APPENDIX 1

Steps OF Numerical Simulation

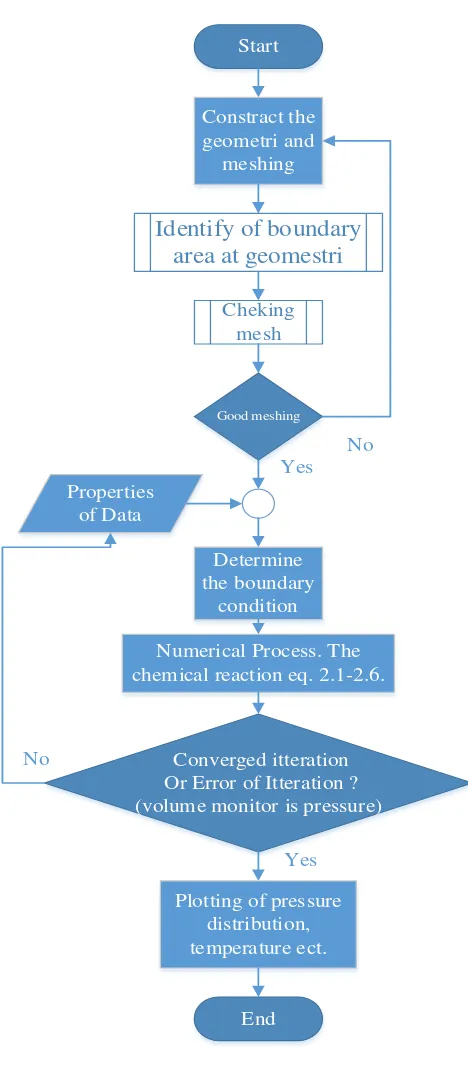

After planning a CFD analysis on the model. Common step in the completion of Fluent CFD analysis as follows:

1. Create geometry and mesh on the model

2. Choosing the right solver for the model (2d or 3d) 3. Importing mesh model (grid)

4. Pass the examination on the mesh models 5. Choosing a solver formulation

6. Selecting the basic equations used in the analysis, such laminar, tubulen, chemical reactions, heat transfer, etc.

7. Determining the material properties 8. Determining the boundary conditions 9. Set the parameters of the control solution 10. Initialization the flow field

11. Calculation / iteration

12. Double check the results of the iteration 13. Saving iteration results.

Start

Constract the geometri and

meshing

Identify of boundary area at geomestri

Cheking mesh

Good meshing

No Yes

Determine the boundary

condition

Numerical Process. The chemical reaction eq. 2.1-2.6.

Converged itteration Or Error of Itteration ? (volume monitor is pressure) Properties

of Data

Plotting of pressure distribution, temperature ect.

