This Industrial Attachment has been prepared by us, we also declare that neither this Industrial Attachment nor any part of this Industrial Attachment has been submitted elsewhere for the award of any degree. This industrial report entitled “Report on Industrial Attachment At Impress-Newtex Composite Textiles LTD'' to Daffodil International University in December 2018, prepared and submitted by Shams Shad-Al-Arafat, Papia Ghosh and Swarna Sarkar, in partial fulfillment of the requirement for the degree of BACHELOR OF SCIENCE IN TEXTILE ENGINEERING has been examined and hereby recommended for approval and acceptance. First of all, we would like to dedicate this Industrial Training Report to the Almighty Creator, because he gives us a good opportunity to prove ourselves.

Abdullah Al Mamun, Assistant Professor at Daffodil International University, who helped me complete this report. And our parents who gave us the opportunity to study textile engineering and have always supported us. Abdullah Al Mamun, Assistant Professor of our supervisor Daffodil International University, to whom we are very grateful for his tremendous support and guidance throughout the period.

Mahbubul Haque Head of Department of Textile Engineering, for his endless support and guidance during our long journey at Daffodil International University and industrial training. Finally, we must acknowledge our parents with due respect for their continuous support, patients and believe in our caliber that drives us to successfully complete this report.

Information of the Factory

- Introduction

- Impress-Newtex Composite Textiles Ltd

- Impress-Newtex Composite Textiles Ltd

- Vision

- Mission

- Certification & Award

- Sister concern of Impress- Newtex Group

- Major buyer

- Logo

Practical knowledge makes it possible to apply theoretical knowledge in practice. For any technical training, practical experience is almost as important in combination with theoretical knowledge. The industrial attachment is the process that builds understanding skills and attitude of the artist, thereby improving his knowledge in driving productivity and services.

University education offers us great theoretical knowledge as well as more practical attachment, despite all these industrial attachments help us to be familiar with the technical support of modern machinery, silence over various operation stages. It also provides us with sufficient practical knowledge about production management, productivity evaluation, work study, efficiency, industrial management, production planning and control, production cost analysis, inventory management, purchasing, usability and maintenance of machinery and their operating techniques, etc. it must be achieved with practical knowledge in which it is based on industrial attachment makes us reliable to accustomed with the industrial atmosphere & improves courage and inspiration to take self-responsibility.

It is one of the leading group of companies in the field of textile sector of Bangladesh. We firmly believe that we are ultimately accountable to each of the constituents we interact with; namely our employees, our customers, our business partners, our fellow citizens.

Details of the Attachment

Organogram of Impress-New-Tex Composite Textiles Ltd

Knitting section

- Organogram of knitting section at INTCL

- Man-power Status

- Shift Change

- Process Definition (Knitting)

- Classification of knitting section

- Layout of knitting section at Impress-newtex Ltd

- Raw Materials

Loops can be loose or tightly formed, depending on the purpose of the garment. If the color depth of the fabric is large, the length of the loop should be larger, because in the case of fabric with a longer loop length, it is less compact. This is the first pattern most buyers make for any style.

Spreading refers to the smooth laying down of the fabric in superimposed layers of a certain length. Shaft - Shaft is the upper part of the needle that is located in the needle bar. Short groove - Short groove is the groove on the side of the needle towards the hook or looper.

Ironing works by loosening the bonds between the long-chain polymer molecules in the fibers of the material. So it is necessary to understand the daily happenings of the star department.

