2013 Intemational Conference on Alternative Energy in Developing Countries and Emerging Economies

On behalf

of

Thaksin

University,

it

is

an honor, and

a

pleasure,

to

welcome all

participants to the 2013 International

Conference

on Alternative

Energy

in

Developing

Countries

andEmerging Economies held

in Bangkok,

Thailand.

Climate

changeis

aserious issue that threatens economic and

social

development

it all

countries. While the

World

has

historically relied greatly on fossil fuels

as

a primary

source

of energy,

humanity

is

rapidly

realizing

that

we

collectively

need

to find

and

adopt

new

patterns

of

energy production

and

consumption,

new

methods

of

transportation, and

different types

of

land use and waste

management

to

reduce

the

impacts

sf slimate

change.The 2013 AEDCEE Conference

will

bring

together

leaders

in

the altsrnative

energy

industy,

acadernic experts, research sectors

and

govenrments

to

meet,

interact,

exchange ideas

and

discuss

the

state

of

the art

of

advanced

technology,

research

anddevelopment related

to

altemative energy

sources.

Solutions

will

also be offered

in

order

to

respond

to

the

growing demand

from

developing countries

who

aspire to

achieve

environmentally

sustainable economic

growth.

I

would like

to

express

my

deepest

gratitude and

sincere

thanks

to

the

Research

andDevelopment Institute

and

the

Research Center

in

Enerry

and

Environment

of

Thaksin

University, along

with

our international

partners,

the Universit6

de

Moncton

(Canada)and the

University of Maryland (USA), who

have

contributed

in

oneway or

another

to

the

successof

the Conference.

I

also

want

to

express

my

deepest

agreciation to

the

sponsoni

of

theConference,

who

believe

in

ourpeople

andin

Thaksin

University.

It

is

by

working

collectively

and

cooperatively

that

we

will

move

towards

the

sustainable

development

of

our

nations.

I

trust

this

Conference

will

help

to

take

us

clossr

to our

goals

of implementing altemative

energy

sourcesfor developing

countries

and

emerging economies.

While in Thailand,

may

you

also take the

opportunity to

visit

our

great

country

and

see,first-hand, why we

arecalled

thel,and

of

Smiles.Cordially,

Associate Professor

Dr. Somkiat

Saithanoo

President, Thaksin

University

-2013 International Conference on Altemative Energy in Developing Countries and Emerging Economies

The

2013 AEDCEE

Conference

follows

amost

successfiil

first

edition held

in 201I

in

Hat

Yai, Thailand.

The interest

in

this

Conference

confirms

a

growing trend

towards

renewable

andalternativL energy

in

developing countries

andin

emerging

economies.Enerry

security

is

an

important

determinant

in

the

economic

development

of

jurisdictions and the quality

of life

of people.

Over the past

two

centuries, countries

from

theNorth

had theprivilege to

develop using abundant

fossil fuel

basedenerry,

and

more

recently,

nuclear

energy.

During this period,

carbon emissions were

not

an issue,and nuclear waste

was

considered,

and

is still

unfortunately considered

in

many

jurisdictions,

aproblem

that

we

leave to future generations

to

solve.

In

the

context

of

climate change

and growing

concerm regarding nuclear

energy,developing counfiies

and ernerging economies

do not

have

the

sameprivilege.

While

this is

achallenge, it is also

anopportunity.

Iadee4

as mentioned

by Kandeh

Yumkella, Chair

of

the

UN-Energy, "Developing

counkies, many

of

them growing rapidly

and

at a large

scale,

have the opportunity to

leapfrog conventional

energy

options

and

move

directly

to

cleaner energy altematives

that

will

enhance economic

and social development". The rapid

development

of

altenrative enerry options

based on renewable energy sources

offers

developing

countries

and

emerging

economies

the possibility

to

accessindigenous

energy

sourcesfor their

economic

andsocial development.

The

objective of

theAEDCEE

Conference

seriesis

to offer opportunities to

disseminate

lnowledge,

and exchange

information

and best

practices,

for

an efficient

development

of

alternative

energyfor

countries

in

the

South.

The

stong

responsefrom

the academic,

industy

and govemment communities

is

an encouraging sign that alternative

energy

and

renewable energy

areviable

energy options

forjurisdictions.

Thaksin University

is emerging as

a

leader for altemative and renewable energy

in

Thailand and South East

Asia.

It

is with honour

that the

Universit6

de

Moncton,

Canadq

is

participating

in

the organisation

of

the 2013

AEDCEE

Conference and on

its

Scientific

Committee.