APPENDIX 2

Space Temperature Space Temperature Space Temperature Space Temperature

0.00 394.08 0.00 304.00 0.00 305.57 0.00 304.05

3.18 394.07 3.18 304.00 3.18 305.57 3.18 304.05

6.35 394.07 6.35 304.00 6.35 305.58 6.35 304.05

9.53 394.08 9.53 304.00 9.53 305.60 9.53 304.05

12.70 394.08 12.70 304.00 12.70 305.63 12.70 304.05

15.88 394.08 15.88 304.00 15.88 305.67 15.88 304.05

19.05 394.09 19.05 304.00 19.05 305.73 19.05 304.06

22.23 394.10 22.23 304.00 22.23 305.82 22.23 304.06

25.40 394.12 25.40 304.00 25.40 305.98 25.40 304.06

28.58 394.17 28.58 304.00 28.58 306.46 28.58 304.06

31.75 394.18 31.75 304.00 31.75 306.79 31.75 304.06

34.93 394.13 34.93 304.00 34.93 306.16 34.93 304.06

38.10 394.10 38.10 304.00 38.10 306.00 38.10 304.07

41.28 394.09 41.28 304.00 41.28 305.97 41.28 304.07

44.45 394.08 44.45 304.00 44.45 305.99 44.45 304.07

47.63 394.08 47.63 304.00 47.63 306.05 47.63 304.07

50.80 394.08 50.80 304.00 50.80 306.13 50.80 304.08

53.98 394.09 53.98 304.00 53.98 306.24 53.98 304.08

57.15 394.10 57.15 304.00 57.15 306.41 57.15 304.09

60.33 394.12 60.33 304.00 60.33 306.70 60.33 304.09

63.50 394.15 63.50 304.00 63.50 307.52 63.50 304.10

66.68 394.12 66.68 304.00 66.68 306.98 66.68 304.10

69.85 394.10 69.85 304.00 69.85 306.90 69.85 304.11

73.03 394.09 73.03 304.00 73.03 306.98 73.03 304.11

76.20 394.08 76.20 304.01 76.20 307.15 76.20 304.12

79.38 394.08 79.38 304.02 79.38 307.38 79.38 304.13

82.55 394.09 82.55 304.04 82.55 307.70 82.55 304.13

85.73 394.10 85.73 304.08 85.73 308.14 85.73 304.14

88.90 394.11 88.90 304.15 88.90 308.77 88.90 304.15

92.08 394.14 92.08 304.29 92.08 309.83 92.08 304.16

95.25 394.19 95.25 304.83 95.25 312.61 95.25 304.17

Continuance

Space Temperature Space Temperature Space Temperature Space Temperature 98.43 394.18 98.43 305.61 98.43 313.25 98.43 304.18 101.60 394.14 101.60 306.15 101.60 313.08 101.60 304.20 104.77 394.13 104.77 307.29 104.77 314.53 104.77 304.21 107.95 394.14 107.95 309.52 107.95 317.15 107.95 304.22 111.12 394.16 111.12 312.96 111.12 321.26 111.12 304.24 114.30 394.19 114.30 318.84 114.30 327.39 114.30 304.26 117.47 394.25 117.47 328.09 117.47 336.30 117.47 304.28 120.65 394.32 120.65 341.20 120.65 349.27 120.65 304.32 123.82 394.43 123.82 362.92 123.82 367.78 123.82 304.36 127.00 394.55 127.00 394.13 127.00 394.30 127.00 304.42

