The discharge volume decreases with increasing conductivity of the water at the same input energy. The propagation velocity of the discharge is 2.7–3.6105m/s in the Ar gas bubble [32] and 5105m/s on the surface of a glass tube filled with air, [31] which corresponds to the surface discharge over a dielectric material under atmospheric pressure [35, 36].

Decomposition of persistent organic pollutants

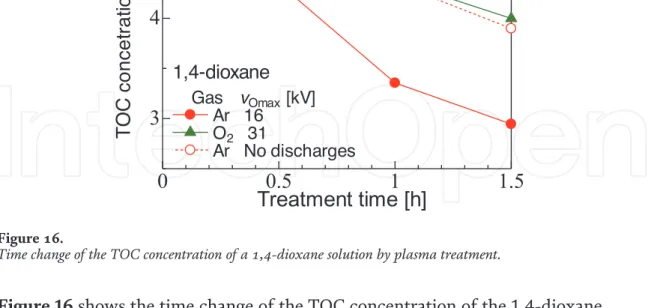

The decolorization of both solutions is much faster with O2 injection than with Ar injection. The rate of OH production in the case of Ar injection is much higher than in the case of O2 injection.

Novel applications for agriculture

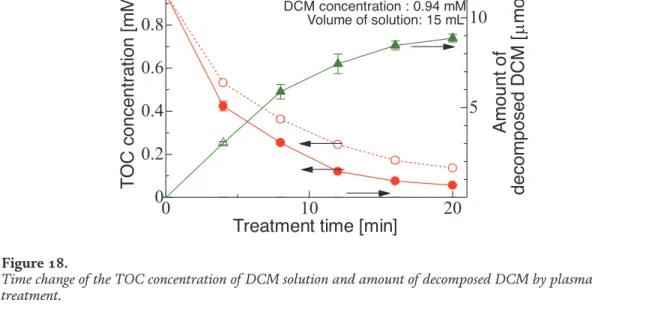

Pulse voltages with an amplitude of 16 kV, a pulse width of 160 ns, and a pulse repetition rate of 250 Hz are applied to the wire electrode placed in the gas phase to generate plasma [91]. This result indicates that almost all DCM is dissolved in the gas phase in the bubble, not in the liquid phase. DCM volatilizes rapidly due to its high volatility and is transferred into the gas phase in the bubble when Ar gas is fed into the DCM solution, and DCM is exposed by plasma discharges generated within the bubble.

A plasma treatment system has been developed for the inactivation of Ralstonia solanacearum bacteria in liquid fertilizer for a tomato hydroponic system [106]. Because these nitrogen species have a long lifetime in the liquid phase, nitrogen species generated by plasma treatment persist for a long time after non-thermal plasma irradiation.

Conclusion

This chapter is distributed under the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/.by/3.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly quoted . Influence of the water surface on the glow-to-spark transition in a metal-pin-to-water electrode system. Investigation of the loss mechanisms of hydroxyl radicals in the degradation of organic compounds using plasma generated over water.

Role of the photo-Fenton reaction in hydroxyl radical production and photobleaching of colored dissolved organic matter in a southeastern United States coastal river. Effect of sodium carbonate on the decomposition of formic acid by pulsed discharge plasma inside the bubble in water.

TOP 1%

Introduction

Although the technology has also been used in environmental applications such as the removal of contaminants from vapor stacks and the decontamination of waste water and sewage sludge, its application at a commercial stage has not been as successful as in the case of medical supplies or food irradiation. . This chapter first presents a historical overview of the field of sewage sludge irradiation and the technologies that have been developed over time. Afterwards, a description of the technologies used for the electron beam treatment of sewage sludge will be presented.

A typical facility that has been developed to irradiate sewage sludge with electrons will be described as well as a current state of use of the technology in several countries around the world. Techniques used to evaluate process quality control will be described including dosimetric techniques and analysis of the effect of electron beam on the reduction of microorganisms contaminating sewage sludge.

Historical development of the technology

To make the use of sewage sludge as a safe valuable soil fertilizer in agricultural applications, it must be disinfected. The use of radiation to decontaminate sludge began in 1973 when an industrial gamma ray facility of Geiselbullach near Munich (Germany) used Co-60 and Cs-137 sources [1]. The use of electron accelerators to disinfect sludge was also started in the 1970s with the work by Trump and co-workers [3] in Cambridge Massachusetts, USA.

Similarly, Hashimoto and colleagues [8] have described the use of process control techniques to make the electron irradiation of wastewater more efficient. In 2014, through a collaboration between Arlington County in Virginia, USA and Kent State University, in Kent Ohio, USA, a sample of sludge was irradiated to demonstrate the feasibility and economic value of the process.

Description of a typical electron beam treatment facility

Quality control of the process

To address the second issue and as part of the operation qualification (OQ) activities of the system [13] a verification of the dose uniformity must be carried out along the strange where the electrons irradiate the sludge. Both of these work on the principle that irradiation causes a change in the optical absorption of the film which can be quantified with a spectrophotometer. Through a suitable calibration with a primary dose meter, these systems can be used to measure the dose along the length of the foreign of the sludge delivery system.

