FAULT FINDING, REPAIR

AND MEASUREMENT

Test Project Document

LKS_2017_TP16_FFRM_EN

Submitted by:

Name : Electronics Indonesia

1. INTRODUCTION TO TEST PROJECT DOCUMENTATION

1. Introduction To Test Project Documentation...2

2. Contents...3

3. Introduction...4

4. Description Of Project & Task...5

5. Instruction To The Competitors...6

6. Equipment, Machinery, Installations And Materials Required...10

7. Marking Scheme...19

2. CONTENTS

This Test Project proposal consists of the following documentation/files:

3. INTRODUCTION

This Test Project is a Stereo Multiplex (MPX) and FM Transmitter test, Instead of

using special purpose ICs to produce the waveforms this design uses ordinary

HCMOS logic. Audio Frequency (AF) signals are produced using binary counters

and combinational logic and then filtered to obtain two very low distortion sine waves

to serve as the test tones. These audio signals are then multiplexed by a 38 KHz

Sub-Carrier to form a Left+Right and a Left-Right Double Side-Band Suppressed

Carrier (DSBSC) signal to form the Stereo Multiplex (MPX). No fault and no

measurement in the oscillator FM/ Modulation FM Block.

4. DESCRIPTION OF PROJECT & TASK

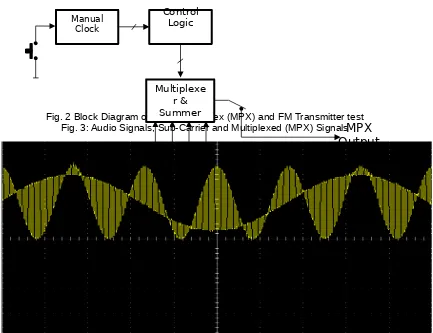

The block diagram of the Stereo Multiplex (MPX) and FM Transmitter is shown in Fig. 2.

Fig. 2 Block Diagram of Stereo Multiplex (MPX) and FM Transmitter test Fig. 3: Audio Signals, Sub-Carrier and Multiplexed (MPX) Signals

The Signal Generator generates the 38 KHz sub-carrier and 19 KHz pilot tone. It

uses an ingenious technique to generate 2 sine waves (audio) with very low

distortion at around 300 Hz and 1.2 KHz.

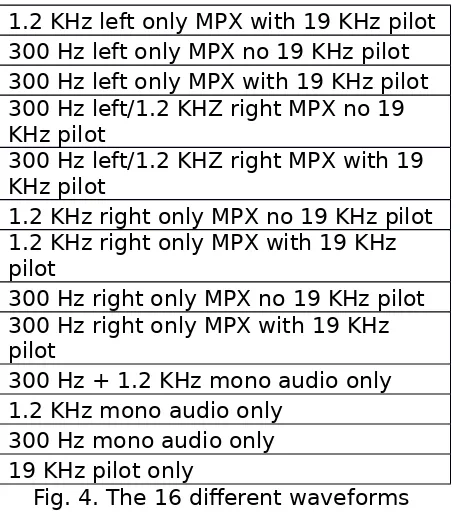

The 38 KHz sub-carrier is used to multiplex the audio signals and then summed with

the 19 KHz pilot tone by the Multiplexer & Summer to form 16 different waveforms

(Fig 4). The audio signals being encoded as Left or Right is based on the phase of

the sub-carrier.

The 16 different waveforms

1.2 KHz left only MPX with 19 KHz pilot 300 Hz left only MPX no 19 KHz pilot 300 Hz left only MPX with 19 KHz pilot 300 Hz left/1.2 KHZ right MPX no 19 KHz pilot

300 Hz left/1.2 KHZ right MPX with 19 KHz pilot

1.2 KHz right only MPX no 19 KHz pilot 1.2 KHz right only MPX with 19 KHz pilot

300 Hz right only MPX no 19 KHz pilot 300 Hz right only MPX with 19 KHz pilot

300 Hz + 1.2 KHz mono audio only 1.2 KHz mono audio only

300 Hz mono audio only 19 KHz pilot only

Fig. 4. The 16 different waveforms

The state of the Control Logic is advanced by the Manual Clock. In manual mode it

6. INSTRUCTION TO THE COMPETITORS

Fault Finding and Repair

1. Supply voltage of 12 + 0.1 volts to be applied to terminal P1, please take note of the polarity.

2. Adjust R5 to set the frequency 153 KHz + 0.5 KHz of the clock output at U7_3. If competitor board doesn’t match with the frequency, competitor can

exchange the board to jury.

3. There are 3 faults which do not correspond to the demand specifications. Find and repair it.

4. Describe Defective Part and Fault Symbol.

5. When you request repair parts, both of the Competitor and the Jury have to sign to part list.

6. Describe the evidence of the repair.

FAULT SYMBOL DESCRIPTION FAULT SYMBOL DESCRIPTION

Open

(part, wire or PCB trace) (Pin, input, output, etc.)Stuck at high voltage Short

(part, wire or PCB trace)

Stuck at low voltage (Pin, input, output, etc.) Part with larger value

(resistor, capacitor, etc.)

