-Based Proceeding of lnternalional Seminar Current Issues and Cha[ienges in Food Su]e@ I

4vailable

1ttp://www.codexalimentarius.net/download/standards/Z3/c

<p-00 1e.pdf;

~f Safety agri-food choin,

~ n i n g ,

Vageningen 2007),303-354.

2001.

dycotoxin FAOIIAEA

,eference 1:AO

lome Page

tp://ftp.fao.org/docrep/fao/OO5/yl390e/y1390e00.pdf;

1 2009.

O n l i t ~ e .

lo Page rn

t t p : / / w w w . t h e f r e e l i b r a r y . c o m / M o l d + a n d + m y t ~ l + c o n t a tn

~ation+of+tea:+contamination+of+processe..-a 1833 1855; Iternet;

Safety Manual. Hoboken john lifey

"jenis Manfaat OnUne. on-

http://www.sosro.com/jenis-manfaat-

!h.php; Februaly

"Tanaman Sosro

taila http://www.sosro.com/tanaman-teh.php:

:ellos, J.A. Quniity ~proach.

ESTABLISHMENT

AND

IMPLEMENTATION SANITATION

STANDARD OPERATING PROCEDURES (SSOP) IN

GREEN TEA PROCESSING

Ratna Handayani and Adolf J.N. Parhusip

Department of Food Technology, Faculty of Industrial Technology, University of Pelita Harapan

ABSTRACT

Implementation of sanitation will be more focus with more detail Sanitation Standard Operating Procedures (SSOP) for each production machine, production supporting facilities, and surrounding environment. The purpose of this research is to arrange SSOP as an implementation of standard procedure in achieving higher quality. Research methods consist

of usage of qualitative and quantitative data, sanitation practical assay,

SSOP arrangement in detail, and SSOP evaluation by using qualitative data. SSOP which was arranged as an implementation of sanitation practical in PT

Cunung Titiran consists of four aspects which are SSOP of water safety,

SSOP of machine and production facilities, SSOP of building treatment and

factory f~cilities, SSOP of cross contamination prevention, and SSOP of

manpower. The research result showed that total microbes on each production stage starts from the tip of fresh tea leaves were 3.0 x 105 cfu/Z5 g [tip of tea leaf), 1.9 x l o 4 cfu/25 g (rotary panner machine), 8.5 x 107 cfu/25 g [jakson machine), 2.3 x

lo6

cfu/25 g (ECPJ, 3.0 xlo4

cfu/25 g (Cold Machine number111,

1.7 x 101 [ball tea machine). SSOP implementationwhich can be done in a few production area comprise of hair covering,

gauze installment to prevent animal, usage of closed shoes in production area, usage o f a special slippers when the workers are in toilet, and usage of a machine cover in unused machine.

Science-Bused Approach for Food SuIey Managemen[

1

oflnternalional Seminor rrrrr~nr Imues Fr~oFigure

INTRODUCTION

Background

Food safety is a condition and an effort to prevent possibility of biological, chemical, physical contamination that can disturb, harm,

a n d dangerous for human health (UU Pangan No. 7/1996). Food safety is a very important aspect in global trade since many countries decide i t a s a prerequisite factor to import food products.

Procedure of sanitation standards is required to achieve high quality and safety food products. It covered the whole aspect of food production such as corporate policy, stages of sanitation, monitoring, documentation, etc. Sanitation standard operating pi-ocedul-es (SSOP) is useful to help food industry in developing and implementing sanitation procedures, sanitation monitoring a n d maintaining sanitary conditions a n d sanitation practices (Thaheer, 2005).

Green tea has low water content (8%) and is categorized as low risk food. However, it is still possible that green tea is contaminated by microorganisms d u e to lack of monitoring on sanitation conditions of green tea d u r i n g production process are not mor~i tored.

SSOP in PT GT is commonly carried out for building maintenance a n d plant facilities, machinery and production facilities, labor and pest control and waste management. In this study, the sanitation implen~entation is focusing on SSOP for production machine, supporting production facilities and environment. The good implementation of SSOP will build employees awareness to produce a good green tea.

