LAMPIRAN 1

PEMASANGAN DAN PENGUJIAN ALAT

Gambar Tahap Pemasangan alat

Gambar 4.1 penyesuaian heatsink pada aluminium penyerap panas

Gambar 4.3 melengketkan thermo glue pada TEG danheatsink

(a) (b) Gambar 4.5.tempat lampu dan dudukan panci dipasang (a);

alat ditempatkan pada kompor LPG (b)

Gambar Tahap Pengujian Alat

(a)

(b)

Gambar 6.8 tampilan hasil pengukuran menggunakan Visual Basic 6.0

LAMPIRAN II

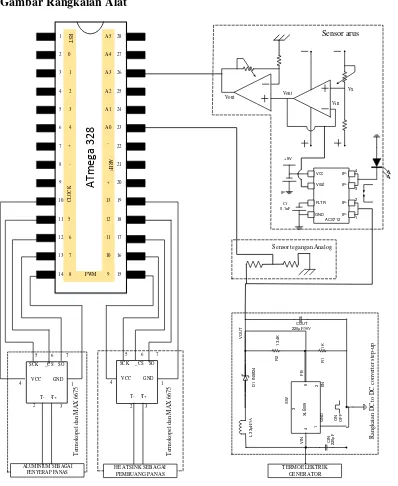

Gambar Rangkaian Alat

A

ALUMINIUM SEBAGAI PENYERAP PANAS

HEATSINK SEBAGAI PEMBUANG PANAS

Sensor tegangan Analog

TERMOELEKTRIK GENERATOR

LAMPIRAN III

Program Alat Secara Keseluruhan

a. Program pada visual basi 6.0

'deklarasi variable object aplikasi Excel Dim oXL As Excel.Application

Private Sub Form_Load() Command2.Enabled = False Timer1.Enabled = False Timer3.Enabled = False Timer4.Enabled = False Label12.Caption = "00" Label13.Caption = "00" Label14.Caption = "00" Label9.Caption = "00" Label10.Caption = "00" Label11.Caption = "00" Timer1.Enabled = False Timer2.Enabled = False Timer1.Interval = 450 Timer2.Interval = 450 End Sub

Private Sub Command1_Click() Timer4.Enabled = True

With MSComm1 .CommPort = 9 .PortOpen = True .Settings = "9600,n,8,1" .NullDiscard = False

.InputMode = comInputModeText End With

MSComm1.RThreshold = 53

Label1.Caption = "SUHU ALUMINIUM" Label2.Caption = "SUHU HEATSINK" Label3.Caption = "NILAI TEGANGAN" Label4.Caption = "NILAI ARUS"

Label5.Caption = Chr(176) + "celcius" Label6.Caption = Chr(176) + "celsius" Label7.Caption = "Volt"

Label8.Caption = "Milli Ampere"

End Sub

Private Sub Command2_Click() Command2.Enabled = False Command4.Enabled = False Command3.Enabled = True oXL.Workbooks.Close End Sub

Private Sub Command3_Click() End

End Sub

Command4.Enabled = False Command2.Enabled = True Command3.Enabled = False Set oXL = New Application 'menambahkanbukukerjabaru oXL.Workbooks.Add

oXL.Visible = True

Sheets("sheet1").Columns("A:F").ColumnWidth = 20 Range("A1:F1").HorizontalAlignment = xlCenter End Sub

Private Sub MSComm1_OnComm()

Dim umum, ya, ye, yi, yo, ka, ke, ki, mo, ma, mi, za, ze, zi, zo As String Dim t1, t2, t3, t4, l11, l10, l9 As String

If MSComm1.CommEvent = 2 Then umum = MSComm1.Input

ya = InStr(umum, "S1") If ya> 0 Then

ye = InStr(umum, "S2") If ye > 0 Then

ze = Trim(ze)

yi = InStr(umum, "S3") If yi> 0 Then

End If End Sub

Private Sub Timer1_Timer() On Error Resume Next

oXL.Worksheets(1).Range("A1") = "SUHU ALUMINIUM" oXL.Worksheets(1).Range("B1") = "SUHU HEATSINK" oXL.Worksheets(1).Range("C1") = "NILAI TEGANGAN" oXL.Worksheets(1).Range("D1") = "NILAI ARUS"

oXL.Worksheets(1).Range("E1") = "MENIT" oXL.Worksheets(1).Range("F1") = "DETIK" ActiveCell.EntireRow.Offset(1, 0).Insert oXL.Worksheets(1).Range("A2") = Text1.Text oXL.Worksheets(1).Range("B2") = Text2.Text oXL.Worksheets(1).Range("C2") = Text3.Text oXL.Worksheets(1).Range("D2") = Text4.Text oXL.Worksheets(1).Range("E2") = Label12.Caption oXL.Worksheets(1).Range("F2") = Label13.Caption On Error Resume Next