?

Incorrect part number orwiring connecting Part with smaller value(Resistor, capacitor,

etc.)

+/-Wrong Polarity

Fig.5 Fault Symbol Table

You may use the following Labels:

LOCATION CATEGORY SAMPLE

Power +5V/+12V/-5V/+5V/GND

Pin of IC IC2_8

Between Two Components R1-R2

Fig.6 Location Symbols Table

DEFECTIVE PART FAULT SYMBOL

Fault #1 IC2_8 - R7_1

BEFORE AFTER

Measurement #1

Node: _ R7_1 ______

Fig.7 Example of description of answer script

(Condition: the frequency of the oscillator is too high.)

DEFECTIVE PART FAULT SYMBOL

Fault #2 R1

BEFORE AFTER

Measurement #2

Node: _TP1______

1.00V/DIV 1.00ms/DIV

Fig.8 Example of description of answer script

(Condition: the frequency of the oscillator is too high.)

Voltage at R7_ 1 below than

7. MEASUREMENT

Measure the following items:

1. Measure and record the frequency at U19_1

2. Press S1 button until signal out U10_12 = LOW, U10_9 = HIGH, U10_8 = HIGH, U10_11 = LOW, then measurement MPX OUT signal at P4.

3. ... 4. ...

For each measurement, sketch a schematic showing how to measure, using

following equipment symbols.

