IV-1 Metals [Zbigniew D Jastrzebski]

Teks penuh

Gambar

Garis besar

Dokumen terkait

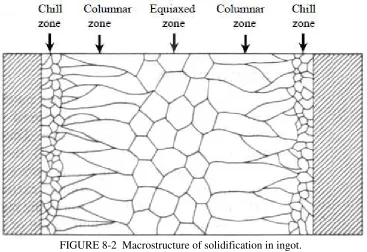

strand. Inside the mould liquid steel solidifies against mould surface controlled by the water cooling mechanism at the back of the surface of the mould. In addition casting

The extrusion limit speed decreases as billet temperature is increased and the increase in concentration of alloying elements decreases the limit speed. High amount of Mg in

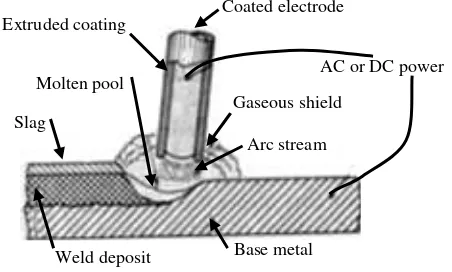

The objective of previous research on the joint of both of the similar and the dissimilar metals, particularly the dissimilar metals (carbon steel and stainless steel) by using the

Corrosion surveillance is done by creating a corrosion coupons made of carbon steel of RSG GAS secondary cooling pipe in the shape of disc and assembled in a

in the cases of titanium, nickel and aluminum alloys.3,4 However, studies concern- ing microstructures and mechanical properties of WAAM-built steel components are still limited.3 In

Under the same applied load, compressive strength of concrete and detailing of main dapped end reinforcement steel had the major effect on the rigidity of main dapped end steel

Results and Conclusions A preliminary analysis of some of the SIBEX chemical data shows the following findings:- Silica An area of decreased silicate and increased oxygen near the

For comparable amounts of alloying elements, the UTS/hardness pairs of the Ti-2.5Al-xMn alloys of this study are similar to other sintered Ti-Mn alloys and the cold-rolled Ti-13Mn