We

wish all participants

agood

andproductive

conference,

frtritful discussions

andnew

friendships.

Yves

Gagnon P.Eng., D.Sc.

Professor

andK.C.

kving

Chair in

Sustainable

Development

Universit6

deMoncton, Carada

2013 International ConfErence on Altemative Enerry in Developing Colmties and Emerging Economies

Following

amost

successfirst

edition

1n20ll,

we

areproud

to

organize and

host

the

2013 Intemational Conference

on

Alternative Energy

in

Developing Countries

and

Emerging

Economies (2013

AEDCEE).

We

hope

this

event

will

enable participants

from

developing as

well

as

developed

counffies

to

meet and

exchange

their knowledge and valuable

experiences

in

dealing

with

alterrative

energy

and

energy efficiency

technologies.

We

also

wish the

Conference

will

result

in

producing recommendations

and inputs

for

establishing

workable

strategies

andaction plans

on these issues.The 2013 AEDCEE

Conference

is

hosting

seasonedauthors

who contribute scientific

and

technical

high

quahty papers

on

the topic

of

the

Conference.

We

hope

the

Conference

will

serve as

a

guideline

for

our

endeavor regarding alternative

energy

development

and

deplo5mrent

that

will

lead

to

a

better

environment

for

future

generations, the

children

ofour

children.

Likewise, we do

hope

you

will

enjoy the Thai hospitality

and

food. We would

like

to

thank

the

official

sponsors

of

the

Conference,

the

National

Research

Council

of

Thailand

(NRCT),

Provincial

Electricity Authority (PEA), Electricity

Generating

Authority

of

Thailand

(EGAT),

the

National

Science and Technology Development

Agency

(NSTDA), the

Research and Development Institute-Thaksin University,

the

Faculty

of

Science-Thaksin

University,

the

Research

Center

in

Energy

andEnvironment-Thaksin University, the Universit6 de Moncton

(Canada),

the University

of Maryland (USA)

and theprivate

sector-On

behalf of Thaksin University,

our

parhers

and

our

sponsors,we

.Iredeeply

grateful

again

for your participation

in

the 2013 AEDCEE

Conference, and

for

presenting

your

great andoutstanding

researchwork.

Thank

you

and Sawasdee,Asst.

Prof. Dr.

Ponrpun Khemakunasai

Director,

Research andDevelopment Institute

ScienceThaksin

University

Asst.

Prof. Dr. JompobWaewsak

Director,

ResearchCenter

in

Energy

andEnvironment

Thaksin

University

Dr.

SarapeeChairat

Dean,

Faculty

of

Thaksin

University

Advisoly Committees

*

Prof.Dr.Prida Wibulswas, Thailand

*

Prof.Or.Ali Sayigh, U.K.

I

Prof.Dr.R.H.B. Exell, U.K.

I

Prof.Dr. Naksitte Coovatanaehai, Thailand

*

Dr.t<rissanapong Kirtikara, Thailand

Oryanizing Committees

General Chair

.)

Assoc. Prof.

Kasem Asawatreerata

nakul,

Tha

i la nd*

Asst. Prof.

Dr.Nugul

Intrasungkha,

Thailand

General Co-Chair

.)

Asst.Prof.Dr.Jompob

Waewsa(

Thailand

*

Prof.Dr.Yves

Gagnon,

Canada

Memberc

*

Prof.Dr.Christian

Masson, Canada

*

Prof.Dr.Jianzhong Xu,

China

*

Prof.Dr.Masatoshi Nakamura, Japan.

*,

Prof.Dr.Eicker Ursula, Germany

*

Prof.Dr.Joachim

Peinke,

Germany

*

Prof.Dr.|.;rzarin

Renato,

Italy

i

Prof.Dr.A.Jagadeesh,

India

*

Prof.Dr.Christos Pagageorgiou,

Greece

*,

Prof.Or.Uqiu

Wang,

Hong

Kong

*

Prof.Or.Kim

Hyung-Tae(

Korea

a.

*

Prof.Dr.Somsak Panyakaew,

Thailand

*

Prof.Dr.Surapong

lirattananon,

Thailand

*

Prof.Dr.Somchart Soponronnarit, Thailand

i

Prof.Dr.Samroeng Jakjai, Thailand

I

Prof.Dr.Tanongkiat Kiatsiriroj, Thailand

*

Prof.Dr.Joreph Khedari, Thailand

*

Prof.Dr.Jongjit

Hirunlabh, Thailand

*

Assoc. Prof

.Dr.

