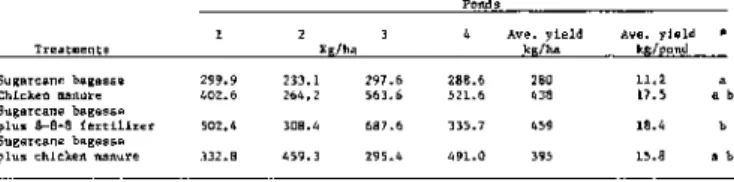

Our estimates are that HFCS production could double over the next three years - to the detriment of the sugar industry. In the fourth treatment, the sugar cane filter cake was applied directly along one side of the. In this study chicken manure gave the highest average yield at 600 kg/ha (Table 2), which is higher than that obtained in the first study for the same treatment probably due to early flooding.

It has been found that pomace, the residual material obtained from the crushing and milling of sugar cane, is used in a number of ways in the sugar producing areas of the world. This was evidently due to the enormous accumulation of seed in the soil (Tables 1 and 2. On December 7, efforts were made to harvest the driest fields in the valley.

In several sites, the electrical conductivity of the saturated extract (ECe) exceeded 4 and 3 mmho/cm, respectively, at the 150-cm depth in the cut and fill areas. A salt water table severely reduced the establishment and growth of the reed plant, especially in the cut-off area.

