ANALISIS SISTEM SERTIFIKASI DAN POTENSIAL PASAR

VULKANISIR BAN UNTUK PESAWAT TERBANG

TUGAS BESAR

Diajukan untuk memenuhi tugas akhir mata kuliah Kelaikan Udara

Disusun Oleh :

Febriyan Prayoga 13610039 Yosua Andre Purnomo 13611015 Abdul Rozak Rivai F 13611025

PROGRAM STUDI AERONOTIKA DAN ASTRONOTIKA FAKULTAS TEKNIK MESIN DAN DIRGANTARA

INSTITUT TEKNOLOGI BANDUNG BANDUNG

1 PRAKATA

Puji dan syukur kami panjatkan kepada Tuhan Yang Maha Esa karena atas rahmat dan kehendak-Nya kami dapat menyelesaikan Analisis Sistem Sertifikasi dan Potensi Pasar Vulkanisasi Ban untuk Pesawat Terbang. Analisis ini disusun sebagai salah satu tugas mata kuliah kelaikan Udara dengan kode AE4060 pada semester genap tahun akademik 2014/2015.

Tujuan dari perancangan ini adalah membuat konsep sertifikasi dari salah satu bagian pesawat terbang yang penting, yaitu ban vulkanisasi. Selain itu dilakukan juga analisis potensi pasar yang dapat dimasuki oleh pabrikan ban di Indonesia yang sudah cukup menjamur jika ada yang ingin merambah kedalam cabang industri ini.

Berbagai proses telah kami lalui dalam rangka menyelesaikan perancangan bandara ini. Berbagai kendala datang sebagai sebuah tantangan yang menarik. Namun dengan kerja sama yang solid, kami dapat menyelesaikannya dengan baik.

Setiap karya pasti memiliki kelebihan dan kekurangan. Kami menyadari berbagai kekurangan baik dalam penulisan, cara penyampaian dan lain-lain sehingga kami sangat mengharapkan kritik dan saran yang membangun untuk penulisan selanjutnya agar dapat menghasilkan karya yang lebih baik lagi.

Penulis mengucapkan terima kasih kepada Bapak Rais Zain selaku dosen mata kuliah Kelaikan Udara atas bimbingan dan arahannya. Penulis juga mengucapkan terima kasih kepada seluruh pihak yang telah membantu dalam penyelesaian makalah tugas besar mata kuliah ini, terutama untuk tim Pak Sulistyo dan Pak Oka dari Direktorat Kelaikan Udara dan Pengoperasian Pesawat Udara (DKUPPU) untuk bimbingannya dalam membantu penulis dalam eneliti sistem sertifikasi dari sudut pandang pengatur kebijakan, dalam hal ini DKUPPU. Tak lupa juga kami ucapkan banyak terima kasih kepada tim dari Pustekbang Lembaga Antariksa dan Penerbangan Nasional (LAPAN) yang sedianya telah hadir pada acara seminar tugas besar dan memberi arahan serta masukannya pada 22 Mei 2015 yang lalu

Pada akhirnya, penulis berharap semoga perancangan bandara ini dapat bermanfaat bagi semua pihak khususnya di program studi Aeronotika dan Astronotika, Fakultas Teknik Mesin dan Dirgantara, Institut Teknologi Bandung.

Bandung, 23 Mei 2015

DAFTAR ISI

PRAKATA ... 1

DAFTAR ISI ... .. 2

BAB I PENDAHULUAN ... 4

1.1 Latar Belakang ... 4

1.2 Tujuan ... 5

1.3 Metode dan Teknik Pengumpulan Data ... 5

1.3.1.Studi Literatur ... 5

1.3.2 Wawancara ... ... 5

1.4 Kerahasiaan Data ... 6

1.5 Deskripsi Produk ... ... 6

1.6 Sistematika Penulisan ... 9

BAB II POTENSI PASAR DAN PRODUSEN INTERNASIONAL ... ... 10

BAB III POTENSI DALAM NEGERI ... ... 13

3.1 Potensi Pasar Ban Vulkanisasi di Indonesia ... 14

3.2 Potensi Produsen ban Vulkanisasi di Indonesia ... 16

3.2.1 Alamat Pabrikan Ban Indonesia ... 17

BAB IV HASIL KONSULTASI DENGAN DKUPPU ... 21

BAB V REGULASI ... 22

5.1 CASR ... 22

5.2 Non-CASR .... ... 22

BAB VI PENGUJIAN ... . 24

3

6.2 Tempat Pengujian ... 26

6.3 Retread Escalation ... . 27

6.4 Retread Reliability Program ... 27

BAB VII LINI MASA SERTIFIKASI PRODUK ... 28

BAB VIII KESIMPULAN DAN SARAN... 30

BAB IX DAFTAR PUSTAKA ... 31

BAB I

PENDAHULUAN

1.1 Latar Belakang

Dewasa ini, kebutuhan akan vulkanisasi ban menjadi cukup penting terutama dalam industri penerbangan. Dengan bertambahnya jumlah pesawat yang beroperasi dan frekuensi penerbangan yang meningkat di Indonesia, maka kebutuhan akan vulkanisasi juga meningkat cepat karena penggunaan ban yang lebih banyak di tiap pesawat tersebut. Proses vulkanisasi ban di Indonesia terbilang cukup kompleks karena tidak adanya pabrikan yang mampu melaksanakan vulkanisasi ban secara tersertifikasi, menyebabkan kebutuhan vulkanisasi hingga saat ini harus dilakukan di luar negeri dan mengakibatkan biaya tambahan yang sangat besar. Oleh karena itu, akan sangat baik jika pabrikan lokal di Indonesia mampu melakukan vulkanisasi ban setelah melihat pangsa pasar yang tumbuh sangat cepat akhir-akhir ini.

Untuk dapat melakukannya, maka pabrikan harus melalui terlebih dahulu sertifikat kelaikan untuk mulai memasuki bisnis ini. Proses sertifikasi dalam pesawat terbang merupakan satu bagian penting dalam satu daur desain pesawat terbang. Salah satu dari tiga proses sertifikasi yang dilakukan yaitu Type Certicate. Type Certificate adalah satu sertifikat yang dikeluarkan oleh badan pengawas kelaikudaraan, dalam hal ini di Indonesia yaitu DKUPPU, untuk menyatakan bahwa suatu desain part (bagian pesawat udara) atau satu komponen terintegrasi tertentu dalam pesawat udara tersebut aman untuk digunakan dalam operasi penerbangan. Oleh karenanya, kami melakukan analisis mengenai proses sertifikasi salah satu komponen penting dalam satu pesawat terbang, yaitu vulkanisasi ban agar dapat mengetahui prosedur yang tepat dengan mengacu pada regulasi-regulasi yang berlaku.

5 1.2 Tujuan

Tujuan dari studi akademik ini adalah untuk mempelajari aspek-aspek yang terkait dengan produk ban dengan regulasi CASR dalam wilayah hukum Indonesia. Beberapa poin penting yang akan dijelaskan dalan laporan ini adalah:

1) Menentukan potensi pasar dan produsen ban vulkanisasi untuk pesawat terbang yang ada saat ini dan prospeknya di masa mendatang

2) Mempelajari proses pada vulkanisasi ban.

3) Menetapkan regulasi-regulasi penerbangan yang berlaku untuk mengatur jalannya proses sertifikasi untuk ban vulkanisasi pesawat terbang.

4) Menentukan alur sertifikasi melalui proses pengujian untuk ban vulkanisasi untuk pesawat terbang.

5) Menentukan linimasa pengujian ban vulkanisasi pesawat terbang.

1.3 Metode dan Teknik Pengumpulan Data

Metode yang digunakan dalam penyusunan laporan ini adalah deskriptif analitis. Proses perancangan bandara dimulai dari perumusan masalah, pengumpulan data, dan analisis penyelesaian masalah.

1.3.1 Studi literatur

Dalam penyusunan laporan ini, kami menggunakan metode studi pustaka untuk mendapatkan berbagai literatur, referensi, dan data yang dibutuhkan dalam proses sertifikasi, data-data tersebut dapat berupa dokumen-dokumen penting, pernyataan dari pihak resmi yang terkait, brosur, dan informasi penting lainnya.

1.3.2 Wawancara

1.4 Kerahasiaan Data

Mengingat data-data yang digunakan dalam laporan ini dapat merupakan data resmi, dan jika perusahaan tidak menginginkan sebagian data tersebut yang bersifat rahasia dimuat dalam laporan karena menyangkut kepentingan internal dan kepentingan bisnis dari pihak-pihak yang terkait, maka tim penulis dalam hal ini menyatakan bahwa laporan ini hanya bertujuan untuk keperluan mata kuliah AE4060 Kelaikan Udara dan berjanji untuk tidak memublikasikan laporan berikut data yang terlampir di dalamnya di luar lingkup perkuliahan mata kuliah terkait.

