This report submitted in partial fulfillment of the requirement for the degree of Bachelor of Science in Textile Engineering. I hereby declare that this internship was done by under the guidance of SumonMozumder, Assistant Professor, Department of Textile Engineering, Faculty of Engineering, Daffodil International University. This report is submitted in partial fulfillment of the requirements for the degree BACHELOR OF SCIENCE IN TEXTILE ENGINEERING.

All pleasure goes to almighty God for giving me strength and ability to complete my two months industrial attachment with Scandex Textile Industries Ltd. We are grateful to our academic supervisor SumonMozumder, assistant professor, Department of Textile Engineering, Faculty of Engineering, Påskelilje international University as well as to Mr. MahbubulHaque, Head, Department of Textile Engineering, Faculty of Engineering, Påskelilje international university for his kind help in completing my training report.

Scandex Textile Industries Ltd” is one of the companies of (Panama Group). This company produces high-quality textile products. With this report I have tried to provide some information about “Scandex Textile Industries Ltd” where textile products for knitting, dyeing and finishing are produced.

Information about factory

Factory Layout

Knitted gray fabric: Plain single jersey, single jersey, Heavy jersey, waffle, Rib, Interlock, Single stripe, Single piqué, Double piqué, Fleece, French.

Organ Gram of the Company

Vision

Here, collars and cuffs of any design are produced on semi-jacquard and jacquard machines. The yarn used in the body fabric is also used to make the collar and cuff. The final GSM in the finished fabric depends on the finish and the parameters of the finishing machines.

GaugeNeedle gauge determines the number of loops in a course which in terms determines the GSM of the fabric. Primary recipe is make from the laboratory and give for large amounts of dust paint in the paint floor. For liquid, X ml/cc chemicals/dyes/aids in the (100 - x ml/cc) water is called x% stock solution.

Purpose: Turn the surface of the fabric to avoid unevenness on the front of the fabric. In this process, the dye molecule partially enters the fabric and ultimately produces colored fabric. During my internship period, I learned a lot of knowledge about my subjects and other subjects in the industry of “Scandex Textile Industries Ltd”.

This opportunity was a better opportunity for my future life to sustain in the job sector. In this section, you will use different types of finishing machines and chemicals that help to finish the fabric. This training period is so much useful for my academic theoretical knowledge that it helped me how can I ask questions in the practical sector.

Daffodil international university"give me this opportunity &"Scandex Textile Industries Ltd."Fulfillment of my complete industrial education.

Mission

List of Buyers

A Short view of the company

KNITTING SECTION

- Introduction

- Organ gram

- Knitting lay-out section

- Machine Specification (Flat Bed Knitting M/C)

- Specification of Single Jersey Circular Knitting M/C……………………16-17

- production flowchart of knitting M/c

- GSM

- Loop length

- production calculation………………………………………………………20-21

Scandex Textile Industries Ltd." is capable of producing stripes of any width and enormous colors. Single jersey fabrics and its derivatives like lacoste, polo-pique, terry fleece etc. are produced. Fabrics of various shapes can be produced from semi-jacquard processed by varying the tucking lengths and loop sequences.

The jacquard design can be easily computerized and transferred to the disc knitting machine. This section is capable of producing versatile circular woven structures especially in engineered stripes and semi jacquard patterns. Rib base collar and cuffs are also produced in flat knit in a different shade equipped with half jacquard and V-bed jacquard flat knitting machines.

In this purpose, we were meant to primarily include production stages, parameters, resources, quality assessments machine specification alone with the machine layout in a short time. It is the crucial parameter that is controlled and controlled at various stages of processing the fabric after knitting to finishing. When the throughput time is very short, the number of revolutions can increase to a certain level for a certain number and strength of the yarn.

So it also depends on the yarn parameter and also on the structure to be produced. It depends on the necessity of production, available cone packages, knitting color and.

DYEING LABORATORY SECTION

- Introduction

- Organ Gram

- Dyeing & physical lab lay-out

- Description of chemical & physical lab lay-out

- Light box

- Sample dyeing m/c

- Washing m/c

- Sample dyeing m/c

- Recipe calculation

- Stock solution making procedure

- For light medium shade (cotton fabric) with cold brand dyestuff

- Dyeing procedure

If here is to produce desire form color fabric, then it goes to for the color of large quantities of production. 1000× concentration % stock solution Amount required % × weight of substrate × LR Required Alkali solution in (cc/ml). Caustic soda: The amounts of alkali recommended for the respective procedures refer to caustic soda 30%, 66Tw (36Be).

For other concentrations, quantities can be calculated with the help of the following table: Density and conc. Then place the beaker in the sample dyeing machine and set the dye bath to 38oc. After that we lower the temperature of the sample dyeing machine and take the sample from the machine and the sample is ready for post treatment.

