The research of this final year project is to investigate the pozzolanic effect of rice husk ash in the cement/binder paste. The paste is ground at the age of 28 days and tested in the TGA machine. The researcher has investigated different types of methods. Improve the properties of concrete and one of the methods that are intensively carried out. the researchers add pozzolanic materials to the concrete to increase the cement.

The finer the particles of rice husk ash, the greater the chemical reaction in the concrete. Finer particles will fill the pores of the concrete and. strength of concrete. When the final position is reached, take the kerosene from the flask (remaining kerosene so that the sample does not stick to the flask) into the cylinder and fill. a flask of cement weighs 1OOg.

In this project, the author intends to maintain the water/cement ratio for the whole mix, but due to the higher water requirement for paste with RHA, the water/cement binder ratio is determined based on the percentage of RHA included in the paste. The graph above shows the relationship between the compressive strength and the percentages of RHA incorporated in the paste. According to the graph, the compressive strength increases with the percentages of the RHA.

The graph above shows that the correlation between compressive strength and the age of the paste. The pozzolan effect in the paste is optimal when 5% RHA is added to the paste. Thus, the remaining RHA will become unhydrated substances in the paste, and this will reduce the compressive strength of the paste.

The author successfully generates astandard burning procedure for rice husk. The rice husk ash can be categorized as the high quality ash after base on the analysis

The following are the conclusions and recommendations that the author makes for this research: .. 1) The author successfully generates the standard procedure of rice husk burning.

The fineness of the rice husk ash is determined by using the conical flask and from the result; it is proving that the fineness ofrice husk ash is almost double the

The optimum water/cement-binder ratio of the paste with the incorporation of

Pozzolanic reactivity ofthe paste is at the optimum when the paste is mixed with

IK Cisse and M Laquerbe, Mechanical characterization of filler sand concrete with additions of rice husk ash - study applied to Senegal, Cem. The Chemistry and Technology of Cement Made from Rice Husk Ash, Proceedings of UNIDO/ESCAP/RCTT Workshop on Rice Husk Ash Cement, Peshawar, Pakistan, Regional Center for Technology Transfer, Bangalore, India,. Malhotra** (22 March 1996), Rice husk ash paste and concrete - some aspects of hydration and the microstructure of the interfacial zone between the aggregate and paste, (*Research Scientists and.

Wailiuddin (26 April 1996), Effect of Rice Husk on High Strength Concrete, (*Department of Civil Engineering, NED University of Engineering and Technology, Karachi, Pakistan tNational Building Research Institute, F-40, S.I.T.E, Hub River Road, Karachi, Pakistan), Construction and Building Materials, Vol. Isojima3 (23 September 2003), The reaction between rice husk ash and Ca(OH)2 solution and the nature of its products, Cem. It is the user of this standard's inability to establish approval and health practices and determine the applicable regulatory limitations prior to use.

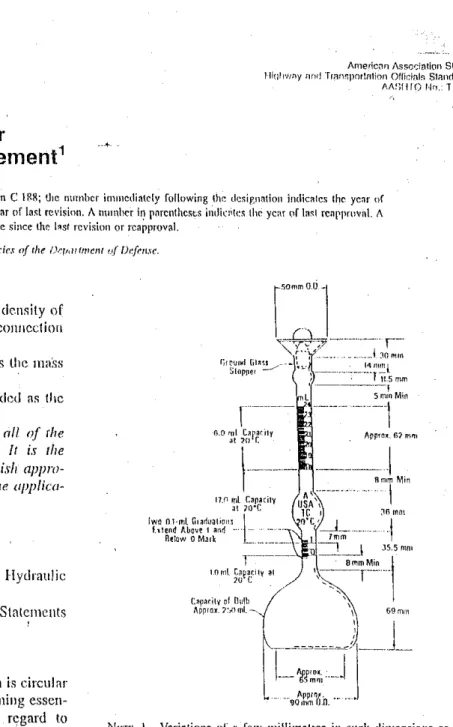

The standard tcmperatui should be indicated and the unit of capacity should be shown with the letters "mL" above the highest tick mark. 0 a point on the stem between the 0 and the 1 ml mark, e in the flask above the liquid level, if. Record the first reading after submerging flask 2ii in the water bath (Note 3).