Objective

The objectives of this research were to establish Sanitation Standard Operating Procedures (SSOP) a s an irnplemcntation of standard procedures to achieve higher food quality and safety, to

evaluate the existing SSOP in PT GT by qualitative and quantitative data analysis, and to evaluate sanitation practices by counting the

total microbes.

3 7 0 I p o s t e r p r e s e n t a t i o n

Cig; lava

_-_ _-

kt-r

\

i----7- &TI* /

I

Dau-4-1

-dm- profrlr, -pmrr.

4 WT W, hod o t p w .

-pates

1

-1rm idmtihntm

-- - -. - -.

\vmF*. t h t

CMIDR mlh ~ o d m d l . prwmmm d cross Cmta-W aortafirn

.- *

--

u

F ~hS

1

p ~ n n(FW

I

sirr a p l r ~ i a w ~ vah ~ S P P

a i a l a n + c t i m v z

Approach Si!fcfy Munugement

(UU Pangan 7/1996).

1

It ~ c t i o n

mentation,

ation ary

(80/u)

!en

ation

mentation

Prclcedures irnplemcntation

laster

Proceeding of lnternaiional Seminar Current Issues und Challenges in h o d Safety

METHODS

This research was done in PT GT Sukabumi, Cigandok,

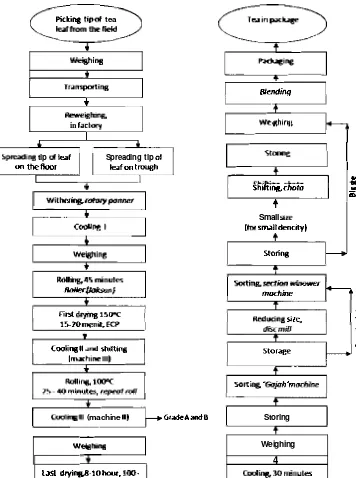

Lengkong, Sukabumi district, West Java province. This research used qualitative and quantitative data (Figure 1).

Figure 1. Flow chart step of SSOP establishment

Science-Based Approach for Food SujL~w hfclnagrrnenl

RESULT

A N D

DISCUSSIONCleaning and Sanitation in

PT

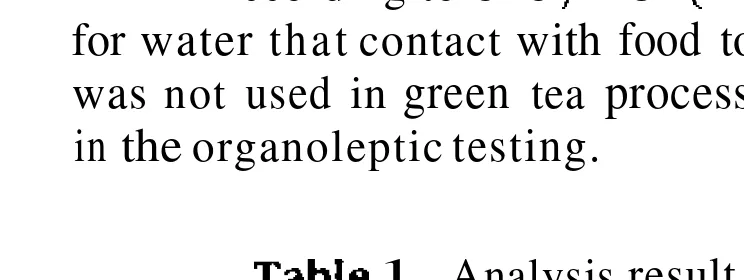

CTFlow chart production process of green tea a t

PT

GI' is outlined in Figure 2. The routine cleaning process in each work u n i t of PT GT was done a t the end of production process by using d r y method. The cleaning process and sanitation for the whole factory area were done on all production machines and buildings every once a week on Friday where the production was off. SSOP was performed by PT GT has not been yet focused for each machine, supporting equipments, and procedures.Things related to SSOP inlplementations which were necessary t o be improved included building condition, ventilation condition, machine sanitary, and employee's personal hygiene. It was found in PT GT that the cleaning facilities was improperly located, no lid of

trash bins, lack of employee awareness about the importance of sanitation, as well as no storage separation between hazardous

cleaning materials and packaging materials.

Aspects of sanitation conditions should be proposed to establish

SSOP for PT

GT

were water safety and its supply, the cleanliness of equipment surfaces which contact with food materials, hands washing facilities, sanitizers and toilet, employee health conditions and personal hygiene. According to that, the SSOP was proposed to PT GT divided into four types of SSOP i.e. water safety; factorybuilding and facilities; machine and production facilities; a n d control of employee health and personal hygiene.

- -

3 7 2 1 p o s t e r p r e s e n t a t i o n

Pro~qeding oflnlrrnunonol Currcnl l s r u e ~ und Cha1len~u.s Fno

Icaffromtkficld

spreading d

k f on t m

Cwlingll

Rollin& 1

-75 - 4 0 minute ~PW d

todw

Ill (machine and Bred package

Last dryinas-lohau,

Weighing

o s i e r

,Based for Safety

,T

:low G I '

Ire C'T

me mcthod.