Yarn package

Types

Raw materials used

Process flow chart of circular knitting section of INCTL

Circular Knitting Machine

Specifications of circular knitting machines of INCTL

Production of INCTL

- Description of Production Process in INCTL

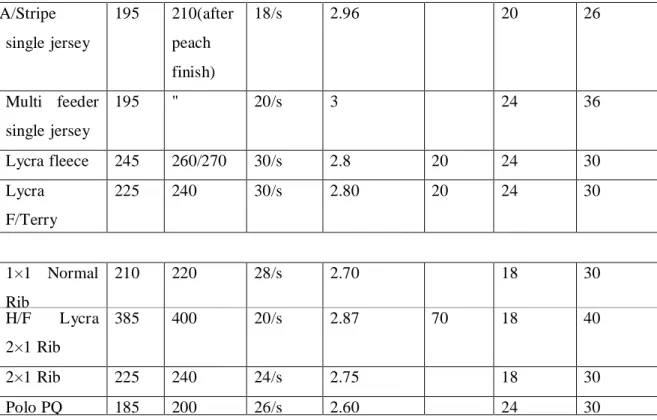

- Production parameters

Yarn count used according to grey GSM

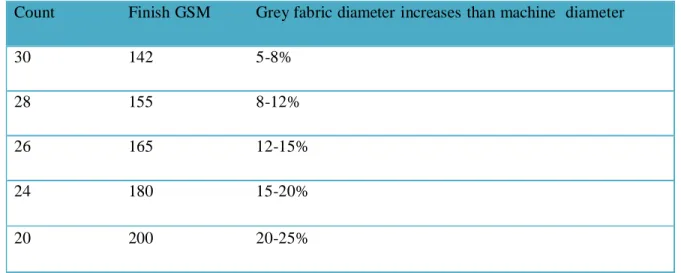

- Relation between fabric diameter and machine diameter

Production calculation

- Industrial calculation of INCTL

If the length of the loop increases, GSM will decrease and vice versa.. measured with GSM cutter & electrical balance.

Considerable points to produce knit fabrics

Important information

Methods of increasing production

Different types of faults and causes

End products of knitting machine

Grey Fabric inspection

- Process of grey fabric inspection

Fabric Inspection Machine

- Following faults are detected

- Four – point system

- Acceptance calculation

- Classification of Inspection Fabric

Acceptance

Dyeing Section

- Layout

- ORGANOGRAM

- Batching

- Dyeing

- Dyeing Machine specification (Bulk)

- Dyeing Machine specification (Sample)

- Dyeing Parameter

- Flow Chart for Dyeing

- Different types of chemicals used in INCTL with their function

- Required Time for different Dyeing Purpose

- Typical Process Flow Chart of Cotton Dyeing

- Typical Process Flow Chart of Polyester Dyeing

- Finishing section

- Machine Specification of Finishing Section

- Slitting machine

- Stenter Machine

- Compactor machine

- Common dyeing faults with their remedies

Lab section

- Layout

- Introduction of lab

- IMS maintains three method,

- Audit system

- Equipment for physical test

- Some common tests are given below

- Color fastness to light

- Color fastness to washing (ISO 105C06)

- Color fastness to water

- Color fastness to perspiration

- Color fastness to Fenoliqourine

- Color fastness to rubbing

- Color fastness to pilling

- PH test

- Twist tester

- Chemical test

The main term for yarn twisting is that the machine runs in the same direction of twist and in the opposite direction of twist. Before mass production, a sample is sent to the customer for approval from the industry according to the customer's requirements, and the shade is prepared in the laboratory taking into account economic aspects. Sampling is one of the main processes in the clothing industry and plays a key role in attracting customers.

Because buyers generally place the order after they are satisfied with the quality of the samples. The fitted sample is made and sent to fit the garment on live models or mannequins and for approval of construction details. The quality of the sample must be up to the buyer's mark; therefore the marketer should be aware and ensure that the product development team is aware of the sample quality parameters.

The main purpose of GPT is to perform physical and chemical testing on the garment to ensure the garment's performance. When expanding, the number of layers should not exceed three hundred, but it depends on the thickness of the fabric and the height of the cutting knife. For example: if the thickness of the fabric is higher than the above number of inserts, this would not apply and in the case of a straight knife cutting instrument, the maximum laying height should be 70% of the blade height.

The width of the marker is equal to the width of the fabric and should not be greater than the width of the fabric, i.e. the width of the marker is kept less than or equal to the width of the fabric. When making the marker, we need to think about the size of the table, the length of the fabric, etc. The ratio between the total areas of the model parts to the total area of the production paper is technically called the Marker Efficiency.

Butt - It is the truncated conical shape at the upper end of the needle, which is necessary to secure the needle with a needle bar or clamp. Eye- Needle eye is a hole in the tip of the needle through which the sewing thread passes. Neck scarf- Scarf or clearance cut is the part across the entire needle surfaces just above the eye.

They form effective seams without breaking or distorting during the life of the product. A work study is a systematic examination of the methods of carrying out an activity in order to improve the efficient use of resources and to establish performance standards for the activities being carried out. While the molecules are hot, the fibers straighten out due to the weight of the iron and retain their new shape as they cool.

Merchandising refers to all planned activities to execute and ship the goods on time, taking into account the 4 Rs of supplying the customer.