2—It is temporary to use a rubber pad on the table runner when the Unsk is idle. 3—Before the cement is added to the flask, a loose vise, g wcight^round the stem of the flask will be useful to maintain the upright position in the water bath, or the flask may be held in the bath by a burette clamp . A vibrating apparatus can be used to reduce (the introduction of the cement into the jar and/or push the cement from sliding towards (the neck).

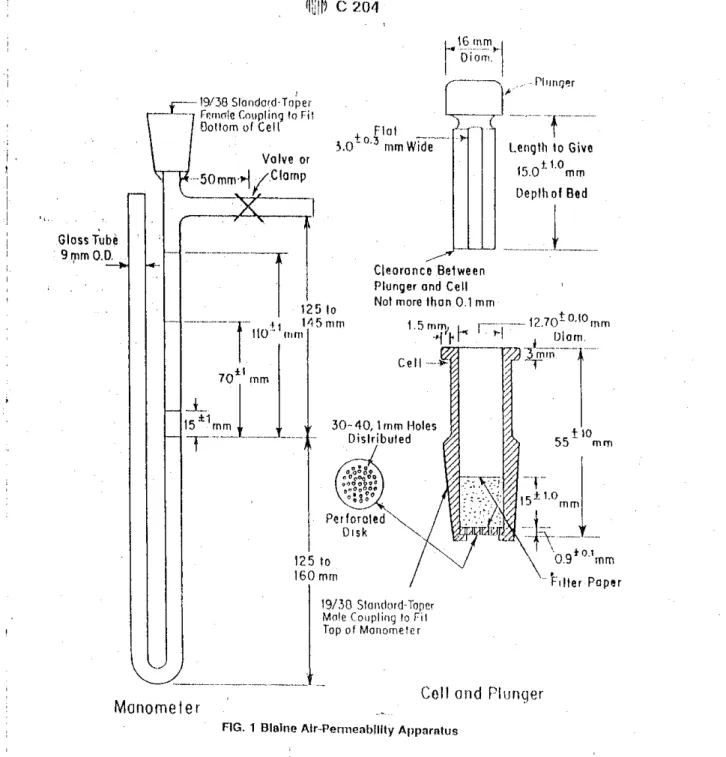

If a good amount of cement has been added, the level of the liquid will reach its final position at a certain point of the upper levels. Immerse the flask in a constant temperature water bath for an extended period of time to avoid flask temperature. This test method includes the determination of the air permeability fineness and Blaine's rm.

Filter paper discs that are too small can leave part of the irrigation to the inner wall of (lying cell above the top disc. 1, using '-mm outside diameter, standard wall, glass tube, f. one arm of the manometer must form an airtight in with the permeability cell There shall be a side outlet at 250 lo 305 mm above the bottom of the manometer for use in evacuating the manometer arm connected to the permeability cell.

The bulk volume value used for subsequent calculations should be the average of two values that agree within ±0.005 cm3 Noki|,c (enipcrnmrc near the cell and note nt. Tap lightly on the side of the cell to level A bed of cement It is suggested that a secondary sample be prepared and screwed to the standard for control determinations of the instrument calibrations with the standard cement sample.

VS - the specific surface area of the standard sample used in the calibration of the apparatus, m2/kg (Note 9). 7's ~ the measured time interval, s, of the fall of the manometer for the standard sample used in the calibration of the apparatus (Note 10). 3°C of the calibration test temperature of the purity standard sample, and Equation 6 is used if the temperature of the bulk of the tesl sample is outside this range.

Your comments will receive careful consideration at the meeting of the responsible local committee, which you can attend. The ability of the user of this standard to establish appropriate safety and health practices and to determine the application. Remove the excess edge with a single motion of the palm of your hand.

Your comments will be carefully considered at a meeting of the relevant technical committee, which you can attend. 2 This standard does not address all, if any, concerns associated with its use. The user of this standard is responsible for establishing appropriate safety and health practices and determining the applicability of legal restrictions prior to use.