A manufacturer that obtains raw materials, processes them into finished products and distributes them to customers is considered a supply chain manager. Estimating the exact amount of inventory at each point in the supply chain without overages and shortages while minimizing total supply chain costs is a major concern for inventory and supply chain managers. In Chapter 3, we propose the concept of agility, the meaning of agility and precedent studies on agile supply chain management.

In Chapter 4, we address the framework for agile supply chain management on global supply chains and agile manufacturing inventory management process in detail.

SCM & Business Performance

Factors for High Performers in SCM

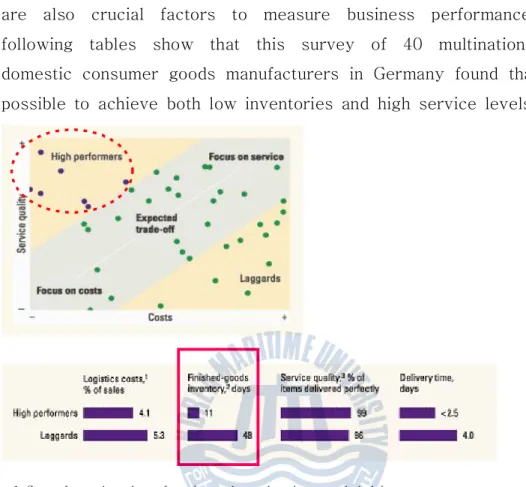

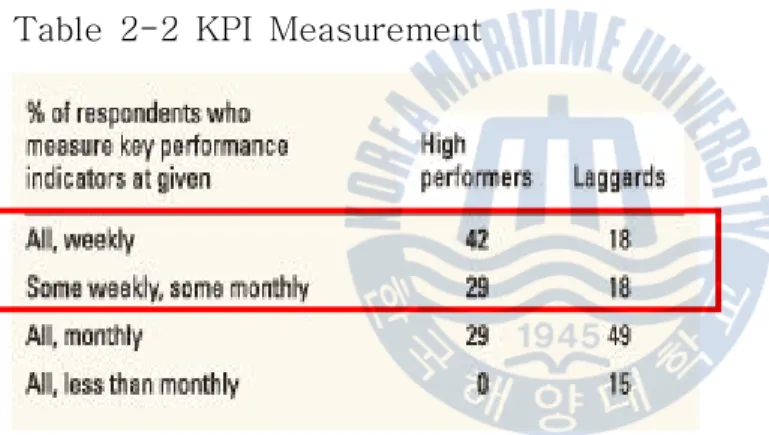

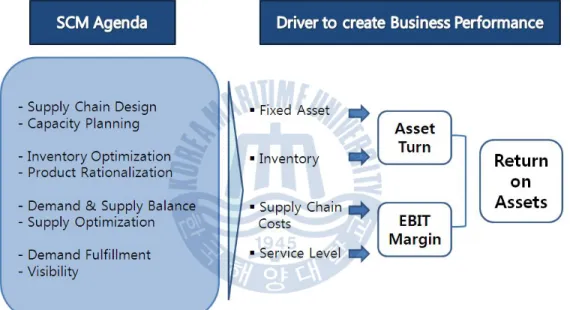

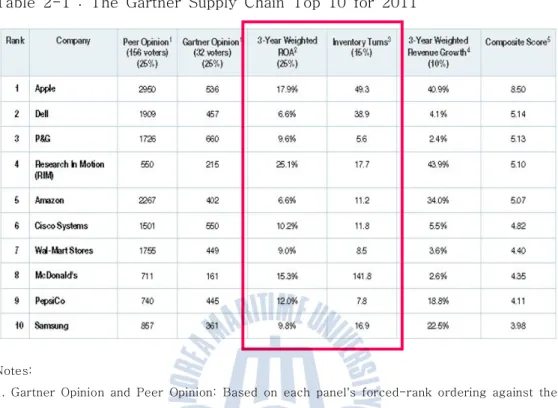

According to the Gartner table (June 2011), it is shown that companies with high inventory management efficiency receive ROA (Return on Assets = Net Income / Total Assets) and Inventory Returns (=Cost of Goods Sold / Average Quarterly Inventory) ) as effective factors to evaluate business performance in SCM. In addition to ROA and Inventory Returns, service quality and cost are also crucial factors to measure business performance. KPI (Key Performance Indicator) is also one of the decisive factors to evaluate business performance.

