The research contained in this dissertation was completed by the candidate while housed in the Discipline of Chemical Engineering, School of Engineering College of Agriculture, Engineering and Science, University of KwaZulu-Natal, Howard College Campus, South Africa. The content of this work has not been submitted in any form to another university and, unless the work of others is acknowledged in the text, the results cited are the result of the candidate's research.

PLAGIARISM

PUBLICATIONS

FS at 60 mm cross-sectional surface diameter, 5 mm thickness and 0.5 m/s air flow velocity without application of air pre-heating under sunny conditions. FS at 60 mm cross-sectional surface diameter, 5 mm thickness and 0.5 m/s air flow velocity without application of air preheating under cloudy conditions. FS at 60 mm cross-sectional surface diameter, 5 mm thickness and 0.5 m/s air flow velocity without application of air preheating under cloudy conditions.

INTRODUCTION

- Background of the study

- Aim of the study

- Scope of the study

- Objectives

- General objectives

- Specific objectives

- Outline of dissertation

The eThekwini Municipality resorted to the use of the Latrine Dehydration and Pasteurization Machine (LaDePa), which produces dried and pasteurized pellets from FS that can be used as fertilizer and soil conditioner. This study is focused on characterizing the solar drying properties of FS from VIP latrines in eThekwini Municipality through analysis of the drying of FS in a specially designed solar dryer. Explains the experimental apparatus and methods used in the study to meet the objectives (of the study.

LITERATURE REVIEW

Faecal sludge (FS)

- Sanitation systems

- Waste disposal

- Water use

- Individual or communal use

- Ventilated improved pit (VIP) latrines

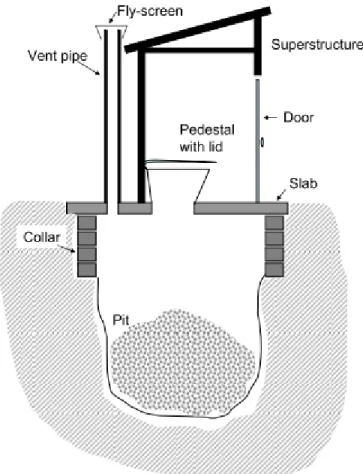

- Description of ventilated improved pit latrines (VIP latrines) and contents

On-site sanitation systems dispose of the waste at or near the location of the sanitation system. Thermal conductivity showed a high dependence on the moisture content of the sludge (Makununika 2016; Mirara 2017; Zuma, Velkushanova et al. 2015). FS has non-biodegradable material in it due to the use of the pit as a disposal option.

Solar energy

- Types of solar energy systems

- Solar thermal systems

- Photovoltaic (PV) systems

- Drying

- Drying technologies

The intermittent nature of solar energy availability results in the need for energy storage systems and subsequently relatively low power density (Bosshard, Hermann et al. 2006). South Africa experiences an average of over 2,500 hours of sunshine per year. solar year and solar irradiance at the surface varies from 4.5 to 6.5 kWh/m2/day (Fluri 2009; Zawilska and Brooks 2011). Thermal energy systems based on solar energy can be designed to satisfy daytime demand and can be combined with energy storage systems to ensure that their operation can be extended to 24 hours of operation while meeting base load requirements (Chaanaoui, Vaudreuil et al. 2016). These systems can be combined to focus the solar energy on the collector (Alsharkawi and Rossiter 2016).

Solar drying

- Components of solar dryers

- Classification of solar dryers

- Direct dryers

- Indirect dryers

- Mixed dryers

- Factors affecting solar drying

- Psychometry

- Drying properties

- Solar irradiance

- Application of solar drying

- Concept of drying

- Moisture in solids

- Types of moisture

- Heat and mass transfer during solar drying

- Process and material related factors that influence solar drying of FS

- Drying kinetics

The drying speed depends on the physical properties of the air and the material. The incident solar radiation is critical, as it is the driving force in the drying process (Kalogirou 2013). The drying rate depends on the difference between the equilibrium moisture capacity of the air and the relative humidity of the air.

MATERIALS AND METHODS

- Description of the feedstock, faecal sludge (FS) from VIP latrines

- Solar thermobalance

- Design of the experimental rig

- Air flow computational simulation model

- Description of the solar thermobalance

- Experimental procedure

- Operating conditions

- Sample and experimental preparation

- Characterisation of the dried sludge

- Quantitative properties

- Qualitative observations

- Data analysis

It was assumed that there would be no expansion of the gas through the drying chamber due to temperature changes. The flow narrows in the last 100 mm of the end to converge and exit the system. The flow meter was previously calibrated in the range of the required flow rates in the drying chamber.

Temperature measurements were performed in the drying chamber, in the ambient air, in the core and surface of the sample. Before the start of the solar drying experiments, solar thermal balance was performed for 15 minutes. Characterization of the samples was carried out to determine the effect of solar thermal drying on the physicochemical properties of the sludge.

Ash content is the amount of material remaining after burning FS in a furnace at 550°C. The quality of dried products is concerned with the color and the visual aspects of the samples. A qualitative analysis of the odor strength was performed before and after the experiment on all samples.

The mass ratio is the ratio between the mass of the sample at a given time and the initial mass.

RESULTS AND DISCUSSION

Drying kinetics

- Effect of weather conditions

- Comparison of open air sun drying and solar drying

- Effect of thickness

- Effect of surface area

- Effect of the air flowrate

- Effect of air preheating

Page | 56 Figure 4-1 and Figure 4-2 show drying curves depicting the change in mass ratio under different weather conditions for open air drying and solar drying respectively. Sun drying varies for a final mass ratio of and 0.97 for sunny, overcast, and overcast conditions, respectively. The solar drying values differ for final mass ratios and 0.55 for sunny cloudy and overcast conditions, respectively.

