I declare that this Industrial Attachments report has not been taken or copied from anywhere. I also declare that neither this Industrial Attachment nor any part of this Industrial Attachment has been submitted elsewhere for the award of a degree or degree. First of all, I would like to express my heartfelt thanks to almighty ALLAH for his kind blessings for the successful completion of this internship report.

I would like to thank the management of Knit Concern Limited for giving me the opportunity to do the industrial training successfully and also their valuable suggestions. I would also like to thank the directors, senior management and other officers of Knit Concern Ltd. I would like to thank the Staff who fully motivated me and other people who have made a significant contribution to make this report a success.

I am only writing to let you know that this report on industrial attachments entitled "Industrial Attachment at Knit Concern Ltd." is drawn up by the student with proof of identity. It will therefore be highly appreciated if you accept this Industrial Annex Report and consider it for final evaluation.

EXECUTIVE SUMMARY

INFORMATION ABOUT FACTORY

INTRODUCTION

HISTORY OF THE FACTORY

FOUNDER & DIRECTORS

GENERAL INFORMATION ABOUT THE FACTORY

Location layout

Layout

Organogram

Sister Concerns

Export growth by graph

Product mix

Brief Profile

Major buyers with their Logo

Certification

Other Facilities & achievement

Mission and vision

Knitting Section

- Layout

- Organogram for Knitting Section

- Production Flow Chart of Knitting Section

- Product Details

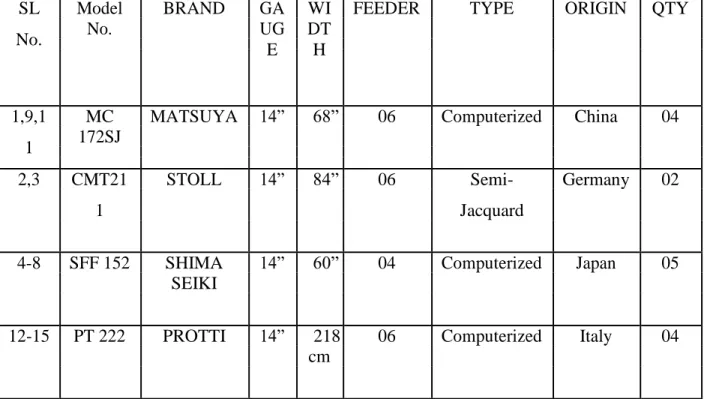

- Machine Description

- Types of Fabric Produced in KCL

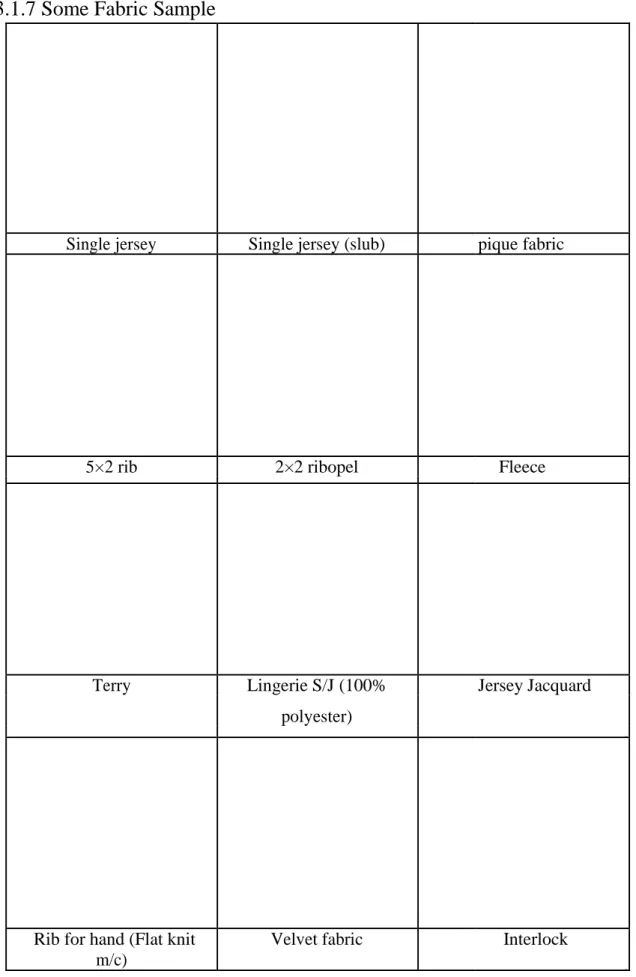