Bundit

Fungtha

mmasan,

Thai

land

*

Assoc. Prof. Dr.

Wattanpong

Rakwich

ian,

Thai

la nd*r

nssoc. Prof.

Dr.V.I.

Kouprianov, Thailand

*

Rssoc. prof. Dr.Su ppacha

ft

Chu

ngpa

ib@n

patana,

Thai Iand

I

Assoc. Prof. Dr.

Bundit

Li mmechokcha i,Tha

i la ndt

Assoc. Prof.

Dr.Serm Janjai, Thailand

*

Assoc.Prof.Dr.Sirichai Thepa, Thailand

*

Assoc. Prof.

Dr.

Pichai

Namprakai, Thailand

I

Assoc. Prof.

Dr. Ratta nacha

i

Pairin,

Thai

land

*

Assoc. Prof.

Dr. Peera

pong

Teekasa

kul,

Tha

i !and

*

Assoc. Prof.

Dr.Yuttha na

Thi

rawanichakul,

Thai

land

I

Rssoc. Prof.

Dr.Supawan Thirawanicha

kul,

Thai

la nd*

Assoc.Prof.Dr.K.S.

Ong,

Malaysia

I

Assoc. Prof

. Ga mpol

Prateepchai

kul,

Thai

la ndProgram

Committees

Chair

'|

Dr.Sompong O-Thong

t

Asst. Prof.

Dr.

lGnokphom

Sangkharak

Memberc

*' Rsst. prof.

Dr.

Prasong

Kessarati

kul

I

Asst.Prof.Dr.Jompob Waewsak

I

Asst. Prof. Dr.

Kornvika Kongkul

I

Asst.Prof.Dr.Usa Onthong

*' Asst.Prof.

Dr.Warangkhana Keerativibool

*

Asst.Prof.Marina

Mani

I

Or.ChonUsa Sukkasem

*

Dr.Asadhawut

Hiranrat

I

Dr.Wariam Chuayjan

*

Dr.Jatuporn

lGew-On

I

Or.Chontira Sangsubun

I

Dr.Tanate

Chaichana

*

Dr.Panita Sumanatrakul

*r

Dr.Thawatchai Tepnual

Local

Committees

+

Assoc.

Prof.Dr.Sumate Chaiprapat,

PSU

*'

Rsst.Prof.Dr.Sate Sampattakul,

CMU

I

Asst.Prof.Dr.Chuleerat Kongruang,

WU

*

Asst.Prof.Dr.Tika Bunnag,

RMUTR

*

Asst.Prof.Dr.Naris Pratinthong

,

KMUTT

*

Asst.Prof.Dr.Nirundorn Matan,

WU

I

Asst.Prof.Dr.Charongpun Musikavong,

PSU

I

Asst.Prof. Dr.Sirinuch Chindaruk,

NU

I

Asst.Prof.Dr.Somchai Maneewan,

NU

I

Asst. Prof.

Dr. Cha

roen

porn

Lertsatittha

nakorn,

MSU

I

Asst.Prof.Dr.Nattapol Poomsa-ad

,

MSU

I

Dr.Pisit Maneechot,

NU

*

Dr.Montana Rungsiyopas,

BUU

#

Dr.Warit

Jawjit,

WU

*

Dr.Warit Weerapan,

PSU

I

Dr.Watsa Khongnakorn,

PSU

*

Dr.Kaokanya Sudapraseft,

KMUTT

I

Dr.Panita Chinvetkivanich,

KMUTT

*

Or.Withaya Puangsombut,

RIvIUTR

2013 International Confereuce on Altemative Energy in Developing Counkies and Emerging Economies

Simple Conversion

Method from

Gasoline

to

Biogas

Fueled

Small Engine to Powered

Electric

Generator

I

Wayan Suratar,ljokorda

GdeTi(aNindhiaz,

I

KetutAdi

Atrnikar,

DewaNgakanKetut

Pufra Negaraa,andI

Wayan Eka Perrnana Puha5 ''''''nD"pr*"rt

of Mechanical Engineering, Udayana University, Denpasar (lzdonesia)5

Undergraduate Student, Department of Mechanical Engineering, Udayana University Denpasar, (Indonesia)