The above graphs justify that high performers focus on service quality, cost and inventory management efficiency on the supply chain.

SCM Pressures and Capabilities

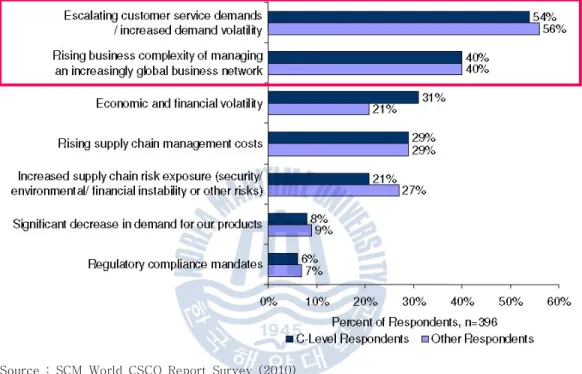

- SCM Key Pressures

- SCM Key Capabilities

In the event that demand volatility increases, the responsiveness of supply chain networks is a crucial factor. Recommended ways to overcome the challenges are visibility, scope and adaptability in the supply chain. The notion of supply chain visibility spans a number of different areas within supply chain management.

These concepts must therefore be considered as part of the supply chain visibility concept. (Simon Johansson, Johan Melin, 2008).

Application Techniques for SCM Framework

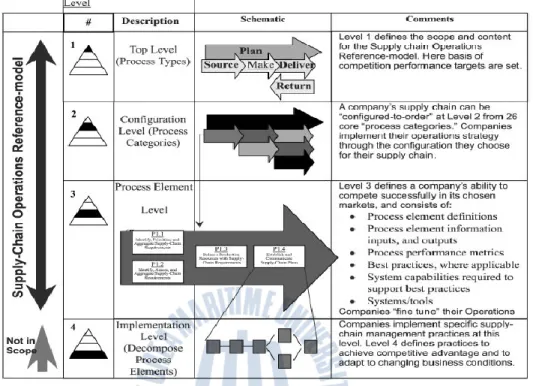

The Supply-Chain Operations Reference (SCOR) model was developed by the Supply Chain Council (SCC) to help companies increase the efficiency of their supply chains and ensure a. The SCOR model provides a common process-oriented language for communication between supply chain partners in the following decision areas: PLAN, SOURCE, MAKE, and DELIVERY. For example, supply chain partners need processes to plan the entire supply chain, as well as planning processes to support sourcing, manufacturing, delivery and returns decisions.

The rationale for its exclusion is that the SCOR model was designed as a tool to describe, measure and evaluate any supply chain configuration.

Agility and Precedent Studies of Agile SCM

The Concept of Agility in SCM

The Agility Forum has defined “agility” as an organization's ability to thrive in a constantly changing, unpredictable business environment (Agility-Forum, 1994). In agile supply chains, the emphasis is on the ability to understand and quickly respond to market changes. The agile supply chain wants the ability to respond quickly and cost-effectively to unpredictable changes in markets and increasing levels of environmental turbulence, both in terms of volume and variety (Agarwal et al., 2007; Christopher used the following definition: “ An Agile supply chain is an integration of business partners to enable new competencies to respond to rapidly changing, constantly fragmenting markets.

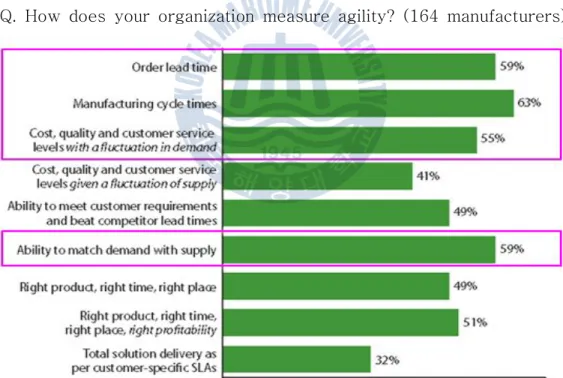

The key capabilities of the agile supply chain are the dynamics of structures and relationship configuration, the end-to-end visibility of information, and the event-driven and event-based management." 1999) used the decoupling point concept to divide the part of the supply chain that responds directly to the customer from the part of the supply chain that uses forward planning and a strategic inventory to counter demand variability (demand is variable and high product variation) (demand is smooth and products are standard). 34;leagile" supply chain where lean principles are followed up to the decoupling point and agile practices are followed this point. 2007) have shown that supply chain agility depends on the following: customer satisfaction, quality improvement, cost minimization, delivery speed, new product introduction, service level improvement and delivery time reduction.