- Some Fabric Sample

- Knitting Faults & Remedies

If a needle or needle hook bends a little, then the needle mark comes into the fabrics. When the sink is corroded due to corrosion, then sometimes it cannot hold a new loop resulting in the sink mark. If the thread is not fed properly during loop formation, i.e. not properly placed on the needle hook.

When the oil licks through the needle trick, it passes onto the fabrics and makes a line.

Sample Section

- Layout

- Organogram of Sample Section

- Sample

- Types of sample & their uses

- Flow Chart Sample Making

- Machineries of Sample Room

- Pattern making

- Some sample Sewing

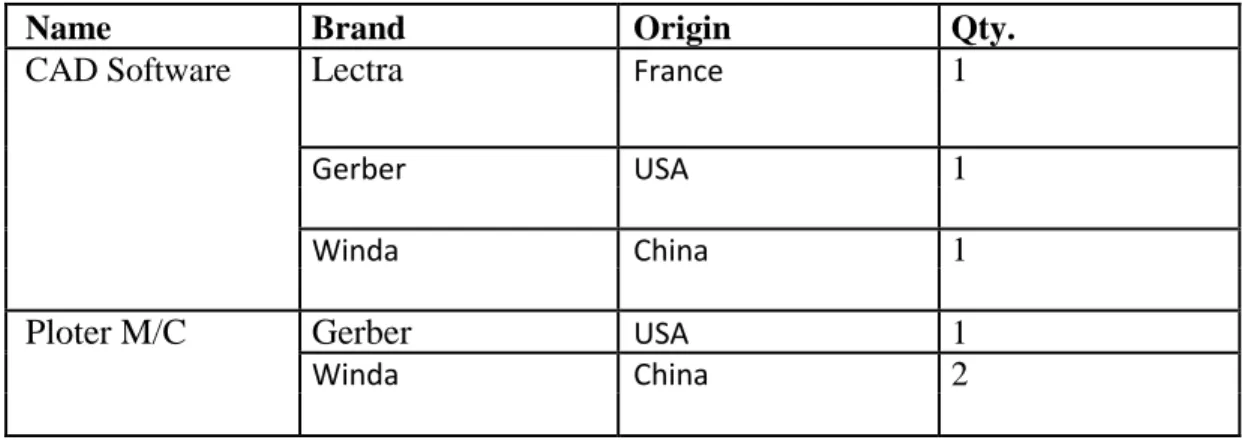

- Pattern & Marker Making Machinery

- Pattern grading

- Marker

- Marker Efficiency

- Sampling Requisition Flow Chart

Knit Concern Limited has a separate sampling department located on the 7th floor of the garment building. This department includes various sections such as pattern making, mark making, consumption of fabric, consumption of thread and accessories etc. The instructions to be sent by the pattern maker to the production department are called production pattern instructions.

The following instruction must be marked on the garment pattern to enable the garment to be made correctly. Knit Concern uses the latest computer aided systems to develop patterns and markers to thrive to ensure that every garment it produces would be an identical reproduction of the approved samples and the fabrics it uses to make the garment would leave as little waste as possible. The ratio of area of pattern pieces placed on the marker to the total area of the marker expressed as a percentage is called marker efficiency.