~g area

~t

,ocedures.

'hings

tion,

ng

ispects

cleanliness

cotlditions 2rsonal

i.e.

~g

~loyee

p o s t e r p r e s e n t a r i o n I373

Pro reeding of International Seminar Currenr issues and Chullenges in Food S~~fety

Picking tipof tea

4

+

T r a n s p t i n g

#ending

+

Fkweighing,in factwy

I

4

+

Spmding tip at leaf Spreading tip u~

un t k h r leafm trough

I 1 - t:

t Shihin~choto H m

z

+

Small sizc

[ f u s m l l dencity)

storing +

Smting,sectiwr rvinomw modline

P

-

Firrt dwlrtg i s m n

Reducing sitc,

E

z

mC

Cwlingll dnd shafting Storape UI

Mrt in& 'Go&h'muchine

Cwlirglll (machine ll) Gr&AamtB Storing

Weiehim

Lasl dryiw-lohow. lMI-

15DT. Mre9

Weighing

4

C d h J O minute

,Tctc.tlze-Based Approai-h for Food Safety Management

I

Proceeding uJ Intcrrtr~tiunul Seminor Current I s s r t ~ ~ t?l~al/unxc.r rn FOGWater Safety Table2. v

According to CAC

/

RCP (2003), water monitoring is only done for water that contact with food to avoid cross-contamination. Water was not used in green tea processing in PT GT; however it was used in the organoleptic testing.Table 1. Analysis result of E. coli and TDS in water

Wash basin before entering production roo rn

1. Hand basin 1

2. Hand basin 2

3. Hand basin 3

Water from laboratory

withering

'Jakson'

\ ! I

from

< 2.5 x 102 (2.3 x lo1) -

c 2.5 x 102 12.3 x l o 1 )

< 2.5 x 102 C2.3

x

l o 1 )4.6 x l o 3

49

Based on the data in Table 1, the proposed SSOP of water safety contained procedures for monitoring water a n d water reservoirs included odor, pH, TDS, and microbial contamination of E.

coli. The monitoring frequency was done every rnonth for water used

in

laboratory and once in every 6 month for water used in otherlocation. The water monitoring frequency was different between both locations because water in laboratory was used for organoleptic testing, thus it needed more often monitoring.

The Cleanliness of Equipment Surfaces Contact with Food

Materials

The equipment surface contact with food materials occurred

since reception of fresh green tea tip leaves until sorting process. In

this study, analysis of total microbe was taken from products during

production process before cleaning, machine surface, and hand palms of e~nployee who directly contact with products (Table 2 - 4).

3 7 4 1 p o s t e r p r e s e n t a t i o n

(cfu/25

x 10s

104

8.5 x

104

10"

1.7 101

< 102

10')

< 2 v 5 102 (1.0 10')

total machine

I

ti1

~ o o l i n ~ 1 1 1

I

[cfu/25

(cfu/25 cm2]

[cfu/25 cm2j (cfu/25 cm2j

3. Point3(cfu/Z5cm')

-

10' 1 0 8 108

I O U

x

l o 8E, (cfu/ml)

1

'ing

I

< 102 lo1)

< 102 C2.3 101) < 102 C2.3

,r 103

,-Bastld .-lpprc~ock ,for

r

/

(2003), iterProrecdrng of lntcrnationai .Em~nar C'~irre.ril Issues and C'hulienges in F o d S a f i p

Table 2. Result analysis of total microbe of product i n various

process step before cleaning

Sample

Fresh tip of tea leaves

Output product from withering machine

Output product from 'Jakson' machine Output product from ECP machine

Output product from cooler I1 I

Output product from

ball tea machine Out product from

sorting machine Output product from section winnower machine

roirs included

In.