ABSTRACT

The gasoliae fueled single cylinrler generator engines are

well

established and availablein the

market vrith reasonable price,in the

other hand the biogas fueled enginefor

elecftic generator is notwell

established yet. The purposeofthis

tesearch is to find simple conversionmethod

from

gasolineto

biogas fueledof the

single cylinder four stoke engines. For this purlrose, the biogas should be upgraded to the level of zero H2S impurity and zero level of HzO content. The carburetor of the gasoline engine was replaced and only component of the mixerof

the fuel and air were used. The intake of the biogas fueledshould

be

completedwith

valve that

canbe

openedautomatically

by

vacuumof

the

zuction skokeof

the engine.To

inctease the performanceof

the engine, the liquefied petroleum gas (LPG) was added to the mixture up to 80% ofbiogas and20%oLPG.Keywords: bioges, convension, electric generetor, four

shoke engine, gasoling single cylinder

INTRoDUCfloN

The

difficulty

in

manufacturingthe

biogas fueled engine still become a problem thatleld

in high priceof

the biogas fueled engine.

This

makethe

progressof

utilization biogas as a fuel for electric generator engine in developing countryis

found

not

as good as

in

the developed country. Biogasquality varies

among the region makeit

difficult to upgrade in to the standard state for fueled the engine. As reported by Osorio and Tores [1], biogas composed of various gases such as methane (6U-7tr/o), CO2QMl%),

nitrogen(<lY),

ard H2S(10-2000 ppm). This various composition make

difficult

for the userin

setting the enginefor

exampleto

rur

the electric generator.The concentrations of the impurities (methane, carbon

dioxide, water,

hydrogensulhde, nitrogen,

oxygen, ammonia, siloxanes and particles) are dependent on thecorposition

of

the

substatefiom

whichthe

gas was produced. However, to prevent corrosion and mechanicalweat of the

upgrading equipmentitself,

it

can

beadvantageous to clem the gas before the upgrading [2].

When flOwing

out from the

digester,biogas

issaturated with water vapor, and this water condensate

in

pipelines and cause corrosion. Water can be removed by

c.ooling

compression, absorptionor

adsorption. Byincreasing the pressure

or

decreasing the ternperature,water

will

condensatefrom the

biogasand can

be removed. Cooling can be simply achieved by burying the gasline

equippedwith a

condensate trapin

the

soil.Water

can also

be

removedby

adsorption usingmolecular sieves, SiO2,

or

activated carbon. Thesematerials are usually regenerated by heating or a decrease

in

pressure. Other technologiesfor

water removal areabsorption

in

glycol solutions or the use ofhygroscopicsalts [2].

During microbiological reduction of sulfur containing compounds (sulfates, peptides, amino acids) hydrogen sulfide is fomred. The concenhations of hydrogen sulfide

in the biogas s31

!g

eliminated either by precipitation inthe digester liquid or by treating the gas either in a stand

alone vessel or while removing carbon dioxide. Addition

of Fe2* ions or Fe3* ions

in

the form of FeCl2, FeCl3 orFeSO+,

to

the digester precipitates the alnost insolubleiron sulfide that is removed together

with

the digestatet2t-Beside its

difficulty for

fueled the engine, biogas hasadvantages as alternative enerry since easy

to

produceeven from municipal waste [3]. This make that the effort

to use biogas

to

fireled the engine should be promotedand

supportedas

vfuat

happenedin

the

developed country. Recently the biogas is possible to use for drivenair

conditioning system[4],

and more even at the subtopical

region, the usedof

biogas was provenwell

for combinedheat and

powered(CHP)

for establishing

electricity and heating during winter[5].

The advantagesof

biogas plants are varied[6]:

economically atEactiveinvestment;

easily

operated and

safe

installation; production ofrenewable elechicity and heat resulting in areduction

of

CO2

emissions; rqductionof

methaneemissions

from

manwe storage and; improvementof

fertilizing qualities of manwe.Biogas systems also lead

to

indirect etrvironmsntal effects that are not direct resultsof

the replacementof

other energy systoms. One

exarple

that was reduced emission of methane from storage of liquid manureif

the manwe is used for biogas production. Another example isthe

anaerobic digestionand

biogas production from organic waste materials that are conrposted. Composting of organic waste causes bioLogical emissions of ammonia,nitrous

odde

and methane and these emissions can besipificant if

gas-cleaning equipmentis

uot used. Thedigesting

of

organic waste

produces

indirect environmental benefits, in the form of reduced emissionsCorre.sponding Author: [email protected]

-714-2013 Inteorational Conference on Altemative Energy in Developing Countries and Errerging Economies

of

greenhouse gases (methane and nitrous oxide) andpollutants contributing to eutophication (ammonia), and

these

indirect

effects

even

exceed

the

directenvironmental benefits

of

replacing fossil vehicle fuelswith

biogas.Another

important advantageof

biogas technology is its application in the freatment of municipalsolid waste

with

a

concomitant reductionin

the waste volume [7].It

is reported that by increasing the compression ratioin the spark

igrition

engine could make possible for thegasoline

tlpe

fueled engineto

replaceby

using biogas,but

spark

ipition

engine

operation

with

biogascontaining signifrcant ftactions of inert gases such as CO2

and N2 exhibit decrease

of

perforrnance cornpared withnatural gas or gasoline.