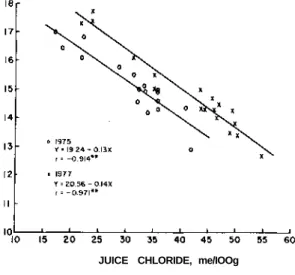

JUICE NITROGEN, me/IOOg

JUICE CHLORIDE, me/IOOg

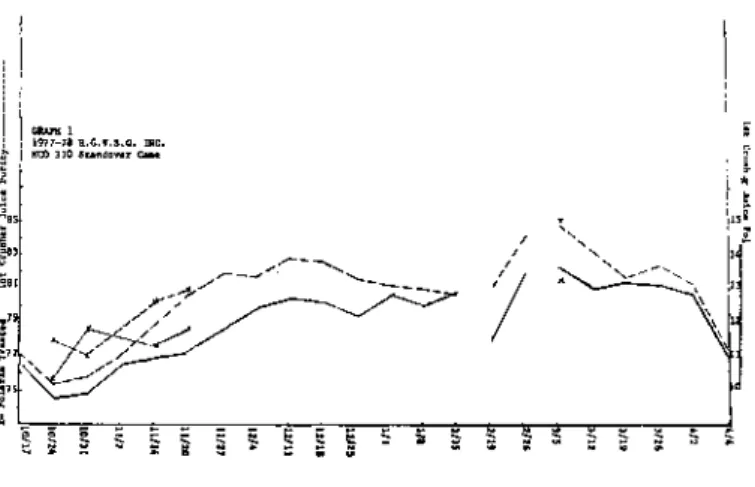

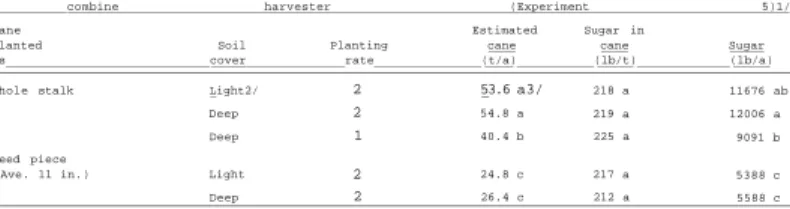

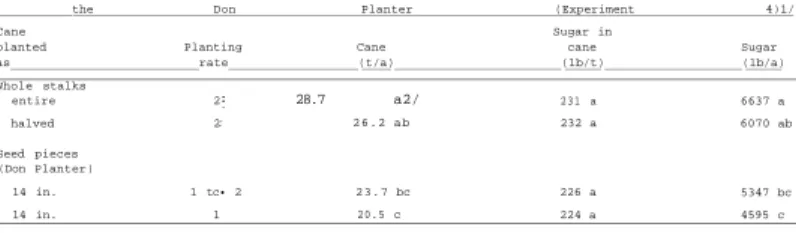

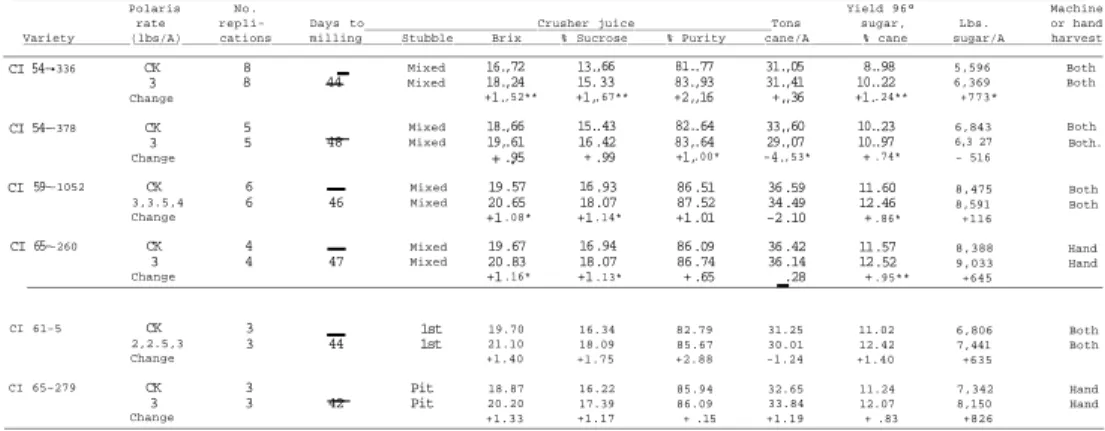

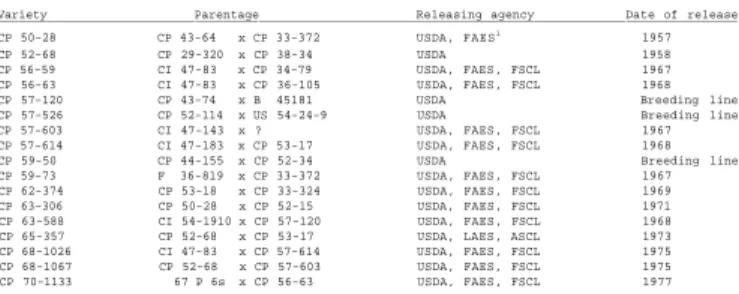

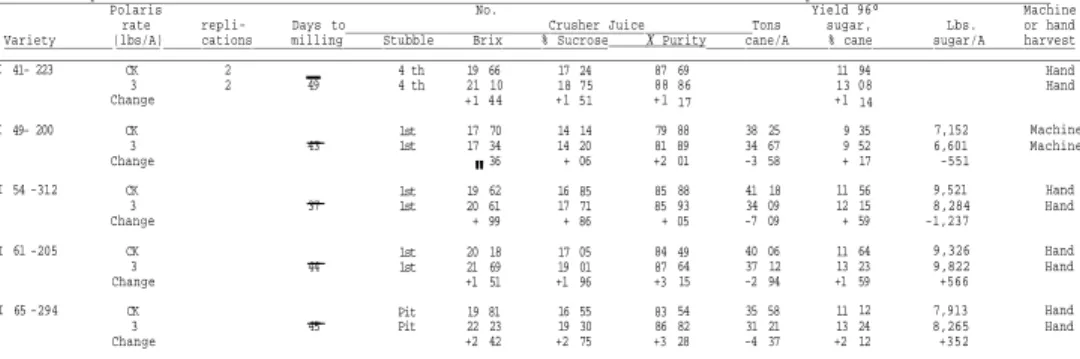

A three-way agreement between the Florida Sugar Cane League, Inc., the University of Florida and the U. Department of Agriculture, the Louisiana Agricultural Experiment Station and the American Sugar Cane League of the U.S.A., Inc. Yield of sugar cane and sugar per acre was estimated from the number of millable stalks and from the average stalk weight and sucrose content of the sample of 15 stalks.

There was no evidence that sticking leaf sheaths and seed cane blades caused any mechanical problem in the Don planter. In one of the two treatments, each stem in the furrow was cut in half. When the ten tests were averaged together, the whole stalks yielded 101.7% of the general sugar average per acre, and the two-bud seed pieces 94.3%.

