F

Regrinding / Recoating

User Support

Needs

G

G

F

F

G

User Support

B

A

A

B

B

C

C

D

D

A

FAQ Processing DataProducts Information

C

Technical InfoWX Super coating

FX (TiAIN) coating

V (composite multi-layered) coating

TiCN coating

WX (TiAIN) coating

WXL coating

Tolerance for drill diameter

Shank Helix Angle Cutting Conditions Tool Materials Surface Treatment

Polycrystalline Diamond

Please keep this page open for your reference.

Guide of (Tool Specification) Icons

Cobalt HSS

HSS

Super Premium HSS

High grade Powder Metallurgy HSS (XPM)

Powder Metallurgy HSS (CPM)

High Vanadium HSS

TiN coating

Diamond coating

Smooth coating

CrN coating

Steam Oxide

Nitride

Tolerance for drill diameter.

Tolerance for shank diameter

Suitable for the shrink holder system.

Display helix angle of flute for drills and taps. Indicates page No.for recommended drilling conditions.

Movie

Animation is listed on our HP.

WD coating

HR coating

OSG was certified by ISO9001 for the management system at the following factories: Yana Factory, Shinshiro Factory, Toyohashi Factory, Oike Factory.

OSG acquired ISO14001 at the following factories and offices: Head Office, Yana Factory, Shinshiro Factory, Toyohashi Factory, Oike Factory, Toyokawa Factory, R&D Center, Academy, and Hongu Center.

JQA-2856

JQA-EM1088

P.

7

Coolant-Through WDO Carbide Drill Series

X Performer Forming Taps Series

INFORMATION FOR THE USER

DRILL SELECTION CHART

CARBIDE DRILLS

NEXUS DRILLS

DIAMOND DRILLS

VP-GOLD DRILLS

TDXL DRILLS

EX-GOLD DRILLS

V-GOLD DRILLS

STEEL FRAME DRILLS

HARD DRILLS

V-SELECT DRILLS

SPECIAL ORDER DRILLS

SPECIAL ORDER POLYCRYSTALLINE DIAMOND TOOL

CUTTING CONDITIONS

DRILLING DIFFICULT TO MACHINE MATERIALS

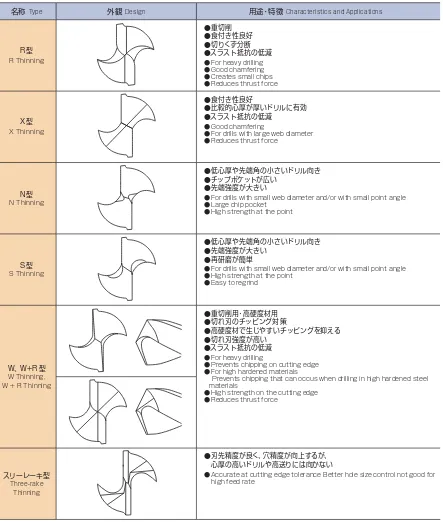

THINNING

RECOMMENDED DRILLING CONDITIONS

TROUBLESHOOTING

REGRINDING METHOD

DRILL RE-GRINDING MACHINE

DRIL

1

2

Margin width

Margin

Lip relief

Radial point thinning

Lip Body clearance Body diameter clearance Secondary relief face Lip relief width

Point

Point angle

Web Flute Run-out

Lip relief angle

Helix angle

Flute length Shank length

Shank diameter Overall length Radial corner Core Drill diameter

Land width Flute width

1

2

R3

R1

h Ds

R2

Ds R1

Make a pilot hole.

For a pilot hole, select same size or below 0.1mm larger size drill than FTO-GDXL/FTO-M-GDXL/FTO-H-GDXL.

The recommended drills for a pilot hole are listed below.

Increase the revolution to the designated speed and start drilling. Insert the FTO-GDXL/FTO-M-GDXL/FTO-H-GDXL into a pilot hole with zero or low revolution.

After drilling, move the drill away from the bottom of the hole; then reduce its speed while pulling it out of the hole.

Make sure to use an internal coolant supply when drilling.

When working on a curved surface, use the FX-ZDS (end mill for counterboring) to counterbore a pilot hole.

FS-GDS, FS-GDN, F T-GDS, FT-GDN : See page 44 51

The sizes for guide holes are available.

To use CAO-GDXL for 30D times the drill diameter, please contact our sales.

Make a pilot hole.

For a pilot hole, select same size or 0.02 0.05mm larger size drill than CAO-GDXL.

The recommended drills for a pilot hole are listed below.

FTO-GDS FTO-GDN FTO-PLT

When working on a curved surface,use the FX-ZDS end mill for counterboring to counterbore a pilot hole.

Insert the CAO-GDXL into a pilot hole with zero or low revolution.

Increase the revolution to the designated speed and start drilling.

After drilling, move the drill away from the bottom of the hole; then reduce its speed while pulling it out of the hole.

Work Material Tensil StrengthHardness Drilling Speed Feed Rate

P

M

K

N

S

DM:Center Cutting Type Drill

Recommended Materials by Application