It

ig likely that emissions of NO*will

increase [8].The idea from Rakopoulos and Michos [9] to make a

mixhre

of

l5Yo hydrogenin

to

the biogasfor

fuel thespark

ipition

engine with result the aildition of hydrogenin biogas that promotes the degree of reversibility of the

buming process mainly during the combustion of the later

buming gas, but the conkibution of the early burning gas

to

the

decreasein

combustionirreversibility

withhydrogen addition seems to be less prominent.

Method

in

mixing biogaswith

city gasis

introducedby the method developed by Yamasaki et al. [10].

It

wasdeveloped

a

gas

engine

system capableof

stableoperation at any

mix ratio

of

ctty

gas and biogas wasdweloped. The gas engine system consists

of

aspark-igrrition gas engine, an additional

elecric

throttle valvefor fuel and control algoritbm. The control algorithm was

also designed

to

adjust the fuel and air ratio to attain ahigher generation efEciency and lower

NO,

emission.It

is

goodfor

referenceto

studythe prwious

researchconducted

by

Chandraet

al.

[1].

The

perfomranceresults

for

comlnessed natural gas, methane emichedbiogas and raw biogas at compression ratio

of

12.65. Theobserved power losses due to conversion of diesel engine

into

spark ignition engine had been 31.8%, 35.6Y, arLd46.3Yo

fot

compressed natural gas, methane emichedbiogas and

raw

biogas, respectively.The

engine testrezults obtained in terms of brake power ouQut, specific

gas

consumptionard

thermal efficiencyon

methaneenriched biogas containing 95% methane has showed that

the

engine perforrnanceis

almostsimilar

to

ftat

of

coryresscd natural gas- Thus, the gaseous fuel metlane

enriched biogas

is

as good as natural gasmix

ratiosof

city gas U 11.

Biogas can be used as flrel

for

natural gas vehicles.The benefit is that fossil fuels like pehol and diesel can

be replaced. For biogas, the reduction ofgreen house gas

emissions can be as much as 100 %. Natural gas used as a

vehicle

fuel

gives 20-30%

lower

CO2 emissions.A

reduction above 100 Yo cwr

be

achieved when biogasproduced

from

manureis

utilized as

a

vehicle fuel.Methane, which is a strong green house gas, is released

into the atnosphere from maurue

in

traditional manrtrestorage. Biogas as a vehicle firel can thus both decrease

the leakage

of

methane from manure and decrease theemissions of fossil carton dioxide. Another atlvantage is

that vehicles running on upgraded biogas or natural gas

have lower emissions ofparticles, NO*and SO. t2].

It

is

the purposeof

this researchto

develop simplemethod

for

conversionAom

gasolineto

biogas fueledsmall engine, without change the compression

ratio

of

original spark ignition englne. The small fueled gasoline

engine was from the specification that easily found in

t}e

market of developing counky that was 4-stroke gasoline

engrne, air-cooled,

inclined single cylinder.

Thedisplacement

is

196 cc,with

compression ration 8.5:1.The ignition system was non contact tansistor igpition

(TCI). This engine was used to run the eleckic generator.

EPnnngrrer

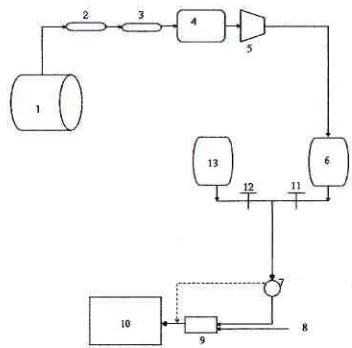

The schematic of the process by using 100% biogas is

presented

in

Fig.

l

The biogas obtained from digesterwas desulfirrized by using annealed and compacted steel

waste chips from the waste

of

turning processin.

Thedetail process

of

processing canbe

accessgdin

ourprevious report [12]. The annealed and compacted billet

used for this research is presented in Fig. 2.

