The aim of this project is to investigate the heat transfer performance of a rotating phase change materials (PCM) based thermal energy storage (TES). Paraffin wax is used as a phase change material in a horizontal cylindrical acrylic capsule, while a water bath as a heat transfer fluid flows through the paraffin wax in a copper tube. The heat transferred during natural convection occurred only in the upper portion of the horizontal cylindrical capsule, limiting the amount of stored heat transfer.

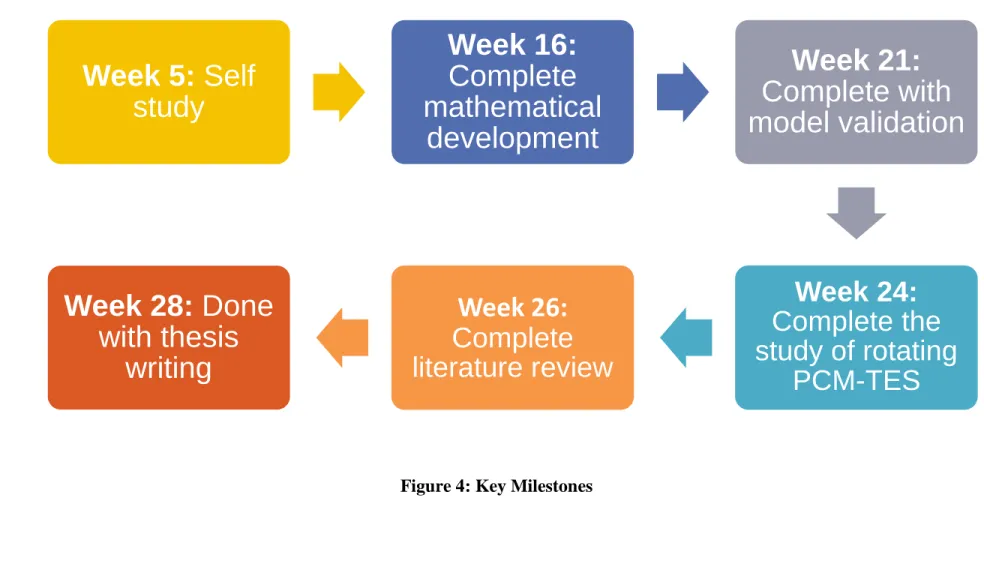

By proposing to rotate the horizontal cylindrical capsule, the idea is to spread the heat transfer uniformly to the top and bottom of the cylindrical capsule. There are two purposes of this study; to develop a computational model for heat transfer in a phase change material (PCM) based thermal energy storage (TES) and to investigate and evaluate the heat transfer performance of a rotating PCM-TES design. The models for PCM-TES are developed, validated and then used to evaluate the key parameters affecting heat transfer performance.

It has been found that the heat transfer performance of rotating thermal energy storage is better than static thermal energy storage.

INTRODUCTION

- Background

- Problem Statement

- Objectives

- Scope of Studies

The advantages of latent heat thermal energy storage are the ability to store large amounts of heat at minimum temperature rise, thereby reducing the heat lost to the environment. Natural convection taking over the process caused the heat transfer to occur only at the upper part of the capsule. This brings to the project where it will evaluate the heat transfer performance of a rotating phase change material (PCM) based thermal energy storage (TES) design using a computational modelling.

Theoretically, by rotating the cylindrical capsule, the heat transfer will spread evenly to the lower part of the capsule. Latent heat can store large amounts of thermal energy, but there are disadvantages where the heat transfer process takes very slowly, causing the phase change material to melt non-uniformly. This project addresses the heat transfer process in latent heat thermal energy storage with the aim of improving heat transfer process.

In order to improve the efficiency of heat transfer through the thermal energy store, a rotary PCM-TES design is proposed.

