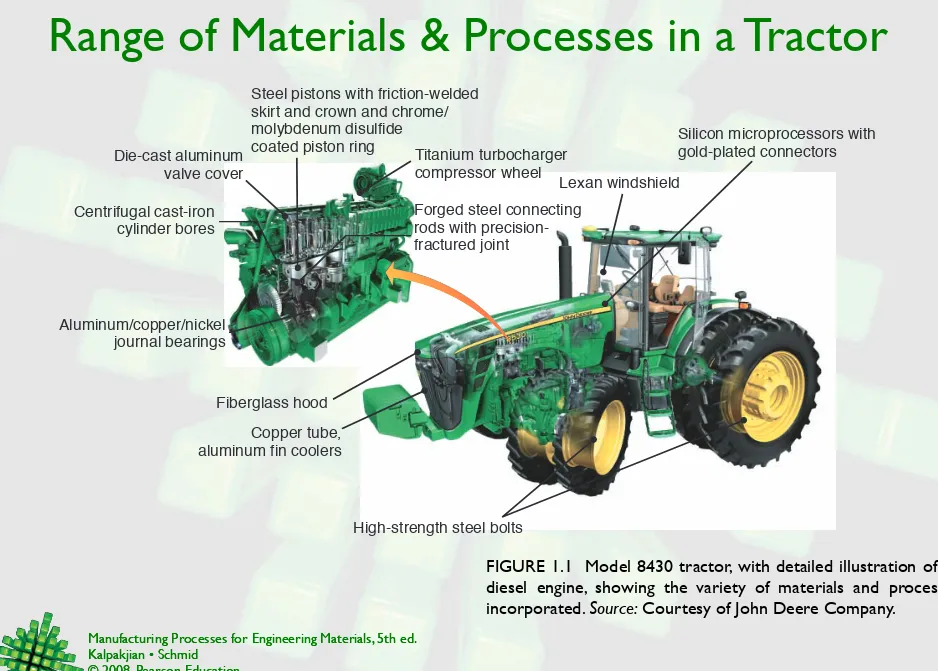

Range of Materials & Processes in a Tractor

FIGURE 1.1 Model 8430 tractor, with detailed illustration of its

diesel engine, showing the variety of materials and processes

Steel pistons with friction-welded

skirt and crown and chrome/

molybdenum disulfide

coated piston ring

Forged steel connecting

rods with

precision-fractured joint

Aluminum/copper/nickel

journal bearings

Centrifugal cast-iron

cylinder bores

Lexan windshield

Fiberglass hood

Copper tube,

aluminum fin coolers

High-strength steel bolts

Silicon microprocessors with

gold-plated connectors

Die-cast aluminum

valve cover

History of Manufacturing

1

.

1

E

L

B

A

T

s

e

s

s

e

c

o

r

P

g

n

i

r

u

t

c

a

f

u

n

a

M

d

n

a

s

l

a

i

r

e

t

a

M

f

o

t

n

e

m

p

o

l

e

v

e

D

l

a

c

i

r

o

t

s

i

H

, g n i n i h c a m , s l o o T g n i n i o J d n a g n i m r o F s u o i r a V d n a s l a t e M s e t a D d o i r e P g n i r u t c a f u n a m d n a g n i p a h s d n a s l a i r e t a m g n i t s a c s m e t s y s s e t i s o p m o c 0 0 0 4 e r o f eB B . C . G o l d , c o p p e r , m e t e o r i c E a r t h e n w a r e , g l a z i n g , H a m m e r i n g T o o l s o f s t o n e , f l i n t , , y r o v i , e n o b , d o o w s r e b i f l a r u t a n n o r i s l o o t e t i s o p m o c 0 0 0

4 – 3 0 0 0 B . C . C o p p e r c a s t i n g , s t o n e S t a m p i n g , j e w e l r y S o l d e r i n g ( C u - A u , C o r u n d u m ( a l u m i n a , ) y r e m e ) n S - b P , b P - u C - t s o l , s d l o m l a t e m d n a , r e v l i s , s s e c o r p x a w e z n o r b , n i t , d a e l 0 0 0

3 – 2 0 0 0 B . C . B r o n z e c a s t i n g a n d G l a s s b e a d s , p o t t e r ’ s W i r e b y s l i t t i n g s h e e t R i v e t i n g , b r a z i n g H o e m a k i n g , h a m m e r e d r o f s l o o t , s e x a l a t e m s l e s s e v s s a l g , l e e h w f a e l d l o g , g n i w a r d d n a g n i k a m n o r i y r t n e p r a c 0 0 0