1.5 Deskripsi Produk

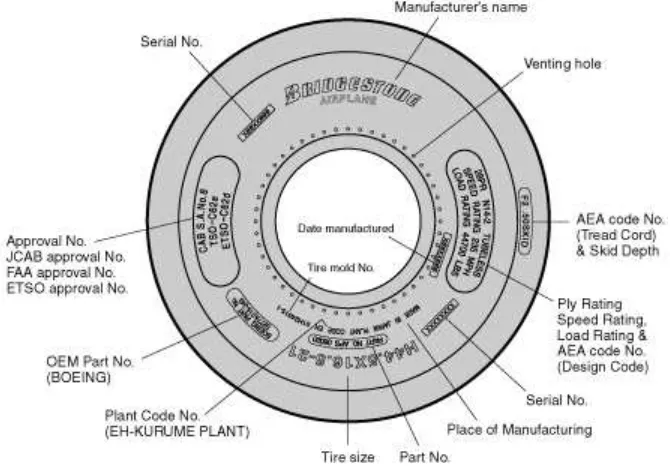

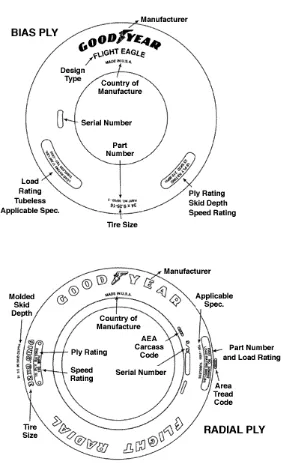

Pada setiap ban, ada kode-kode khusus yang menunjukkan karakter dari ban yang disebut juga marking. Beberapa istilah yang digunakan dalam marking ban :

R-level escalation : proses untuk menyatakan bahwa ban hasil vulkanisasi layak digunakan untuk beberapa waktu

7

Gambar 1. 2 Tire Marking Ban Goodyear

Load rating : beban maksimum yang diijinkan pada tekanan pompa spesifik

Ply rating : indeks kekuatan ban, mengidentifikasikan maksimum load rating dan tekanan pompa spesifik

Compatible casing : casing alternatif yang memenuhi kriteria ukuran, ply rating, dan speed rating ban tersebut

Skid depth : kedalaman alur ban dalam satuan inch

Serial number : biasanya berisi informasi mengenai tanggal pembuatan ban

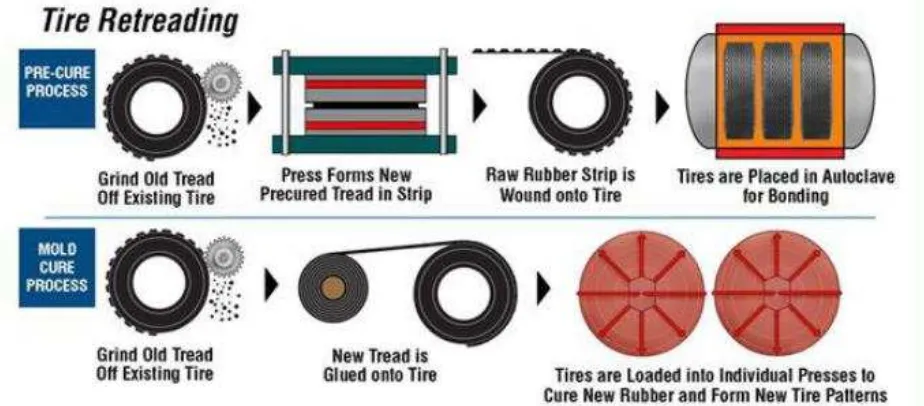

Vulkanisasi ban (retread/recap/remold) adalah proses pembuatan ulang (remanufacturing) untuk ban yang mulai botak untuk mengembalikan alur ban. Vulkanisasi biasanya dilakukan terhadap casing dari ban yang sudah terpakai setelah diinspeksi dan direparasi. Proses vulkanisasi biasanya mengawetkan sekitar 90% material dari ban yang terpakai, dan biaya material yang digunakan rata-rata sekitar 20% dari harga pembuatan ban baru. Ada 2 proses utama untuk vulkanisasi ban, mold cure dan pre-cure. Kedua proses diawali dengan inspeksi terhadap ban, lalu diikuti metode NDE (nondestructive examination) untuk menentukan lokasi kerusakan yang tidak terlihat (hidden damage) dan serpihan-serpihan kecil yang tertanam. Beberapa casing yang masih layak akan diperbaiki, sementara yang kerusakannya parah akan dibuang. Untuk metoda pre-cure, tread strip yang sudah disiapkan ditempelkan ke ban dengan lem, sementara untuk metoda mold cure, karet leleh mentah diaplikasikan ke ban dan lalu ditempatkan ke dalam cetakan alur ban.

Gambar 1. 3 Dua Proses Vulkanisasi Ban

9

perusahaan lebih memilih untuk mengambil ban yang sudah habis alurnya dan dikirim kepada perusahaan ban untuk divulkanisasi.

1.6 Sistematika Penulisan

Laporan ini berjudul Analisis Sistem Sertifikasi dan Potensial Pasar Ban Hasil Vulkanisasi Untuk Pesawat Terbang. Sistematika laporan ini menjelaskan tahapan dan proses pengerjaan.

- Bab I berjudul Pendahuluan. Bab ini terdiri atas 9 bab dan menjelaskan tentang hal – hal yang mendasari pengerjaan laporan ini.

- Bab II membahas profil pasar vulkanisasi ban pesawat terbang yang ada saat ini. Pembahasan dilakukan dengan mengidentifikasi pabrikan yang bermain dalam bisnis ini berikut dengan variasi produk dan tingkat keuntungan dalam bisnis ini.

- Bab III membahas analisis potensi bagi pabrikan vulkanisasi ban dalam negeri untuk dapat terjun dalam pembuatan vulkanisasi ban untuk pesawat terbang.

- Bab IV membahas proses sertifikasi yang mana hasilnya sendiri didapat dari wawancara dengan otoritas kelaikan udara Indonesia atau DKUPPU.

- Bab V membahas regulasi-regulasi yang mengatur proses sertifikasi untuk vulkanisasi ban pesawat terbang. Regulasi-regulasi tersebut menyangkut antara lain pasal-pasal dalam CASR, Service Bulletin, Technical Standard Order, dan dokumen-dokumen penting lainnya.

- Bab VI membahas proses dan tempat pengujian yang potensial untuk melakukan proses sertifikasi tersebut.

- Bab VII membahas penyusunan lini masa dari proyek sertifikasi satu vulkanisasi ban pesawat terbang dengan data yang akurat dan berdasarkan tahapan yang ada dalam uji sertifikasi.

BAB II

POTENSI PASAR DAN PRODUSEN INTERNASIONAL

Dibanding pasar ban lainnya, pasar untuk ban pesawat terbang bisa dibilang relatif lebih kecil dibanding pasar ban untuk keperluan otomotif lainnya, seperti industri ban mobil, sepeda motor, truk, ataupun kendaraan lainnya.

Meskipun pertambahan jumlah pesawat yang besar dengan banyaknya transaksi pembelian pesawat baru seperti pembelian 234 pesawat baru Lion Air beberapa tahun lalu dari Boeing dan Airbus, keluarnya beberapa tipe pesawat baru yang akan hadir dalam waktu dekat, sebut saja A320neo, B737 MAX, dan B787 yang baru keluar tiga tahun lalu, yang tentu saja memungkinkan terjadinya pertambahan lalu lintas penerbangan dengan munculnya maskapai berbiaya rendah pada dekade terakhir ini, namun para analis memperkirakan bahwa industri ini akan tumbuh sebesar 3,10 persen. Pertumbuhan ini pun masih mungkin berubah dengan adanya perkembangan teknologi ban cerdas (intelligent tire) dan peningkatan penawaran terhadap OEM. Selain itu, yang menarik dari pasar ban ini adalah adanya beberapa pelaku bisnis yang menguasai hampir seluruh pasar. Ada lima ban yang menguasai sekitar 85 persen dari keseluruhan pasokan ban untuk pesawat terbang. Namun, salah satu dari lima pabrikan tersebut, Yokohama Rubber, menarik diri dari industri ban pesawat terbang sejak 2009 meskipun termasuk lima pemain besar dalam bisnis ini dikarenakan oleh rendahnya permintaan pasar sehingga menghasilkan profit yang rendah.

