In India, the bell metal (a copper-tin alloy with 75-80 percent copper and 20-25 percent tin on a weight basis) provides employment to nearly 1 million people. First, the thesis addressed the mechanical properties of bell metal processed in different conditions for improvisation of the current production process.

Introduction

Background

Out of all the copper and copper alloys, copper and bell metal products are used extensively and alternatively in India. Bhutan, Nepal, Sri Lanka and Bangladesh are the largest exporter of bell metal items manufactured in India [15, 16].

Bell metal

The bell industry accounts for nearly 3% of India's total SSI economy and provides direct and indirect employment to nearly 1 million people [ 25 , 26 ].

Properties and applications of bell metal

Overview of bell metal industry

In Himachal Pradesh, the metal bell industry is present in Chamba and Palampur, which are known for making hand bells [15]. The metal bell industry is also present in Thiruvananthapuram, Kerala and is famous for making deities.

Motivation to this study

Therefore, research is necessary to develop a high-demand industry to preserve the heritage status.

Field survey

- Selection of study location

- Data collection

- Report from the field survey

- Summary of the field survey

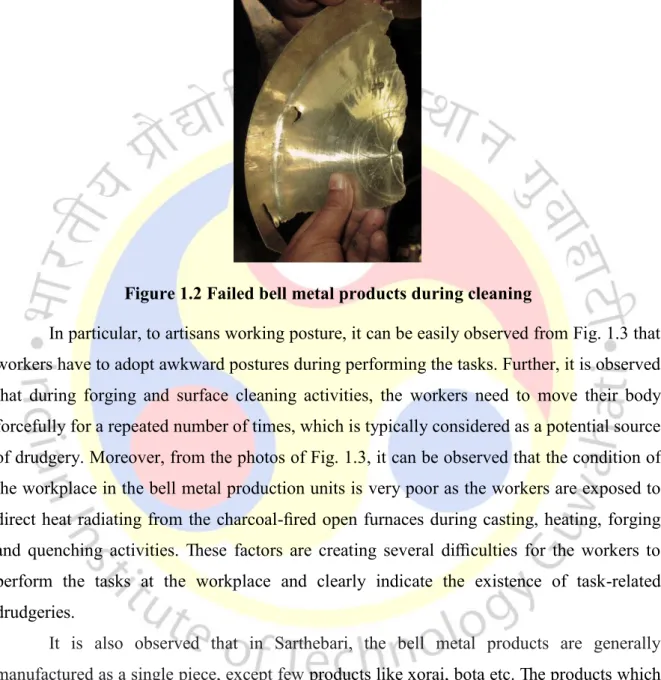

The metal bell items that overflowed during maintenance due to various reasons are the source of the old scrap. It was also found that few of the bell metal products are manufactured in parts and joined by riveting.

Literature review

Metallographic and mechanical properties of bell metal

1997) [75] reported that glow twins formed in secondarily treated bell metal are of type II. It is rather surprising to note that no author has reported or studied the fracture toughness of secondary treated bell metal.

Bell metal products manufacturing process

Park and Shinde studied the manufacturing process of bell metalware, practiced in Nagpur, India, based on the microstructure of various ancient bronze objects excavated from megalithic sites. Therefore, from the above literature, it can be said that the process of making bell metal products varies from cluster to cluster.

Technical aspects of each manufacturing stage

The forging process is the most crucial process in the bell metal production line as it directly controls the thickness of the final product [71, 72]. No published literature has been found toward explaining and eliminating the bell metal oxidation process to reduce oxide residues and thus production time.

Current scenario of other production centers

In the clock industry, different types and sizes of hammers are used to perform forging and art work activities. Various sizes of anvils are used in the clock industry to perform forging work.

Bell metal joining techniques

In view of the above literature, it is found that the entire metal bell set uses old traditional hand-crafted tools. In this regard, the literature reporting the presence of drugs in bell metal clusters is reviewed and reported in the following section.