Ins

;,

Ials

Total Microbe

(cfu/2 5 g]

3.1 x 105

1.9 x 104

8.5 x 107

5.9 x 1 0 4

3.0 x 10"

1.7 x l o 1

< 2.5 x 102 14.7 x 101)

< 2-5

[1.0 x

lo1)

~ l o y e e

o s t e r p e e s e n l a l i o n

Location

Receiving fresh tip of leaf

Withering section

Rolling section

First drying section

Cooling I1 I

Last drying

Sorting section

Sorting section

Table 3. Result analysis total microbe o n machine surface

Location

I

3. Point 3 (cfu/25 cm2) Output (machine)

1. Point 1 [cfu/25 cm2)

2. Point 2 (cfu/25 cm2)

3. Point 3 (cfu/25 em2)

Total Microbe

p o s t e r p r e s e n t a t i o n 1375

I

1.5 x 108

3.8 x

lo8

3.2 x 1 O B 1.1 xlo7

WITHERING SECTlON

2.2 x 10"

Input [machine)

1. Point 1 [cfu/25 c m Z j

2. Point 2 Fcfu / 2 5 cm:l

1.3 x 109

Science-Rased ,4pproach l o r Food Safety Managem~nr

1

(cfu/ml)1 [cfu/rnl) 10"

(cfu/ml] 108

(cfu/ml) 106

2nd

I. [cfu/ml) 1 0 7

2. [cfu/rnl) 106

3. (cfu/ml) 1 0 7

1 [cfu/ml) 104

[cfu/ml) 106

(cfu/ml) 106

ROLLING SECTION a. Jakson machine

1. Point 1 [cfu/25 cmz) > 2.5 X l o b

(TBUD)

2. Point 2 (cfu/25 cm2] 4.5 x

l o 7

3. Point 3 (cfu/25 cm2] 4 . 5 ~ 106 b. Container to product collect1. Point 1 (cfu/25

cm2]

1.8 x 1062 . Point 2 (cfu/25 crn2] 1.4 x 106

3. Point 3 (cfu/25 cm2] 1.8 x 106

FIRST DRYING

1. Point 1 (cfu/25 cm2) 2.0 x 106

2. Point 2 [cfu/25

cm2]

1.0 x 1063. Point 3 (cfu/25 cm2) 2 . 3 x 1 0 6 BALL TEA MACHINE

1. Point 1 [cfu/25 cm2) 8.0 x lor, 8.4 x 1 0 5

2. Point 2 (cfu/25 cm2)

I

2.4 x 106 1.2 x 1061

incli3. Point 3 (cfu/ZS cm2) SORTING SECTION

a . Conveyor

1 . P o i n t 1 [ c f u / 2 5 c m 2 ) 2 . Point 2 [cfu/2S cm2]

1 . Point 3 (cfu/25 cm2)

b. Sorting machine (shifting)

1. Point 1 (cfu/25 cm2) 2. Point 2 (cfu/25

cm

2)

3. Point 3 [cfu/25 cm2)

c. Section Winower machine

1. Point 1 (cfu/25 cm2)

2. Point 2 [cfu/25 cm2)

3. P n i n t 3 [cfu/25 cm2)

d. Container to product collect I . Point 1 (cfu/25 ern*) 2. Point 2 (cfu/25 cmz]

3 . Point 3 (cfu/25

cm

2)

3 7 6 1 p o s t e r p r e s e n t a t i o n

I

p r e s e u t a t i o nc 2.5 x 104

(1.3 x lo4)

1.2 x

l o 6

1.4 x 1 0 61 . 6 ~ 10"

1.4 x

lo6

1.2 x 106

1.7 x 106

< 2.5 x 104

(5.0

x 103)9.7 x 105

2.1 x 106

8.4 x 105

1.2 x 106 7.1 x 106

f'r uceeding uf Jnrcrnutionui Semitlar Current Issues and C'ha/kcnxr c In t'ood Sgfet~

' L L I N G

I. P o ~ n t [cfu/ZS ~ Z 5 X l 0 6 ( T B U D L

:

2. (cfu/25 cm2]

l o 7

(cfu/'LS cm2] x 106

(cfu/25

cmZ]

10"(cfu/25 cm2)

--

106[cfu/25

-

cm2) 1.8 x 105I. Pamt 1 (cfu/25 cm2) x 106

(cfu/Z5

c r n n 1063. 3 ~ ~ U / Z S

c m 2 ~

2 5 1 0 6LL

I. (cfu/Z5 c m 2 10"

(cfu/25 cm2] 10" 106

Point [cfu/25 cm2] < 2.5 104 1 0 6

-

--- u 104)lTING SECTlON :onveyo r

(cfu/25 cm2) 1.2 lo6 -

?. Polnt 2 (cfu/25 cm2] l o 6

(cful25

cm?)