2 – 1 0 0 0 B . C . W r o u g h t i r o n , b r a s s 0

0 0

1 – 1 B . C . C a s t i r o n , c a s t s t e e l G l a s s p r e s s i n g a n d S t a m p i n g o f c o i n s F o r g e w e l d i n g o f I m p r o v e d c h i s e l s , s a w s , s e h t a l g n i k r o w d o o w , s e l i f , l e e t s d n a n o r i g n i w o l b g n i u l g

1 – 1 0 0 0 A . D . Z i n c , s t e e l V e n e t i a n g l a s s A r m o r , c o i n i n g , E t c h i n g o f a r m o r s d r o w s l e e t s , g n i g r o f 0 0 0

1 – 1 5 0 0 B l a s t f u r n a c e , t y p e C r y s t a l g l a s s W i r e d r a w i n g , g o l d - S a n d p a p e r , w i n d m i l l - w a s n e v i r d k r o w h t i m s r e v l i s d n a , s l l e b f o g n i t s a c , s l a t e m r e t w e p 0 0 5

1 – 1 6 0 0 C a s t - i r o n c a n n o n , C a s t p l a t e g l a s s , W a t e r p o w e r f o r H a n d l a t h e f o r w o o d g n i l l o r , g n i k r o w l a t e m s s a l g t n i l f e t a l p n i t s p i r t s e g a n i o c r o f l l i m 0 0 6

1 – 1 7 0 0 P e r m a n e n t - m o l d P o r c e l a i n R o l l i n g ( l e a d , g o l d , B o r i n g , t u r n i n g , s c r e w - s s e r p l l i r d , e h t a l g n i t t u c g n i l l o r e p a h s , ) r e v l i s m o r f s s a r b , g n i t s a c ) d a e l ( c i l l a t e m d n a r e p p o c c n i z Egypt: B . C . to B . C . Greece: B . C . to B . C . Roman Empire: B . C . to 476 A . D . Middle Ages: to 1492

Renaissance: 14th to 16th centuries

History of Manufacturing (cont.)

1 . 1 E L B A T ) . t n o c ( s e s s e c o r P g n i r u t c a f u n a M d n a s l a i r e t a M f o t n e m p o l e v e D l a c i r o t s i H , g n i n i h c a m , s l o o T g n i n i o J d n a g n i m r o F s u o i r a V d n a s l a t e M s e t a D d o i r e P g n i r u t c a f u n a m d n a g n i p a h s d n a s l a i r e t a m g n i t s a c s m e t s y s s e t i s o p m o c 0 0 71 – 1 8 0 0 M a l l e a b l e c a s t i r o n , E x t r u s i o n ( l e a d p i p e ) , g n i l l o r , g n i w a r d p e e d s r a b n o r i ( l e e t s e l b i c u r c ) s d o r d n a 0 0 8

1 – 1 9 0 0 C e n t r i g u f a l c a s t i n g , W i n d o w g l a s s f r o m S t e a m h a m m e r , s t e e l S h a p i n g , m i l l i n g , c o p y i n g t e r r u t , s k c o t s n u g r o f e h t a l , e b u t s s e l m a e s , g n i l l o r t h g i l , r e d n i l y c t i l s , s s e c o r p r e m e s s e B g n i l l i m l a s r e v i n u , e h t a l , g n i l l o r l i a r - l e e t s , n o i t a z i n a c l u v , b l u b , m u n i m u l a c i t y l o r t c e l e d e i f i r t i v , e n i h c a m , g n i l l o r s u o u n i t n o c , g n i s s e c o r p r e b b u r , t t i b b a b , s l e e t s l e k c i n l e e h w g n i d n i r g g n i t a l p o r t c e l e , e n e r y t s , r e t s e y l o p , l e e t s d e z i n a v l a g r e b b u r , d i o l u l l e c , y g r u l l a t e m r e d w o p g n i d l o m , n o i s u r t x e l e e t s h t r a e h - n e p o 0 0 9

1 – 1 9 2 0 A u t o m a t i c b o t t l e T u b e r o l l i n g , h o t O x y a c e t y l e n e ; G e a r e d l a t h e , a u t o m a t i c , g n i b b o h , e n i h c a m w e r c s - l a c i r t c e l e , c r a n o i s u r t x e , e t i l e k a b , g n i k a m , s l o o t l e e t s - d e e p s - h g i h d n a , e c n a t s i s e r s s a l g e t a c i l i s o r o b d n a e d i x o m u n i m u l a g n i d l e w t i m r e h t ) c i t e h t n y s ( e d i b r a c n o c i l i s 0 2 9