Fig. I . Schenratic of conversion method from gasoline to biogas fueled electric generator engine. 1. Digester, 2. Desuffurizer, 3. Dehumidifier,

4.Bag ofgas holder, 5. Compressor, 6. Gas conainer, T.Vaccum opened valve, 8. Air intake, 9. Biogas and air mixo, 10. Engine.

Fig. 2. Annealed md corryacted billet of steel wrote chips as

desulfurizer-To ensure that the biogas is free from H2S impurities,

the HzS content

in

the biogas was checked before andafter passing the desulfluizer.

If

the HzS still found in thebiogas, the addition

ofbillel

ofannealed and compacteddesulfurizer should

be

done.The

biogaswith

freeirrpurities

of

H2S

was

flowed

to

entering

the-2013 Intemational Conference on Alternative Etergy in Dweloping Countries and Emerging Economies

dehrmridifiEr.

Again

shouldbe

enswed herethat

thebiogas should be free from water

content-Aftenvard the biogas was let to

flow in

to the bagof

gas holder, which from here was ready to be coryressed

in

to

the biogas containeruntil

reach about 6 bar. Thevalve that

will

open by vacuum mechanism was installedto arrange the flow of the biogas. With this valve the gas

will

flow in to the intake of therunifold

andwill

stopif

the engine not runs. The biogas fhen'continues to flow in

to

the mixerparl

This mixer cornponentis

partof

thecarburetor

in

the

gasoline

fueled

engine but

thecarburetion cUp

wrs

replaced andonly mixer part

isremain. Together with biogas, the air was flowed in to the

mixer,

and

directedin

to

the

intake

valve

of

thecombustion chambs.

It

should be noted here that duringstarting the engine, the

flow

rateof

the biogas was letmaximum and reduce

the rate

until the

engine startnmning. After that, the rate

of air flow

in

to the mixerwas adjustetl until the engine run stably.

The composition

of

COzin

the biogas was notin

toaccount in this research since the process for purification

of

biogasfrom

CO2 contamiftIntis corylicated

forimplementation as demonstrated by Chien [13] and also

Tippayawong

and

Thanompongchart[14]. This

workalso can be used as a proof, that the biogas can run the

engine even

with

still

contain CO, impurity. The detailschematic for the process is provided in Fig. 3.

Fig. 3. Schematic ofconversion metbod ftom gasoline to biogas fucled electric generator engine. I, Digester, 2. Desulfurizer, 3. Dehumidifier,

4. Bag ofgas bolder, 5. Compressor, 6. biogas container, T.Vaccnn

opened valve, 8. Air intake, 9. Gas and air mixer, 10. Fnging. I l. Biogas valvq 12. LPG valve, 13. LPG container.

The

selected enginefor

this

purpose was 4-strokegasoline engine,

air-coold

inclined single cylinder. Thedisplaccment

is

196 cc,with

comprcssion ration 8.5:1.The ignition system was non contact transistor ignition (TCI).

It

was planed in this research thatwill

not changethe specification

of

the enginefor

the easy conversionmethod from gasoline to biogas fueled.

ln

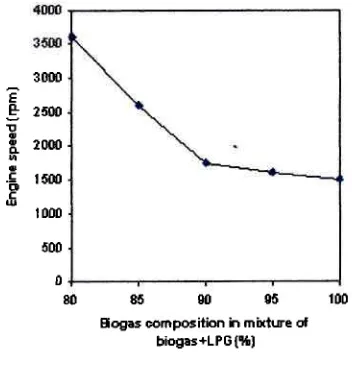

this research investigation on the effect of mixingbiogas

with

liquefied petroleum gas(LPG)

was alsoconducted. The variations

of

biogas compositionin

themixture

of

biogas-LPGin

this

research namely 80o/o,85yo, 90y,, 95Yo and 100%. The effect of variation of the

biogas-LPG

mixture

on

engine

speed

was

theninvestigated.

The

schernaticof

the

experimental isdepicted in the Fig. 3. The both gas container in the Fig. 3

have the same initial pressure i.e about 6 bar, The valve

I

I

at the beginning was let flrll open and the valve 12 wasfull

closed. The engine was thenoperatd

and tho enginespeed was measurgd, The experiment then was continued

by making a mixture 95yo,90yo,85yo, and 80% of biogas

composition in the mixture by arranging the valve 11 and

valve

12

and

ttre

engine

speedswere

measuredrespectively.

The

graphof

gas mixture

conrpositionversus the engine speed was provided.