1.6lo6

iortir~g rrlauh~ne(cfu/25 cm2) x 1 0 6

{cfu/2S cm2] x

l o 6

[cfu/2S cm2] 106

< 2.5 x 104 1. (cfu/25 cm2)

--- (s.0 x 103)

!. [cfu/25 cnl2] 1 0 5 - - .

I. [cfu/25 cm') 106

[cfu/25 cm2) 1 O S -

P u i r ~ t (cfu/Z5

cmz)

106

(cfu/25 c r n n --- 106

-

Table 4. Result total microbe on palm

of

handParameter

I

Total microbe-

Employee on withering section (cfulml)

1. Person 1 (cfulml) 1.7 x 106

2. Person 2 [cfu/ml) 1.0

x

108-

3. Person 3 [cfujml) 2.7 x l o c )

Employee on cooling, rollin% and ECP

1. Person 1 (cfu/ml) 1.2 x 1 0 7

2. Person 2 (cfu/rnl) 4.9

x

1063. Person 3 (cfu/ml) 1.0 x 107 -

Employee on sorting

1. Person 1 (cfu/mf) 2.7 x 1 0 4

2. Persun 2 [cfu/ml) 1.3 x

lo4

3. Person 3 [cfu/mlI) 1.5 x 106

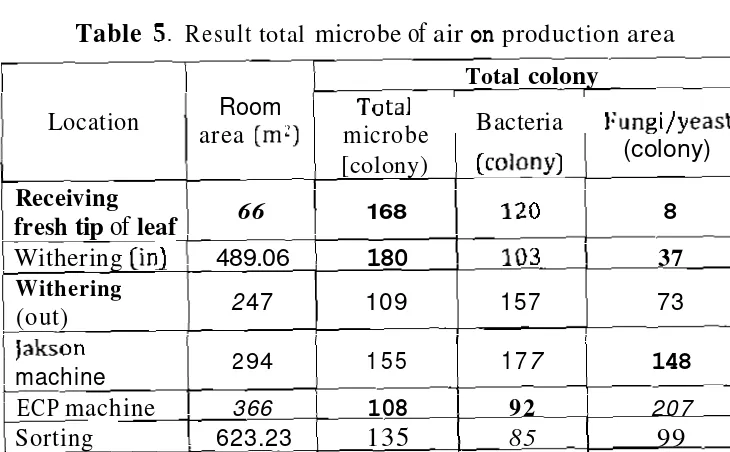

Prevention of Cross-Con tamination

Cross-contamination can occur from various sources including employees (Table 41, who directly handle the products production

environment, equipment, packaging material, and products [Table 5).

Table 5 . Result total microbe

of

airon

production areaI

I

Total colony1

Room

Location area (m:) Bacteria I:ungi/yeast microbe

(colonyl (colony) [colony)

Receiving

66 168 120 8

fresh tip of leaf

Withering (inJ 489.06

180

2 0 3 37Withering

2 47 109 157 73

(out)

jakson

2 94 1 5 5 1 7 7 148

machine

ECP machine 366 108 9 2 207

Sorting 623.23 135 85 99

-

Chop/blending 118.50 2 1 14 3

p o s t e r p r e s e n t a t 1 0 1 1 ( 3 7 7

Location

of cmployees

(

em]

needed

from c

1

Foruin

corr

tation,

hait.

ma]; machinr

coverirlg t

p r e s e n ~ a t i o i

According to Table 5 , total microbe on receiving fresh tip of leaf location where be in contact with outside factory are bigger.