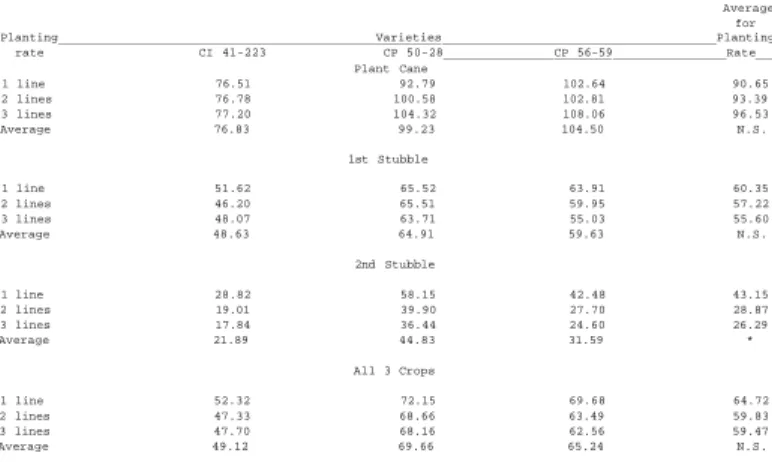

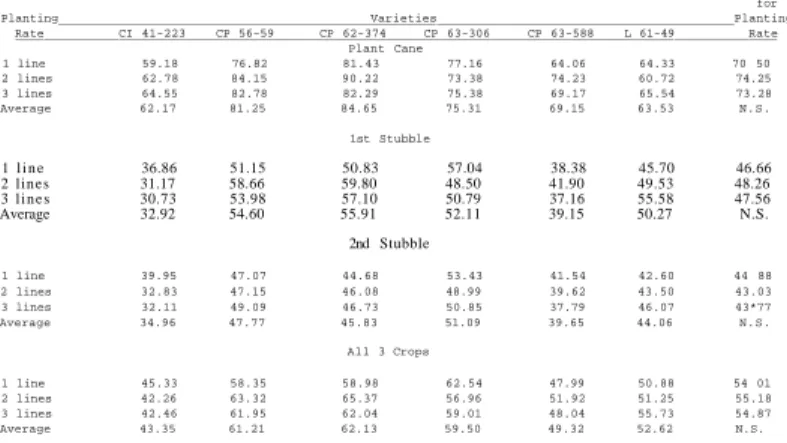

The expansion of Florida's sugarcane industry in the early 1960s resulted in increased acreage and different planting rates. In trial B, there were no significant differences between planting rates in any of the 3 crops.

47 Mixed

Sugarcane producers were then interested in the best method of disposing of the unharvested sugarcane. The simplified Winter-Carp-Geerlig's formula was used to calculate the sugar content of the sugar cane. Sugar/ha was the product of the calculated sugar content and the harvested cane weight.

Since the burned/unburned treatments were not randomized, statistical comparison of the disposal methods in the two experiments could not be made. However, due to the rapid closure of the canopy in the 0.5 m plots, much less weed control was required in 0.5 m rows than in 1.5 m. The top of the bar is fresh weight and the bottom portion is dry weight.

Equivalent harvesting capabilities in both crops can be achieved by increasing either the harvester's cutting width or its ground speed in sweet sorghum. First, these machines cannot harvest sweet sorghum at an economical rate due to the lower yield of sweet sorghum compared to sugarcane. The sweet sorghum tested had an initial leaf litter content of 25 percent with dry leaf condition.

This unit was first tested without a device to hold the tops of the sweet sorghum trees. The modification has been very successful in increasing the capacity of the harvesters in sweet sorghum. Sweet sorghum cropping system research is a necessity before large-scale production of the crop becomes feasible.

My presentation indicates some of the techno-economic factors affecting sugarcane and sweet sorghum as a renewable resource for energy or chemical production. Tables 4 and 5 show some of the estimated effects of close spacing on sugarcane and sweet sorghum production costs. The salt concentration or ionic strength of the solution is another important factor in the reaction.

The concentration of sugars in the treated sample was determined as a percentage of the original 7.2 g sucrose sample. It reduces the effect of the relative concentrations of sugars in the samples and the sample size ratio.

1 10 Time (h), log scale

SUGAR POL 97.6 4. FINAL MOLASSES PURITY 30

In 1973, the OPEC countries drastically raised the price of fuel oil, and since then the world's fuel oil consumers have realized that they are making better use of energy; this is especially true for the sugar industry. Recently, much attention has been devoted to the dehydration of bagasse using waste flue gases from mill boilers as the primary heat source. The main reason most mills are interested in dehydrating bagasse is the potential to increase its value as a fuel, which thermodynamically means increasing its heat of combustion.

The result of this effort is the reduction or elimination of supplemental heating of fuel oil. Several manufacturers now offer bagasse dehydration systems that can reduce bagasse moisture to much lower levels. This report is an economic study based on fixed costs, operating costs, and performance of a typical rotary drum dryer using flue gas as the primary and only heat source.

