Literature review on the properties of PV A fiber and the benefits it would bring to concrete are studied. Experimental laboratory has also been conducted to test the compressive strength of concrete with PV A fiber. Although fresh concrete is only of passing interest, we must note that the strength of concrete with given mixing ratios is very seriously affected by the degree of its compaction.

Strength of concrete is generally considered to be its most valuable property, although, in many practical cases, other properties, such as durability and permeability, may in fact be more important. Nevertheless, strength usually gives an overall picture of the quality of concrete because strength is directly related to the structure of the hydrated cement paste. In addition, the strength of concrete is almost invariably an important element of structural design and is specified for compliance purposes.

The scope of study will include research through journals and reading materials related to fatigue, PV A fiber and concrete. In addition, laboratory experiments will be conducted to investigate the effects of the infusion of PV A-fiber m-concrete mix.

LITERATURE REVIEW

Historical Development

Consequently, the addition of randomly spaced discontinuous fiber elements should help arrest the development or propagation of the microcracks known to generate in the early stages of the loading history. While fibers have been used to reinforce brittle materials such as concrete since time immemorial, newly developed fibers have been widely used throughout the world in the last three decades. They have proven that they can improve the mechanical properties of concrete, both as a structure and material, not as a substitute for continuous reinforcement when needed, but as a supplement to it.

The introduction of fiber addition to concrete in the early 1900s was primarily aimed at improving the concrete's tensile strength. As is known, the tensile strength is 8-14% of the compressive strength of normal concrete with resulting cracking at low stress levels. Fibers, on the hands, are discontinuous and randomly distributed in the matrix, both in tensile strength and.

The method chosen depends on the available capacity and work requirements, namely plant hatching, ready-mixed concrete or manual mixing in the laboratory. The most important factor is to ensure uniform dispersion of the fibers and to prevent separation or aggregation of the fibers during mixing.

Mechanics of Fiber Reinforcement

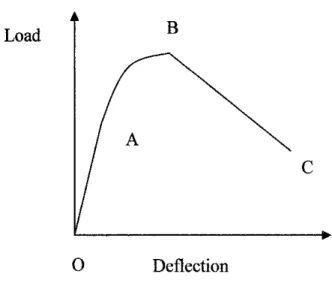

In the falling branch BC of the load-deflection diagram, matrix cracking and fiber pullout continue. If the fibers are long enough to maintain their bond with the surrounding gel, they may fail by yielding or by rupture of the fiber element, depending on their size and spacing. The orientation of the fibers with respect to load determines the efficiency with which the randomly oriented fibers can resist the tensile forces in their directions.

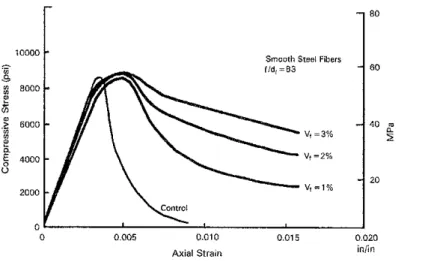

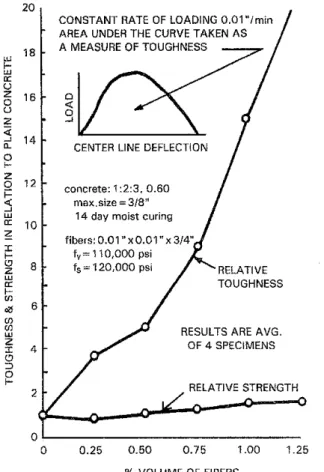

The effect of fiber contribution on the compressive strength of concrete appears to be small for testing using steel fibers. However, ductility and toughness increase significantly as a function of increasing volume fractions and aspect ratios of the fibers used. The effect of different shapes of fiber elements on the tensile stress behavior of steel fiber reinforced mortar in direct tension is shown in Fig.

Both the initial crack load and the ultimate flexural capacity are affected by the product of the fiber volume concentration, p, and the aspect ratio, l!dJ. The rate of increase in diagonal tension capacity is a function of the beam shear span/depth ratio.