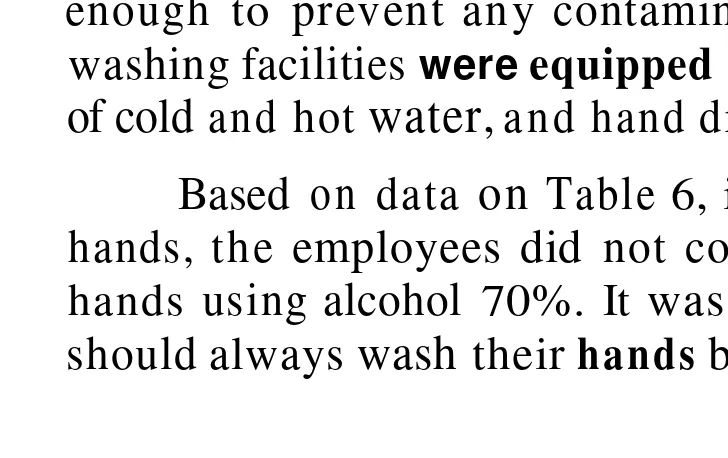

Hand Washing Facilities and Toilets

According to CAC/RCP (2003), sanitary facilities for employees included toilet and hand washing facilities should bc available enough to prevent any contamination of t h e product. Ideally, hand washing facilities were equipped with soap, sanitizers, the availability

of cold and hot water, a n d hand dryer facilities (Cramer, 2006).

Based on data on Table 6, it was suggested that after washing hands, the employees did not contact with the tap or re-clean their hands using alcohol 70%. It was also recommended t h a t employees should always wash their hands before working.

Table 6. Result total microbe on toilet and hand wash facilities

Total microbe (cfu/ml]

-

(cfu/ml)

Outside toilet

-

1. Hand basin 1

2. H a n d basin 2

3. Hand basin 3

Basin before enter-ing production room

1. Hand basin 1 2. Hand basin 2

3. Hand basin 3

Office Toilet

Control

of

Employee Healthand Personal

HygieneThe SSOP of employee health and personal hygiene must be performed not only for the employees but also for visitors who came

to PT CT.

EmployeesJ

health conditions were very influential on product quality. According to Winarno and Surono (20043, thc standard

3 7 8 i p o s t e r p r e s e n t a t i o n

6.4 1 0 5

1.9 x l o 4 3.0 x

lofi

3.5 x

l o 7

3.9 10'

2.7 x 106

5.9 x 106

1.4 x

l o 5

1.4 x 104

1.9

x

l o 4

*e-Based for Sa& Mana~emenl

tu

biggcr.

CAC/RCP

ied be

;h

sanitizers,

;,

: d

ble

(cfu/mll

-1

6.4~105 1 . 4 ~Hand 1 0 4 10"

106 10'

I

107 106

1 0 7 2 . 1 ~ 106

106 c: 2.5 105 105)

106 3 . 6 ~ 106

11

rnployees'

Winarno (2004], the

1.

Procecdtng of l n ~ m a t i u n a l Seminrrr Current ISSUE.T and C h a l l e n ~ e ~ s in k b o d Safepprocedures for hygiene and health of employees should be started

from plan for new employee acceptation until they were working.

SSOP Implementation

The study of SSOP implementation in PT GT was carried out for 2 weeks. The SSOP implementation was proposed covered employee habits such a s use of hair cover and shoes in the production area, locating the proper cleaning equipments, use of different shoes in the toilet, and covering the clean engine after cleaning.

CONCLUSION

Hygiene and sanitation practices a t PT CT were needed to be improved. It can be seen from the qualitative and quantitative data of total microbe on samples taken. The critical point that needed

more

attention was product after sorting process because a t this stage it was no longer received any heat treatment.

SSOP was compiled and approved by the management of PT GT through Forum Croup Discussion (FCD). The FGD members were equipped with check list form

for

monitoring the SSOP implementation. The proposal of SSOP was detailed compiled covered objectives, scope, definitions for several terminologies used, personnel who responsible for SSOP implementation, working procedures of sanitation practices, the frequency of SSOP implcmcntation, monitoring and other related forms.The SSOP implementation had been done in some areas included employee personal hygiene such as hair covering a n d use of closed shoes

in

the production area; netting installation on eachventilations to prevent entry of animal; covering clean machine after

production finished; and covering the bottom of the machine that is difficult to be reached a t the time of cleaning and sanitation.

