After completing the editing of the last two volumes of the Proceedings, it is clear that by the fact that some authors do not follow the editorial style that has been established. The editor is probably at fault in this because I do not make the details of the desired style more readily available to all members of ASSCT. Adopting the recommended style in writing takes a lot of extra time in editing and typing, especially the latter, and this extensive editing invites mistakes.

However, abstracts are not as suitable as full papers, and authors are requested to submit manuscripts of all papers presented at the three annual meetings of the. However, this information will be of interest and value to many readers, and the organizers of these panel discussions are requested to make some provision for the inclusion of the information in the Proceedings. Operation of an Anti-Fouling Evaporation Process Pilot Plant at the Raceland Factory of the South Coast Corporation - Jay Dornier.

In preparing for this talk, I first made a list of problems of the Louisiana sugar industry. Then I made a list of things that encourage me regarding the future of the Louisiana sugar industry.

WORRY ABOUT

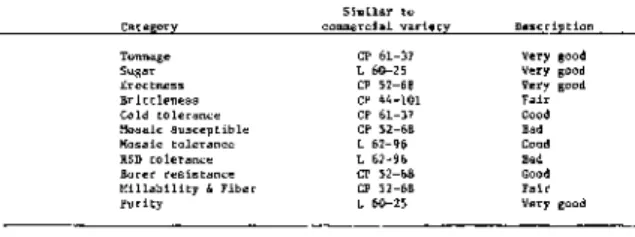

A NEW SUGARCANE VARIETY FOR LOUISIANA!/

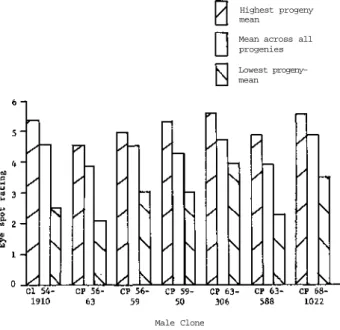

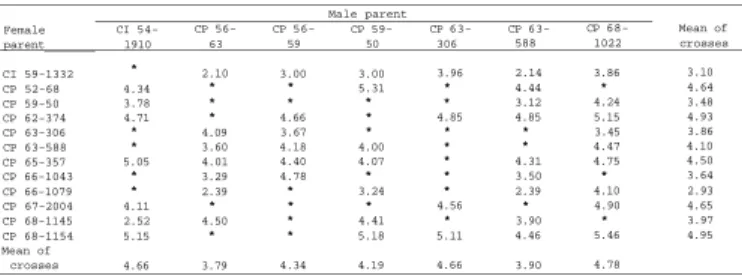

The role that the sugar cane mosaic played in the decline of the Louisiana sugar cane industry in the mid-1920s needs no retelling. A large mosaic inoculum set was constructed in the 1960s in all but the northern Louisiana sugarcane belt. More than half of the seedlings (57.2%) remained mosaic-free in the cross progeny between the 1971 CP varieties from US 56-15-8.

The developmental stage of the plant was assessed by the number of leaf symptoms, i.e. the number of leaves with leaf surfaces that developed on the mother shoot up to and including the oldest leaf with symptoms. Sugarcane mosaic in the United States with special emphasis on virus strains. However, Ceratocystis (2) and Phytophthora often caused severe seed rots in poorly drained areas where the soil remained wet and relatively cool (8). The impact of pathogenic fungi on cane stands can result from two different modes of action: 1) attack on roots, thereby indirectly affecting the growth of developing shoots (Pythium spp.), 2) direct attack on seeds and buds (other fungi).

To test the effect of the 5 fungi on the germination of the 7 varieties in the field, a factorial design was applied. It was therefore possible to determine the effect of the 3 fungi on the viability of non-germinated buds.