Berikut adalah masing-masing dari keempat pemain besar yang tersisa tersebut:

1. GOODYEAR

Goodyear merupakan salah satu pionir produksi ban untuk pesawat terbang dimulai tahun 1909, menjadikan Goodyear sebagai produsen yang paling tua diantara pabrikan lainnya. Hingga saat ini, Goodyear dibawah bendera Goodyear Aviation Inc. yang memiliki markas di Akron, Ohio, Amerika Serikat ini menyuplai ban untuk tiga jenis pesawat. Yaitu pesawat umum, pesawat komersial, dan pesawat militer. Pada tahun 2013, Goodyear dianugerahi penghargaan oleh Boeing sebagai penyuplai ban terbaik.

11

- Kingman, Arizona, Amerika Serikat (aircraft tire retreading). - Stockbridge, Georgia, Amerika Serikat (aircraft tire retreading). - Tilburg, Belanda (aircraft tire retreading).

- Sao Paulo, Brazil (aircraft tire production dan retreading). - Bangkok, Thailand (aircraft tire production dan retreading).

Disamping itu, berikut daftar pabrikan pesawat terbang yang bannya disuplai oleh Goodyear adalah:

- ACAC

- ATR

- Aermacchi - Aerospatiale - Airbus - Alenia

- American Champion Aircraft

- BAC

- Bell Helicopter - Boeing

- Bombardier - British Aerospace

- CASA

- Diamond Aircraft

- Dan 40 pabrikan lainnya.

2. MICHELIN

13

Selain itu, Michelin Air juga bahkan menjadi pabrika tunggal ban khusus digunakan untuk Program Space Shuttle yang dijalankan oleh Amerika Serikat (NASA) juga oleh Uni Eropa (EASA).

Michelin memiliki beberapa pabrik khusus untuk produksi ban untuk pesawat terbang, yaitu di India, RRC, dan Thailand.

3. BRIDGESTONE

Bridgestone adalah pabrikan ban asal Kurume, Jepang yang sudah mulai memproduksi ban untuk pesawat terbang sejak 1939. Bridgestone menguasai sekitar 20 persen pangsa pasar ban untuk pesawat terbang di dunia. Dengan pusat untuk vulkanisasi ban di beberapa tempat sebagai berikut:

BAB III

POTENSI DALAM NEGERI

3.1 POTENSI PASAR BAN VULKANISASI DI INDONESIA

Selama ini, pasar ban vulkanisasi di Indonesia hanya berfungsi menjadi pasar bagi pemain asing dimana maskapai-maskapai penerbangan Indonesia membeli ban-ban yang telah divulkanisasi di luar negeri untuk dipakai kembali di Indonesia. Hal ini cukup merupakan hal yang ironis bagi industri Indonesia karena sebagai negara dengan penghasil karet terbesar di dunia. Indonesia dengan teknologi yang cukup akan sangat mampu untuk mandiri dalam menjalankan industri ban vulkanisasi pesawat terbang. Setiap harinya, ban-ban pesawat yang harus divulkanisasi harus dibawa ke pabrik vulkanisasi milik perusahaan besar seperti Goodyear, Michelin dan Bridgestone, pabrikan-pabrikan ban pesawat terbang yang paling mendominasi permintaan ban vulkanisasi pesawat terbang di Indonesia, masing-masing di Bangkok dan Chonburi, Thailand.

Vulkanisasi ban sendiri jauh lebih menguntungkan daripada membeli ban baru dalam segi produksi dan konsumsi. Sebagai bukti, produksi ban baru membutuhkan 3,2 kali lebih banyak minyak dibanding produksi vulkanisasi ban. Selain itu, produksi ban vulkanisasi selain dapat menghemat sumberdaya, juga membantu menurunkan biaya hingga 33-50 persen terhadap konsumen ban retread. Sehingga dengan keuntungan yang besar tersebut, hingga saat ini, 85 persen pesawat yang terbang menggunakan ban vulkanisasi.

15 Tahun

Jumlah Kedatangan

Pesawat

Jumlah Penumpang Kedatangan

Growth Pax (%)

Growth Airplanes (%)

2003 340,467 21,171,281

2004 446,651 29,150,506 37.69% 31.19%

2005 440,520 24,812,276 -14.88% -1.37%

2006 470,956 33,816,344 36.29% 6.91%

2007 454,267 33,963,707 0.44% -3.54%

2008 430,961 36,388,502 7.14% -5.13%

2009 513,132 42,565,099 16.97% 19.07%

2010 574,423 50,519,023 18.69% 11.94%

2011 671,377 59,035,279 16.86% 16.88%

2012 719,030 69,494,439 17.72% 7.10%

*Sumber: Badan Pusat Statistik Nasional 2015

15.21% 9.23%

Dengan demikian, jumlah pesawat yang tiba di Indonesia mencapai 719.030 pesawat per tahun 2012 dengan kenaikan rata-rata jumlah pesawat mencapai 9,23 persen per tahunnya. Sehingga melalui kalkulasi kasar didapat nilai jumlah kedatangan mencapai 937.072 kedatangan pada tahun 2015 ini.

landas dan mendarat 1.704 kali per tahunnya. Dimana tiap retread dilakukan setelah 20 siklus lepas landas- mendarat. Maka demikian dibutuhkan 85 kali vulkanisasi untuk tiap pesawatnya per tahun. Dengan konfigurasi 550 pesawat tersebut terdiri dari 438 pesawat penumpang diatas 30 orang dan sisanya merupakan pesawat kecil, maka diperkirakan akan ada 289.850 ban yang akan divulkanisasi tiap tahunnya di Indonesia. Dan jumlah tersebut merupakan jumlah yang besar dan berpotensi untuk berkembang pesat melihat perkembangan di bidang dirgantara karena semakin banyaknya pesawat karena pembelian pesawat besar-besaran oleh maskapai-maskapai besar di Indonesia.

3.2 POTENSI PRODUSEN BAN VULKANISASI DI INDONESIA

Jika menilik dari kemampuan finansialnya, maka PT. Gajah Tunggal memiliki potensi besar untuk dapat masuk dalam industri ban nasional. Pangsa pasar PT. Gajah Tunggal yang besar di Indonesia (hampir 71 persen). Masih kuatnya dominasi pabrikan ban luar negeri yang merajai sisa pangsa pasar yang tidak dikuasai PT. Gajah Tunggal dan masuknya pabrikan ban luar negeri baru seperti Hankook dan Summi Rubber, menjadikan perusahaan ini menjadi satu-satunya pabrikan dominan asal Indonesia yang mampu menguasai industri ban Indonesia, termasuk vulkanisasi ban. PT. Gajah Tunggal memiliki dua pusat produksi, yaitu di Tangerang dan Serang, Banten. Sementara dalam waktu dekat, pabrikan ini akan membangun pusat produksi ketiga di wilayah Karawang, Jawa Barat dengan luas area 100 hektar.

Di lain pihak terdapat setidaknya 13 perusahaan ban lainnya yang berkompetisi di industri ban untuk sepeda motor industri, pertambangan, dan pertanian. Semua perusahaan ban di Indonesia ini kemudian tergabung dalam satu asosiasi pabrikan ban tersendiri yang dikenal dengan nama Asosisi Perusahaan Ban Indonesia (APBI) yang beralamat di Gani Djemat Plaza Lt.3 Jl. Imam Bonjol, Jakarta Pusat 10310. Berikut nama beberapa pabrikan yang juga cukup menguasai pasar ban di Indonesia:

1. PT Multi Strada Arahsarana 2. PT Elang Perdana

17 5. PT Mega Safe Tire Industry

6. PT United KingLand

7. PT King Rubber Indonesia 8. PT Pentasari Ban

9. PT Indomas Prima Sejati 10. PT Banteng Pratama 11. Vulkanisir Badak

3.2.1 Alamat Pabrikan Ban Indonesia

Pabrikan-pabrikan ban yang telah disebutkan di atas bertempat di daerah yang berbeda, tersebar di Pulau Sumatra dan Jawa. Berikut merupakan alamat dari masing-masing pabrikan:

1. PT. GAJAH TUNGGAL

Kawasan Industri Gajah Tunggal

Jl Jend Gatot Subroto Km 7 Kawasan Industri Gajah Tunggal Jatake, Jatiuwung

Tangerang 15136 Banten

Jl Raya Serang Km 7 RT 002/01 Cikupa

Tangerang 15710 Banten

Kedungwaringin

Bekasi 17540 Jawa Barat

3. PT Elang Perdana Jl Elang

Citeureup, Citeureup Cibinong 16810 Jawa Barat

4. PT Suryaraya Rubber Indonesia Kawasan Industri Menara Permai

Jl Raya Narogong Km 23,8 Kawasan Industri Menara Permai Cileungsi

Cibinong 16820 Jawa Barat

5. PT Industri Karet Deli Jl Kom L Yos Sudarso Km 8,3 Tanjung Mulia, Medan Deli Medan 20241 Sumatera Utara

6. PT Mega Safe Tire Industry Kantor Utama

19 Ledok, Argomulyo

Salatiga 50732 Jawa Tengah

Pabrik

Jl Perintis Kemerdekaan 88-92 Pudakpayung, Banyumanik Semarang 50265 Jawa Tengah

7. PT United KingLand Ruko Jatibaru

Jl Jend Gatot Subroto Km 5 Ruko Jatibaru RT 003/01 Gembor, Jatiuwung

Tangerang 15133 Banten

8. PT King Rubber Indonesia Jl Singoyudan 1 RT 009/04 Semarang Jawa Tengah

9. PT Pentasari Ban Jl Tambak Aji I 1 Tambakaji, Ngaliyan

10.PT Indomas Prima Sejati Plaza Kelapa Dua, Lantai 5,

Jl. Panjang Arteri Kelapa Dua No. 29 RT 007/ 005 Kelapa Dua Kecamatan Kebon Jeruk Jakarta 11550