EQUIPMENT SYMBOL

Fig.9 Equipment Symbol Table

Fig.10 Example of Measurement Schematic

5. EQUIPMENT, MACHINERY, INSTALLATIONS AND MATERIALS REQUIRED

ITEM QTY MATERIAL DESCRIPTION NOTES

1 1 FFRM PCB Material for the

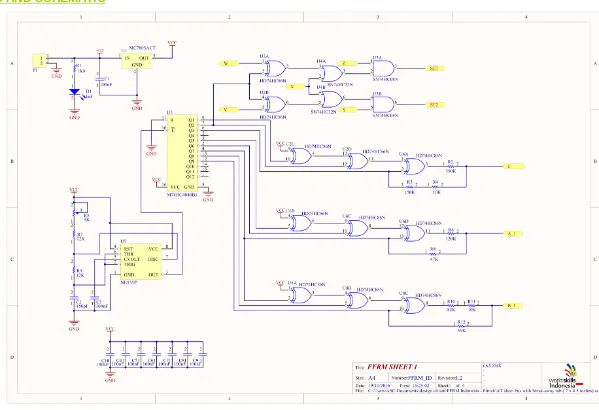

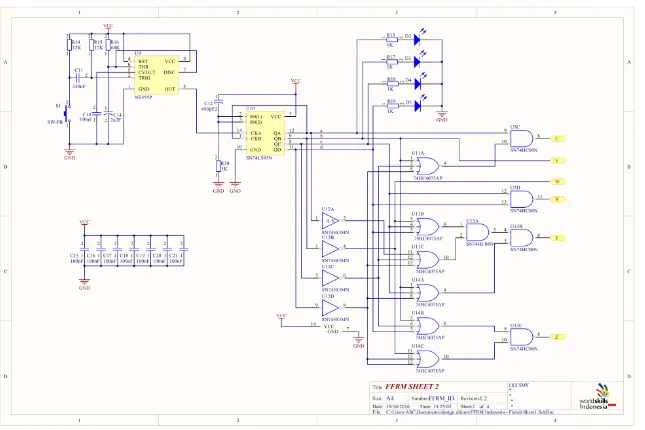

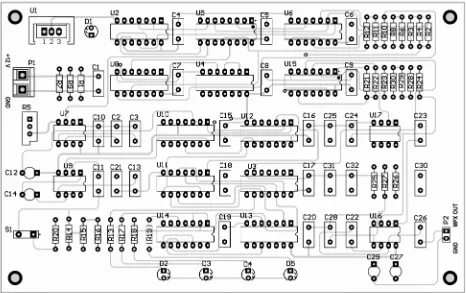

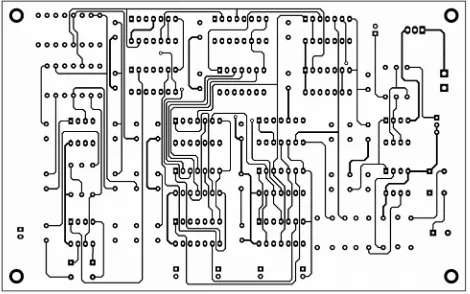

8. PCB AND SCHEMATIC

Fig. 12. Schematics – Sheet 1

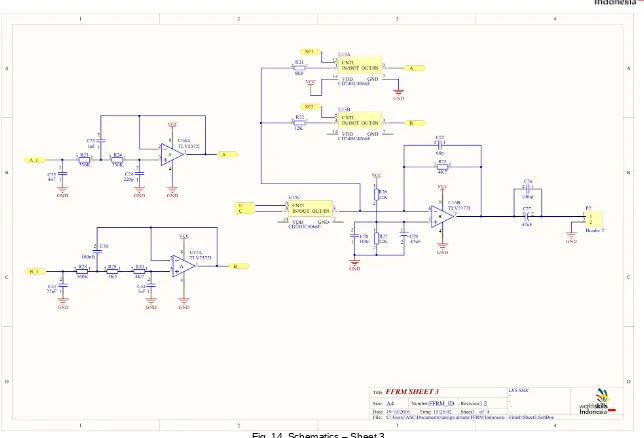

Fig. 14. Schematics – Sheet 3

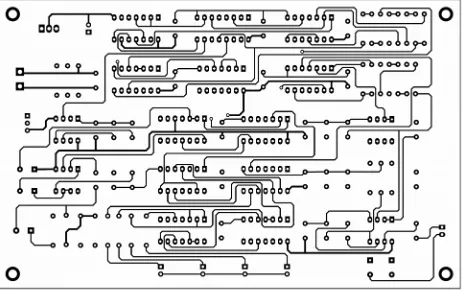

Fig. 16. PCB Bottom layer

9. MARKING SCHEME

MAX MARK ASPECT OF CRITERION - DESCRIPTION

12 Finding faulty spots and evidence 3 Repairing (IPC-A-610-D)

8 Validity of measuring results

10.OTHERS

1. Part List for repairing

2. Fault Finding and Repair – Answer Script 3. Measurement – Answer Script

Part list for repairing

S/N DESCRIPTION VALUE DESIGNATOR QTY. COMPETITOR

REQUEST COMPETITORSIGNATURE SIGNATUJURY RE

17 Multiturn / Variabel Resistor

S/N DESCRIPTION VALUE DESIGNATOR QTY. COMPETITOR

REQUEST COMPETITORSIGNATURE SIGNATUJURY RE C26, C28, C30

20

19 Cap. Ceramic 150 pF C2 1

20 Cap. MKM 330 nF C11 1

21 Cap. Ceramic 680 pF C12 1

22 Cap. Tantalum 2,2 uF C14 1

23 Cap. Ceramic 68 pF C22 1

24 Cap. MKM 1 nF C23, C32 2

25 Cap. Ceramic 220 pF C24 1

26 Cap. MKM 4,7 nF C25 1

27 Cap. Electrolit 47 uF C27, C29 2

28 Cap. MKM 22 nF C31 1

Counter 12 74HC4040 U5, 1

34 IC Timer NE555 U7, U9 2

35 IC Counter SN 74LS93 U10 1

36 IC Logic Gate 74HC4075 U11, U14 2 37 IC Logic Gate SN 74HC04 U12 1

S/N DESCRIPTION VALUE DESIGNATOR QTY. COMPETITOR

REQUEST COMPETITORSIGNATURE SIGNATUJURY RE

39 IC Op Amp TLV2372 U16, U17 2

40 Led Red Led Red 3mm D1 1

41 Led Red Led Green3mm D2, D3, D4, D5 4

42 Push Buttom PB 2 Pin S1 1

43 Terminal Block

3 Pin T-Block 2 Pin P1 1

44 Header Molek 2 Pin

Header

Molek P2 1

45 Soket Molek 2

Pin Soket Molek P2` 2

46 Headsink Almunium 50 Spiser 1 Cm Spiser Hexagonal 4

Fault Finding & Repair – Answer Script

DEFECTIVE PART FAULT SYMBOL

Fault #1

BEFORE AFTER

Measurement #1

Node: _______

DEFECTIVE PART FAULT SYMBOL

Fault #2

BEFORE AFTER

Measurement #2

Node: _______

DEFECTIVE PART FAULT SYMBOL

Fault #3

BEFORE AFTER

Measurement #3

Measurement – Answer Script Measurement #1

Measurement Output

Vertical Settings:

/div

Horizontal Settings:

/div

Verification output graph

Measurement #2

Measurement SCHEMATIC

Measurement Output

Vertical Settings:

/div

Horizontal Settings:

Verification output graph

Calculation Volt peak to peak with formula

Measurement #3

Measurement SCHEMATIC

Measurement Output

Vertical Settings:

/div

Horizontal Settings:

Verification output graph

Calculation Volt peak to peak with formula

Measurement #4

Measurement SCHEMATIC

Measurement Output

Vertical Settings:

/div

Horizontal Settings:

Verification output graph

Calculation Volt peak to peak with formula Calculation frequency with formula