So, there were "dark" spots on both sides of the strange where the sludge was not irradiated. The situation was corrected by placing some plates on both sides of the alien which reduced its length so that all the sludge that passed through the alien was irradiated [9].

Bactericidal effect

Similarly, the efficiency of the killing of the microbial populations, including that of bacteria, increases with radiation dose. The effectiveness of electron beam radiation on killing microorganisms is better represented by the so-called D10 value, which is the radiation dose required to kill 90% of the population of microorganisms present in the sludge sample. Recent studies conducted by Engohang-Ndong and his research collaborators have shown that the electron beam technology could be used on an industrial scale to eliminate potential microbial pathogens from sewage sludge [9].

The US-based research team showed that a dose of 25.7 kGy was sufficient to eliminate Ascaris eggs at a level indistinguishable from the available technique used to count helminth eggs in sewage sludge including the use of of Sedgwick Rafter cells to enumerate detectable ascaris. ovary. The dose required to eliminate faecal coliforms at the rate set by the US EPA to convert sewage sludge to Class A biosolids is much lower.

Economic aspects

The chemically active species produced in water due to the irradiation will cause oxidative damage to nucleic acids, proteins and lipids in microorganisms, leading to their death. Typically, at a given electron beam radiation dose, the killing of microorganisms occurs at a constant rate over time. Due to the difference in structural complexity of microorganisms, D10 values can vary more or less significantly from one microorganism to another.

According to US Environmental Protection Agency (EPA) standards, to be considered Class A biosolids, sewage sludge must contain less than one Ascaris egg per four grams of sludge dry weight [21]. In other words, when the risks of sewage sludge contamination by helminth eggs are reduced as in highly urbanized areas, the doses required to convert sewage sludge into Class A biosolids which in turn can be used to enrich the soil for landscape and agricultural purposes. very useful and requires low power consumption.

Conclusions

- Fundamental principles of MFC

- Evaluation of MFC’s performance during domestic wastewater treatment In most cases, the performance of MFC can be evaluated by measuring three

In most cases, MFC performance can be evaluated by measuring chemical oxygen demand (COD) removal efficiency, coulombic efficiency, and MFC power density output. I believe that the information provided in this chapter will illuminate the current and future prospects of the versatile applications of MFC during domestic wastewater treatment. In this mini-review, the principle of MFC, performance evaluation of MFC in domestic wastewater treatment and varieties of MFC configurations are all covered.

Thus, the performance of MFC is evaluated by calculating the true potential in closed circuit by using the standard potential as follows [8]:. ɳji is the sum of both activation and concentration overpotentials, I is the current, Ri is the internal resistance in the circuit. Ecathodes and Eanodes are electrode potentials for cathode and anode, respectively, which can be calculated using the Nernst equation [6]:. The second parameter used for evaluating the performance of MFC is done by estimating the Coulomb efficiency.

Domestic wastewater treatment and energy harvesting simultaneously by MFC

- Principle of wastewater treatment and energy generation by MFC

- Configurations of MFCs for wastewater treatment

Of the various operating parameters that affect the performance of MFC during wastewater treatment, only three configurations of MFC are summarized in the following sections. Furthermore, since there is no need for aeration in the cathode chamber, SCMFC is more cost-effective [15, 19]. A high level of COD increases the removal of COD in the wastewater and generates higher power density to the optimum point where microorganisms are inhibited.

Resistance • The lower the external resistance, the higher the energy generation and COD removal efficiency. The higher the oxygen level in the cathode chamber improves COD removal and current production.

Resource Recovery from domestic wastewater by MFC

Similarly, phosphorus from domestic waste water can deposit on the surface of the cathode in the form of struvite (NH4MgPO46H2O) [39]. The loading rate of organic substrates in wastewater significantly affects the recovery/removal of nutrients and electrical generation by MFC. For example, the maximum power density and COD removal efficiency by MFC at 435 and 870 mg COD/L day loading rate of the organic substrate is 253.84 mW/m2 with 90% COD removal efficiency and 71.66 mW/m2 with 70% COD removal, respectively.

When the organic substrate loading rate was increased to 870 mg COD/L day, the average PO removal efficiency was 43. Strictly speaking, these results showed that the loading rate of organic substrate significantly affects COD removal, power generation and nutrient recovery from domestic wastewater using MFC technology.

Challenges of MFC for domestic wastewater treatment

However, for the recovery of NH4+-N from domestic wastewater using MFC, the average recovery decreased from 85.11%.

Conclusion

An overview of the use of microbial fuel cells in wastewater treatment, resource recovery and energy production. Recent advances in microbial fuel cells (MFCs) and microbial electrolysis cells (MECs) for wastewater treatment, bioenergy and bioproducts. Effect of organic loading on nutrient and energy recovery in a two-chamber microbial fuel cell.

Continuous electricity generation from domestic wastewater and organic substrates in a flat plate microbial fuel cell. Microbial fuel cell for nutrient recovery and electricity generation from municipal wastewater under various ammonium compounds.