LITERATURE REVIEW

Thermal energy storage

For years, researchers have been finding ways to improve the performance of phase change material-based thermal energy storage. Bellan et al [9] investigated the effect of capsule size on the performance of the thermal energy storage system. Kurnia et al [10] studied the design of heat transfer performance of a new phase change material where they conclude that a new pendulum design is suggested to obtain the highest heat transfer rate.

In order to ensure that the storage materials have long-term stability, the material properties should be stable, and no corrosion should occur between the phase change material and the container. It comes to the conclusion that all studied inorganic phase change materials cannot be used for the storage of latent heat thermal energy. In their research, Liu et al [16] conduct an experimental study of heat transfer between phase change materials in a horizontal cylindrical latent heat energy storage system.

This statement is supported by Sun et al [17] where she studied on the enhancement of the heat transfer during the phase transition processes of solid-liquid phase change materials.

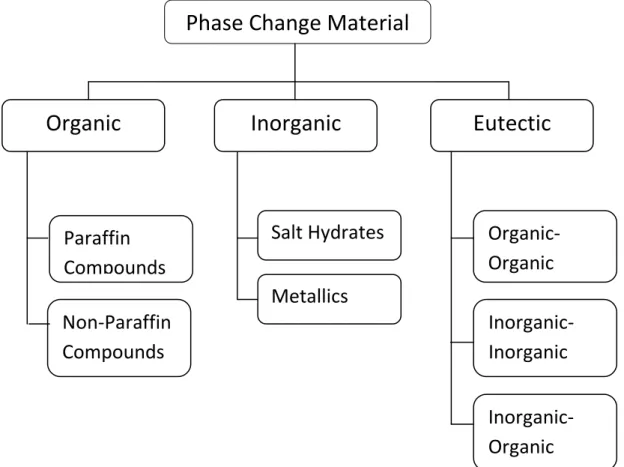

Phase Change Material

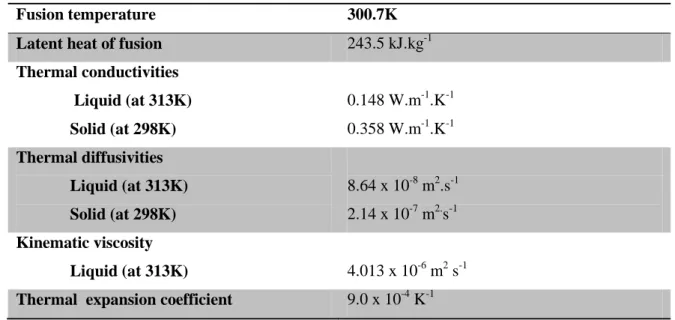

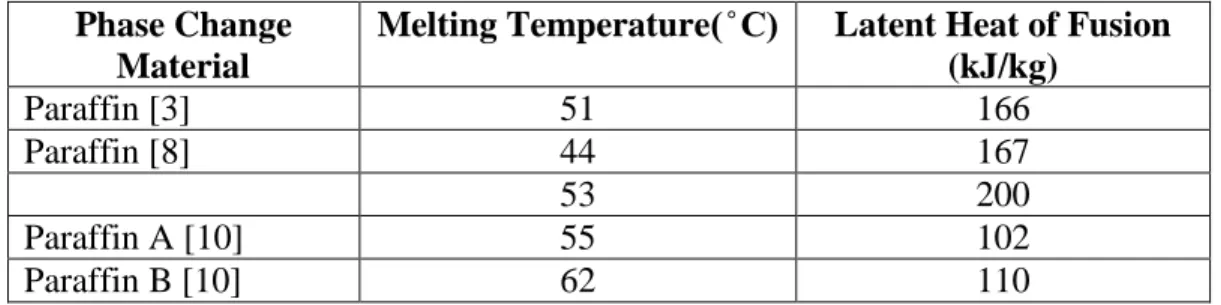

Paraffin wax has many advantages, including the chemically inert, stable and no phase segregation factors [7, 13]. In terms of thermal stability, paraffin wax is known for its stability even after several cycles. Paraffin wax is known for its low thermal conductivity, is not compatible with plastic and is moderately flammable.