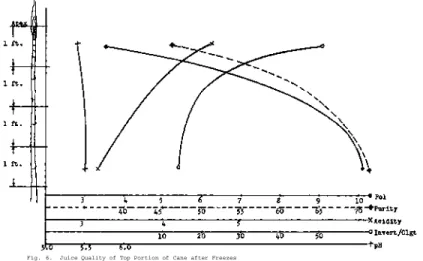

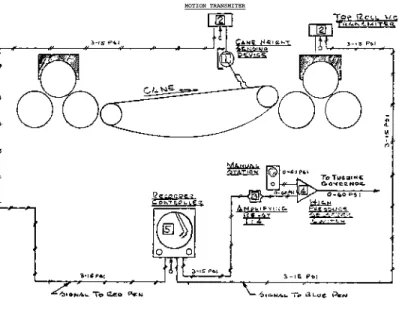

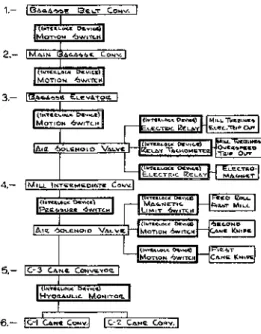

The quality of juice in the tops indicates the degree of decomposition and its effect on the quality of the stems. Automation of the mills: The first mill is set to a certain fixed speed according to the desired grinding speed. It is at this stage of the sugar manufacturing process that automation results are most beneficial.

So, we move on to the automatic control of the feeding of syrup and/or molasses. One of the biggest losses of sugar in our industry is that which goes to the final molasses. Two important facts were revealed from the analyzes of the final molasses in the comparison table:

In addition, the particle size distribution of carbon particles and solid mineral particles was required. An isokinetic sample should be taken to obtain a truly representative sample of the particles flowing in the stack. The gas velocity in the stack and the velocity and total volume of the entrained sample are also measured.

The location of the sampling ports and the position of the probe in the stack are critical factors. One element that is very important in the grinding procedure is the cleanliness of the mill. Due to corporate relationships stemming from the establishment of The South Coast Corp., our company's bagasse production has historically been dedicated to the Marrero plant of Celotex Corporation.

We can add that the highest operating cost of the pneumatic system has also been considered. The only remaining alternative was to operate at reduced capacity for most of the crop. It was clear that the high density was due to excess mud or lowland soil in the bagasse, which was the result of abnormal rainfall.

The soil varied from Loring silt loam (Soil I) on the upper part of the experimental area (slope = about 3%) to Loring-Olivier silt loam (Soil II) to Olivier silt loam (Soil III) on the lower part of the area . This weight, divided by the weight of a known area of the same paper, yields the leaf area.

SES 196

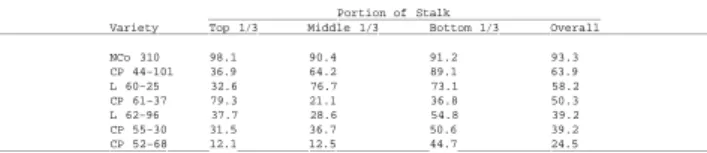

Juice carbonate ash content of the 3 varieties in Table 3 for the period before the Mar. Data for the variety CP 61-37 showed good viability in the upper third of the stalks and poor in the rest. The variation in the amount of vapor that is blown out is due to the operational sequence of the vacuum pans.

The use of water on top of the massage to reduce viscosity should be completely avoided. In Table 1 we show a comparison of the decline in purity in high grade masakas in 3 different sugar houses. In table 2 we can see the calculation of sugar recovery from each massage in the above cases.

This article reports the results of field studies conducted during the 1972-1973 crop season to evaluate field losses, waste content, and length of cut resulting from the use of various mechanical harvesting systems in the Florida sugarcane region. In addition, the composition of the waste (amount of green and dry matter) can have a negative effect on the quality of the extracted juices and the recovery of raw sugar. Losses for the two manual mowing systems averaged 2.84 tonnes per hectare, or an average loss of 5.3% of total yield.

The schedule for estimating CRS per ton of sugar cane is related to the cane's NJS (7). The mechanical harvesting cost estimates for the 1972 crop are weighted averages of the costs of 3 mechanical harvesting systems. In contrast, the labor cost component of the hand-cutting system is likely to continue to rise.