Drudgeries in the bell metal industry

Again, from the field survey report, it was found that workers adopt awkward postures while performing tasks in high temperature environments with inadequate/poorly designed tools viz.

Drudgeries in other SSIs

Ansari and Sheikh have conducted a painstaking analysis of 15 workers working in various manufacturing industries under the Mumbai Industrial Development Corporation located in Wardha, India and reported that 53% of the workers are performing tasks at a high level of risk. Dewangan and Singh have done a painstaking analysis of 7 operators performing pulpit operation in a steel plant and reported that 60% of the workers suffer from neck pain, 80%.

Benefits of drudgery removal

Some authors have reported that removing drudgery is also beneficial in increasing the benefit-cost ratio. Therefore, it is highly likely that removing the strain present in the bell metal industry will improve the benefit-cost ratio and health outcome of workers employed in the industry.

Drudgery assessment tools

For example, Guimarães et al. studied a shoe company in Brazil and reported that productivity increased after removing heavy work. ratio to have studied a fabric processing industry in Southwestern Ontario, Canada, and found that the benefit-cost ratio increased from 3 to 5.5 due to a reduction in the grind. Therefore, the selection of the assessment tool will be crucial to assess the level of monotony in the industry.

Methods of drudgery removal

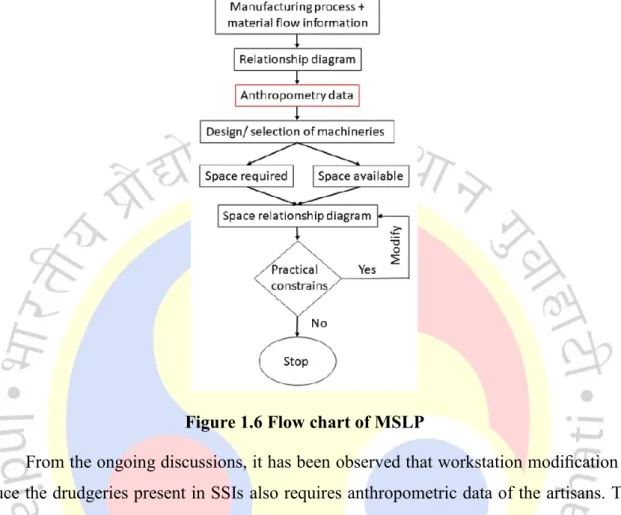

The consideration of anthropometric data of the persons who will work in that industry is essential to correct the working posture that ergonomics-. From the ongoing discussions, it was observed that workstation modification to reduce the drudgery present in SSIs also requires anthropometric data of the artisans.

Health benefits of using bell metal utensils

Summary of published literature

Research gaps

However, based on the available research facility and time, the scope of the current thesis has been limited to study only a few of the unfilled gaps. The next section discusses the scope of the present thesis work and the objectives chosen for the present work.

Scope of the present work and objectives

To design an ergonomically correct workstation for reducing the strain of workers engaged in the bell metal industry.

Organization of this thesis

Introduction

Background

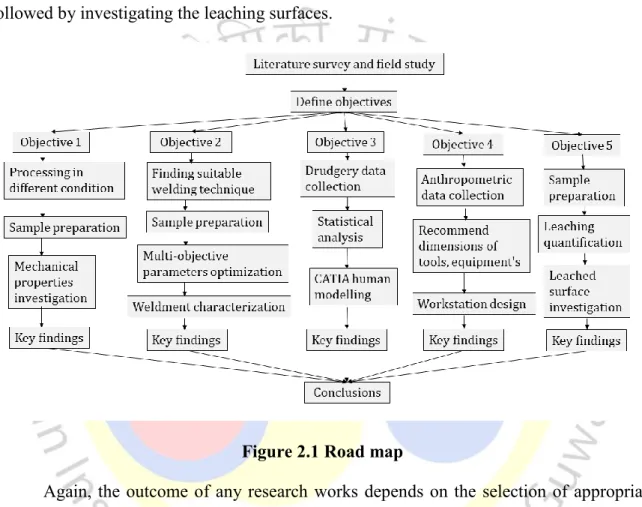

Road map

The fifth objective, i.e. the investigation into copper leaching properties of bell metal tools was completed by measuring the amount of copper leached from the bell metal tools into drinking water for different periods of time, followed by examining the leaching surfaces. In light of this, the next section describes the data collection methods from the field surveys.