3] The addition of conductive fillers in a thermal energy storage filled with paraffin wax will help to increase the thermal conductivity. Pure paraffin is expensive and the use of commercial paraffin would therefore be one of the alternatives to overcome this problem. With the presence of a large amount of hydrocarbon mixtures in commercial paraffin wax, it brings a wide range of melting temperature rather than a specific melting temperature [7].

Sharma et al [5], the melting temperature will increase as the number of carbon atoms increases. Some researchers have come up with different values of melting temperature and melting latent heat [5, 13]. The reasons behind the latent heat of fusion changes at different melting temperatures are caused by the presence of impurities in the commercial paraffin wax used by various researchers [7].

METHODOLOGY

CDF Modeling

Model description

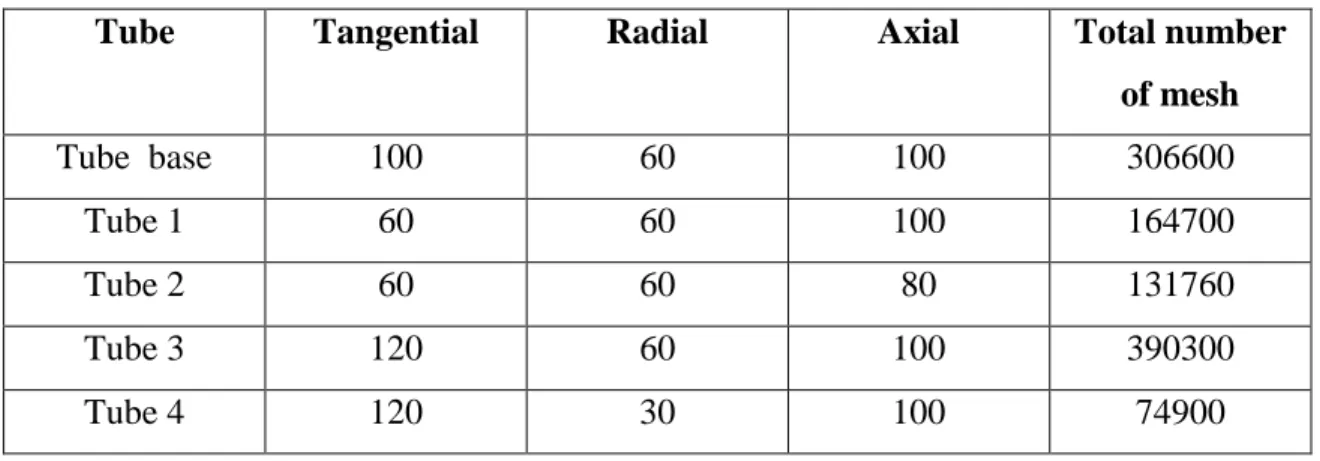

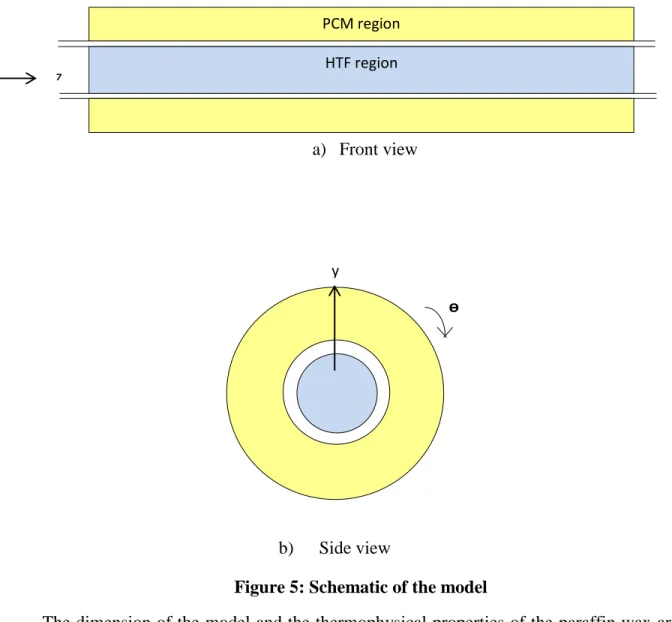

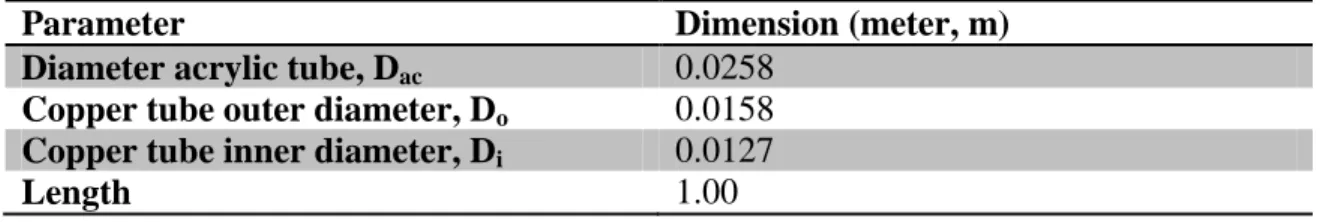

For this research, the model will include an acrylic tube as an outer capsule to hold the paraffin wax, and a copper tube running through both, through which the heat transfer fluid (water in this case) passes. The model dimension and thermophysical properties of paraffin wax are summarized in Table 3 and Table 4, respectively.

Governing equation

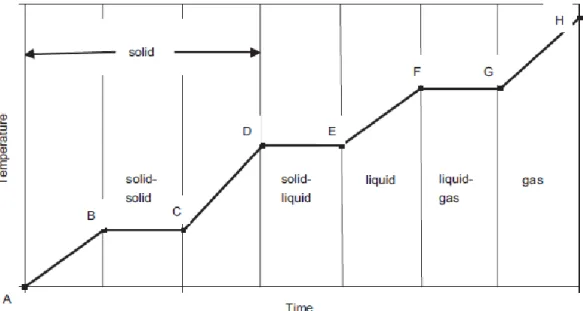