Cutting Section

- Layout

- Organogram of Cutting Section

- FABRIC CUTTING

- PROCESS SEQUENCE IN CUTTING ROOM

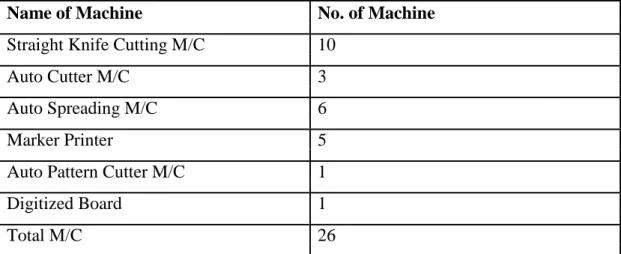

- List of Machines

- Cutting Table Specification

- Spreading

- Methods of Fabric Spreading

- Description of Cutting Machine

- Numbering

- Quality Inspection and Replacement

- Bundling

- Sample of Bundling

Cutting is the most important operation of the cutting room, when the dispersed fabric is cut into garment components. Of all the operations in the cutting room, this is the most crucial, because once the fabric is cut, very little can be done to correct serious mistakes. Spreading is a process by which layers of material are spread to get the desired length and width according to marker dimension.

In other words, spreading is the process of stacking layers of fabric to allow for simultaneous cutting. A roll of cloth is taken and its edge is attached to one end of the table and then spread on the table without any apparatus, completely by hand. There is an automatic spreading machine with a layer cutting device with an automatic catcher to hold the end of the layer in place.

In this method, the spreading machine works with the help of electrical and mechanical speed. It is designed with a low center of gravity for easy handling and has the best power-to-weight ratio in the industry. All components of the same size are grouped together and numbered by workers using a numbering machine.