Data collection methods from the field surveys

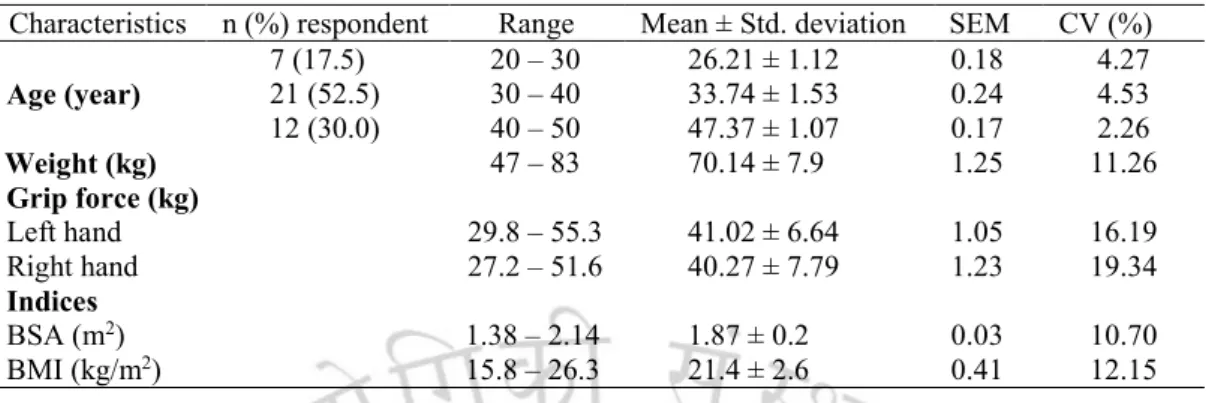

An electronic hand dynamometer (Make: Camry Scale, China) was used to collect the changes in hand strength of the artisans in the morning and afternoon. The third survey was conducted from 1 to 10 February 2021 to collect the anthropometric data of artisans.

Data analysis

Drudgery data

Again, a Vernier caliper with a smaller count of 0.1 mm was used when measuring hand dimensions.

Anthropometric data

Digital human modelling

Workstation design

Freshly collected anthropometric data of bell makers were used in workstation design to minimize worker ergonomic risk factors. Again, somatotype was used to design the workstation, i.e. covering the extreme range of dimensions from endomorph to ectomorph recommended by Tilley.

Materials preparation

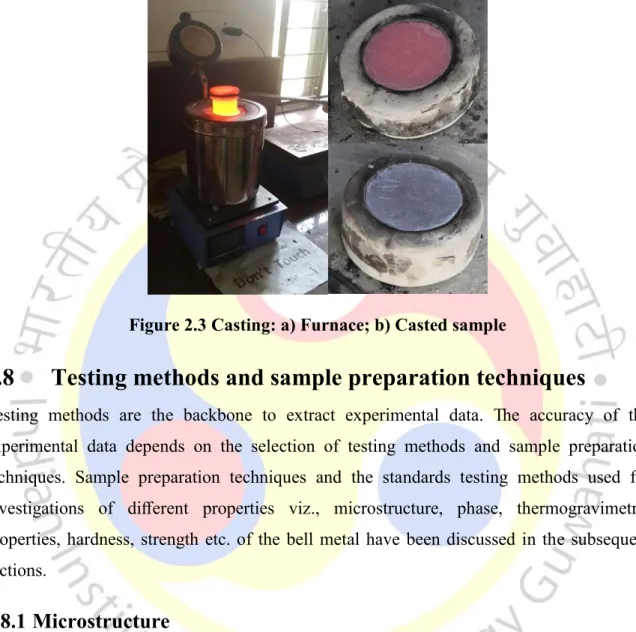

Casting

Post Srinivasan's contributions on the process of producing bell metal objects and the field survey report were used to begin the design of the workstation. The principle of "design for adjustable scope" proposed by Taifa and Desai is applied to the design of workstation equipment and machinery.