Conservation of mass, momentum and energy involves fluid flow, heat transfer and phase change processes. Where is the density for the phase is the change material and is the dynamic viscosity of the phase change material. For the enthalpy porosity formulation, it is represented by Smom for enthalpy in terms of the momentum equation while; enthalpy in terms of the energy equation is represented by Hpcm in the above equation.

For the specific heat of water, it will be considered constant at 4200 kJ/kg K-1 Since this paper will use paraffin wax, the density of paraffin wax is given by. To determine the viscosity of the phase change material, the following equation can be used. In the previous equations, enthalpy was introduced in terms of the energy equation, Hpcm, and in terms of momentum energy, Smom.

The following equation is used to calculate the latent heat of a phase-changed material. Where L is the latent heat of the phase-changed material and the molten mass fraction of the phase-changed material is given by Since the partially solidified region (mushy region) is considered a porous medium, each of the cells is set to equal the proportion of liquid in the cell.

RESULT AND DISCUSSION

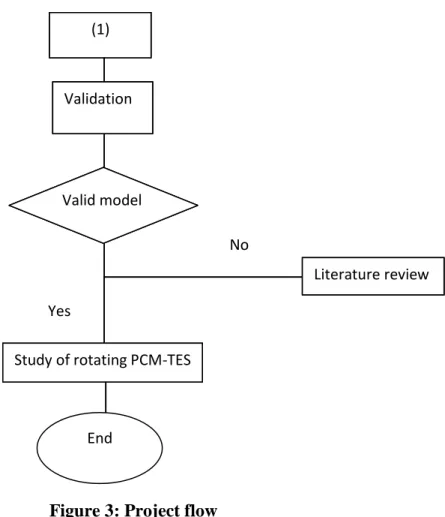

Model validation

As shown in Figure 6, the physical model and simulation code in the previous research paper are correct and reliable.