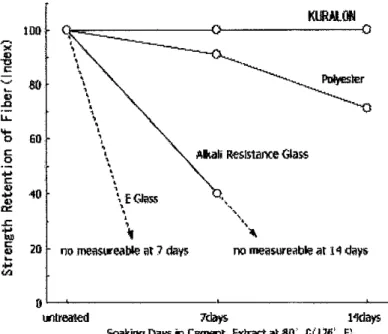

Environmental Effects

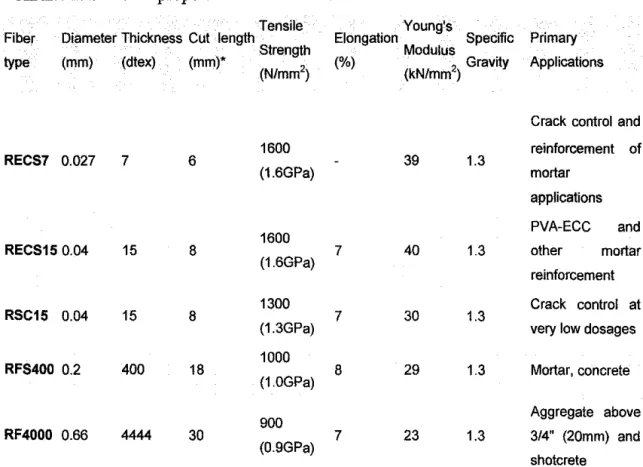

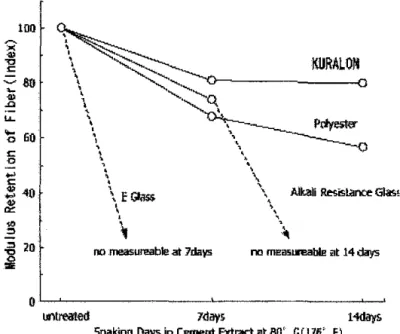

Polyvinyl alcohol (PV A) is an organic material that we use to make concrete reinforcing fibers, among many other uses. However, these properties depend on humidity; in other words, with higher humidity, more water is absorbed. Water acting as a plasticizer will then reduce its tensile strength but increase its elongation and tear strength.

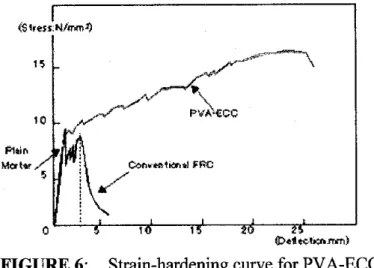

But after the first 24 hours, they are largely ineffective in inhibiting drying shrinkage or other cracking because their modulus of elasticity is less than that of concrete. To be a true structural fiber, the fiber must be stiffer than the reinforcing concrete. In Figure 6, the graph shows that PV A-ECC is stronger in tension than any fiber-reinforced mortar.

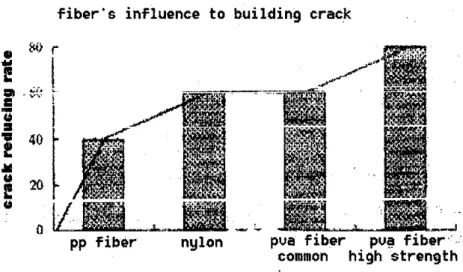

PV A fibers are also unique in their ability to create a molecular bond with mortar and concrete that is 300% greater than other fibers. High bond strength with concrete helps to hold the plaster together even if damaged. 2. To limit shrinkage cracking, the fiber must be stiffer than the concrete it reinforces.

PV A fibers reduce normal cracks to micro cracks that limit water penetration and protect the steel reinforcement. Being less "stretchy" with a higher modulus of elasticity, PV A fibers are more effective than other fibers in reducing long-term drying cracks. Relatively low dosages of PV A fibers can effectively reduce many types of cracking, including drying shrinkage, settling, and fatigue-related cracking.

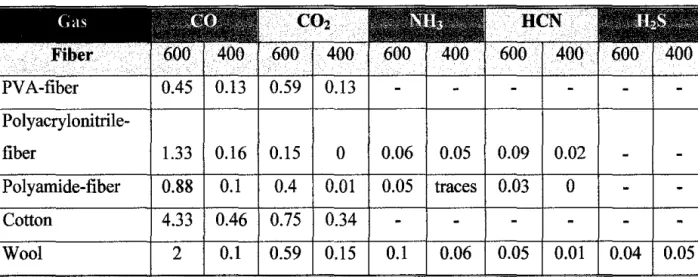

Comparison of PV A fiber with other fibers

Because of their high elongation, or "stretchability," these fibers are essentially useless for the drying shrinkage and other types of cracking that plague all concrete. Because PYA fibers are composed of carbon, hydrogen and oxygen, only water and carbon dioxide are generated during combustion.

METHODOLOGY

PROJECT PLANNING

LABORATORY WORKS

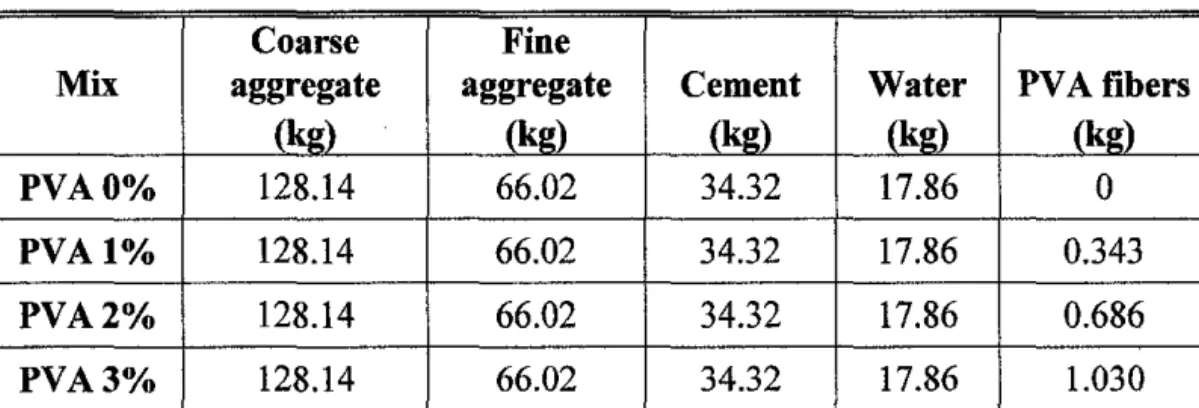

Mix Proportioning (Mix Design)