Quenching

Again, Somatotype, i.e. covering the extreme range of endomorphic to ectomorphic dimensions recommended by Tilley, has been used to design the workstation. from the high temperatures to carry out the quenching process. The quality of the quenched bell metal ingots was then examined by various standard processes to measure the mechanical properties.

Testing methods and sample preparation techniques

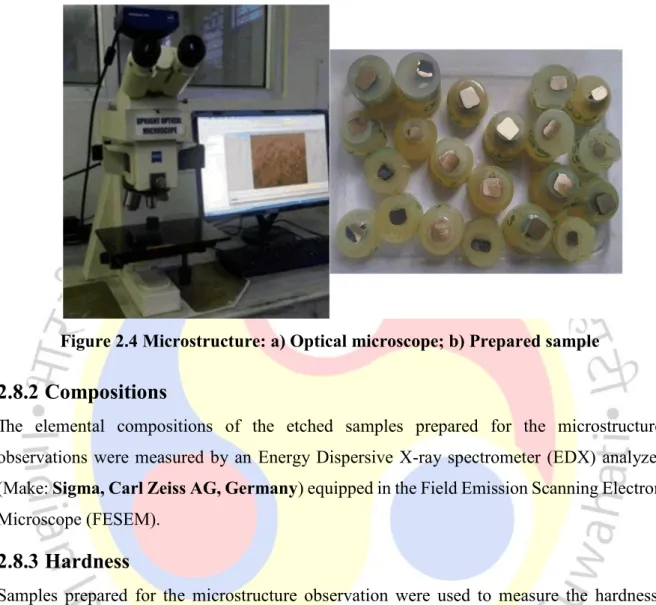

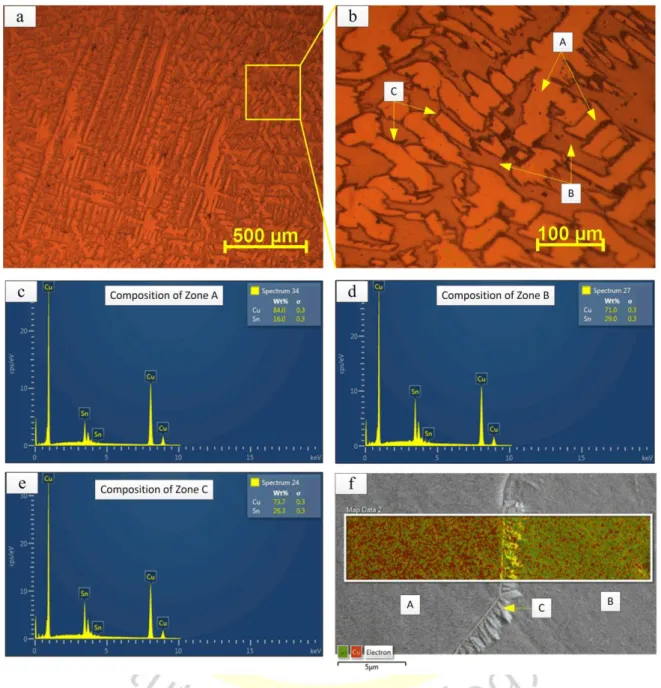

Microstructure

Compositions

Hardness

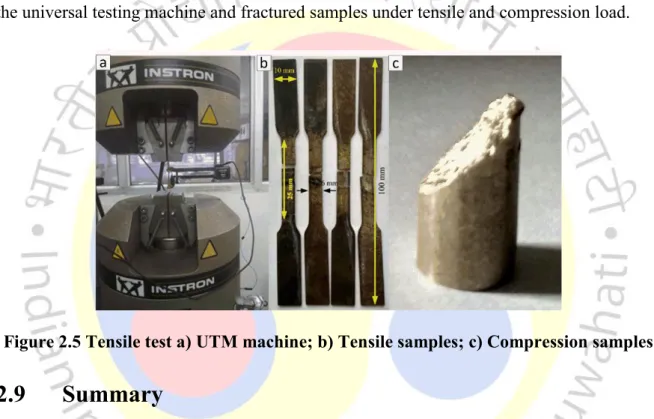

For the determination of the tensile and compressive strengths, samples were prepared using the wire electrical discharge machines (WEDM) according to ASTM standard E8 and E9 respectively [199, 200]. The specimen used for the tensile test has a thickness of 1 mm, length of 100 mm (25 mm length) and grip width of 10 mm (6 mm specimen width).

Summary

The length/diameter (L/D) ratio of 1.3 of the samples has been maintained throughout the thesis in order to carry out the pressure tests.

Introduction

Background

Choice of experimental conditions

RESULTS AND DISCUSSION

- Properties of cast products

- Properties of water quenched products