1 – 1 9 4 0 D i e c a s t i n g D e v e l o p m e n t o f T u n g s t e n w i r e f r o m C o a t e d e l e c t r o d e s T u n g s t e n c a r b i d e , m a s s r e f s n a r t , n o i t c u d o r p r e d w o p l a t e m , g n i t s a c , s c i t s a l p s e n i h c a m l y n i v y l o p , g n i d l o m e s o l u l l e c , e d i r o l h c , e n e l y h t e y l o p , e t a t e c a s r e b i f s s a l g 0 4 9

1 – 1 9 5 0 L o s t - w a x p r o c e s s f o r A c r y l i c s , s y n t h e t i c E x t r u s i o n ( s t e e l ) , S u b m e r g e d a r c P h o s p h a t e c o n v e r s i o n y t i l a u q l a t o t , s g n i t a o c g n i d l e w r e d w o p , g n i g a w s , s e i x o p e , r e b b u r s t r a p g n i r e e n i g n e l o r t n o c g n i r e e n i g n e r o f s l a t e m s s a l g e v i t i s n e s o t o h p s t r a p 0 5 9

History of Manufacturing (conc.)

1

.

1

E

L

B

A

T

)

.

t

n

o

c

(

s

e

s

s

e

c

o

r

P

g

n

i

r

u

t

c

a

f

u

n

a

M

d

n

a

s

l

a

i

r

e

t

a

M

f

o

t

n

e

m

p

o

l

e

v

e

D

l

a

c

i

r

o

t

s

i

H

, g n i n i h c a m , s l o o T g n i n i o J d n a g n i m r o F s u o i r a V d n a s l a t e M s e t a D d o i r e P g n i r u t c a f u n a m d n a g n i p a h s d n a s l a i r e t a m g n i t s a c s m e t s y s s e t i s o p m o c 0 6 91 – 1 9 7 0 S q u e e z e c a s t i n g , A c e t a l s , H y d r o f o r m i n g , P l a s m a - a r c a n d T i t a n i u m c a r b i d e , , d n o m a i d c i t e h t n y s m a e b - n o r t c e l e , n o i s u r t x e c i t a t s o r d y h d l o c , e t a n o b r a c y l o p l a t s y r c - e l g n i s , l o r t n o c l a c i r e m u n e v i s e h d a , g n i d l e w g n i m r o f o r t c e l e , s c i t s a l p f o g n i m r o f s e d a l b e n i b r u t p i h c t i u c r i c d e t a r g e t n i g n i d n o b , s c i t s a l p d e c r o f n i e r g n i d n i w t n e m a l i f 0 7 9

1 – 1 9 9 0 C o m p a c t e d g r a p h i t e , A d h e s i v e s , c o m p o s i t e P r e c i s i o n f o r g i n g , L a s e r b e a m , C u b i c b o r o n n i t r i d e , d n o m a i d , s l o o t d e t a o c g n i d n o b n o i s u f f i d , g n i g r o f l a m r e h t o s i , s l a i r e t a m , g n i t s a c m u u c a v n o i s i c e r p a r t l u , g n i n r u t d e n i b m o c o s l a ( , g n i m r o f c i t s a l p r e p u s , s r o t c u d n o c i m e s d e d n o b y l l a c i n a g r o - r e t u p m o c , g n i n i h c a m c i t s a l p r e p u s h t i w y b e d a m s e i d , s r e b i f l a c i t p o f o n o i t a m o t u a , d n a s , g n i r u t c a f u n a m d e t a r g e t n i - e c a f r u s , ) g n i m r o f n g i s e d d e d i a - r e t u p m o c , s c i m a r e c l a r u t c u r t s , g n i r u o p d n a g n i d l o m , s t o b o r l a i r t s u d n i g n i r e d l o s t n u o m , g n i r u t c a f u n a m d n a x i r t a m - c i m a r e c , n o i t a c i f i d i l o s d i p a r g n i n r u t d n a g n i n i h c a m d n a g n i g r o f e p a h s - t e n , s e t i s o p m o c x i r t a m - l a t e m - e l b i x e l f , s r e t n e c r e t u p m o c , g n i m r o f e l b a d a r g e d o i b d i l o s i m e s , s e t i s o p m o c , s m e t s y s g n i r u t c a f u n a m n o i t a l u m i s y l l a c i r t c e l e , s c i t s a l p , g n i k r o w l a t e m , y g o l o n h c e t r o s n e s s r e m y l o p g n i t c u d n o c , s l a t e m s u o h p r o m a s y o l l a y r o m e m - e p a h

s a u t o m a t e d i n s p e c t i o n , , ) s l a i r e t a m t r a m s

( e x p e r t s y s t e m s , a r t i f i c i a l n o i t a l u m i s r e t u p m o

c i n t e l l i g e n c e , c o m p u t e r d n a n o i t a l u m i s n o i t a z i m i t p o 0 9 9