11.PT Banteng Pratama

Jl P Jayakarta 68 Ruko Bl C/9-10 Mangga Dua Selatan, Sawah Besar Jakarta Pusat 10730 DKI Jakarta

21

BAB IV

HASIL KONSULTASI DENGAN DKUPPU

Di bawah ini merupakan respon dari DKUPPU mengenai draft tugas yang dikirimkan sebelumnya :

1. Pada BAB V : Regulasi

5.1 CASR, bisa dimasukan CASR seperti yang disebutkan dalam FAA AC 145-4A, karena retreaded tire termasuk proses repair dan proses repair yang dilakukan hanya dapat dilakukan oleh repair station (AMO).

5.2.4. Airworthiness Directive, surat terkait yang disebutkan adalah safety circular bukan Airworthiness Directive.

2. Pada BAB VI : Pengujian

6.1 Jenis pengujian, jenis pengujian dapat dilengkapi dengan mengacu pada FAA AC 145-4A dan sebaiknya diambil secara utuh termasuk penamaan ban hasil vulkanisasi dan perlu dilengkapi dengan retread escalation dan reliability system untuk menentukan kehandalan dan periode pemakaian dari ban hasil vulkanisasi. Untuk tempat pengujian, apakah Balai Besar Bahan Barang Teknik (B4T) mempunyai kualifikasi yang diminta untuk melakukan pengujian seperti yang disebutkan dalam FAA AC 145-4A, karena hanya AMO (Approved Maintenance Organization) dengan capability list retreaded tire yang bisa melakukannya.

3. BAB VII : Lini Masa Sertifikasi Produk

BAB V

REGULASI

5.1 Civil Aviation Safety Regulation (CASR) Beberapa CASR yang mengatur perihal ban adalah

1. CASR 21 subpart O Technical Standard Order Authorizations (terlampir) 2. CASR 23 part 733

3. CASR 25 part 733 (terlampir)

4. CASR 43 Maintenance, preventive maintenance, rebuilding, and alteration 5. CASR 145 Repair stations

5.2 Non-CASR

5.2.1 Service Bulletin

Sampai saat ini kami masih mencari service bulletin yang membahas tentang vulkanisasi ban.

5.2.2 Technical Standard Order (TSO)

TSO yang membahas mengenai ban adalah TSO-C62d tahun 1990 (terlampir)

5.2.3 Advisory Circular (AC)

Advisory Circular yang membahas mengenai vulkanisasi ban adalah

1. AC 20-97B : Aircraft Tire Maintenance and Operational Practices (terlampir)

2. AC 145-4A : Inspection, Retread, Repair, and Alterations of Aircraft Tires (terlampir)

5.2.4 Safety Circular (SC)

23 5.2.5 Dokumen Industri

1. ARP 4834 : Aircraft Tire Retreading Practice – Bias and Radial 2. AS 4833 : Aircraft New Tire Standard –Bias and Radial

3. TRA : Tire and Rim Association Aircraft Yearbook

BAB VI

PENGUJIAN

6.1 Jenis Pengujian

Berdasarkan AC 145-4A ban pesawat hasil vulkanisasi harus menunjukkan kemampuan yang cukup cocok dengan ban pesawat baru sehingga perlu dilakukan beberapa pengujian pada ban pesawat hasil vulkanisasi.

a. General

Prosedur pengujian yang dijelaskan di sini dimaksudkan untuk memastikan kompatibilitas antara casing ban asli dan ban vulkanisasi yang baru dipasangkan. Uji kualifikasi ini diperlukan dengan aplikasi (R-1) pertama dari tread baru dan berlaku sebaliknya seperti yang telah ditentukan dalam Advisory Circular. Vulkanisasi tidak boleh gagal dalam uji dinamometer atau menunjukkan tanda-tanda kerusakan struktural lain yang tidak diprediksi kecuali setelah overload take off cycle dilakukan (lihat poin b). Casing yang dipilih untuk uji vulkanisasi harus memiliki sekurang-kurangnya 80 persen dari kedalaman skid ban yang baru dibentuk yang dihapus oleh keausan (contohnya dikarenakan oleh penggunaan pesawat).

(2) Perbedaan desain dan konstruksi antara ban radial dari berbagai produsen mengharuskan pengujian vulkanisasi dinamometer dilakukan pada satu sampel dari masing-masing produsen casing ban pada aplikasi (R-1) pertama tread baru. Kualifikasi ban vulkanisasi bias pada produsen casing yang sama memenuhi persyaratan ban vulkanisasi pada produsen casing yang cocok dengan ukuran, ply rating dan speed rating yang sama.

b. Siklus Uji Dinamometer

25

siklus bersifat opsional. Namun, jika overload take off cycle tidak berlangsung, ban seharusnya tidak menunjukkan tanda-tanda kerusakan yang dapat terdeteksi setelah siklus selesai, selain dari abrasi permukaan tread ban yang sudah diperkirakan. Sebuah spesimen tunggal ban harus digunakan untuk menyelesaikan siklus ini. Selama uji siklus dinamometer ini, juga dilakukan uji tire/rim slippage, dengan parameter selip ban pada velg selama pengujian dinamometer harus tidak merusak katup tabung pada ban tube, atau segel gas dari tire bead pada ban tubeless dan uji inflation retention, dengan parameter tekanan akhir tidak boleh berkurang lebih dari 10% dibanding tekanan awal.

c. Uji Kualifikasi Ulang

Sebuah ban vulkanisasi yang telah diubah, dan yang memiliki perubahan

bahan, desain dan /atau proses manufaktur yang dapat mempengaruhi kinerja dan keandalan ban, harus dikualifikasi ulang untuk uji dinamometer yang telah disebutkan pada poin b di atas, terlepas dari tingkat eskalasi . Contoh perubahan tersebut meliputi, namun tidak terbatas pada, perubahan konstruksi tread, seperti jumlah atau komposisi yang memperkuat tread dan/atau lapisan pelindung, formulasi senyawa tread, jumlah dan lokasi alur tread, dan meningkatkan kedalaman skid dan/atau ukuran tread. Kualifikasi ulang menggunakan kesamaan, seperti yang dibahas dalam paragraf ( 1 ) dan ( 2 ) di bawah ini, berlaku untuk semua ban bias yang cocok dengan desain tread baru dan/atau yang bahannya berubah. Namun, kualifikasi ulang berdasarkan kesamaan untuk ban radial hanya berlaku untuk ban yang desainnya sebanding dari produsen yang sama. Kualifikasi ulang berdasarkan kesamaan tidak diperbolehkan untuk ban radial dari produsen yang berbeda.

( 1 ) Kualifikasi ulang berdasarkan Kesamaan (Berdasarkan Load Rating)

Kualifikasi ulang dari ban vulkanisasi dengan loa d rated yang telah diberikan diperlukan sebagai hasil dari perubahan desain tread atau bahan akan lolos secara otomatis untuk perubahan yang sama dalam ban vulkanisasi dengan load rated yang lebih rendah pada ukuran, speed rating, dan kedalaman skid yang sama membuat ban vulkasisasi dengan load rated lebih rendah memenuhi syarat yang berlaku yang ditetapkan dalam standar ini.

Kualifikasi ulang perubahan apapun yang mempengaruhi berbagai ukuran dapat dilakukan berdasarkan kesamaan, asalkan:

(a) Lima perwakilan ukuran, termasuk ban dengan beban, speed rating dan kecepatan sudut tertinggi, telah memenuhi persyaratan untuk standar kinerja minimum bersama dengan perubahannya.

(b ) Data yang mendukung perubahan ukuran yang tercantum harus diserahkan dan disetujui oleh FAA.

d. Overpressure

Sebuah ban vulkanisasi, diproses dengan cara yang sama dengan contoh yang diuji pada dinamometer, sebaiknya berhasil menahan tekanan hidrostatik hingga tiga kali dari yang seharusnya selama 3 detik tanpa kegagalan. Ban yang digunakan dalam pengujian kualifikasi dinamometer dapat digunakan jika diinginkan.