- Fracture strength at elevated temperature

- Thermogravimetric properties

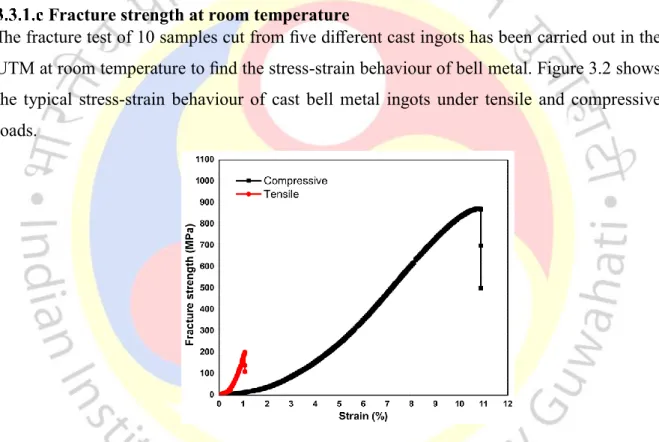

The drastic change in stress-strain behavior of bell metal at temperature 700ºC is attributed to the superplasticity behavior of the β phase. Again, in the α temperature range ºC, the bell metal starts to become semi-liquid due to the presence of the β phase in molten states.

Key findings

Furthermore, from the previous section, it has been observed that bell metal shows midday plasticity at 700ºC. All the results together can be deduced that the bell metal in the ºC temperature range can be plastically deformed in the solid state, and it is practically advantageous because of the deepest and widest high-temperature transformation range.

Introduction

Background

Choice of the experimental conditions

Results and discussion

Cast bell metal

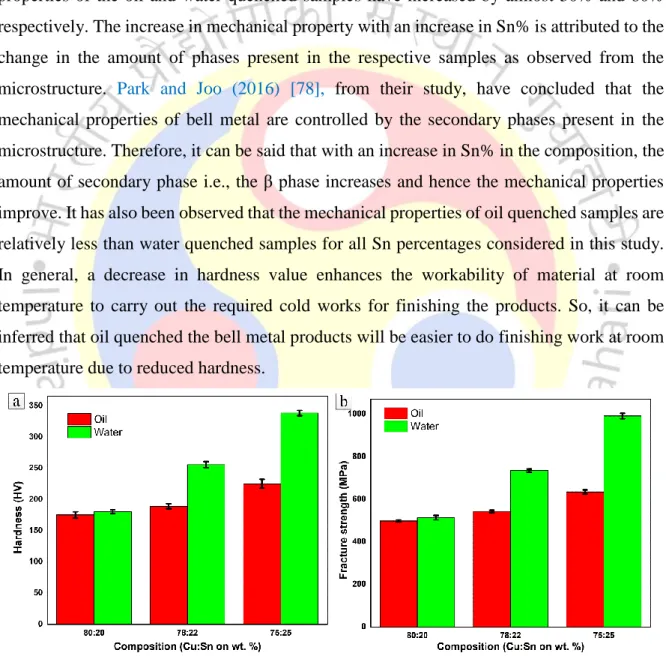

Quenched bell metal

4.4, it was found that the mechanical properties of samples hardened in oil and water increase with an increase in the tempering temperature. In addition, the temperature of 700 °C was found to play a very important role in controlling the mechanical properties of the bell metal.