Temperature Distribution inside The Chamber at 400 S

APPENDIX 3

Space Temperature Space Temperature Space Temperature Space Temperature

0.00 540.55 0.00 304.00 0.00 311.46 0.00 305.72

3.18 540.55 3.18 304.00 3.18 311.47 3.18 305.72

6.35 540.55 6.35 304.00 6.35 311.52 6.35 305.72

9.53 540.55 9.53 304.00 9.53 311.60 9.53 305.73

12.70 540.56 12.70 304.00 12.70 311.72 12.70 305.74

15.88 540.57 15.88 304.00 15.88 311.90 15.88 305.75

19.05 540.58 19.05 304.00 19.05 312.14 19.05 305.77

22.23 540.61 22.23 304.00 22.23 312.49 22.23 305.79

25.40 540.64 25.40 304.00 25.40 313.02 25.40 305.81

28.58 540.71 28.58 304.00 28.58 314.58 28.58 305.83

31.75 540.73 31.75 304.00 31.75 315.65 31.75 305.86

34.93 540.65 34.93 304.00 34.93 313.77 34.93 305.89

38.10 540.60 38.10 304.00 38.10 313.29 38.10 305.92

41.28 540.58 41.28 304.00 41.28 313.23 41.28 305.96

44.45 540.57 44.45 304.00 44.45 313.34 44.45 306.00

47.63 540.57 47.63 304.00 47.63 313.57 47.63 306.04

50.80 540.57 50.80 304.01 50.80 313.92 50.80 306.09

53.98 540.58 53.98 304.01 53.98 314.40 53.98 306.14

57.15 540.59 57.15 304.02 57.15 315.06 57.15 306.19

60.33 540.63 60.33 304.04 60.33 316.13 60.33 306.25

63.50 540.69 63.50 304.10 63.50 318.93 63.50 306.31

66.68 540.63 66.68 304.16 66.68 317.60 66.68 306.38

69.85 540.59 69.85 304.22 69.85 317.60 69.85 306.44

73.03 540.58 73.03 304.34 73.03 318.17 73.03 306.52

76.20 540.57 76.20 304.54 76.20 319.09 76.20 306.60

79.38 540.57 79.38 304.86 79.38 320.37 79.38 306.68

82.55 540.58 82.55 305.35 82.55 322.08 82.55 306.76

85.73 540.60 85.73 306.09 85.73 324.32 85.73 306.85

88.90 540.63 88.90 307.19 88.90 327.37 88.90 306.95

92.08 540.68 92.08 308.80 92.08 331.94 92.08 307.05

95.25 540.76 95.25 313.93 95.25 342.55 95.25 307.16

Temperature Distribution inside The Chamber at 800 S

Continuance

Space Temperature Space Temperature Space Temperature Space Temperature 98.43 540.74 98.43 321.24 98.43 348.34 98.43 307.27 101.60 540.68 101.60 324.93 101.60 350.31 101.60 307.39 104.77 540.67 104.77 330.74 104.77 356.57 104.77 307.52 107.95 540.69 107.95 340.00 107.95 366.17 107.95 307.65 111.12 540.72 111.12 352.95 111.12 379.55 111.12 307.80 114.30 540.77 114.30 371.51 114.30 397.40 114.30 307.96 117.47 540.86 117.47 397.09 117.47 420.73 117.47 308.15 120.65 540.97 120.65 430.50 120.65 451.14 120.65 308.42 123.82 541.12 123.82 477.99 123.82 490.37 123.82 308.76 127.00 541.28 127.00 540.63 127.00 540.94 127.00 309.17