Pengujian yang lain adalah pengujian kimia yakni pengujian reaksi ban jika terkena zat kimia tertentu dan pengujian thermal, namun hingga saat ini kami masih belum menemukannya.

6.2 Tempat Pengujian

Aero Wheel & Brake Service Corporation. 6900 Acco Street, Montebello, CA 90640.

www.aerowbs.com

Lutfhansa Technik Frankfrut. Airporting gate 23 Flughafen Frankfrut am Main. 60546 Frankfurt am Main.

Balai Besar Bahan Barang Teknik (B4T). Jalan Sangkuriang No. 14, Bandung 40135*.

27 6.3 Retread Escalation

Jumlah maksimum ban boleh divulkanisasi harus ditentukan oleh regulator berdasarkan hasil inspeksi dan pengujian. Pada umumnya, ban boleh divulkanisasi sampai 3 (tiga) kali (R-3). Semakin tinggi nilai R pada suatu ban hasil vulkanisasi, maka semakin kecil masa pakai yang diijinkan.

6.4 Retread Reliability System

BAB VII

29

*Pre-General Testing (mengacu pada AC 145-4A) mencakup :

1. Marking

a. Retread identification

b. Casing identification

c. Regarding procedure

d. Marking maximum cut limit repairs

2. Casing selection

a. Inspection

b. Disposition of tire casings

3. Repair process

BAB VIII

KESIMPULAN DAN SARAN

8.1 Kesimpulan

Indonesia memiliki potensi yang cukup besar dalam industri vulkanisasi ban. Pertama,

Indonesia merupakan negara penghasil karet terbesar. Kedua, penerbangan di Indonesia sedang

bertumbuh dengan cukup pesat ditandai dengan bertambahnya jumlah pesawat yang dimiliki

maskapai-maskapai yang beroperasi.

Pada dasarnya, vulkanisasi ban adalah tindakan repair karena mengganti bagian pada suatu

part sehingga part tersebut bisa digunakan lagi. Vulkanisasi bisa dilakukan dengan dua cara,

menempelkan karet dalam bentuk strip dengan lem atau melapisi ban dengan karet leleh mentah dan

dicetak. Regulasi yang digunakan dalam sertifikasi ban hasil vulkanisasi untuk pesawat terbang

mencakup CASR (Civil Aviation Safety Regulation), TSO (Technical Standard Order), AC (Advisory

Circular), dan SC (Safety Circular).

Alur sertifikasi beserta lini masanya kami buat dengan asumsi/perkiraan dan berpedoman

pada konten dalam Advisory Circular (AC) 145-4A dan TSO C62d.

8.2 Saran

Saran yang bisa kami berikan :

Untuk DKUPPU : menyiapkan dokumen yang berisi alur sertifikasi yang jelas, sehingga ketika

nanti ada pihak yang ingin mengajukan sertifikasi akan jadi lebih mudah.

Untuk pemerintah : mendorong industri untuk bisa mulai bergerak di pasar yang sedang

berkembang. Berkembangnya industri juga bisa berarti bertambahnya lapangan pekerjaan.

Untuk industri : mulai menyiapkan fasilitas yang menunjang sehingga tidak akan banyak

31

BAB IX

DAFTAR PUSTAKA

www.caa.gov.tw/BIG5/download/fsd/C62d.pdf

www.dephub.go.id

www.faa.gov

www.aerowbs.com

www.goodyearaviation.com/tires/

www.airmichelin.com

www.dunlopaircrafttyres.com/

en.wikipedia.org

Subject: TSO-C62d, TIRES

Department of Transportation

Federal Aviation Administration

Aircraft Certification Service

TSO-C62d

Washington, DC

Date: 9/7/90

Technical Standard Order

a. Applicability.

(1) Minimum Performance Standard. This Technical Standard Order (TSO) prescribes the minimum performance standard that tires excluding tailwheel tires must meet to be identified with the applicable TSO marking. Tires that are to be so identified and that are manufactured on or after December 31, 1979, must meet the requirements of the document titled “Federal Aviation Administration Standard for Aircraft Tires” dated December 31, 1979,

September 12, 1984, or September 7, 1990 (Appendix 1).

b. Marking. In lieu of the marking requirements of Federal Aviation Regulations Part 21, Section 21.607(d), each tire must be legibly and permanently marked at least with the following:

(1 ) Brand name and the name or registered trademark of the manufacturer responsible for compliance.

(2) Speed rating, load rating, size, skid depth, serial number, date, manufacturer’s part number and plant code, and nonretreadable, if appropriate.

(3) Applicable TSO number. c. Data Requirements.

(1) In addition to § 21.605, the manufacturer shall furnish the manager, Aircraft Certification Office (ACO) having geographical purview of the manufacturer’s facilities, one copy each of the following technical data: tire speed rating, load rating, rated inflation pressure, size, width, outside diameter, mold skid depth, nominal loaded radius at rated load and inflation pressure, and permissible tolerance on the nominal loaded radius; the actual loaded radius of the test tire at rated load, and inflation pressure, weight, and static unbalance; wheel rim designation; manufacturer’s tire part number; and, for a high-speed tire, a load deflection curve at loads up to

TSO-C62d 9/7/90

1.5 times load rating and a summary of the load-speed-time parameters used in the dynamometer tests. As used in this section, the term “high-speed tire” means a tire tested at a speed greater than 120 miles per hour (mph).

(2) The manufacturer shall furnish the applicable maintenance and repair instructions to the regional office identified in paragraph c.(1) of this section. The maintenance data provided by the manufacturer must include inspection criteria for the tire to determine eligibility for used tires of the same part number to be continued in service. Special

nondestructive inspection techniques and retreading procedures, if applicable, must be included in the maintenance information along with any special repair methods applicable to the tire.

(3) The manufacturer shall furnish either on complete set of design drawings for the tire or a photograph of the tire cross section to the regional office identified in paragraph c.(1) of this section. The manufacturer shall also furnish details of design changes (if the tire is being requalified).

d. Data to be Furnished with Manufactured Units. The existence of TSO approval does not automatically constitute authority to install and use the article on an aircraft. A note with the following statement must be included:

“The conditions and tests required for TSO approval of this article are minimum performance standards. It is the responsibility of those desiring to install the article on or within a specific type or class of aircraft to determine that the aircraft operating conditions are within the TSO standards.”

“If not within the TSO standards, the article may be installed only if further evaluation by the user/installer documents an acceptable installation that is approved by the Administrator.”

“If within the TSO standards, the article may be installed only if the user/installer documents an acceptable installation that is approved by the Administrator.” e. Previously Approved Articles.

(1) Notwithstanding § 21.603(a) and (b) and the provisions of any specific previous TSO approval, after December 31, 1982, no person may identify or mark a tire having a speed rating above 160 mph with TSO numbers TSO-C62, TSO-C62a, or TSO-C62b. Further , a tire having a special rating above 160 mph approved prior to December 31, 1979, may not be manufactured under the provisions of its original approval.

(2) A tire, except for those specified in paragraph e.(1) of this section, may continue to be manufactured under the provision of its original approval.

9/7/90 TSO-C62d

reviewed at the Federal Aviation Administration Headquarters, Aircraft Certification Service, Aircraft Engineering Division (AIR-100), and at all ACO’s.

/S/ John K. McGrath Acting Manager, Aircraft

Engineering Division, AIR-100 Aircraft Certification Service

9/7/90 TSO-C62d

Appendix 1

APPENDIX 1. FEDERAL AVIATION ADMINISTRATION STANDARD FOR AIRCRAFT TIRES DATED SEPTEMBER 7, 1990

1.0 Purpose. This document contains minimum performance standards for new and requalified aircraft tires, excluding tailwheel tires, that are to be identified as meeting the standards of TSO-C62d.

2.0 Scope. These minimum performance standards apply to aircraft tires having speed and load ratings that are established on the basis of the speeds and loads to which the tires have been tested.

3.0 Material requirement. Materials must be suitable for the purpose intended. The suitability of the materials must be determined on the basis of satisfactory service experience or

substantiating dynamometer tests. 4.0 Design and construction.

4.1 Unbalance. The moment (M) of static unbalance in inch-ounces may not be greater than the value determined using the formula, moment (M) = 0.025D2, rounded off to the next lower whole number: where D = maximum outside diameter of the tire in inches.

4.2 Balance marker. A balance marker, consisting of a red dot, must be affixed on the sidewall of the tire immediately above the bead to indicate the lightweight point of the tire. The dot must remain for any period of storage plus the original tread life of the tire.

4.3 Overpressure. The tire shall withstand for at least 3 seconds a pressure of at least 4.0 times the rated inflation pressure (as specified in paragraph 5.2) at ambient temperature.