Timer1.Enabled = False Timer2.Enabled = True

End Sub

Private Sub Timer2_Timer() Timer1.Enabled = True Timer2.Enabled = False End Sub

Private Sub Timer3_Timer()

If Len(Label11.Caption) = 1 Then Label11.Caption = "0" & Label11.Caption If Label11.Caption = "60" Then

Label11.Caption = "00"

Label10.Caption = Val(Label10.Caption) + 1

If Len(Label10.Caption) = 1 Then Label10.Caption = "0" & Label10.Caption End If

If Label10.Caption = "60" Then Label10.Caption = "00"

Label9.Caption = Val(Label9.Caption) + 1

If Len(Label9.Caption) = 1 Then Label9.Caption = "0" & Label9.Caption End If

End Sub

Private Sub Timer4_Timer()

Label14.Caption = Val(Label14.Caption) + 1

If Len(Label14.Caption) = 1 Then Label14.Caption = "0" & Label14.Caption If Label14.Caption = "60" Then

Label14.Caption = "00"

Label13.Caption = Val(Label13.Caption) + 1

If Len(Label13.Caption) = 1 Then Label13.Caption = "0" & Label13.Caption End If

If Label13.Caption = "60" Then Label13.Caption = "00"

Label12.Caption = Val(Label12.Caption) + 1

If Len(Label12.Caption) = 1 Then Label12.Caption = "0" & Label12.Caption End If

b. Program AlatMenggunakanArduino

#include "max4.h" #include "max3.h" int t3DO = 5;

MAX4 t4couple(t4CLK, t4CS, t4DO); MAX3 t3couple(t3CLK, t3CS, t3DO); int v3 = 6;

pinMode(v4, OUTPUT); digitalWrite(v4, HIGH); pinMode(g4, OUTPUT); digitalWrite(g4, LOW); pinMode(v3, OUTPUT); digitalWrite(v3, HIGH); pinMode(g3, OUTPUT); digitalWrite(g3, LOW); }

for(inti=0; i<50; i++){

ce=ce/y;

Serial.print("S1 = "); Serial.println(ce-7.00); }

void t3() { float num[50]; int y; floatce=0;

for(inti=0; i<50; i++){

num[i] = t3couple.readCelsius(),DEC; ce=ce+num[i]; if(num[i]>0){ y++;} }

ce=ce/y;

Serial.print("S2 = "); Serial.println(ce+7.00); }

void S3() {

intNilaiSensor = analogRead(A0); floathasil=0;

floatTegangan =NilaiSensor*0.260064935; hasil=hasil+Tegangan;

hasil=hasil/5;

Serial.print("S3 = "); Serial.println(hasil); }

void S4()

{ float total=0; int tot=0; float Z[10]; int E=0; float W=0; float G=0; int max=0;

floatBil=0; int Go=0;int byk=0; intmin;floatkalkulasi=0; for (int z=0; z<10; z++){

float h5=0; float h4=0; float h6; int j=0; int j2=0; int j1=0; float hasil=0; int hasil1=0;

for (int i2=0; i2<10; i2++){j2=0; h6=0;

for (int i1=0; i1<30; i1++){ j1=0; h5=0; hasil=0; for(inti=0;i<50;i++){

X[i]=analogRead(A3),DEC;

if (j>=48){h5=h4;} else {h5=hasil/j1;} Y[i1]=h5; j2++;

floattmp; float B=0; float banyak=0; float semua=0; int C=0; int D=0; int E=0;float F=0; int G=0; int go=0;

for(int j=0; j<10; j++){ if (num[j]!=0){

num[h] = tmp;

if (num[h]==num[i]){jumlah++;} }

if (h == 0) {

max = jumlah; //memunculkannilaimax,min min = jumlah;

if (jumlah == max){D++; gis[D]=num[h]; }

for (int h = 1; h < D+1; h++) { intjumlah=0;

for (inti=1; i<D+1; i++){ if (gis[h]==gis[i]){jumlah++;} }

if (gis[h] != gis[h - 1]) { F=F+gis[h];C++; }

}}

if(C==1){if (F!=0){semua=F;} if (F==0){semua=B/banyak;}} if(C>1){semua=F/C;}

Bil=Bil+Z[j]; byk++; } G++; Go=Go+Z[j];} if(Go=0){kalkulasi=0.00;} if(Bil!=0){

if (Z[h] > Z[i]) { G = Z[i]; Z[i] = Z[h]; Z[h] = G;} }}}

for (int h=0; h<10; h++){{if(Z[h]!=0){ intjumlah=0;

for (inti=0; i<10; i++){ if (Z[h]==Z[i]){jumlah++;} }

if (h==1){max=jumlah; min=jumlah;} else if(min>jumlah){min=jumlah;} else if(max<jumlah){max=jumlah;} else{}