1 – 2 0 0 0 s R h e o c a s t i n g , N a n o p h a s e m a t e r i a l s , R a p i d p r o t o t y p i n g , F r i c t i o n s t i r M i c r o - a n d n a n o - A G I L , n o i t a c i r b a f e e r f - d a e l , g n i d l e w , g n i l o o t d i p a r , s m a o f l a t e m n g i s e d d e d i a - r e t u p m o c m y n o r c a n a m r e G a ( - t t u b r e s a l , s r e d l o s y l l a t n e m n o r i v n e , s g n i t a o c d e c n a v d a , s e i d d n a s d l o m f o g n i v l o v n i s s e c o r p a r o f ) d e r o l i a t ( d e d l e w g n i k r o w l a t e m y l d n e i r f e r u t a r e p m e t - h g i h g n i l o o t d i p a r , s k n a l b l a t e m - t e e h s s d i u l f . s r o t c u d n o c r e p u

s l i t h o g r a p h y , e l e c t r o p l a t i n g , y r d , ) g n i d l o m d n a y l l a c i r t c e l e , s c i m a r e c e l b a n i h c a m r o t o m r a e n i l , g n i h c t e g n i t c u d n o c n o b r a c e k i l d n o m a i d l a r u e n l a i c i f i t r a , s e v i r d s e v i s e h d a a m g i s x i s , s k r o w t e n : e c r u o

S J . A . S c h e y , C . S . S m i t h , R . F . T y l e c o t e , T . K . D e r r y , T . I . W i l l i a m s , S . R . S c h m i d , a n d S . K a l p a k j i a n .

Information Age

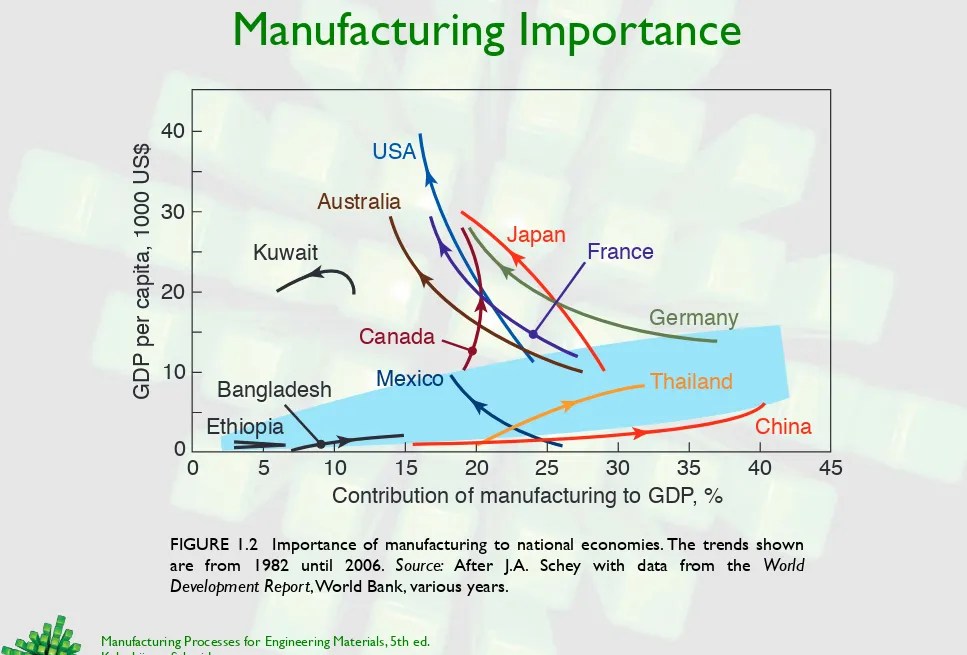

Manufacturing Importance

FIGURE 1.2 Importance of manufacturing to national economies. The trends shown

are from 1982 until 2006.

Source:

After J.A. Schey with data from the

World

Development Report

, World Bank, various years.