4.4 Temperature.

4.4.1 Ambient. It shall be substantiated by applicable tests or shown by analysis that the physical properties of the tire materials have not been degraded by exposure of the tire to the temperature extremes of not higher than -40°F and not lower that +160°F for a period of not less than 24 hours at each extreme.

4.4.2 Wheel rim heat. It must be substantiated by the applicable tests or shown by analysis that the physical properties of the tire materials have not been degraded by exposure of the tire to a wheel-bead seat temperature of not lower that 300°F for at least 1 hour, except that low-speed tires or nose-wheel tires may be tested or analyzed at the highest wheel-bead seat temperatures expected to be encountered during normal operations.

4.5 Tread design. Moved. (See paragraph 7.0)

4.6 Slippage. A tire tested in accordance with the dynamometer tests provided in paragraph 6.0 may not slip on the wheel rim during the first five dynamometer cycles. Slippage

TSO-C62d 9/7/90 Appendix 1

that subsequently occurs may neither damage the gas seal of the tire bead of a tubeless tire nor otherwise damage the tube or valve.

4.7 Leakage. After an initial 12-hour minimum stabilization period, the tire must be capable of retaining inflation pressure with a loss of pressure not exceeding 5 percent in 24 hours from the initial pressure equal to the rated inflation pressure.

5.0 Ratings.

5.1 Load ratings. The load ratings of tires shall be established. The applicable dynamometer test in paragraph 6.0 must be performed at the selected rated load.

5.1.1 Load rating (helicopter tires). Airplane tires qualified in accordance with provisions of this standard may also be used on helicopters. In such cases, the maximum static load rating may be increased by 1.5 with a corresponding increase in rated inflation pressure without any additional qualification testing.

5.2 Rated inflation pressure. The rated inflation pressure shall be established at an identified ambient temperature on the basis of the rated load as established under paragraph 5.1. 5.3 Loaded radius. The loaded radius is defined as the distance from the axle centerline to a flat surface for a tire initially inflated to the rated inflation pressure and then loaded to its rated load against the flat surface. The nominal loaded radius, the allowable tolerance on the nominal loaded radius, and the actual loaded radius for the test tire shall be identified.

6.0 Dynamometer test requirements. The tire may not fail the applicable dynamometer tests specified herein or have any signs of structural deterioration other than normal expected tread wear except as provided in paragraph 6.3.3.3.

6.1 General. The following conditions apply to both low-speed and high-speed tires when these tires are subjected to the applicable dynamometer tests:

6.1.1 Tire test load. Unless otherwise specified herein for a particular test, the tire must be forced against the dynamometer flywheel at not less than the rated load of the tire during the entire roll distance of the test.

6.1.2 Test inflation pressure. The test inflation pressure must be the pressure required at an identified ambient temperature to obtain the same loaded radius against the flywheel of the dynamometer at the loaded radius for a flat surface as defined in paragraph 5.3. Adjustments to the test inflation pressure may not be made to compensate for increases created by temperature rises occurring during the tests.

9/7/90 TSO-C62d

Appendix 1

6.2 Low-speed tire. A tire operating at ground speeds of 120 mph or less must withstand 200 landing cycles on a dynamometer at the following test temperature and kinetic energy and using either test method A or test method B.

6.2.1 Test temperature. The temperature of the gas contained in the tire or of the carcass measured at the hottest point of the tire may not be lower than 105°F at the start of at least 90 percent of the test cycles. For the remaining 10 percent of the test cycles, the contained gas or carcass temperature may not be lower than 80°F at the start of each cycle. Rolling the tire on the flywheel is acceptable for obtaining the minimum starting temperature.

6.2.2 Kinetic energy. The kinetic energy of the flywheel to be absorbed by the tire must be calculated as follows:

K.E. = CWV2 = 162.7W = Kinetic energy in foot-pounds. where:

C = 0.0113

W = Load rating of the tire in pounds, and V = 120 mph.

6.2.3 Test method A - variable mass flywheel. The total number of dynamometer landings must be divided into two equal parts having speed ranges shown below. If the exact number of flywheel plates cannot be used to obtain the calculated kinetic energy value of proper flywheel width, a greater number of plates must be selected and the dynamometer speed adjusted to obtain the required kinetic energy.

6.2.3.1 Low-speed landings. In the first series of 100 landings, the maximum landing speed is 90 mph and the minimum unlanding speed is 0 mph. The landing speed must be adjusted so that 56 percent of the kinetic energy calculated under paragraph 6.2.2 will be absorbed by the tire. If the adjusted landing speed is calculated to be less than 80 mph, the following must be done: the landing speed must be determined by adding 28 percent of the kinetic energy calculated under paragraph 6.2.2 to the flywheel kinetic energy at 64 mph, and the unlanding speed must be determined by subtracting 28 percent of the kinetic energy calculated under paragraph 6.2.2 from the flywheel kinetic energy at 64 mph.

6.2.3.2 High-speed landings. In the second series of 100 landings, the minimum landing speed is 120 mph and the nominal unlanding speed is 90 mph. The unlanding speed must be adjusted as necessary so that 44 percent of the kinetic energy calculated under paragraph 6.2.2 will be absorbed by the tire.

TSO-C62d 9/7/90 Appendix 1

6.2.4 Test method B - fixed mass flywheel. The total number of dynamometer landings must be divided into two equal parts having speed ranges indicated below. Each landing must be made in a time period, T, calculated so that the tire will absorb the kinetic energy determined under paragraph 6.2.2. The time period must be calculated using the equation:

Tc =

For the 90 mph to 0 mph test, the equation reduces to:

Tc =

Tc = Calculated time, in seconds, for the tire to absorb the required kinetic energy.

KEc = Kinetic energy, in foot pounds, the tire is required to absord during each landing cycle.

KEw = Kinetic energy, in foot pounds, of the flywheel at given speed.

TL = Coast down time, in seconds, with rated tire load on flywheel.

Tw = Coast down time, in seconds, with no tire load on flywheel.

(UL) = Subscript for upper speed limit. (LL) = Subscript for lower speed limit.

6.2.4.1 Low- speed landings. In the first series of 100 landings, the tire must be landed against the flywheel with the flywheel having a peripheral speed of not less than 90 mph. The flywheel deceleration must be constant from 90 mph to 0 mph in the time Tc.

6.2.4.2 High-speed landings. In the second series of 100 landings, the tire must be landed against the flywheel with the flywheel having a peripheral speed of not less than 120 mph. The flywheel deceleration must be constant from 120 mph to 90 mph in the time Tc.

6.3 High-speed tire. Except as provided in the alternate test, a tire operating at ground speeds greater than 120 mph must be tested on a dynamometer in accordance with paragraph 6.3.3. The curves to be used as a basis for these tests shall be established in accordance with paragraph 6.3.3.2. The load at the start of each test must be equal to the rated load of the tire. Alternate tests involving a landing sequence for a tire operating at ground speeds greater than 120 mph and not over 160 mph are set forth in paragraph 6.3.4.

9/7/90 TSO-C62d

Appendix 1

6.3.3.2 and 6.3.4. For the remaining 10 percent of each group of cycles, the contained gas or carcass temperature may not be lower than 80°F at the start of each cycle. Rolling the tire on the dynamometer is acceptable for obtaining the minimum starting temperature.

6.3.2 Dynamometer test speeds. Applicable dynamometer test speeds for corresponding maximum ground speeds are as follows:

Maximum Ground Speed of

For ground speeds over 245 mph, the tire must be tested to the maximum applicable load-speed-time requirements and appropriately identified with the proper speed rating.

6.3.3 Dynamometer cycles. The test tire must withstand 50 takeoff cycles, 1 overload takeoff cycle, and 10 taxi cycles described below. The sequence of the cycles is optional.

6.3.3.1 Symbol definitions. The numerical values which are used for the following symbols must be determined from the applicable aircraft load-speed-time data: L0 = Tire load at start of takeoff, pounds (not less than rated load).

L1 = Tire load at rotation, pounds.

L2 = Zero tire load (liftoff)

RD = Roll distance, feet. S0 = Zero tire speed.

S1 = Tire speed at rotation, mph

S2 = Tire speed at liftoff, mph (not less than speed rating).

T0 = Start of takeoff.

T1 = Time to rotation, seconds.

T2 = Time to liftoff, seconds.

6.3.3.2 Takeoff cycles. For these cycles the loads, speeds, and distance must conform to either Figure 1 or Figure 2. Figure 1 defines a test cycle that is generally applicable to any aircraft. If Figure 2 is used to define the test cycle, the loads, speeds, and distance must be selected based on the most critical takeoff conditions established by the applicant.