if(Z[h]!=0){E++; W=W+Z[h]; }}}}

kalkulasi= W/E;

if(W==0){kalkulasi=0.00;}

if(kalkulasi<=1.16){kalkulasi=0; total=kalkulasi; } if(kalkulasi>=1.17){if(kalkulasi<2.00){

total=kalkulasi/11.7;}}

if(kalkulasi>2.00){if(kalkulasi<2.145){

if(kalkulasi>2.979){if(kalkulasi<3.10){ total=kalkulasi/0.64;}}

if(kalkulasi>3.10){if(kalkulasi<3.12){ total=kalkulasi/0.622;}}

if(kalkulasi>=3.12){if(kalkulasi<=4.42){ total=kalkulasi/0.442;}}

if(kalkulasi>=4.31 &&kalkulasi<4.33){total=(kalkulasi/0.431)+0.00;}

if(kalkulasi>=4.34 &&kalkulasi<4.37){total=(kalkulasi/0.361666667)+0.00;} if(kalkulasi>=4.37 &&kalkulasi<4.42){total=(kalkulasi/0.336153846)+0.00;} if(kalkulasi>=4.42 &&kalkulasi<5.62){total=(kalkulasi/0.315714286)+0.00;} if(kalkulasi>=5.62 &&kalkulasi<5.63){total=(kalkulasi/0.374666667)+0.00;} if(kalkulasi>=5.63 &&kalkulasi<5.66){total=(kalkulasi/0.351875)+0.00;} if(kalkulasi>=5.66 &&kalkulasi<5.69){total=(kalkulasi/0.332941176)+0.00;} if(kalkulasi>=5.69 &&kalkulasi<5.7){total=(kalkulasi/0.316111111)+0.00;} if(kalkulasi>=5.7 &&kalkulasi<6.85){total=(kalkulasi/0.3)+0.00;}

if(kalkulasi>=6.85 &&kalkulasi<6.86){total=(kalkulasi/0.3425)+0.00;} if(kalkulasi>=6.86 &&kalkulasi<6.87){total=(kalkulasi/0.326666667)+0.00;} if(kalkulasi>=6.87 &&kalkulasi<6.935){total=(kalkulasi/0.312272727)+4.0;} if(kalkulasi>=6.935 &&kalkulasi<7){total=(kalkulasi/0.301521739)+0.00;} if(kalkulasi>=7 &&kalkulasi<8){total=(kalkulasi/0.291666667)+0.00;} if(kalkulasi>=8 &&kalkulasi<8.2){total=(kalkulasi/0.32)+0.00;}

if(kalkulasi>=8.2 &&kalkulasi<8.4){total=(kalkulasi/0.315384615)+0.00;} if(kalkulasi>=8.4 &&kalkulasi<8.6){total=(kalkulasi/0.311111111)+0.00;} if(kalkulasi>=8.6 &&kalkulasi<8.8){total=(kalkulasi/0.307142857)+0.00;} if(kalkulasi>=8.8 &&kalkulasi<10){total=(kalkulasi/0.303448276)+0.00;} if(kalkulasi>=9 &&kalkulasi<10.2){total=(kalkulasi/0.3)+1.00;}

if(kalkulasi>=9.2 &&kalkulasi<10.4){total=(kalkulasi/0.296774194)+6.00;} if(kalkulasi>=9.4 &&kalkulasi<10.6){total=(kalkulasi/0.29375)+6.00;} if(kalkulasi>=9.6 &&kalkulasi<10.8){total=(kalkulasi/0.290909091)+6.00;} if(kalkulasi>=9.8 &&kalkulasi<10){total=(kalkulasi/0.288235294)+6.00;} if(kalkulasi==10){total=kalkulasi/0.280526316;}

if(kalkulasi>10){total=kalkulasi/0.24;}

LAMPIRAN IV

DATA SHEET TEG1 241-1.4-1.2

Power low, over the years has not been people's attention. In recent years, because the energy crisis, the development of new energy has become an urgent matter, power generation chip is taken seriously. Now there are many state-level research institutions to invest in this area of research and development. Improve energy conversion efficiency and increase the service life as the primary goal. Currently fruitful. The future direction of development is combined with solar energy, catch up and go beyond the solar power generation module technology.

Power generation chip commonly used areas of application are as follows: factory thermal power generation, geothermal power generation, vehicle ship exhaust pipe heating power generation, oil pipeline or gas pipe cathodic corrosion

Installation Precautions:

The power generation chip must be mounted on a flat surface (especially by the cold side). Installation surface height error shall not exceed 20 microns

The pressure is less than 12-15 kg / cm2

Often used when the heating surface temperature shall not exceed 200 ℃