Sccie)lce-Based Approach for Food Sujeo: Mu>lugemmt

References

Association of Official Analytica Chemist. AOAC, inc. Arlington. 1995. Anonim. Code of Federal Regulation, 2 1 CFR. Ch.1 14-1-08 edition).

Available from: http://frweb~ate.access.rrno.~ov/cai- bin/multidb.c~i Internet: accessed 8 Februari 2009.

BPOM.

Pedoman Penerapan Cara Produksi Makanan Yang Baik[CPMB), lakarta: Direktorat Pengawasan Makanan dan Minuman, Direktorat Ienderal Pengawasan Obat dan Makanan

Departemen Kesehatan RI. 1996.

Badan Standarisasi Nasional (BSN). SNI 01-3945-1995. Teh Hijau. Jakarta : Dewan Standarisasi Nasional. 1995.

Badan Standarisasi Nasional (BSN). SNI 01-3553-2006. Air Dalam Kemasan. Jakarta: Dewan Standarisasi Nasional. 2006.

Bacteriological Analytical Manual Online (BAM). 2001. Aerobic Plate

Count. Available from:

h

t

t

D

diakses tanggal8 Maret 2009.

Belitz,

H.D.,

Crosch, W. Food Chemistry. Springer. New Yark. 1999.Brown, Amy. Undertstanding Food: Principle and Preparation. 2 n d

Edition. Thomson Wadsworth, 2004.

Buckle, K.A, Edwards,

R.

A, Fleet, G.H., Wootton,M.

Ilmu Pangan. Penerjemah Hari Purnomo, Adiono. UI Press. 1987.CAC/RCP.

CAC/RCP

1-1 969, Rev 4-2003: Recommended International Code of Practice General Principks of Food Hygiene. 20 03.Clontz, L. Microbial Litnit and Bioburden Tests : Validation Approaches and Global Requirements. CRC PI-ess, New York. 2009.

Cramer, M.M. Food Plant Sanitation: Design, Maintenance, a n d Good Manufacturing Practices. CRC Press. 2006.

Corlett, A. Donald. HACCP User's Manual. Aspen Publishers, Inc.

GaiTEHrsburg, Maryland. 1998.

Doyle, P.M., Beuchat, R. L., Montville, J.

T.

Food Microbiology:Fundamental and Frontiers. ASM Press. Washingthon DC. 2001.

3 8 0 i p o s t e r p r e s e n t a t i o n

I

Procreding nf fnrcr~~arionnl Smmir~trr. IYJ.UCS und Ch{rllengc.r Fou 1996. Opsratit~g Proce blerant.ore~onstnte.edu!s~pu bs!onJinepu bsii97C

ml. 2009. Univf

-

1.

P.und Pro&

www.foodsci.purdue.edu/outreach. Int

KO

M.

ldentiflcation Guilsinensis).

Reso Hawai'i. 2006.

H.

Processin,q.

Magan, Food: Oetectio,

Woodhcad Ava~lable

:http:l/ books.google.co.id/books?id=CZ3iEh PeejoC&pg=P!

&lpg=PA184&dq=growth+optimum+OTA&source=bl&ots=

9LynPb&sig=VKq7uzvpSz43qRoD lgkzPFAktVg&hl=id&ei= oStajLNONkAWx-bG1 Bw&sa=X&oi=book~rtlsult&ct=resultS

u m = 3 # P P P l , M l . Mei

QualiQ

Ston

http:/!www.pcd.go.th~info serv/en reg water0l.html

J u n i Reso

D.,

]enis Manfaat

h t t ~ : / / w w w . s o s r o . c o m ~ . Ilrite~

Thaheer, Manajernen Rumi A1

Jakarta.

9used jor

tion of0flcial Analytica 1995.

I. 2 1 Ch.1

vailable httw: //frweb~ate.access.gp~~gov/c~i-

n / ~ n u l t i d b . c g Februari Pedoman

:PMB).

Jenderal 0

:partemen

RI.

1996.[BSN). 01

Dewan 1995.

!masan. Dewan 2006.

~Iogical 2001.

t m o d s a f e t v . ~ o v / - e b a m - m i tanggal daret

'.D.,

Grosch, 1999.Undertstanding 2 n d

ition.

