

appropriate formulation related to lupin tempe. All these activities are included

in the Creation phase. What is more interesting here, in the Creation phase there

was also Sharing activities, such as knowledge/Lupin tempe production

technology sharing activities from Jakarta Primkopti to Salatiga Primkopti. In the

sharing phase there was also new knowledge creation as the results of

combining the test results of each producer in making Lupin tempe. The sharing

phase occurred when the producers were in discussions in the FGD forums and

non-formal meetings to share experiences to enhance the results of lupin tempe.

In general, knowledge and technology transfer activities on using Lupin

bean both in tempe producers in Jakarta Primkopti and tempe producers in

Salatiga Primkopti have reached the implementation stage. Jakarta tempe

producers have managed to make tempe Lupin and has tried to market to a

limited circle. However, because there was no positive response from the

market, the Lupin tempe producers inJakarta Primkopti stopped producing, it

means not proceed until the commercialization stage.

The study found different things concerning the stages of knowledge/ technology transfer in tempe producers in Salatiga who were more successful than producers in Jakarta. This is indicated by the presence of several producers

who have entered the commercialization stage by producing a other derived products from lupin beans, as one solution to overcome the problems that Lupin tempe was slimy and less preferred by consumers. Some producers such as Mrs.

and Mr. Basori Nurchayati made Lupin tempe chips which were received a positive response from the market and were often overwhelmed by consumer demand. Achievement stages in the process of knowledge transfer in the lupin

tempe production can be described as follows:

CONCLUSION AND RECOMMENDATIONS CONCLUSION

This study found that the knowledge and technology transfer process among

tempe producers for members Primkopti Jakarta and Primkopti Salatiga has been

running fine. This can be observed from the transfer achievement that have

reached the implementation stage for Primkopti Jakarta and commercialization

stages for tempe producers in Primkopti Salatiga. A number of factors were

found to be the key to success in the knowledge and technology transfer process

for tempe SMES are:

1. The agent must have organization reliability and adequate support resources.

The agents should be able to cooperate with the government, universities

and industrial world.

2. Media that covers the mechanisms and forms of transfer in accordance with

the conditions and characteristics of the target to be transferred should be

utilized. The transfer mechanism to SMES was performend through the

provision of samples, testing, training, meetings, mass media and internet

media as suitable media characteristics for the transfer of tacit knowledge

such as the process of making tempe from Lupin beans in this study

3. The form and usability of knowledge and technology transfer must be clear,

explicit, and does not cause ambiguity. This study found the the ambiguity of

transferred knowledge and technology so that the transfer activity was slow.

4. Environmental factor, especially social relations in the transfer process is one

important key to success. In this study, the agent’s (producer) effort to ask

officers from Jakarta Primkopti to assist the transfer of knowledge for

Primkoptis in regions is a smart move. Good social relationships between

Jakarta Primkopti as the founder of Primkopti with regional Primkopti may

smoothen the transfer activity of the agent to the regional Primkopti.

5. Environmental factor associated with market acceptance is also a

in Jakarta is not up to the commercialization stage because the market has

not been able to receive Lupin bean tempe. From the conducted focus group

discussions and study results, in fact it was found that tempe producers did

not object and face difficulties in adopting Lupin as a substitute for soy

beans, as long as Lupin tempe products were acceptable to consumers so

that their production could be sold.

6. In this case target motivation of tempe SMES is highly determine the success

of the transfer. Tempe producers in Salatiga were more successful than in

Central Jakarta because of their very high motivation to create and innovate

so they can produce Lupin tempe derivative products that can be

commercialized. Different with the producers in Jakarta, they were less

motivated to try new things because they were already comfortable with

producing soybean tempe with a relatively large turnover.

RECOMMENDATIONS

Some of the following suggestions are put forward based on the study results:

1. There was ambiguity of knowledge to be transferred that was a production

process that is always changing with no gold standard. Although from the

point of Lupin tempe production process did not show any significant

complexity, impressed even easier and more efficient to handle than

soybeans, but the absence of clear production standards cannot guarantee

the quality of the products (slimy and hard if they are fried) which make the

transfer targets hesitated to adopt lupin beans as a substitute raw material

of soy beans. Likewise, the production process activity have not include the

post-production management when Lupin tempe do not sold well in the

market, how to make use of products that do not sold well since tempe is a

perishable product. It is the duty of the Lupin producers in future, whether

to make Lupin tempe that is identical with soybean tempe, or want to make

soybean tempe, the task of Lupin producers in the future iw to generate a

production process that is capable to produceg output that is similar to the

quality of soybean tempe. For this goal, they may need to make

improvements at the input ranging from changing Lupin bean cultivation,

and at the production process until post-production. Conversely, if Lupin

tempe is expected to be acceptable for consumers with all of their specifics

(harder and somewhat slimy), then the producers would need to convince

consumers of the advantages and benefits of consuming tempe Lupin while

continuing to work on improving the production process of Lupin tempe.