SEWING SECTION

- Layout of sewing section

- Organogram of Sewing Section

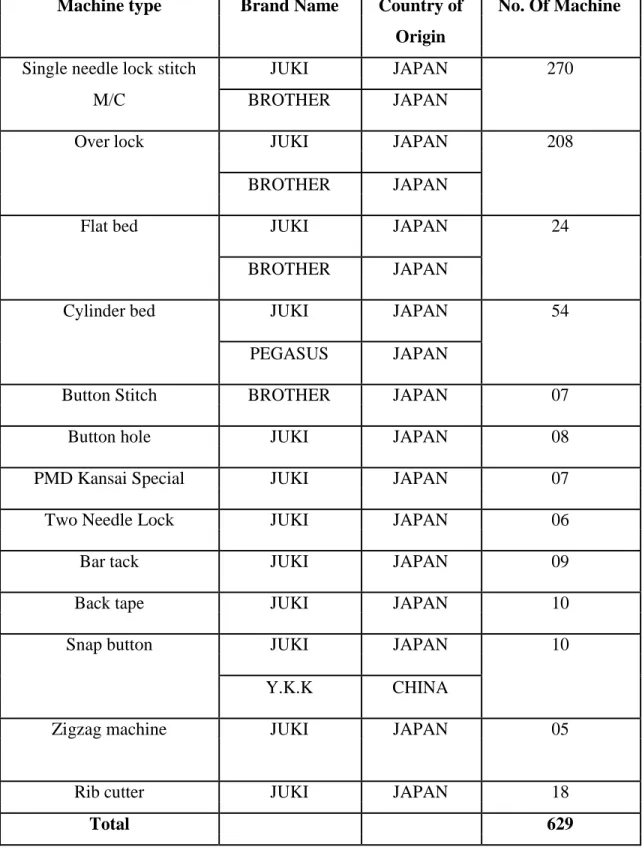

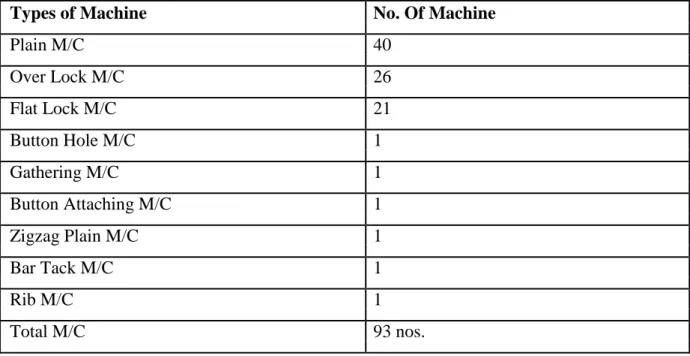

- No. of Machines used in sewing section

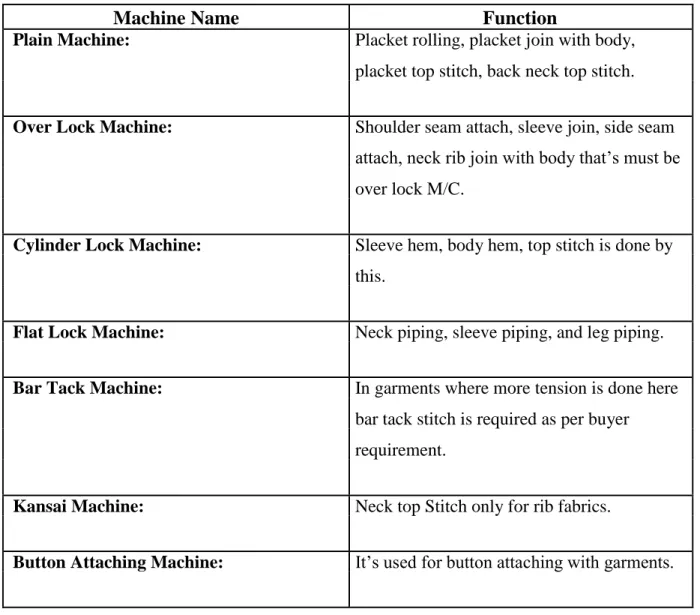

- Function of Sewing Machine in Knit Garments

- WORKING PROCEDURE OF SEWING DEPARTMENT

- Sewing Defects

- Some Accessories Sample

Regular machine: wrinkle rolling, wrinkle connected to body, wrinkle top stitch, back neck top stitch. Overlock machine: Shoulder seam seam, sleeve seam, side seam, neck rib seam with body to be over lock M/C. Bar stitch machine: In garments where more tension is done here, bar stitch is required as per buyer's requirement.

Sewing is a process in which the cut surfaces of the fabric are joined with thread to form the garment. Like open seams, incorrect sewing techniques used, same color garment but using different color threads on the garment, missing stitches in between, wrinkling of the garment, incorrect thread tension and raw edges are some of the sewing mistakes that can occur, so be careful. When two or more layers of fabric are sewn together, one layer will feed more than the other, resulting in an uneven seam, causing seam puckering.

When two or more layers of fabric are sewn together, one layer shrinks more than others, resulting in a second seam pucker. We must test the shrinkage percentage of both fabrics before sewing and it must be less than 2%. Mainly due to needle damage, we can see this type of defect at the seam line.

With this fabric damage, the sewing strength becomes low and more fabric damage can cause the fabric to tear at the sewing line.

Finishing Section

- Garments Finishing

- Process Flow Chart of Garment Finishing

- Work flow in the Finishing Section

- Machine Description of finishing section (Knit Concern Ltd.)

- Accessories used in garment finishing

- Spot Removing

- Pressing

- Folding

- Packing

- Barcode

- Metal Check

- Cartooning

- Final inspection

At this stage, attach the necessary tickets (price tickets) or tags (hang tags) etc. to the clothes. Label pin Paper tissue Al pin Elastic clip Hanger Poly bag Size label Gun barrel. Pressing is a finishing process applied to fabric by heating and pressing with or without steam to remove wrinkles and give the fabric or garment a flat appearance.

Checking the metal type component in the garment or its accessories such as button, chain, etc.