K.A, llmu Pangan.

nerjemah

UI

P. CAC/RCP 4-2003:

le Principks of

Bioburden 1 Reqr~irements.

Maintenancc,

lnc.

TEHrsburg, 1998.

'.M., L , Montville, J. Micr+obiology:

~ d a m e n t o l 2001.

Proceeding of International Sen~linur C'urrcrir 1ssut.s and C h a I l e n ~ e > rn Fovd S~&rl.

Hilderbrand, Ken. 1996. Sanitation Standrrrd Operntirtg Procedures.

Available from:

http://seagrant.oregonstate.edu/s~~u bs,/odimpu bs/i97003.ht ml. Internet: accessed 5 Februari 2009. Oregon Statc University. -

Hui, Y.H., Bruinsma, B. L. , Gorham, ). R., Nip, W. K., Tong, P. S.,

Ventresca P. Food Plant Sanitation. Ma]-ce\ Dekker, Inc. New York. 2003.

Keener, Kevin. 2007. SSOP and

G M P

Practices and Programs. Available from: www.fo~dsci.purdue.edu/ou treach. Internet:accessed 5 Februari 2009. Purdue University.

Keith Lisa, KO Wen-Hsiung, Sato M. Dwight. Identification Guide for

Disease of Tea {Camellia sinensis). Cooperative Extension

Service, College of Tropical Agricuf tural and Human Resources. University of Hawai'i. Manoa. 2006.

Lelieveld, H. L. M., Mostert, M. A., Holah, J., White, B. Hygiene In Food Processing. CRC Press. New York. 2003.

Magan, N., Olsen, M., Knovel. 2004. Mj~cotoxins in Food: Detection and

Control. Woodhead Pct blishing Limitid Available from : h t t p : / / books.google.co.id/boo ks?id=CZ3i EhPeejoC&pg=PA184

&Ipg=PA184&dq=gt~owth+optimum+0TA&source=bl&ots=1NPf

9LynPb&sig=VKc~7uzvpSz43qRoDlgkzPFAktVg&hl=id&ei=umo

oStaJ L N O N kAWx-bG1 Bw&sa=X&oi=book~result&ct=result&resn

u m = 3 # P P P l , M l , internet: accessed 25 Mei 2009.

Pollution Control Departemen t (PC@], 2009. Water Quality Standard.

Available from:

httn:/fwww.pcd.go.th/info serv/en reg std water0l.html. Internet: accessed 26 Juni 2009. Ministry of Natural Resources

and Environtmen t. Thai Environmental Regulations.

Roberts U., Greenwood M. Practical Food Microbiology. Blackwell Publishing Ltd. USA. 2003.

Sosro. 2008. Jenis dan Manfaat Teh. Available from: h t t p : / / w w w . s o s r o . c o m f i e n i s - m a n f a a t - t e h - h i p . Internet : accessed 29 April 2009.

Thaheer, Hermawan. Sistem Manajemen HACCP. Rumi Aksal-a. Jakarta. 2005.

- - - .- .- .-

Proceedirig #f In[ ernarronal Challenges k

Winarno dan Surono. CMP Cara Pengolahan Pangan Yang Balk, M-

Brio Press. Bogor. 2002.

Wood, J.B. Brian. Moicrobiology of Fermented Foods. Blackit. Academic & Professional. UK. 1998.

USD*. 1999. Food SafeV and Inspection Service, 54 16. Avail a b]e fronl:

h p : //edocket.access.pno.eov/cfr 2007/ianqtr/~df/9cfr4 16.11

af.

Internet: accessed 1 Maret 2009.3 8 2 l p o s t e r p r e s e n t a t i o n

(CURCUI

DOMESTICA

(OClMUM

CRA

TlSSlMUM.

(NOTHOPACUTELLARIUM

(RASTRELLIGER

Andalas

kuny

(Curcurna domestica (Ocimum gratissimum

(Nothoponox cuteIIarirrm org;

tempera1

conlposition

n

i.e. 3x103, 3.2 >

E.coli.

microbiologica:

wi!l (Irawan (19951 Puspita,

preseri procl

[Suseno,l978).

art