Literature on supply chain agility describes the dependence of agility on some performance variables; but the influence of interrelationships between the variables on supply chain agility has hardly been considered (Agarwal et al., 2007).

The Importance of Agility

They use state-of-the-art sorting and material handling technologies to ensure that distribution does not become a bottleneck when responding to demand volatility. As we know from the examples above, despite the obvious advantages of agility, companies in complex environments in international markets face challenges in implementing the measures necessary to increase their agility. For example, an internationally operating company that ships components or products by sea may find it difficult to supply niche markets with individualized goods.

Furthermore, it may be difficult for this company to react quickly to changes in demand. Therefore, if the firm is not willing to significantly increase its administrative and logistics costs in the value and supply chains, it may be forced to take counter-agile actions to remain competitive and limit its market vulnerability. The supply chain is often the part of a company that is so seriously affected by changes in international circumstances.

For example, it may be difficult to adjust the structure or geography of the supply chain to respond to changes in production or policy. In these cases, supply chain agility can immediately become a limiting factor in overall enterprise agility. Thus, a supply chain describes a series of related activities between companies that contribute to the process of planning, manufacturing, and delivering products and services.

The agility of a supply chain is a measure of how well the relationships involved in the processes mentioned above enhance the four main objectives of agile manufacturing (Hoek et al., 2001). In short, an agile company has designed its organization, processes and products that can respond to change in a useful time frame.

Limits of Precedent Studies of Agile SCM

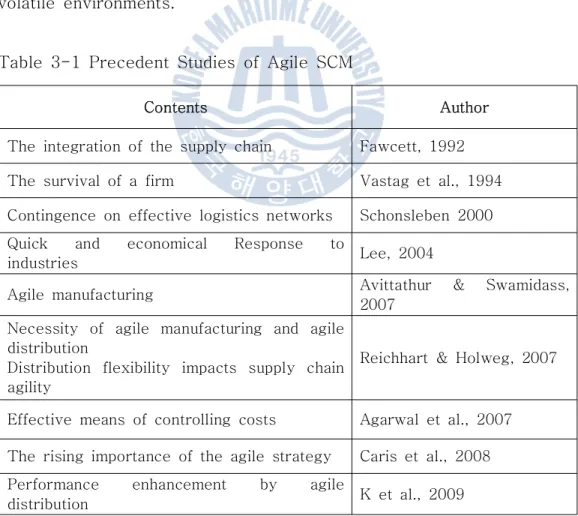

Until recently, supply chains were primarily understood in terms of long-term upstream collaboration with suppliers, downstream collaboration with customers and lateral collaboration with competitors as a means of integrating the overall value creation process. Clearly, we need to examine the constraints of supply chains in order to offer advice to companies on how to address demand volatility and complexity in supply chain networks. Recently, the main trend in SCM is to increase supply chain agility (Ivanov et al., 2010; Lancioni, 2000).

Agile supply chains are considered an effective survival strategy for companies facing intense global competition and a turbulent environment (Bottani, 2009). Specifically, an agile supply chain should respond appropriately to the changing business environment (Bottani, 2010). In addition, an agile supply chain can respond quickly and economically to industries facing wide and rapidly changing supply and demand (Lee, 2004).

Companies such as Volvo, Argos and HP have used agile supply chain practices to quickly respond to turbulent business environments. Qi et al.(2009) investigated the phenomenon of companies that focused on supply chain agility outperforming other companies. Braunscheidel and Suresh (2009) further argued that agile firms can quickly adapt to environmental changes and disruptions and can also contribute to extended supply chain agility.