6.3.3.3 Overload takeoff cycle. The cycle must duplicate the takeoff cycles specified under paragraph 6.3.3.2 except that the tire load through the cycle must be

TSO-C62d 9/7/90 Appendix 1

increased by a factor of at least 1.5. Upon completion of the overload takeoff cycle, the tire must be capable of retaining inflation pressure with the loss of pressure not exceeding 10 percent in 24 hours from the initial test pressure. Good condition of the tire tread is not required after

completion of this test cycle.

6.3.3.4 Taxi cycles. The tire must withstand at least 10 taxi cycles on a dynamometer under the following test conditions:

Number of Test

6.3.4 Alternative dynamometer tests. For a tire with a speed rating of 160 mph, test cycles which simulate landing may be used in lieu of the takeoff cycles specified in

paragraphs 6.3.3.2 and 6.3.3.3. The tire must withstand 100 test cycles at rated load in

accordance with paragraph 6.3.4.1 followed by 100 test cycles at rated load in accordance with paragraph 6.3.4.2.

6.3.4.1 Low-speed landings. In the first series of 100 landings, the test procedures for low-speed landings established under paragraph 6.2.3 or 6.2.4, as appropriate, must be followed.

6.3.4.2 High-speed landings. In the second series of 100 landings, the test procedures for low-speed landings established under paragraph 6.2.3 or 6.2.4, as appropriate, must be followed, except that the tire must be landed against the flywheel rotating at a speed of 160 mph with the rated load applied for the duration of the test. The unlanding speed must be adjusted as necessary so that 44 percent of the kinetic energy, as calculated in paragraph 6.2.2, is absorbed by the tire during the series of tests.

7.0 Requalification tests. A tire shall be requalified unless it is shown that changes in materials, tire design, or manufacturing processes could not affect performance. Changes in material, tire design, or manufacturing processes that affect performance or changes in number or location of tread ribs and grooves or increases in skid depth, made subsequent to the tire qualification, must be substantiated by dynamometer tests in accordance with paragraph 6.0. Requalification in accordance with paragraph 6.0 of a given load rated tire required as a result of a tread design or material change will automatically qualify the same changes in a lesser load rated tire of the same size, speed rating, and skid depth provided --

7.1 The lesser load rated tire has been qualified to the applicable requirements specified in this standard; and

9/7/90 TSO-C62d

Appendix 1

Advisory

Circular

Subject:Inspection, Retread, Date: 7/10/06 AC No: 145-4A Repair, and Alterations of Initiated by: AFS-309

Aircraft Tires

1. PURPOSE. This advisory circular (AC) provides guidance for the development, qualification, and approval of bias and radial aircraft tire retreads, their repair and process specifications, and the use of special nondestructive inspection (NDI) techniques. This material is neither mandatory nor regulatory in nature and does not constitute a regulation. It describes acceptable means, but not the only means, for developing specifications to be submitted to the proper Federal Aviation Administration (FAA) office for approval. The FAA will consider other methods of demonstrating compliance that an applicant may elect to present. Terms such as “shall” and “must” are used only in the sense of ensuring applicability of this particular method of compliance when the methods of compliance described in this document are used.

2. CANCELLATION. AC 145-4, Inspection, Retread, Repair, and Alterations of Aircraft Tires, dated September 27, 1982, is canceled.

3. RELATED REGULATIONS AND REFERENCES (current editions). a. Title 14 of the Code of Federal Regulations (14 CFR).

(1) Part 21, Subpart O, Technical Standard Order Authorizations.

(2) Part 23, Airworthiness Standards: Normal, utility, acrobatic, and commuter category airplanes.

(3) Part 25, Airworthiness Standards: Transport category airplanes. (4) Part 27, Airworthiness Standards: Normal category rotorcraft. (5) Part 29, Airworthiness Standards: Transport category rotorcraft.

(6) Part 43, Maintenance, preventive maintenance, rebuilding, and alteration. (7) Part 145, Repair stations.

AC 145-4A 7/10/06 c. Technical Standard Order (TSO). TSO-C62, Tires.

d. Industry Documents.

(1) ARP 4834, Aircraft Tire Retreading Practice—Bias and Radial. (2) AS 4833, Aircraft New Tire Standard—Bias and Radial.

(3) TRA, Tire and Rim Association Aircraft Yearbook.

(4) ETRTO, European Tire and Rim Technical Organization Standards Manual. 4. DEFINITIONS.

a. Retreading. The term retreading refers to the methods of restoring a worn tire by renewing the tread area or by renewing the tread area plus one or both sidewalls. Repairs are included in the tire retreading process.

b. Specification. Documents approved by the Administrator containing information for performing specialized maintenance, such as retreading of tires.

NOTE: Repair stations with limited ratings for specialized services are required under part 145, § 145.61(c) to include a specification on their operations

specifications.

c. Retread Level (R-Level) Escalation. R-level escalation is the process used to verify that a population of retreaded tires is suitable for an additional service life.

d. Load Rating. Load rating is the maximum permissible load at a specific inflation pressure. The rated load combined with the rated inflation pressure will be used when selecting tires for application to an aircraft and for testing to the performance requirements of this

document.

e. Ply Rating. This term is used to identify the maximum recommended load rating and inflation pressure for a specified tire. It is an index of tire strength.

f. Speed Rating. The speed rating is the maximum takeoff speed to which the tire has been tested.

g. Bias Tire. A pneumatic tire in which the ply cords extend to the beads and are laid at alternate angles substantially less than 90 degrees to the centerline of the tread.

h. Radial Tire. A pneumatic tire in which the ply cords extend to the beads and are laid substantially at 90 degrees to the centerline of the tread, the casing being stabilized by an essentially inextensible circumferential belt.

i. Casing. The casing is the structural part of the tire.

7/10/06 AC 145-4A k. Skid Depth. The distance between the tread surface and the deepest groove as measured

in the mold.

l. Maximum Outside Diameter (D0). For the bias tire, it is the maximum new (ungrown) diameter along the centerline of the tire as denoted in TRA and ETRTO. For the radial tire, it is the maximum new (ungrown) diameter of its bias tire equivalent.

5. BACKGROUND. In parallel with the introduction and installation of new radial tire designs on the U.S. civil aircraft fleet, the FAA initiated a project to update appropriate safety standards and advisory support material. This includes revisions to TSO-C62, AC 145-4, and AC 20-97. The retreader’s quality and escalation plans are based in part on the manner in which the airline operator maintains the retread tire in service. The long term integrity and reliability of the retread tire is significantly influenced by the inflation pressure schedule, the frequency of tire pressure checks, and the identification of tire removal conditions that may impact the continued airworthiness of the tire. This revision will ensure that repair stations which retread bias and/or radial tires, and aircraft operators who use these tires, have proper guidance which assures the continued performance of a tire through testing, as originally approved under the TSO (and requirements under part 43, § 43.13), and provides the basis for the development of a specification covering the inspection, retread, and repair of tires, as set forth under part 145. 6. SPECIFICATION REQUIREMENTS.

a. Title 14 CFR Requirements.

(1) Repair Station. A repair station that is certificated to retread aircraft tires is

required by § 145.61(c). to perform that work in accordance with a specification approved by the FAA or in accordance with an operator’s manual as outlined in § 43.13(c).

(2) Operator. A holder of an air carrier operating certificate or an operator with a 14 CFR part 125 operating certificate may adopt a retreading agency’s approved specification and include it as a part of its manual as outlined in 14 CFR part 121, 125, or 135.

b. Specification Requirements. The retreader of bias or radial aircraft tires is required to establish maintenance and repair practices, including special nondestructive inspection

techniques and retreading procedures. These practices could be techniques defined, developed, and validated by the retreader and approved by the FAA or from information provided by the tire manufacturer. The minimum requirements and issues to be addressed for a specification that would be developed and submitted for FAA approval by a repair station and retreader are identified within this document.

c. Applicability. For retreading bias and radial aircraft tires manufactured under TSO-C62, a specification and requirements defined here shall be developed and complied with by the repair station and retreader for all repaired and retreaded tires after the effective date of this AC. Bias tires that were manufactured to prior TSO standards may be repaired in accordance with

maintenance instructions identified under AC 145-4, dated September 27, 1982. However, further escalation of these existing tires should comply with the escalation of these requirements.

7. MARKING.

AC 145-4A 7/10/06 a. Retread Identification. The following minimum information must appear in permanent markings between the wearing surface and the edge of the newly applied rubber.

(1) The retreader’s name or registered trademark. (2) The retread plant identification code.

(3) The month and year the retread was performed.

(4) The letter “R” followed by the number of times the casing has been retreaded. b. Casing Identification. Retread processing may destroy some or all of the casing identification. The following information must be restored if removed during retreading:

(1) Airworthiness compliance markings (only restore at the direction of the original casing manufacturer);

(2) Size and load rating;

(3) Casing manufacturer’s name or trademark; (4) Ply rating;

(5) Casing manufacturer’s plant code; (6) Date of manufacture;

(7) Serial number; (8) Speed rating;

(9) Casing manufacturer’s part number; and

(10) Tire type. Tires requiring a tube in their operation shall be marked with the words “Tube Type.”

c. Regrading Procedure.