Comparative mechanical properties of brass and bell metal

Microstructure

Practical limitations regarding the processing of high hardness bell metal at room temperature have already been discussed in the previous section. It is recommended that the products, which are to be finished at room temperature, should be quenched with oil.

Tensile strength

Furthermore, a list of mechanical properties of bell metal processed under different conditions along with some other Cu-based alloys is also attached in Appendix A to create a database. This database helps the engineers choose the right working condition of bell metal for specific applications over other alloys.

Introduction

Background

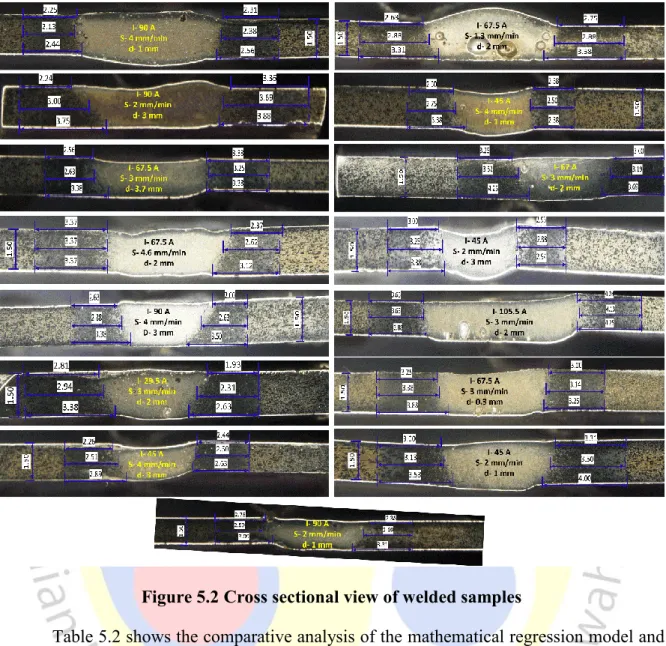

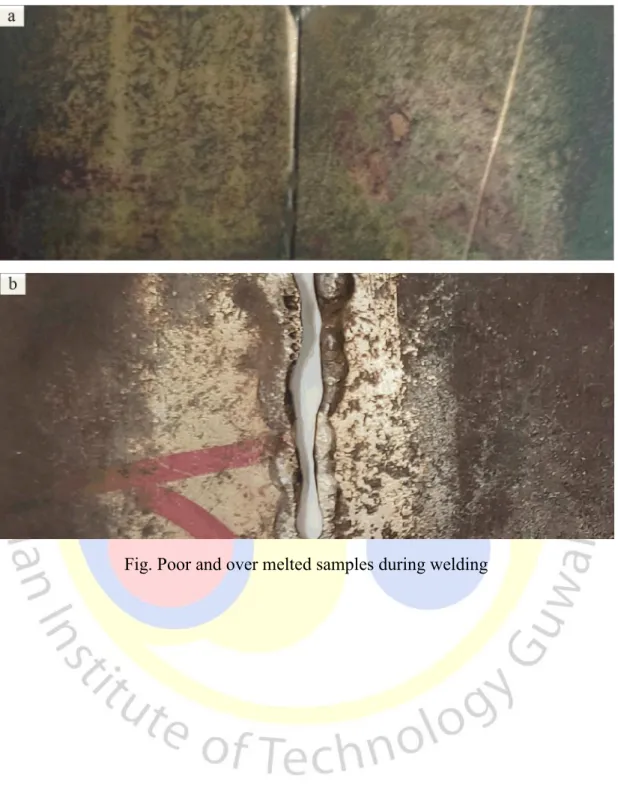

In view of the above, an attempt has been made in this present chapter to investigate the feasibility of the bell metal welding process.