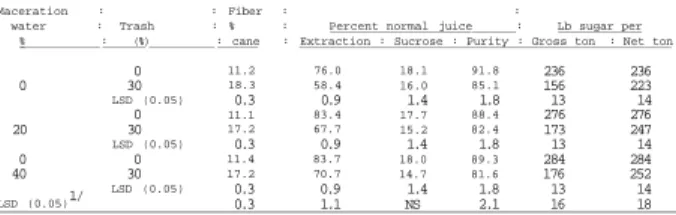

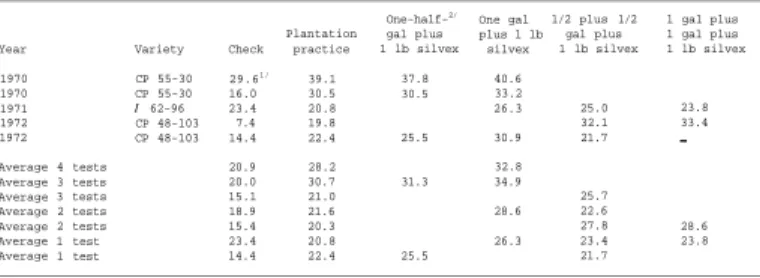

Not since the early 1940's and the advent of the mechanical harvester have there been so many concerns about the quality of cane fertilizer and milling. The first experiment conducted in the 3 milling seasons 1971-72 and 1972-7 investigated the effects of cane fertilizers on the milling quality of the variety CP 61-37 in cane culture. Twenty percent cane waste was added to duplicate 80-1b cleaned, random stem samples of variety CP 61-37 on plant cane in the following forms: 1.

In a combined analysis of the 2 years of data for the first experiment, there was a significant increase in both bagasse and fiber% cane with each successive increase in cane litter. At 30% litter, normal juice extraction was only 87% of that of the no litter control.

Percent

- EQUIPMENT DESCRIPTION

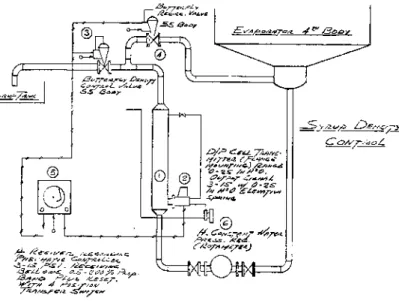

- OPERATION OF THE PROCESS AS A 2ND BODY

- OPERATION AS A 4TH BODY

In the fourth experiment, maceration water led to a recovery of the sugar that would have been lost in cane waste (Table 5. This was due to the decrease in extractable normal juice and the decreased normal juice purity. The poor effect of waste mixing on fiber% of cane and at normal juice extraction was in proportion to the amount of added dry waste.

This initial phase of the investigation covered (a) cane quality as determined from small scale (100 lb) samples and (b) cane quality and processing response at plant scale (2 to 3 tons). The cane quality criteria were gum and dextran content and the number of Leuconostoc mesenteroides in the extracted juice. These factors created difficulties in coordinating cutting and delivery with mill requirements and controlling field operations.

Audubon Sugar Factory's primary area of focus is the processing response of conventionally harvested cane and alternative harvesting systems. This phase of the studies looked at the processing response of cane harvested by (a) conventional mechanical top and bottom cutting, stacking, burning and transfer by mechanical loader to field carts and (b) a combine harvester in which the cane is cut top and bottom in the usual way, chops to 20 inches. Particularly striking is the similarity in quality of the hand-cut cane samples (although they were obtained from different fields) and the large differences in factory cane quality.

Both the dextran and gum analyzes gave a good indication of the cane quality and in the processing response of the juices. Although there is a difference between core samples from the same shipment, there is no bias relative to the location of the sample in the load. Transfer of the cane shipment and core samples from Cinclare to the Audubon Sugar Factory was accomplished by means of a 2 1/2 ton truck.

After de-sampling, the cane was milled in the factory milling tandem with the addition of 20% maceration water and a final mill rotation speed of 30 fpm. As previously mentioned, core samples were removed from the back, middle, and front of the package in most cases and processed separately in the Farrel mill. The correlation of the amount of liquid in the cane is shown in Table 3 as a bagasse factor relating the plant to the base sample of bagasse cane.