(1) The ply rating, load rating, and/or speed rating on either the casing or the retread may be decreased without approval. All performance and qualification parameters under the new rating must be met.

(2) If the ply rating, load rating, and speed rating markings of the casing do not agree with the retread qualification status, they must be buffed off and the correct markings applied.

(3) The casing manufacturer’s part number must not be altered without the original casing manufacturer’s approval.

7/10/06 AC 145-4A d. Marking Maximum Cut Limit Repairs. Casings containing maximum allowable cut

limit repairs in the tread area should be identified with a sidewall brand in line with the repair. The guidelines and conditions under which this brand is applied should be specified in the retreader’s specification.

8. CASING SELECTION. The new tire casing must be approved by the FAA. Unless

otherwise restricted by the tire manufacturer or FAA, any eligible tire may be retreaded provided it meets the inspection and defect limitation criteria, and has met the R-level escalation

inspection and test criteria established in the FAA-certificated repair station and the retreader’s FAA-approved specification.

a. Inspection. The following are commonly available NDI techniques that should be used when necessary and as specified in this document.

(1) Visual. All tires should be visually inspected in the tread, sidewall, bead, and liner areas for conditions that need repair or which require that the tire be scrapped.

(2) Air Injection. Tubeless tires may be air injected with a dry filtered gas (e.g., air or nitrogen) to inspect the casing for proper venting, separations, bead and liner condition, etc.

(3) NDI. Holography, shearography, ultrasonic, X-ray, and other NDI methods should be used as necessary and where applicable.

b. Disposition of Tire Casings.

(1) Acceptable Casings. Tires which meet the acceptable limits for repair listed in the FAA-approved retreader’s specification may be repaired/retreaded and returned to service.

(2) Unacceptable Casings. Tires that fail the acceptable limits for repair listed in the retreader’s specification should be rejected from further aircraft use. Casings not returned to the customer should have all airworthiness compliance markings removed. Removal of the serial number is at the discretion of the retreader. Further, the casing should be marked in a

conspicuous manner indicating the casing is not suitable for aircraft use.

9. REPAIR PROCESS. Repairs are permitted if the anomaly (i.e., damage or fatigue) does not exceed limitations specified by the tire manufacturer or the rejection criteria identified in the repair station and retreader’s specification, as approved by the FAA. Maximum permissible repairs identified in the process specification shall be validated by tests and/or analysis for FAA approval before returning to service. The specification shall include each of the repair types for bias and radial tires, as identified in the Appendix 1, and additional repairs identified by the retreader.

10. RETREADING PROCESS. The retreading process includes removal of old material, renewing the tread area, and curing and bonding of the new material to the casing. A retreading process identified by the repair station and retreader must be provided in the specification for approval by the FAA. Provisions should be included that assure that the retreaded tire weight will not exceed the maximum allowable weight (where it has been determined by the landing gear or airframe requirements established by the aircraft manufacturer).

AC 145-4A 7/10/06

11. QUALIFICATION TESTING. a. General.

(1) The test procedures described herein are intended to ensure compatibility between the original tire casing and newly applied retread. This qualification test is required with the first (R-1) application of a new tread and as otherwise specified in this AC. The retread should not fail the applicable dynamometer tests specified herein nor have any signs of structural

deterioration other than normal expected tread wear except when the overload takeoff cycle is run last (see paragraph 11b below). Casings selected for retread tests should have at least 80 percent of their new molded tire skid depth removed by wear (i.e., worn by aircraft usage).

(2) Design and construction differences between radial tires of different manufacturers dictate that retread dynamometer testing be conducted on one sample of each manufacturer’s radial tire casing at the first (R-1) application of a new tread. Qualification of bias tire retreads on a single manufacturer’s casing qualifies the retread on other manufacturer’s compatible casings of the same size, ply rating and speed rating.

b. Dynamometer Test Cycles. The retread test tire shall satisfactorily withstand

61-dynamometer cycles as specified in TSO-C62 , as a demonstration of overall performance. The 61-dynamometer cycles shall consist of 50-takeoff cycles, 8-taxi cycles at rated load, 2-taxi cycles at 1.2 times rated load, and 1-overload takeoff cycle starting at 1.5 times rated load. Good condition of the tire tread is not required after completion of the overload takeoff cycle if it is run last. The sequence of the cycles is optional. However, if the overload takeoff cycle is not run last, the tire must not show detectable signs of deterioration after the cycle completion, other than normal expected tread surface abrasion. A single tire specimen must be used to complete these cycles.

c. Requalification Tests. A retread tire that has been altered, and which has changes in materials, design and/or manufacturing processes that could adversely affect the performance and reliability of the tire, shall be requalified to the dynamometer tests described in paragraph 11b regardless of the escalation level. Examples of such changes include, but are not limited to, changes in tread construction, such as the number or composition of tread reinforcing and/or protector plies, tread compound formulation, number and location of tread grooves, and increases in skid depth and/or tread gauge. Requalification by similarity, as discussed in paragraphs (1) and (2) below, applies to all bias tires that are compatible with the new tread design and/or material change. However, requalification by similarity for radial tires only applies to tires of comparable design by a single manufacturer. Requalification by similarity is not allowed for radial tires from different manufacturers.

(1) Requalification by Similarity (Based on Load Rating). Requalification of a given load rated retreaded tire required as a result of a tread design or material change will

7/10/06 AC 145-4A (2) Requalification by Similarity (Blanket Change). Requalification of any change

that affects multiple sizes may be made by similarity providing that:

(a) Five representative sizes, including tires of the highest load, speed rating, and angular velocity, have been qualified to the minimum performance standard with the change. (b) The data in support of the change in the listed sizes should be submitted to and approved by the appropriate FAA office.

d. Overpressure. A retreaded tire, processed in a manner similar to the example tested on the dynamometer, shall successfully withstand a hydrostatic pressure of three times its rated pressure for 3 seconds without failure. The tire used to do the dynamometer qualification testing may be used if desired.

e. Tire/Rim Slippage. Slippage of the tire on the rim during dynamometer testing must not damage the tube valve of tube type tires, or the gas seal of the tire bead of tubeless tires. 12. RETREAD TIRE DIMENSIONS. The tire dimensional envelope for a given tire size should be within industry accepted practices (e.g., TRA or ETRTO guidelines). When inflated to its rated inflation pressure and allowed to stretch for 12 hours, the tire should not exceed a “grown” tire dimensional envelope.

13. RETREAD BALANCE. All tires must be tested for static unbalance. a. Auxiliary Tires.

(1) The moment of static unbalance (M) for auxiliary tires shall not be greater than the value determined by Eq. 1.

Equation 1. M = 0.025 D02

(2) Computed Eq. 1 values must be rounded off to the next lower whole number where M is in inch/ounces and D0 is the standardized maximum outside diameter in inches. Tires

outside the limits must be corrected for balance before entering service. b. Main Tires.

(1) The moment of M for main tires shall not be greater than the value determined by Eq. 2.

Equation 2. M = 0.035 D02

(2) Computed Eq. 2 values must be rounded off to the next lower whole number where M is in inch/ounces and D0 is the standardized maximum outside diameter in inches. Tires

outside the limits must be corrected for balance before entering service.

14. INFLATION RETENTION. The pressure retention of the tire must be confirmed in accordance with TSO-C62.

AC 145-4A 7/10/06

15. RETREAD ESCALATION.

a. The wide variation in tire operating environments, which affects the individual casing life, makes it inadvisable to arbitrarily specify the maximum number of times a tire should be retreaded. The number of times a tire can be retreaded should be controlled by an inspection and test system based on the retreader’s reliability program and the use of nondestructive

interferometric (shearography) tire inspection. This procedure is applicable to both bias and radial ply tires.

b. Following successful qualification of retreaded tires at the first retread level by size/ply rating/speed rating, and before entering into service tires of the first or subsequent R-levels, each part number should be escalated in accordance with the retread manufacturer's escalation plan. Each plan should be submitted to and approved by the FAA.

16. RETREAD RELIABILITY SYSTEM.

a. The Retread Reliability Program should monitor the in-service reliability of the retreaded aircraft tires. The reliability control system, to be consistent with the requirements of the aircraft it supports, should consist of a means to recognize a repetitive in-service issue, determine what plan of action would be needed to address this issue, and follow up on the action taken to remedy the issue.

b. The corrective action taken depends on the results of the data collection and analysis. The corrective action should result in the identified tire issue being reduced within a reasonable timeframe.

Original signed by Carol Giles for James J. Ballough