Similar to the American Concrete Institute (ACI) approach, the British method explicitly recognizes durability requirements in mix selection.

Concrete Mixing

Concrete Testing

RESULTS AND DISCUSSION

FRESH CONCRETE TEST .1 Slump Test

Hardened concrete test

All the specimens have almost the same projection on the line, but the difference is that the plain concrete has less strength compared to the others. From this we can say that fiber concrete can increase the strength of concrete. For fiber concrete, it shows that concrete with 3% PV A fiber has the highest strength at 28 days followed by 1% and 2%.

This is because the interaction between the fibers and the matrix becomes more intense and consequently the cracks are distributed more widely throughout the samples. For example, at day 19, the concrete with the highest strength is concrete with 1% PV A fibers, followed by 2% and 3%, respectively. There may be some defects that refer to the fibers may not be mixed evenly, causing the fibers to separate or twist.

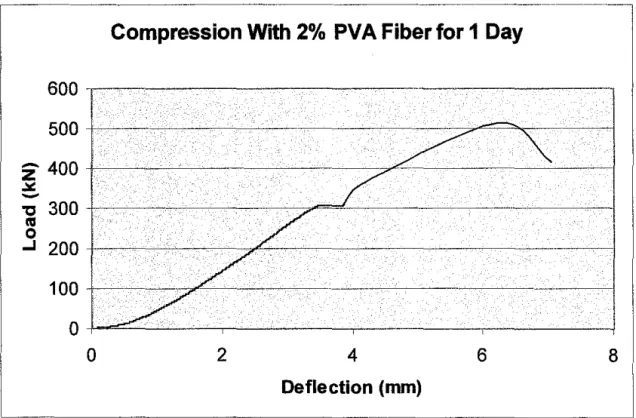

From the graph, the sample with 2% PV fiber A gives high maximum load which is 514.73 kN compared to others. But after that particular point, the line went down to the left, which is very different from the theory. This is because, as the test passes, the load continues to increase without any cracks in the sample.

The technicians conducting the test decided to shut down the machine because they were concerned that it could damage the test equipment. PV A fibers, the test was carried out to the end, even though the load was more than one wish. During this time we decided to continue the test because cracks occurred during 400 kN.

It is assumed that the result also gives a high value for the 2% sample, but the 3% sample can achieve more than that.

Compression With 0% PVA Fiber for 1 Day 180

Compression With 1% PVA Fiber for 1 Day

The voltage diagram below was interpolated from data obtained from the UTM machine. For the overall result, we can conclude that the PV A content affects the concrete strength. Uneven mixing of the fibers can affect the result, since the author mixes the fibers by hand.

It has also been proven that using PV A fibers in concrete can increase the durability of concrete compared to normal concrete. This can be seen from the results, which fiber samples give high load value compared to the control mixture.

Stress-Strain Diagram With 0% PVA Fiber for 1 Day

Stree-Strain Diagram With 1% PVA Fiber for 1 Day

Stress-Strain Diagram With 3% PVA Fiber for 1 Day

CONCLUSION AND RECOMMENDATION

In the first half of the semester, the project focused more on literature review of PV A fibers and fiber reinforced concrete. To achieve that, a few self-concrete trial mixes were made to determine the appropriate mix to be used for the mix using PV A fibers and to arrive at the suggested mix proportion. In the second half of the semester, the concrete mix was carried out with the PV A fibres.

Plain concrete was also mixed as a control mix to be compared with concrete with PV A fibers. The main focus was to determine the hardened properties of PV A fiber-reinforced concrete, especially on the compressive and flexural strength. Some recommendations to improve this project would be to make more mixes with varying contents of PV A fibers.

The aim is to observe on a larger scale how PV A fibers will behave with concrete. In addition to that, variation of tests can also be performed to determine other properties of PV A fiber reinforced concrete. Some other admixtures can also be added to the concrete mix to modify or improve the properties of PV A reinforced concrete.

Some of the limitations in this project came from the concrete laboratory conditions and environment. The tests could not be performed at the specified time because the test machine had some problem and could not function properly. It is critical to ensure that all equipment and machinery in the laboratory is ready before a mixture or test is to be performed.

It is also essential that all procedures are followed throughout the project to ensure it runs smoothly.

APPENDICES