Rrsurr.nNn DISCUSSION

The convsrsion msthods that was developed

in

thisresearch was successfrrl to run the eleckic generator that

previously fueled

by

gasoline to be convertedby

usingbiogas. The engine run stable and can produce electricity.

The maximum RPM (revolution per minutes) that can be

obtained

by

using 100% biogas was found about 1500rpm. This makes sense since the energy of the biogas is

lower

thm

the gasoline one that is about 6.0-6.5 kwm-3[5].

When The LPG is added to about 5% (95% biogas) in to the mixture, the engine speed was found about 1600rpm- The engine speed is still not increased significantly

with addition 10% LPG which the speed was about 1750

rpm. The significant increase in engine speed was found

with

addition 15% LPG that yielded about 2600 rpmof

engine speed.Finally the

engine speed reached itsmaximum value about 3600 rpm

by

adding abott 2OY"LPG. The maximum value of the engine speed by using

gasoline

fuel

is

3600 rpm.

Thereforeto

obtainedmaximum engine speed by using technique developed

in

this research, the biogas need to be added abortt20Yowith

LPG in order to reach the same maximum speed by using

gasoline as presented in Fig.4.

By

using desulfi:rizer the biogas can be upgraded tozero

contentof

H2S

impuritiesthat

lead

to

avoidiacreasing

acidity

[l2]

of

the

lubricant therefore thecorrosion

in

the combustion chamber canbe

avoided.Previousty

the

existenceof

H2Sin

the

biogas wasovercome

by

increased frequencyof

engineoil

chang6,which

will

increa$e the operating cost[6].

Other urgentthing that make H2S should be eliminated due to H2S is a

Toxic

gas[7].

By

reducing the water contentin

thebiogas

up

to

zerolevel

affectin

easysAning

of

theengrne.

The use ofthe bag gas holder ofthe biogas was useful

during compressing of the biogas in to the gas container

because this is make easy to be observed whether biogas

available or not during gompression.

It

should be notedhere that biogas, containing mainly methane, could not be

stored easily, as

it

doesnot

liqueff

under pressure atambient temperature (critical temperature and pressure

required are -82.5 oC and 47.5 bar). Coryressing the

biogas reduces

the

storage requirements, concenfratesenergy content

and

increases pressureto

the

levelrequired overcoming tesistance to gas

flow

[18].-716-2013 Intemational Conference on Altemative Energy in Developing Countries and Emerging Economies

3m

25m

20m

tffi

I 000 5m

0

80

85

S0

S5

100Eogns compocitbn h mhtre oI

biogas+LPG (ltJ

Fig. 4. Thp effect of compositioo of biogre-LPG mixture on tbe speed of the engile.

It is good to suggest here a useflrl method to reduce the

CO2 irryurities in the biogas.

A

method that is inEoduce by Mohseni et al. [19]. To increase the biogas yield, theseparated carton dioxide could be used as a component to

produce additional methane through

the

well-lnown Sabatier reaction. [n such process the carbon could act ashydrogen carrier

of

hydrogen originatingfrom

water electrolysis driven by renewable sources.CoNcLUSIoN

The conversion from gasoline to biogas fueled engine can be achieved by desulfiuizing of the biogas at the fust

step continued

with

dehumidification and put the gas in to the bag ofgas holder. The biogas afterward should becompressed

in

to the

gas containerfor

easy mixingprocess

with

oxygenfrom the air- The

carburetioncoryotrent was replaced and only mixer part of the fuel is used. During starting process, the biogas is let to

flow

in

maximunflow

rate and reduce the rateuntil

engine start running. The process is followed by adjusting the airflow in to

the mixeruntil

the

enginerun

stably. Theengrne is running even witlr still contain CO2 impurities.

To

increasethe

speedof the

engine,the

liquefied pefrolzum gas (LPG) is added to the mixture up to 80% ofbiogas antdZ0/oLPG.AcxNowr.socrrENT

The authors wish to thank the Ministry of National and Culhre ofThe republic oflndonesia for finanslall support

under

schemeof

competitive researchgrant (shz

penelitian hibah

b*saing)

for the yearof

2013 granted through Udayana University, Jimbaran, Bali, tndonesia.E E

\,

o{r

$ .E E L U REFERENCEStll

F.

Osorio and J. C. Torres; Biogas Purification fromAnaerobie Digestion in a Wastewater Treabnent Plantlor

Biofuel Productinn. Renewable Energy, Vol. 34, 2ffi9, pp.2164-2171.