Temperature Distribution inside The Chamber at 800 S

APPENDIX 4

Space Temperature Space Temperature Space Temperature Space Temperature

0.00 630.25 0.00 304.00 0.00 320.29 0.00 313.05

3.18 630.25 3.18 304.00 3.18 320.31 3.18 313.05

6.35 630.25 6.35 304.00 6.35 320.40 6.35 313.06

9.53 630.25 9.53 304.00 9.53 320.57 9.53 313.08

12.70 630.26 12.70 304.00 12.70 320.82 12.70 313.11

15.88 630.27 15.88 304.00 15.88 321.15 15.88 313.15

19.05 630.28 19.05 304.00 19.05 321.60 19.05 313.20

22.23 630.30 22.23 304.01 22.23 322.21 22.23 313.25

25.40 630.32 25.40 304.01 25.40 323.12 25.40 313.31

28.58 630.38 28.58 304.01 28.58 325.56 28.58 313.38

31.75 630.39 31.75 304.02 31.75 327.32 31.75 313.46

34.93 630.33 34.93 304.02 34.93 324.62 34.93 313.55

38.10 630.30 38.10 304.03 38.10 323.97 38.10 313.65

41.28 630.28 41.28 304.04 41.28 323.97 41.28 313.75

44.45 630.27 44.45 304.06 44.45 324.28 44.45 313.87

47.63 630.27 47.63 304.09 47.63 324.81 47.63 313.99

50.80 630.27 50.80 304.14 50.80 325.56 50.80 314.12

53.98 630.27 53.98 304.21 53.98 326.56 53.98 314.26

57.15 630.29 57.15 304.32 57.15 327.88 57.15 314.41

60.33 630.31 60.33 304.48 60.33 329.90 60.33 314.57

63.50 630.36 63.50 304.99 63.50 334.80 63.50 314.74

66.68 630.31 66.68 305.51 66.68 333.66 66.68 314.92

69.85 630.29 69.85 305.92 69.85 334.24 69.85 315.10

73.03 630.28 73.03 306.58 73.03 335.83 73.03 315.30

76.20 630.27 76.20 307.56 76.20 338.14 76.20 315.51

79.38 630.27 79.38 308.95 79.38 341.18 79.38 315.73

82.55 630.28 82.55 310.85 82.55 345.08 82.55 315.96

85.73 630.30 85.73 313.43 85.73 349.99 85.73 316.20

88.90 630.32 88.90 316.88 88.90 356.33 88.90 316.45

92.08 630.37 92.08 321.44 92.08 365.08 92.08 316.71

95.25 630.44 95.25 334.33 95.25 383.27 95.25 316.99

98.43 630.43 98.43 352.27 98.43 396.53 98.43 317.28

Temperature Distribution inside The Chamber at 1200 S

Continuance

98. 3 630. 3 98. 3 35 . 7 98. 3 396.53 98. 3 3 7. 8

Space Temperature Space Temperature Space Temperature Space Temperature

101.60 630.39 101.60 360.62 101.60 402.65 101.60 317.58

104.77 630.39 104.77 371.79 104.77 413.89 104.77 317.89

107.95 630.41 107.95 387.82 107.95 429.46 107.95 318.23

111.12 630.44 111.12 409.06 111.12 449.63 111.12 318.59

114.30 630.48 114.30 436.95 114.30 474.79 114.30 318.97

117.47 630.54 117.47 472.38 117.47 505.34 117.47 319.43

120.65 630.62 120.65 516.42 120.65 541.74 120.65 320.04

123.82 630.71 123.82 569.19 123.82 583.90 123.82 320.82

127.00 630.78 127.00 630.31 127.00 630.57 127.00 321.76

Temperature Distribution inside The Chamber at 1200 S

APPENDIX 5

Transient Temperature a. Furnace

At the furnace, the transient temperature is given by the bottom temperature from the experimental data that recorded every 60 seconds. We give the profil of the transient temperature as bellow:

683

On the top furnace is given the transient temperature of top temperature T2 from the experimental data. We give the profil of the transient temperature as bellow:

APPENDIX 6 UDF Used in this Analysis

a. Velocity Inlet:

Inlet velocity is an initial of volatile inlet, in this boundary condition the user define function (UDF) is given. However, the velocity adjusted to obtain a good deal on increasing the pressure inside chamber when the wood pyrolysis process started. We give the profil of the transient temperature as bellow: Volatile sublimation are:

#include "udf.h" #include "mem.h"

DEFINE_PROFILE(soblimation,t, i) {

if(timma>=120.0) {

vola=1.0e-6/(1.0e-7*(timma-120.0)*(timma-120.0)+1.0e-4); if(vola<=5.0e-3) vola=5.0e-3;

b. Chemical reaction Arrheneus Equation: #include "udf.h"

#define ACTIVE 2.36e+08 #define BETA 0

DEFINE_VR_RATE(multistep_volrate, c, t, r, mw, yi, rr, rr_t) {

double tempei; double PRE_EXP; double nmt; double waktu; double acfactor=2.0; waktu=CURRENT_TIME; tempei=C_T(c,t);

nmt=15.0+acfactor*2.0*450.0*tempei/(tempei*tempei+450.0*450.0); PRE_EXP=pow(10.0,nmt);

{

PRE_EXP=1.0e+25; tempei=300;

}

*rr=PRE_EXP*pow(tempei,BETA)*exp(-ACTIVE/(UNIVERSAL_GAS_CONSTANT*tempei)); if(*rr>5.0e-2) *rr=5.0e-2;

APPENDIX 7

0 -0.078 1.7.E+04 305 305 305

60 -0.078 1.7.E+04 312 306 306

120 -0.078 1.7.E+04 316 306 306

180 -0.078 1.7.E+04 338 306 306

240 -0.078 1.7.E+04 349 306 306

300 -0.078 1.7.E+04 368 306 306

360 -0.078 1.7.E+04 382 307 306

420 -0.078 1.7.E+04 407 307 306

480 -0.078 2.4.E+04 419 308 306

540 -0.062 2.9.E+04 444 310 306

600 -0.062 2.9.E+04 468 312 306

660 -0.062 2.9.E+04 498 315 306

720 -0.06 3.0.E+04 524 317 307

780 -0.06 3.7.E+04 545 319 307

840 -0.06 3.7.E+04 573 324 308

900 -0.06 3.7.E+04 591 327 308

960 -0.05 6.0.E+04 607 333 310

1020 -0.04 7.7.E+04 622 336 310

1080 -0.03 9.3.E+04 640 344 311

1140 0 1.2.E+05 652 348 313

1200 0 1.4.E+05 662 355 315

1260 0.03 1.8.E+05 671 365 318

1320 0.08 2.0.E+05 603 381 319

1380 0.1 2.0.E+05 449 391 355

1440 0.1 2.0.E+05 558 401 358

1500 0.1 2.0.E+05 455 387 366

1560 0.1 2.0.E+05 452 390 368

1620 0.1 2.0.E+05 453 411 371

T 3 (Surface)

As furnace boundary condition

As top furnace boundary condition

: 22 Februari 2013 Experiment

Material (kg)

Continuance

T 1 (Bottom) T 2 (Top)

(Sec.) (MPa) Pressure (Pa) (K) (K) (K)