0

10

20

30

40

GDP

per capita, 1000 US$

0

5

10

15

20

25

30

35

40

45

Contribution of manufacturing to GDP, %

USA

Australia

Japan

Germany

China

Thailand

Mexico

Ethiopia

Bangladesh

France

Canada

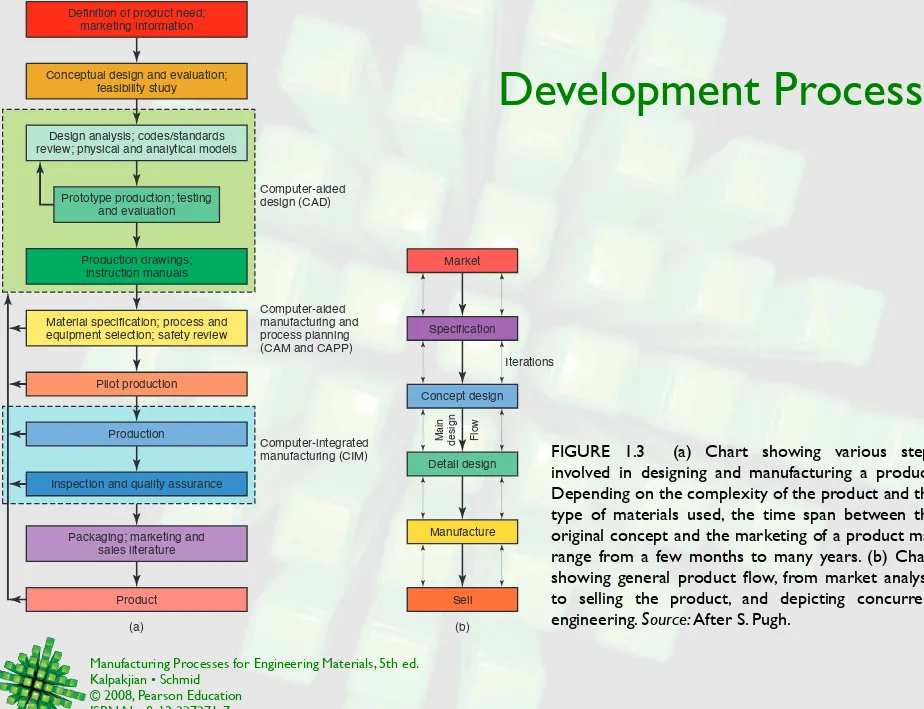

Development Process

FIGURE 1.3 (a) Chart showing various steps

involved in designing and manufacturing a product.

Depending on the complexity of the product and the

type of materials used, the time span between the

original concept and the marketing of a product may

range from a few months to many years. (b) Chart

showing general product flow, from market analysis

to selling the product, and depicting concurrent

engineering.

Source:

After S. Pugh.

Packaging; marketing and sales literature

Material specification; process and equipment selection; safety review

Pilot production

Production

Inspection and quality assurance Production drawings;

instruction manuals

Conceptual design and evaluation; feasibility study

Prototype production; testing and evaluation

Design analysis; codes/standards review; physical and analytical models

Computer-integrated manufacturing (CIM) Computer-aided manufacturing and process planning (CAM and CAPP) Computer-aided design (CAD)

Main design Flow

Iterations Market

Specification

Concept design

Detail design

Manufacture

Sell

(a) (b)

Definition of product need; marketing information

Shapes &

Manufacturing

Process

TABLE 1.2 Shapes and some common methods

of production.

Shape or feature

Production method

aFlat surfaces

Rolling, planing, broaching, milling, shaping, grinding

Parts with cavities

End milling, electrical-discharge machining, electrochemical

machining, ultrasonic machining, blanking, casting, forging,

extrusion, injection molding, metal injection molding

Parts with sharp features

Permanent-mold casting, machining, grinding, fabricating

b,

powder metallurgy, coining

Thin hollow shapes

Slush casting, electroforming, fabricating, lament winding,

blow molding, sheet forming, spinning

Tubular shapes

Extrusion, drawing, lament winding, roll forming, spinning,

centrifugal casting

Tubular parts

Rubber forming, tube hydroforming, explosive forming,

spin-ning, blow molding, sand casting, lament winding

Curvature on thin sheets

Stretch forming, peen forming, fabricating, thermoforming

Openings in thin sheets

Blanking, chemical blanking, photochemical blanking, laser

machining

Cross-sections

Drawing, extrusion, shaving, turning, centerless grinding,

swaging, roll forming

Square edges

Fine blanking, machining, shaving, belt grinding

Small holes

Laser or electron-beam machining, electrical-discharge

ma-chining, electrochemical mama-chining, chemical blanking

Surface textures

Knurling, wire brushing, grinding, belt grinding, shot

blast-ing, etchblast-ing, laser texturblast-ing, injection moldblast-ing, compression