Garments section

- Sample Section

- Organogram

- Flow sequence of sample section

- Types of Sample produce

- Cutting Section

- Process Sequence of Cutting Section Fabric

- Fabric Relaxation

- Fabric Spreading

- Types of Fabric Spreading

- Ideal Lay height

- Requirements of fabric spreading

- Spreading system in factory

- Marker making

- Objects of marker making

- Types of marker making

- Factors considered during marker making

- The factors which influence the Marker Efficiency

- Marker Setting

- Fabric Cutting

- Methods of Fabric Cutting

- Different Types of Cutting Machine

- Numbering

- Bundling

- Quality Check

- Limitation of Cutting Section

- Sewing Section

- Lay out of sewing section

- Flow process of sewing section

- Element of sewing

- Sewing machine

- Sewing needle

- Sewing thread

- Different types of stitch

- Lay out of a polo shirt

- Lay out of long sleeve T shirt

- Sewing Line quality Check List

- Sewing Quality checking points

- Sewing Table Quality Check List

- Work Study

- SMV related formula

- Sewing defects

- Sewing problems in a factory

- Finishing section

- Lay out of finishing section

- Garment finishing

- Flow process of garment finishing

- Machine Description of finishing section

- Metal detector machine

- Thread sucker

- Materials used in garment finishing

- Ironing

- Iron machine

- Objects of Finishing

- Work flow in the Finishing Room

- Garments inspection

- Trims

- Merchandising Section

- Objects of Merchandising

- Flow Chart of Garments Merchandizing

- Merchandising Calculation

At this stage of sampling, the buyer ensures that the factory thoroughly understands the construction and quality details and standards. The sample is mostly sent in medium and large sizes mentioned by the buyer. Buyer uses this image for marketing purposes either on catalog or various media such as print, TV or websites to see consumer reaction. The merchandising department is the star of the department among all the working departments of the export group because Merchandising is the only department that has maximum control over the departments and is totally responsible for the profit and loss of the company.

Compliance

- Different compliance issues which

- Health and Hygiene

There are emergency procedures in the facility to handle cases of trauma or serious illness. On each floor they have a first aid kit and a first aid trainer on each floor. Each floor has a sub-distribution point (SDB). For three to four fans there is a switch.

They also have health and safety team at their organization and they have regular health and safety meetings. This factory employs workers without regard to race, color, sex, nationality, creed, age, maternity or marital status. This factory pays workers' wages and provides benefits without regard to race, color, sex, nationality, religion, age, maternity or marital status.

This factory does not use involuntary labor of any kind, including prison labor, bonded labor, or forced labor by governments. After using water in the dyeing department and other household activities, the waste water goes to the ETP for treatment. ETP recycles the water and finally drains the recycled water out to the canal, where water is not harmful to the environment.

A workspace is in order if there are no unnecessary objects in the space and if all necessary items are in the right place.

First aid box

Doctor’s room

Emergency medical policy

Maternity policy

Pure drinking water

Safety Management

They collect all the fabric burlap, Garbage, Wasted paper, Empty drum, Empty container, Empty bottle, Waste plastic, Broken wooden box, Waste table, Chair, Waste furniture, Button, Hanger, Fabric, Polly, Zipper, Melted tube light, Broken Glass & other waste from the concerned departments and they dispose of this waste at the reassigned location after a certain period.

Fire equipment

Fire control panel

CO2 cylinder

Fire alarm switch

Fire siren

Risk assessment & Prevention

MDB/SDB policy

Working condition

Emergency light & Emergency Exit Door

Holidays are given such as Eid-Ul-Fiter, Eid-Ul-Adha, Durga Worship etc. These garments employ workers based on their ability to do the job, not on their personal characteristics or beliefs. Procedures and standards for waste management, treatment and disposal of chemical and other hazardous materials, emissions and wastewater treatment must exceed minimum legal requirements.

Housekeeping is more than just sweeping floors and dusting machines and equipment Eliminates the causes of accidents and fires.

Light

Emergency light

Leaves & holidays

Salary & wages

Salary and wages chart

Overtime wages calculation

Discrimination

Forced Labor

Child Labor

Environment

Employment relationship

Others

Wastage Management

Housekeeping

Effluent Treatment Plant

ETP

ETP

Impacts of the Attachment

- Knitting

- Dyeing and Finishing

- Sample development

- Cutting

- Sewing

- Finishing

- Quality

- Merchandising

- ETP

- Utilities

- Compliance

Conclusion