Effect of tube orientation

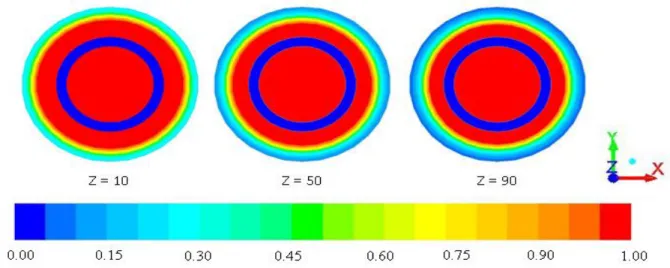

In the z-direction of the tube, the temperature of the paraffin wax is constant for each of the cross sections. The paraffin wax surrounding the copper tube takes the heat from it and causes it to move to the top of the tube. The temperature at the top of the tube also shows higher than the bottom side of the tube.

As mentioned earlier, there will be heat loss throughout the z-direction of the tube. The paraffin wax begins to melt at the top of the tube, leaving the bottom as a solid paraffin wax. The region with liquid fraction equal to 1 becomes smaller as the length of the tube increases.

To improve the heat transfer performance from the liquid to the paraffin wax, a rotating phase change material based thermal energy storage is proposed. At the end of the study, computational heat transfer models in a phase change material based thermal energy storage are developed using GAMBIT. In terms of liquid fraction of the paraffin wax, the paraffin wax is completely in the region close to the heat transfer fluid.

When the tube is oriented horizontally, the effect of natural convection can be clearly seen where only the top of the tube experiences the melting of paraffin wax. This can result in a limited amount of heat transfer from the heat transfer fluid to the paraffin wax. The study should further investigate whether the inlet temperature and velocity affect the heat transfer performance of the phase change material-based thermal energy storage.

The main medium of the phase change material will later focus on paraffin wax as it is the cheapest and the most promising phase change material. Groulx, “Experimental study of the phase change heat transfer within a horizontal cylindrical latent heat energy storage system,” International Journal of Thermal Sciences, vol.

Effect of rotational speed

CONCLUSION & RECOMMENDATION

Recommendation

A number of studies have been done resulting in the effects of temperature and inlet velocity on heat transfer performance. Hydrated salt and microencapsulated phase change material are suggested as it has shown an impressive result in terms of their heat transfer performance. Since adding a fin or using a new festoon can improve the heat transfer performance, further study should also focus on this aspect.

It is hoped that these recommendations will be considered as the study has a significant impact on the world of thermal energy storage. In the study, the flow of the heat transfer fluid will be focused only on laminar flow, where this means that it will not be considered if the flow of the heat transfer fluid changes into turbulence. El Hammouti, “Heat transfer characteristics of thermal energy storage for PCM (phase change material) fusion in horizontal pipe: Numerical and experimental investigations,” Energy, vol.

Buddhi, “Review on thermal energy storage with phase change materials and applications,” Renewable and Sustainable Energy Reviews, vol. Hasnain, "Review on Sustainable Thermal Storage Technologies, Part 1: Heat Storage Materials and Techniques," Elsevier Science Ltd, vol. Mujumdar, “Improved design for heat transfer performance of a novel thermal energy storage (TES) phase change material (PCM),” Applied Thermal Engineering , vol.

Wang, “Hydrated salts/expanded graphite composite with high thermal conductivity as a shape-stabilized phase change material for thermal energy storage,” Energy Conversion and Management , vol. Erek, “Experimental study on water loading and unloading periods in a latent heat storage unit,” International Journal of Thermal Sciences, vol. Al-Hallaj, “A review on phase change energy storage: materials and applications,” Energy Conversion and Management, vol.

Sawhney, "Thermal cycling test of some selected inorganic and organic phase change materials," Renewable Energy, vol. Lee, “On natural convection enhancement of heat transfer during phase transition processes of solid–liquid phase change materials (PCM),” Energy Proceedings , vol.