molding

Detailed surface features

Coining, investment casting, permanent-mold casting,

ma-chining, injection molding, compression molding

Threaded parts

Thread cutting, thread rolling, thread grinding, injection

molding

Very large parts

Casting, forging, fabricating, assembly

Very small parts

Investment casting, etching, powder metallurgy,

nanofabrica-tion, LIGA, micromachining

Notes:

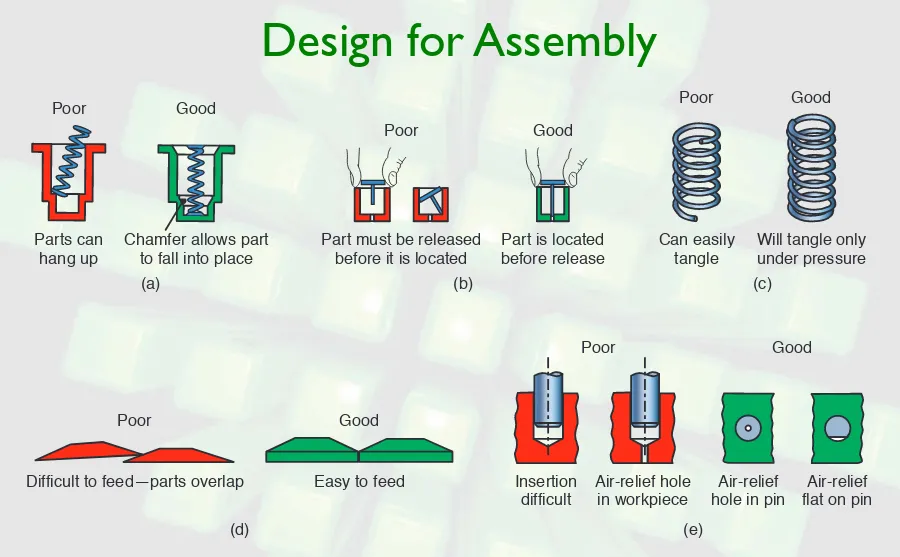

Design for Assembly

FIGURE 1.4 Redesign of parts to facilitate automated assembly.

Source:

Reprinted from G. Boothroyd and P. Dewhurst,

Product Design for Assembly

, 1989, by courtesy of Marcel Dekker, Inc.

(d)

(e)

Poor

Good

Difficult to feed—parts overlap

Easy to feed

Poor

Good

Insertion

difficult

Air-relief hole

in workpiece

Air-relief

hole in pin

Air-relief

flat on pin

(a)

Poor

Parts can

hang up

Chamfer allows part

to fall into place

Good

(b)

(c)

Poor

Good

Part must be released

before it is located

Part is located

before release

Poor

Good

Can easily

tangle

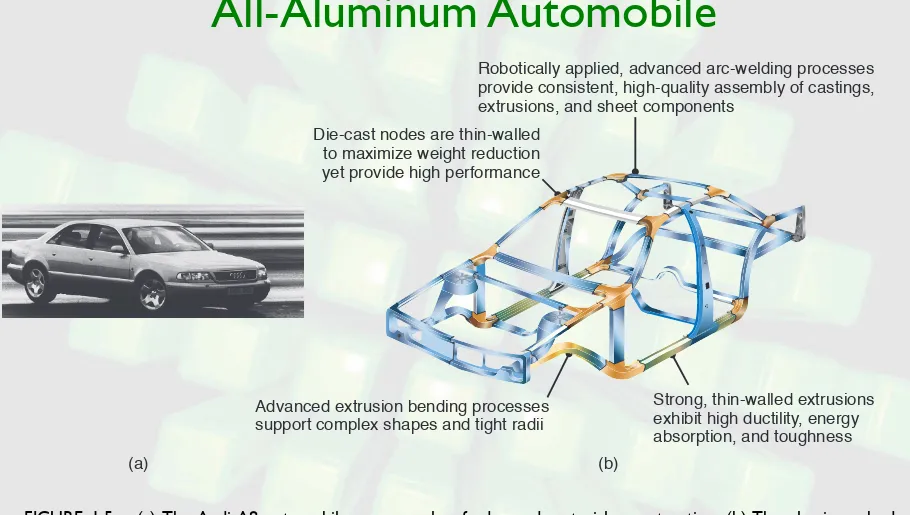

All-Aluminum Automobile

Robotically applied, advanced arc-welding processes

provide consistent, high-quality assembly of castings,

extrusions, and sheet components

Strong, thin-walled extrusions

exhibit high ductility, energy

absorption, and toughness

Die-cast nodes are thin-walled

to maximize weight reduction

yet provide high performance

Advanced extrusion bending processes

support complex shapes and tight radii

(a)