TIG welding

Selection of welding parameters

The factorial design process provides sets of input parameters in various combinations to reduce the number of experiments that must be performed to find accurate correlations between weld quality and welding process parameters. Therefore, in the present work, a factorial design based on RSM was used to obtain the minimum set of input parameters required to find an accurate correlation equation with the output quality of bell metal welds.

Materials, experiment procedure and testing methods

Further, the prepared welds were cut in a WEDM machine according to the standards described in Section 2.8 to investigate the mechanical properties of the welds in order to optimize the bell welding process. The HAZ length and FZ area of the welds were measured using a NIKON SMZ 25 stereo microscope software package available at the Indian Institute of Technology Guwahati.

Results and discussion

- Experimental results

- Multi-objective optimization

- Pareto optimality

- Confirmation test

- Microstructure of weldments

- Effect of welding process on mechanical properties

Then the length of the HAZ and the area of the FZ of the new welds are measured. The next section discusses the effect of the welding process on the mechanical properties of the bell metal.

Key findings

Brittle failure of an unwelded bell metal sample is attributed to the predominant nature of the martensitic β phase over the α phase, as discussed in section 3.3.2.c. The brittle failure of bell-metal welds is attributed to the dominant nature of the δ phase formed in the FZ during the welding process over the α and β phases, which is also responsible for the lower UTS value.

Introduction

Background

This study has shown that ergonomic interventions reduce rework by 85%, thus increasing productivity by 3% due to less wear and tear on workers. have shown that correct ergonomic interventions such as the use of appropriate tools, correct lighting, an accurate tilt of the work table, correct control of dust and noise, etc.

Methods

- Task characteristics

- Drudgery data collection and analysis

- Digital human modelling

- Workstation design

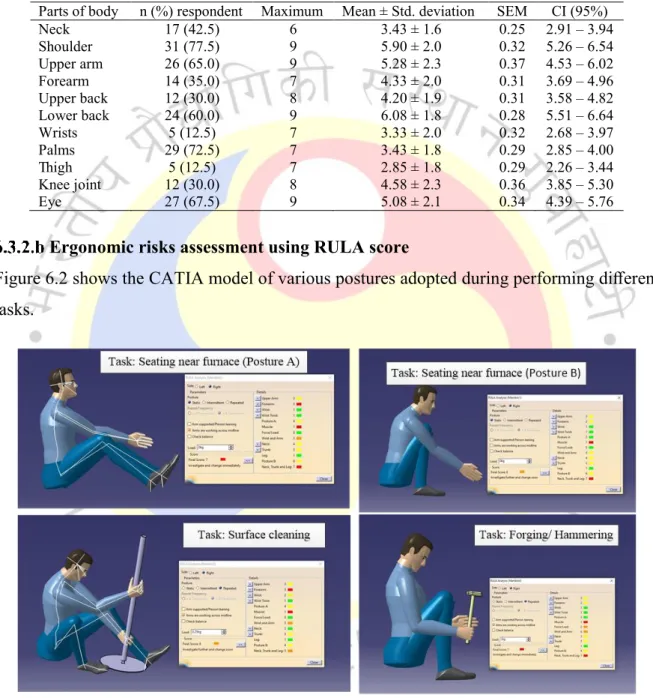

For “Task 1,” the workers' body bent forward at some angle (ie, flexion/.extension) accompanied by lateral bending. The workers' responses were analyzed to determine the prevalence of discomfort as described in Chapter 2.

Results and discussions

Characteristics of participants

The result of the descriptive statistics for anthropometric data of the employees is shown in table 6.2. In this study, the comparative variability of the data by mean value, i.e. CV values for most anthropometric dimensions, appears to be low (less than 10).

Drudgery assessment

The RULA score for the upper arm is found to be 3 for all three tasks due to more than 20º extension along with the abduction of. For trunk, RULA score for all tasks is 3 due to lateral and forward bending during operations.

Workstation design

However, it is possible to improve the forging conditions to reduce the effort of the workers working on the bell metals. Especially in the bell metal industry, the height of the workpiece varies from a few mm to cm.