BATCHING SECTION

- Introduction

- Objectives of batching

- Name turning m/c

- Flowchart of the batching M/c

Batch preparation can be defined as a process where the visually inspected gray fabric is divided into different batches. It is part of the dying process and is done to feed the dyeing machine.

DYEING SECTION

- Introduction

- Organ gram

- Dyeing section lay-out

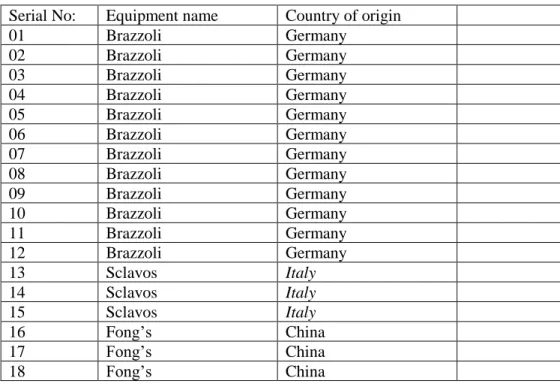

- Description of fabric dyeing floor lay-out

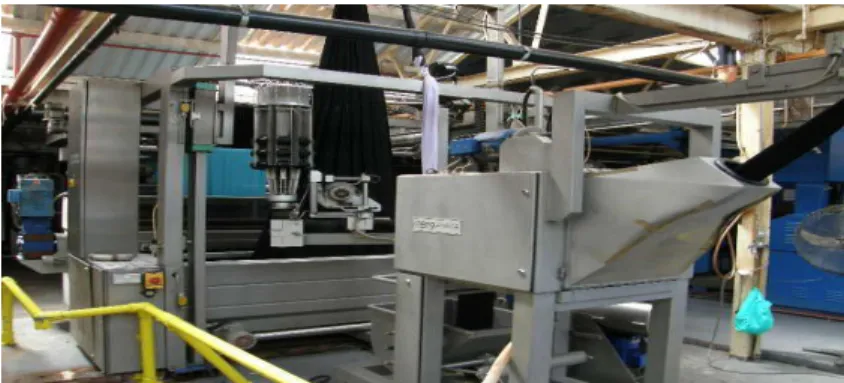

- Fong sample dyeing M/c

- Sclovos dyeing M/c

- Flow chart of fabric dyeing

Different types of dyeing process are used like cushion dyeing process, continuous, semi-continuous dyeing process like steam dyeing process, jigger dyeing process etc.

FINISHING SECTION

- Introduction

- Organ gram

- Finishing section lay-out

- Finishing section flowchart

- Description fabric finishing machine…………………………………………46-49

- Introduction

- Utilities ensure the followings

What is the final processed fabric that before the fabric is cut for clothing or made into any textile component. The final task is heat setting, napping, embossing, dyeing and using chemicals that change the character of the fabric. Maximum fabric passing speed: 60 m/min Maximum fabric diameter capacity: 225 cm Minimum fabric diameter capacity: 65 cm Maximum over feed (%): 40%.

Scandex Textile has two generators that always supply on time and ensure dyeing. Scandex Textile has a submersible well which always supplies water on time which is very important for dyeing and other parts. There is a treatment plant to help control the PH of the water. Reduce utility costs by using this process.

EFFLUENT TREATMENT PLANT

- Introduction

- Effluent analysis report

- Effluent plant lay-out

- Equipment of ETP laboratory

- Biochemical reaction

- Process water test report

Here, bacteria and protozoa are the catalyst of biochemical reaction to convert the toxic material into environmentally friendly gases and substances. Bacteria decompose the organic matter and other substances relate to oxygen through microbial action, biochemical reaction and produce gases and free radicals.

MAINTENANCE

Introduction

Maintenance is the process of keeping equipment running smoothly.

Maintenance system used in SKFL

In this section I also learn about different types of fabric design like Single jersey, rib fabric, interlock fabric, Lacoste etc. Here it is used for small amount of dyes and chemicals for small amount of fabric sample.

This industrial training was a great opportunity for me to get to know the industries &. During the training I also learned the finishing work, how to finish after dyeing the fabric. Finally, I said that this training period was very important for me to realize the difference between theoretical and practical knowledge.

I also learned about the dyeing process, which is very important for my future, and I also learned about finishing. This training gave me real practical learning about man, machine, material, production process and global market. I will be able to directly familiarize myself with the raw materials and the state of the ongoing processing of the machine.

This opportunity bridges the gap between theoretical and practical knowledge and increases the level of thinking about current textile technology. I have completed my industrial attachment from "Scandex Textile Industries Ltd." During the two-month training. I believe this industrial training will be of great help in my future life in textile engineering.

Maintenance check list