(b)

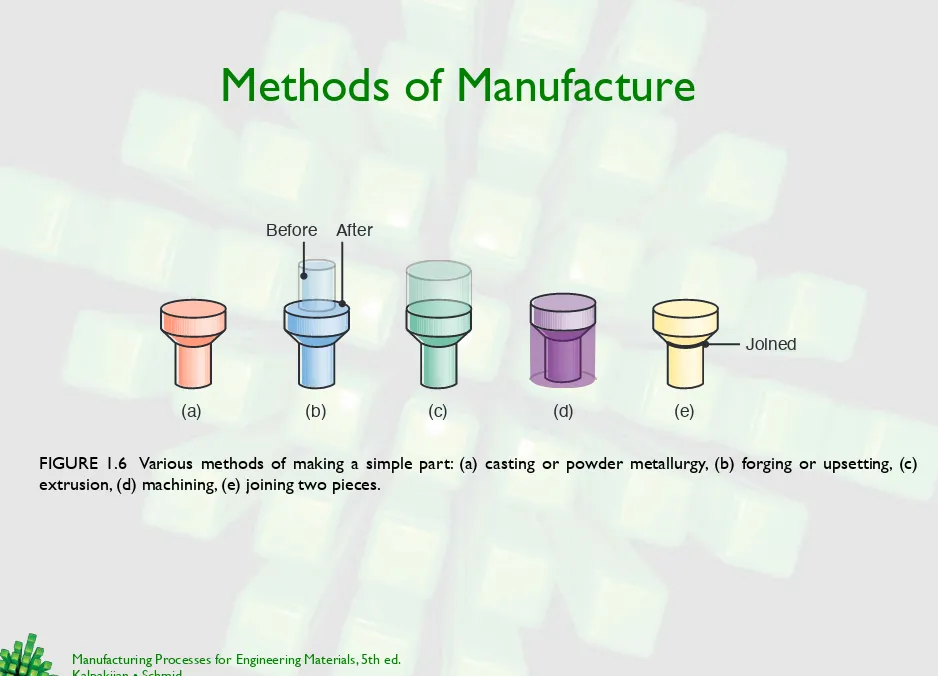

Methods of Manufacture

FIGURE 1.6 Various methods of making a simple part: (a) casting or powder metallurgy, (b) forging or upsetting, (c)

extrusion, (d) machining, (e) joining two pieces.

(a)

(b)

(c)

(d)

(e)