Open air sun drying refers to the exposure of the sample to direct sunlight without enclosure, whereas sun drying occurs in the drying chamber with a controlled environment (Adair 1985). The results show that solar drying has better performance in each case with a final mass ratio difference of and 0.45 for sunny, overcast, and overcast conditions, respectively. As expected, solar drying gave a better performance with a difference of 0.35 and 0.25 for the 5 mm and 10 mm samples, respectively, with respect to air drying.

Again, the drying rates are comparable, showing the same drying kinetics per surface unit. The samples exposed to 1 m/s formed hard crusts and this limited the drying process by hindering the transfer of moisture to the surface. The natural convection and 0.5 m/s drying kinetics were similar, this was due to natural convection with a low flow rate, which aids the drying rate and makes it comparable to 0.5 m/s, and also highlights the possibility of no significant effect on the drying rate between 0 .0 m/s and 0.5 m/s airflow velocity.

The effect of air preheating was investigated to determine how temperature affects the drying air during the solar drying kinetics of FS.

Analysis of physico-chemical properties of faecal sludge

- Moisture content

- Ash content

- Shrinkage

- Density

- Thermal conductivity

- Heat capacity

- Calorific values and Nutrient analysis

The initial moisture content of the sludge was measured at 78 %, consistent with the findings of Makununika (2016) and Mirara (2017). Indeed, this result is consistent with the typical moisture content of FS from VIP toilets in eThekwini municipality, with the average value recorded at 80. The moisture content showed a high dependence on the drying performance of the investigated drying conditions.

There is no apparent change of ash content under different conditions explored, demonstrating that there was no thermal degradation of the sludge during solar and open air drying. Shrinkage refers to the final volume of the sample compared to the initial volume. The results show that shrinkage is directly related to the amount of moisture lost.

The lower the recorded shrinkage and the higher the moisture content resulted in a higher density, close to the density of the wet FS sample. The thermal conductivity of the wet sludge was measured at 0.56 W/m.K, comparable to the thermal conductivity of water (0.6 W/m.K). This may be due to the high moisture content of the FS, which controls its thermal conductivity.

Therefore, thermal conductivity was observed to decrease with decreasing moisture content during drying of the sample.

Qualitative analysis

As a result, it is critical to analyze the nutrient concentration of the sludge to determine the value of dried FS for agriculture. The results for the caloric values and nutrient analysis were not reliable due to conflicting findings. This showed that the drying temperature significantly affected the color variation as these samples were exposed to higher temperatures.

Crust formation was experienced in most of the conditions, with the exception of cloudy conditions in both sun and sun dry conditions. Less cracking was noted for 60 °C air preheating (11) as it caused a rapid formation of a hard crust, as cracking becomes more difficult. It was found that the moisture content greatly affects the odor strength of the samples - the lower the moisture content, the stronger the smell.

Drying temperature also played a role, with samples preheated at 30 °C (10) and air preheated at 60 °C (11) having a stronger odor, even though the latter had a higher moisture content.

CONCLUSIONS

Page | 83 The moisture content of wet mud was measured at 78%, similar to previous research. The final moisture content depended on the drying parameters, with an average final moisture content of 26% recorded for air preheating at 30 °C, solar drying under sunny conditions and natural convection airflow characteristics. Shrinkage, thermal conductivity, heat capacity, odor intensity and color characteristics closely followed the moisture content.

Final recorded shrinkage average values of 67 % for 30 °C air preheating, sunny conditions sun drying and natural convection air flow characteristics. The color varied slightly with drying, as the dried samples had a darker brown color than the wet samples. The ash content remained uniform throughout the experiments, showing that no thermal degradation of the sludge was experienced in both sun drying and open air sun drying.

Cloudy open air solar drying properties showed no variation with shrinkage, density and moisture content. The average calorific value for the wet sludge was recorded as 13 MJ/kg and for the dried sludge as 6.364 MJ/kg. Airflow rate and preheating were critical in the formation of cracks and crusts and were found to be the critical contributors to crust hardness and amount of cracks.

RECOMMENDATIONS

Improved solar drying and solar drying: basic considerations and selected applications: Food and Agriculture Organization of the United Nations. Evaluation of the influence of housefly magmeal diet on catalase, glutathione S-transferase and glycogen concentration in the liver of Oreochromis niloticus Fingerling. The characterization of stool and urine: a review of the literature to inform advanced treatment technology.

Care must be taken to prevent compaction of the sample in the teaspoon (eg vibrations, rearrangement of sample with spatula, and tapping on the teaspoon). Place the weight on the sample so that it sits on the edge of the test cell. Discard the contents of the sample from the test cell or remove it with a paper towel.

The use of a cover is optional, but it will prevent unwanted evaporation of liquid from the cell. The thermal combustion of the sample is then calculated by multiplying the temperature rise in the calorimeter by a previously determined energy equivalent or heat capacity determined from a standard material. Always keep all parts of the bomb - especially O-rings, insulated electrode assemblies and valves - in good condition.

After firing, move away from the calorimeter for at least 15 seconds and avoid the upper part of the calorimeter. If the bomb explodes, it is likely that the force of the explosion will be directed directly upwards. Remove the gas connection and attach the lifting handle to the two holes on the side of the screw cap and partially lower the bomb into the water.