WASHING SECTION

- ORGANOGRAM of washing section

- List of Machines

- Different types of washing

- Working Flowchart of Washing Section

- Washing Process of Normal Wash

ETP

- EFFLUENT TREANTMENT PLANT (E.T.P.)

- Types of E.T.P

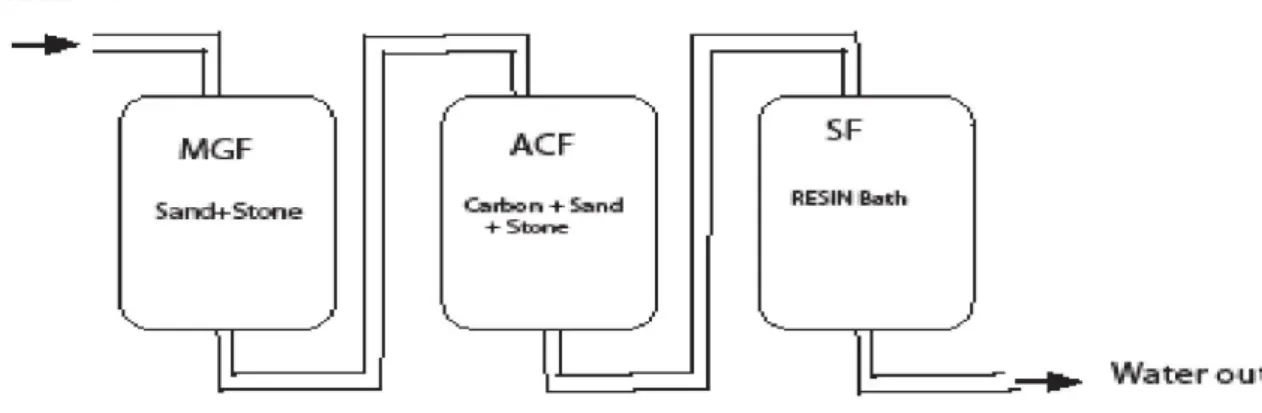

- KNIT CONCERN LTD E.T.P

- Project Description

- Plant Equipment

- Chemical used in different Section

- Function of different chemicals

- Types of micro-organisms used in KCL

- Object of ETP

- Process Sequence

- Specification of the Blower

- Standard Testing Parameters

COMPLIANCE

- Definition

- List of Compliance issues

Utility Sections

- Water

- STEAM BOILER

- ELECTRICITY/GENERATOR

- Compressed Air/Compressor

By means of the booster pump, the treated water is supplied to the dyeing m/c pipeline line, where the pressure of 4 kg is always kept constant by the automatic control of the booster pumps. Steam produced by the boiler Feed water is simply treated in the boiler section by the two softener tanks Then the water is stored in the feed water tank and this water tank heats the water and then the water goes to the boiler which produces steam and that steam is supplied to factory. Natural gas is piped through the filter above the compressor and the air is compressed.

Thus the cold water becomes slightly hot and passes through the outlet pipe to the upper tank. Moist compressed air is transferred to the dryer and a light warm compressed air is distributed to search sections of KCL.

IMCACT OF INTERNSHIP

- KNITTING SECTION

- SAMPLE SECTION

- FABRIC CUTTING SECTION

- SEWING SECTION

- IMPACT OF FINISHING SECTION

- WASHING SECTION

- ETP

- COMPLIANCE

- UTILITY & MAINTENANCE

Learned about the different types of machines used on a sewing floor (ie single or double needle sewing machine, Multi needle chain stitch machine, Overlock machine, Arm machine feed etc.). Learned about the different types of accessories used to attach to clothing (eg security alert, hang tag, price tag, barcode tag, etc.).

Conclusion

Figure: .1 Circular Knitting Machine

Figure: .1 Sample room

Figure: .2 Fabric spreading by mechanical method 38

Fig .3: Folding

Figure .2: Washing m/c (Side loading)

Figure .1: ETP plan