2. From 5 years the producers make introdusir efforts, knowledge and

technology transfer of Lupin beans that are performed to impress the

market in Indonesia, it seems that Lupin producers give focus more on

exporting Lupin beans in large quantities into the Indonesian market.

Therefore, the efforts carried out by the producers are more focused on

efforts to convince the users those are Lupin bean tempe producers. There

is an impression that the Lupin producers as the knowledge transfer agent

ignore the acceptance of market / consumer to the tempe Lupin product. In

fact it is the most important element that can regulate the activity and

amount of Lupin tempe production of the producers. Therefore, prior to

the transfer to perform, the agents should also have information about the

market / customers well.

REFERENCE

Bozeman, B., 2000. Technology Transfer and Public Policy: A Review of Research and Theory. Journal of Research Policy, 29: 627-655.

Devine, M. D., T. E. James, Jr., and I. T. Adams. 1987. Government Supported Industry Research Centers: Issues for Successful Technology Transfer. Journal of Technology Transfer, Vol. 12, No.1, pp. 27-38.

Djmbp.esdm.go.id., 2008. Undang – Undang RI tentang Usaha Kecil dan

Menengah. Diunduh dari

Gibson, David and Smilor, Raymond. 1991. Key Variables in Technology Transfer: A Field-Study Based Empirical Analysis. Journal of Engineering and Technology Management, Vol.8, pp. 287-312.

Hidayat, Sukardi dan Nurul Insani. 2004. Analisis perbandingan pembuatan tempe. Laporan Penelitian Jurusan Teknologi Industri Pertanian

Universitas Brawijaya. Diunduh dari

http://ptp2007.wordpress.com/2007/08/31/ , tanggal 20 Januari 2012 Indriartiningtias, R., dan Wirajmadja, I.I. 2012. Pengembangan Model Konseptual

Transfer Pengetahuan dari Perguruan Tinggi ke Industri Kecil. Diunduh dari ejournal.umm.ac.id/index.php/industri/article/.../613, tanggal unduh 3 Desember 2013.

Julianto, D. E dan Wahyudi, E. 2010. Model Peningkatan Kapabilitas Daya Saing

Usaha Kecil Di Tulungagung. Diunduh dari

http://www.jurnalinspirat.com/Download/JI2_8.pdf, tanggal unduh 5

Maret 2014.

Lupinfoods.com.au. 2013. Informasi Bagi Pengrajin Tempe. Diakses dari

http://www.lupinfoods.com.au/indonesian-information-for-tempe-producers/, tanggal akses 17 Agustus 2014.

Nokes, T.J. 2009. Mechanismm of Knowledge Transfer.Thinking and Reasoning, Vol. 15, No. 1, pp. 1-36.

Profetto, J. 2004. Knowledge transfer : what it is and what it takes to do it best.

Diakses dari;

http://doc.mbalib.com/view/78ddb71531aa1561f55d2e8741435525.html

, tanggal akses 17 Maret 2014.

Sumarno, Muhammad. 2010. Tingkat Adopsi Inovasi Teknologi Pengusaha Sentra Industri Kecil Kerajinan Gerabah Kasongan Kabupaten Bantul. Jurnal Manajemen dan Kewirausahaan, Vol.12, NO. 1, MARET : 1-10.

Sung T.K., dan Gibson D. 2001. Knowledge and Technology Transfer: Levels and

KeyFactors. Diunduh dari

web.bsru.ac.th/~orapim/my_doc/knowledge.pdf, tanggal unduh 18 Maret 2014.

Tempo.co. 2014. Perajin Tempe di Malang Tergoda Kacang Lupin. Diakses dari

http://www.tempo.co/read/news/2014/01/26/090548396/Perajin-Tempe-di-Malang-Tergoda-Kacang-Lupin, tanggal akses 17 Agustus 2014.