In addition, the increasing importance of agile strategy forces companies to pay attention to logistics services (Caris et al. emphasized that supply chains must offer an effective means of cost control for agile distribution systems. In addition, based on a survey approach, K et al. 2009) empirically demonstrate that agile distribution can improve company performance. 2009) further suggested that greater agility can increase the global competitiveness of container terminals. 2010) found that agility is one of the key factors of customer satisfaction that affects customer satisfaction of logistics providers.

2007 Necessity of agile manufacturing and agile

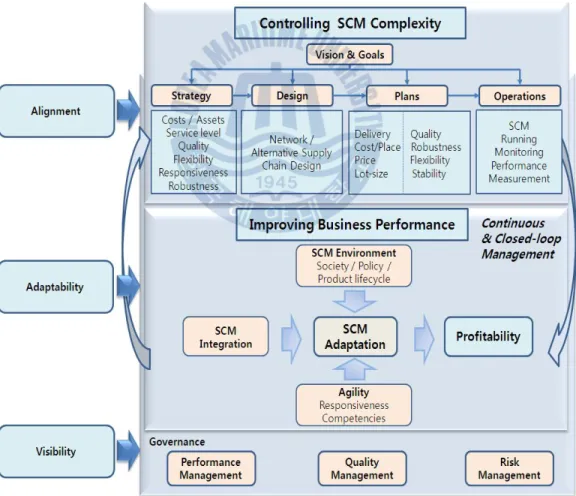

Agile SCM framework

- Visibility - Supply Chain Governance

- Performance Management

- Risk Management

- Quality Management

- Alignment to control complexity

- Vision & Goals

- Network design

- Controling product complexity

- Adaptability

- Supply Chain Integration

- Agile Manufacturing Inventory Management

- Solution for Agile Inventory Management Process

- Risk of Agility & Necessity of Hybrid SCM

A study of supply chain adaptation models is proposed to assess the impact on agile inventory management. In addition, companies consist of the basic model of the supply chain structure, considering alternative scenario selection. We consider supply chain strategy, design, tactics and operations as an integrated system in detail.

Supply chain structures are configured based on the competitive and supply chain strategy. While running a supply chain, various disruptions can affect the supply chain and cause anomalies and disruptions. The results of the supply chain monitoring are reflected in the supply chain performance block.

In this process, the responsiveness, which is the goal of agile inventory management, is guaranteed on the global supply chain. The virtual alliance and partnership environment is an adaptation reserve of the real supply chain environment. Companies along the supply chain are starting to exchange planning data in addition to real-time tracking.

Here, business leaders come to an agreement on how best to manage the supply chain to achieve business goals. The result of a successful agile inventory management process is shared knowledge of the company and its supply chain, a shared view of the supply chain's capabilities, strengths and weaknesses. The rigor of the process thus allows the company to manage the supply chain more flexibly as conditions change.

Changes in the supply chain can be easily implemented by adding or removing segments that correspond to the change.

Conclusion

This process is a shared knowledge of the company and its supply chain, a shared view of the capabilities, strengths and weaknesses of the supply chain. This framework can help companies become more aware of the dynamics and performance of their supply chain. When developing agile supply chain inventory management, first and foremost, a good understanding of the entire supply chain is paramount.

Braunscheidel MJ, Suresh NC Organizational Antecedents of Firm Supply Chain Agility for Risk Reduction and Response", J. Strategic Logistics in Coordinated Global Manufacturing Success", International Journal of Production Research 30(4), p. 2010), Robust Supply Chain Planning under Uncertain Demand in Agile Manufacturing. Joines J.A., & Thoney, K, Kay M.G Optimization of multi-objective supply chain simulation", Proceedings of the 4th International Conference on Industrial Simulation, Palermo, p.

Logility Collaborative Transportation Management: An Executive White Paper", Atlanta, GA: Logility, Inc Implementing Collaborative Forecasting to Improve Supply Chain Performance", International Journal of Physical Distribution &. Scott An Algorithm for Procurement in Supply Chain Management", AAMAS-04 Workshop on Trading Agent Design and Analysis, New York. Supply-chain operations reference model (SCOR): the first cross-industry framework for integrated supply-chain management", Logistics Information Management, 10(2), pp.

Changing customer and technological demands are forcing companies to develop agile supply chain capabilities to be competitive. A wealth of valuable approaches to supply chain strategic, tactical and operational planning has been extensively developed.