In 1973, the OPEC countries raised the price of fuel oil drastically, and since then the world's fuel oil consumers have found that they need to make better use of energy. In recent months, much attention has been paid to the drying of bagasse, which uses the flue gases from the mill's boilers as the primary heat source. The primary reason most mills are interested in dehydrating bagasse is to increase its value as a fuel, which thermodynamically means increasing its heat of combustion.

Several dryer manufacturers now offer bagasse drying systems that can reduce the moisture content of the bagasse to much lower levels. This report is an economic study based on the fixed costs, operating costs and capacity of a typical drum dryer using flue gas as the primary and sole heat source. While the process itself is not complex, the savings that can be achieved, and thus the justification for the capital investment, are elusive.

This paradox is true since the capacity of the dryer varies with the temperature of the flue gases, and the bagasse combustion heat varies with the initial and final moisture content of the bagasse. The return on investment for a single system is further based on the total increase in heat of combustion of the bagasse in terms of fuel equivalence and the local price of that fuel. The return on investment will be shown in terms of the number of years required to pay back the initial capital invested for the dryer system.

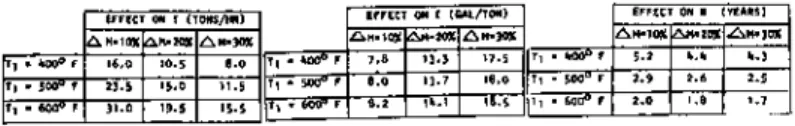

DRYER CAPACITY VERSUS STACK GAS TEMPERATURE

INCREASE IN HEAT OF COMBUSTION OF BAGASSE IN TERMS OF FUEL OIL EQUIVALENCE

COST OF DRYER SYSTEM

OPERATING COSTS

The cost of materials to repair and replace parts is assumed to be approximately $15,000 per year.

RETURN ON INVESTMENT

Sample analysis of the effect of varying stack gas temperature (T1) and moisture reduction (ΔM) on dryer capacity (T), fuel oil equivalence (E) and return on investment (R). The following derivation is used to determine the heat of combustion of bagasse as burned in the boiler at varying moisture and ash contents. Populations of the sugarcane borer, Diatraea saccharalis, were unusually high in the Rio Grande Valley of Texas in 1977.

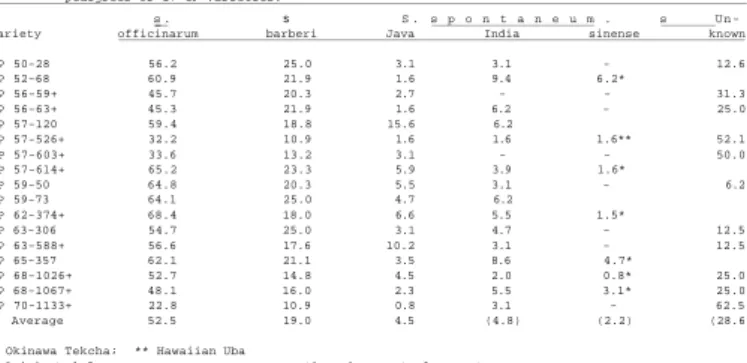

The intensity of color development in the ELISA test is directly related to the number of bacteria present in a sample. The sugarcane variety CP 65-357 was planted in the fall of 1976 on flat land in Houma, Louisiana. Sugar Cane Field Laboratory, USDA Science and Education Administration, Houma, Louisiana (in collaboration with the Louisiana Agricultural Experiment Station).

A study of the relationship between seed set in sugarcane crosses and floral organ condition was made in Houma, Louisiana. Thirty-two varieties of sugarcane were grown in the greenhouse in the fall of 1977. This will probably result in the transmission of some cold resistance to commercial varieties of sugarcane.

Sugarcane in the Rio Grande Valley of Texas is harvested from mid-October to mid-April. FIELD EVALUATION OF INSECTICIDES FOR THE CONTROL OF BOTHYNUS SUBTROPICUS WHITEGROUP IN FLORIDA SUGAR CANE. The application of high pressure liquid chromatography to the fractionation of sugarcane saccharides using cation exchange resins is described.

Previously, it was impossible to provide an outlet for the pool of sugarcane juice lying on top of the cane blanket entering a mill. A higher grinding rate and a higher extraction are expected from the use of the Lotus Roll. The determination of ash in bagasse poses a similar problem to that of determining Pol or fiber in cane.