Key findings

This study has reported that in the cost-benefit analysis, artisans do not consider the long-term effects of ergonomic health risks and therefore, the group of workers shows irresponsible interest in the development/modifications of workstations. It is further expected that the use of an optimal level of lighting in the workplace will reduce the risk of errors, prevent premature fatigue and improve the concentration of workers and thus, the quality of processing will increase and therefore to increase the efficiency of workers; therefore, workstation productivity will improve. h).

Introduction

Background

EXCHANGE PROPERTY OF BELL METAL KITCHENWARE. from an ancient time due to its high thermal conductivity, aesthetic appearance, light weight and antimicrobial activity [281]. Certainly, the bell metal utensils are already widely used in India due to the existing perception of various health benefits due to the leaching copper.

Experimental procedures

The ongoing discussions have revealed that utensils are used to fight various diseases by changing the nutritional composition of the food and water. Furthermore, a FESEM coupled to EDX has been used to find the leaching area and composition of the samples before and after the immersion test.

Results and discussions

Leaching from cast utensils

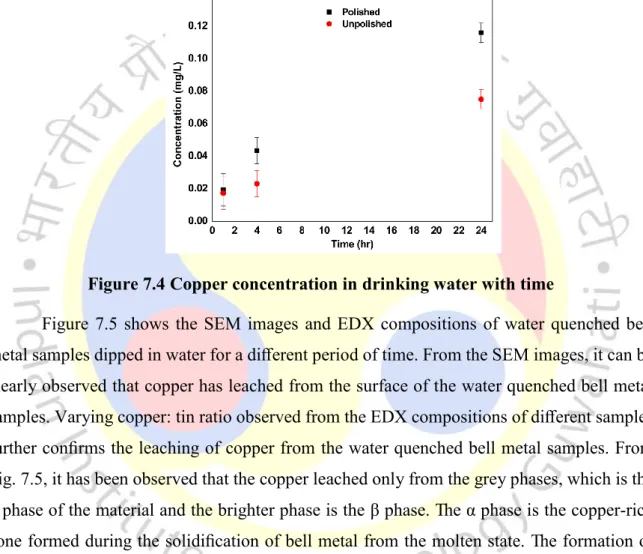

The copper concentration in water samples collected after the immersion test was measured according to the Food Safety and Standards Authority of India (FSSAI) guidelines published in 2015 using Atomic Absorption Spectroscopy (AAS) techniques.

Leaching from waters quenched utensils

Therefore, it can be concluded that water-hardened metal appliances provide the advantage of various health benefits due to the leaching properties of copper in drinking water. The α-phase of bell metal tools can be increased by changing the manufacturing process.

Key findings

Introduction

Background

Key contributions from the present thesis work

- Mechanical properties of bell metal

- Welding of bell metal

- Drudgery assessment and elimination

- Copper leaching from bell metal utensils

Furthermore, from the analysis of the water-quenched bell metal product in section 3.3.2, it has been observed that the compressive strength is higher (1100 MPa) than the tensile strength (500 MPa). In this thesis, the copper leaching property of the bell-shaped utensils has been investigated and reported in chapter 7.

Recommendations from the present thesis work

Concluding remarks

With the implementation of the proposed workstation, along with the tools and equipment, there is a potential to increase the productivity of the plant in addition to improving the health status of the employees. An approximate estimated cost-benefit analysis before and after the recommended adjustments to the workplace has also been added to appendix G&H.

Limitations of present study and scope of future works

Ghosal, D.: Present Scenario of the Traditional Copper and Bell Metal Industry of Khagra, Murshidabad, West Bengal. Dewangan, C.P., Singh, A.K.: Ergonomic study and design of the pulpit of a thread mill at a.

![Figure 1.5 Natural and Awkward posture [129]](https://thumb-ap.123doks.com/thumbv2/azpdfnet/10342086.0/44.892.89.746.147.861/figure-natural-and-awkward-posture.webp)