Before

After

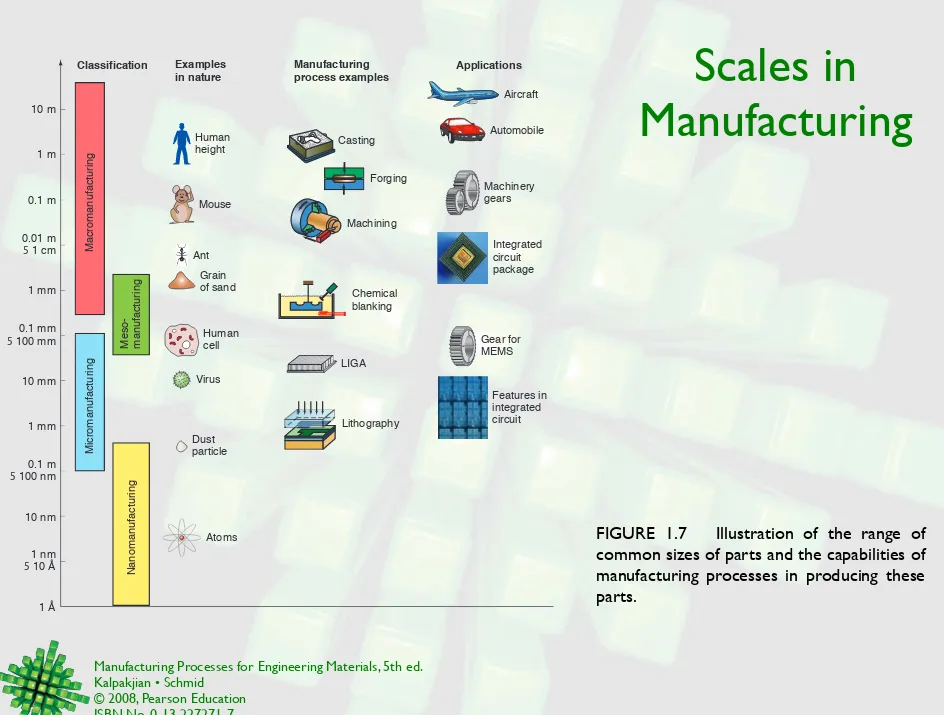

Scales in

Manufacturing

FIGURE 1.7 Illustration of the range of

common sizes of parts and the capabilities of

manufacturing processes in producing these

parts.

Size

0.1 m

0.01 m

5 1 cm

1 mm

0.1 mm

5 100 mm

10 mm

1 mm

0.1 m

5 100 nm

10 nm

1 nm

5 10 Å

1 Å 10 m

1 m

Examples in nature

Manufacturing process examples

Applications Classification

Macromanufacturing

Micromanufacturing

Meso- manufacturing

Nanomanufacturing

Automobile

Machinery gears

Gear for MEMS

Features in integrated circuit Integrated circuit package

Aircraft

Casting

Forging

Chemical blanking

Lithography LIGA

Machining Human

height

Mouse

Grain of sand

Atoms Human cell

Virus

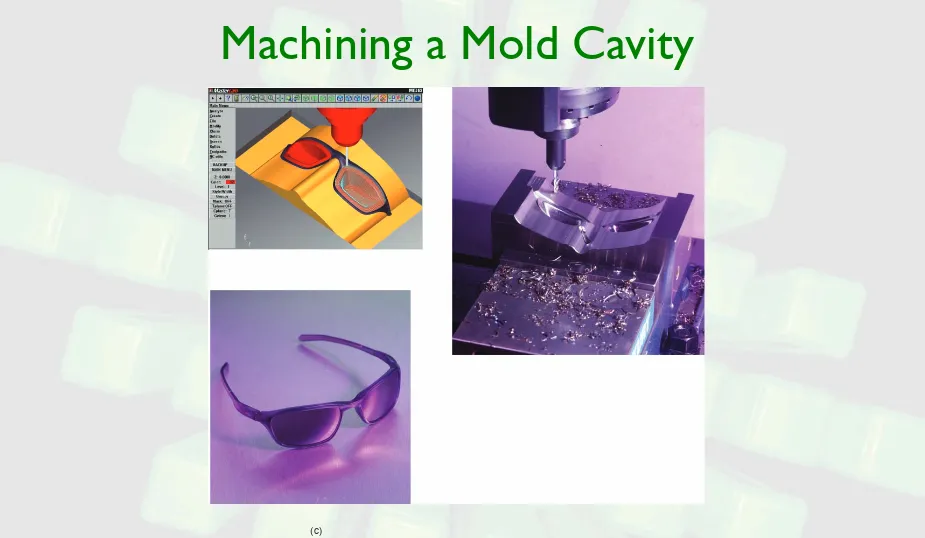

Machining a Mold Cavity

FIGURE 1.8 Machining a mold cavity for making sunglasses. (a) Computer model of the sunglasses as designed and

viewed on the monitor. (b) Machining the die cavity using a computer numerical control milling machine. (c) Final

product produced from the mold.

Source:

Courtesy Mastercam / CNC Software, Inc.

(b) (a)

Flexible Manufacturing

Global Labor Rates

FIGURE 1.5 (a) The Audi A8 automobile, an example of advanced materials construction; (b) The aluminum body

structure, showing various components made by extrusion, sheet forming, and casting processes.

Source:

Courtesy of

ALCOA, Inc.

TABLE 1.3

Source:

Courtesy of U.S. Department of Labor, November 2004.

Approximate Relative Hourly Compensation for Production Workers,

for 2003. United States = 100. Compensation Costs Vary Depending

on Benefits and Allowance.

Denmark

147

Norway

144

Germany

136

Belgium, Switzerland

127

Finland, Netherlands

123

Austria, Sweden

116

United States

100

France

96

United Kingdom

93

Australia, Canada, Japan

90

Ireland, Italy

85

Spain

67

Israel

53

New Zealand, Korea

48

Singapore

33

Portugal, Taiwan

27

Czech Republic

20

Brazil, Mexico

11

China, India

10

European countries

111