1680 0.1 2.1.E+05 507 426 376

1740 0.1 2.0.E+05 631 433 383

1800 0.1 2.0.E+05 673 437 388

1980 0.11 2.1.E+05 718 445 401

2160 0.1 2.0.E+05 755 463 414

2340 0.1 2.0.E+05 761 490 429

2520 0.12 2.1.E+05 683 489 441

2700 0.1 2.0.E+05 793 530 453

2880 0.1 2.0.E+05 776 550 465

3060 0.1 2.0.E+05 802 557 475

3240 0.1 2.0.E+05 809 569 486

3420 0.1 2.0.E+05 818 589 500

3600 0.1 2.0.E+05 809 617 519

Time P1 Absolute As furnace T 3 (Surface)

boundary condition

Date Tar : 1.73 kg

: II Chart : 1.25 kg

: 5 kg gas : 1.00 kg

Pressure : 0.1 MPa

Time P1 Absolute T 1 (Bottom) T 2 (top) T 3 (surface)

(Sec.) (MPa) Pressure (Pa) (K) (K) (K)

0 -0.09 10000 303 303 303

60 -0.09 10000 310 303 303

120 -0.09 10000 328 305 304

180 -0.09 10000 341 305 304

240 -0.09 10000 361 307 304

300 -0.09 10000 371 308 304

360 -0.09 10000 388 311 305

420 -0.09 10000 411 311 305

480 -0.08 20000 430 315 305

540 -0.08 20000 444 317 305

600 -0.08 20000 458 320 306

660 -0.08 20000 478 326 308

720 -0.08 20000 496 330 309

780 -0.07 30000 517 338 310

840 -0.07 30000 536 347 312

900 -0.07 30000 546 348 313

960 -0.04 60000 564 356 315

1020 -0.02 80000 581 352 318

1080 0 100000 599 357 320

1140 0.03 130000 612 363 324

1200 0.06 160000 626 369 328

1260 0.1 200000 633 379 337

1320 0.1 200000 586 435 358

1380 0.1 200000 609 398 362

: 26 Februari 2013 Expe riment

Time

P1

Absolute

T 1 (Bottom) T 2 (top) T 3 (surface)

(Sec.)

(MPa) Pressure (Pa)

(K)

(K)

(K)

1680

0.11

210000

708

475

414

1740

0.1

200000

726

482

420

1800

0.1

200000

737

486

426

1980

0.1

200000

761

510

442

2160

0.1

200000

779

526

454

2340

0.1

200000

810

539

465

2520

0.1

200000

816

551

473

2700

0.1

200000

822

560

480

2880

0.1

200000

815

571

489

3060

0.1

200000

802

575

498

3240

0.1

200000

805

578

505

3420

0.1

200000

807

596

525

APPENDIX 9

Date : 20 Maret 2013 Tar : 1.73 kg

Experiment : II Chart : 1.25 kg

Material (kg) : 5 kg gas : 1.00 kg

Pressure : 0.1 MPa

Time P1 Absolute T 1 (Bottom) T 2 (top) T 3 (surface)

(Sec.) (MPa) Pressure (Pa) (K) (K) (K)

0 -0.080 20000 306 306 306

60 -0.080 20000 321 306 306

120 -0.080 20000 331 307 306

180 -0.080 20000 338 307 306

240 -0.080 20000 347 307 306

300 -0.080 20000 363 308 306

360 -0.080 20000 379 308 306

420 -0.080 20000 396 309 306

480 -0.080 20000 418 310 306

540 -0.080 20000 447 312 306

600 -0.080 20000 482 314 306

660 -0.080 20000 512 318 309

720 -0.070 30000 545 320 307

780 -0.070 30000 573 327 309

840 -0.060 40000 604 336 311

900 -0.060 40000 622 336 311

960 -0.050 50000 638 339 314

1020 -0.030 70000 654 341 317

1080 -0.020 80000 656 343 318

1140 0.000 100000 686 346 320

Continuance

Time P1 Absolute T 1 (Bottom) T 2 (top) T 3 (surface)

(Sec.) (MPa) Pressure (Pa) (K) (K) (K)

1680 0.100 200000 737 446 408

1740 0.100 200000 743 444 409

1800 0.100 200000 753 454 413

1980 0.100 200000 762 474 427

2160 0.100 200000 776 471 431

2340 0.100 200000 765 489 448

2520 0.100 200000 764 509 454

2700 0.100 200000 772 541 465

2880 0.100 200000 778 547 471

3060 0.100 200000 815 562 483

3240 0.100 200000 832 582 499

3420 0.100 200000 853 589 509