12)

Papacz, W.; Biogos as Vehicks Fuel. Jotrral of KonesPowertrain and Transpor! VoL 18, No.

l,

2011, pp. 403-411.[3] Kuwahara N., Bern, M.D., and Bajay, S.Y; Biogas is Easy to Produce Even Jrom Municipol Waste and Potential to

Replace the Petrolaan Base Fuel. Renewable Energy,

Vol. 16, 1999, pp-1000-1ffi3.

l4l

Darnrongsk,D.

and Tippayawing,N;

Expeimental Investigation of an Automotive Air-conditioning SystemDiven by

a

Small Biogas Engine. Applied Thermal Engineering Vol. 30,2010, pp. 400-405.t51

Raven, R.P.J.M- and Gregersen,K.H.; Biogas Plants in Denmark: Successesand

Setbacb. Renewable andSustainable Enerry Reviews, Vol. I 1, 20O7,pp. 116-132.

t6l

Akbulut, A.; Techno-economic Analysis of Electricity andHeat

Generotionfiom

Farm-scale Biogas Plant:Qigekdagr Case Study. Energy, Vol. 44,2012,

pp.

381-390.

t7l

Borjesson, P. md Mattiassot,B.; Biogas as aResource-eficient Yehicle Fuel. Trerds in Biotechnology, Yol. 26

No.I,2007, pp. 7-13.

t8l

Crookes,R.I.;

Comparative Bio-fuel Performance inInternal Combustion Engines. Biomass ard Bioenergy,

Vol. 30, 2ffi6, pp. 461468.

l9l

Rakopoulos, C.D. and MichosC.N.;

Generationof

Combustion Irreversibilities in a Spark ignition Engineunder Bioga*hydrogen Mtxures Freling. Intemational Joumal of Hydrogen Enerry, Vol. 34, 2009,

p.

M22-4437.

[10]

Yamasaki,Y.,

Kanno,M.,

Suzuki,Y.,

Kaneko, S.;Development of an Engine Control System Using City Gas

and Biogas Fuel Mixture. Vol. 101,2013, pp.465474.

U

ll

Chandra, R, Vijay, V.K., Subbamo, P.M.V., Khura, T.K.;Pedormance Evaluation of a Coaslant Speed IC Engine

on CNG, Methane Enriched Biogas and Biogas. Applied

Energr, VoL 88, 201 I, pp. 3969-3977 .

[2]

NindhiaTGT.;

Removalof

llydrogen SulJille (HrS)contailinanl

in

Biogasby

Utilizing Solid Waste Steel Chips Jrom The Process of Twning. The Twenty+eventh Intetnational Conference on Solid Waste Technology andManagemeng Philadelphia, PA U.S.A., March 2012, pp. I l-14.

[3]

Chien,Y.I(

Sheng,Y.C.,Try

T.H., L€, D., Ling,K. H.,md

Chih,S.L;

Ability

of

a

Mutant Strainof

theMicroalga Chlorella sp. to Capture Carbon Diaxide

for

Biogos Upgrading. Applied Energy, Vol. 93, 2012, pp. 176-183.[4]

Tippayawong,N.,

and Thanompongchart,P.;

Biogasfualig

Upgrode by Simulnneous Renoval of CO2 and H2S in a Packed Column Reactor. Energy, Vol. 35, 2010,pp.453l-4535.

t15l

Deublin,D.

and Steinhaus€r,A.;

Wiley-VCH VerlagG,mbH & Co. KGad Germany,

2008-[6]

Huanga, J., and Crookesb,R.J.; lssesszrent of Simulated Biogas as a Fuel for the Spark lgnition Engine. Fuel, Vol.77, No. 15, 1998, pp. 1793-1801.

flfl

Ryckebosch,E.,

DrouilloqM.,

and Verv'aercn, H-;Techniques

for

Transformation of Biogas to Biomethane,Biomass and Bioenergr, Vol. 35,

20ll,g.

1633-16/.5.-2013 International Confe,rence on Alternative Enerry in Dweloping Countrles and Emerging Economies

tl81 Krydi

S.S.VijayJJL,

RajG6h, S.K, PrrEaA R-; Biogu*,nAing

Conprwioaatd

Stomge: Percrytived

pro,cper,au In ladtst,

Coit&.

Renew$lc Eocrgr, Vol.30,2m5,!p. 1195F12tr2.

[l9]

Mohscni F., Magutrssoa M., Gdrling M., Alvforg P.;Biogas

fum

Retrewable Blwtricity- Inoafing

a ClturueNeutral Fuel &ry|y. Amlied Entrey, Vol. 90, 2012,

p.

ll-16.