UNIVERSITI TEKNIKAL MALAYSIA MELAKA

Study the Process of Total Preventive

Maintenance (TPM) of Injection Moulding

Machine Arburg 420C

Thesis submitted in accordance with the requirements of the Universiti Teknikal

Malaysia Melaka for the Degree of Bachelor of Engineering (Honors)

Manufacturing (Process)

By

HIDAYATULLAH BIN MUSA

Faculty of Manufacturing Engineering

UTeM Library (Pind.1/2005)

UNIVERSITI TEKNIKAL MALAYSIA MELAKA (UTeM)

BORANG PENGESAHAN STATUS TESIS*

JUDUL: STUDY THE PROCESS OF TOTAL PREVENTIVE MAINTENANCE (TPM) OF INJECTION MOULDING MACHINE ARBURG 4 2 0 C

SESI PENGAJIAN: 2 0 0 7 / 2 0 0 8

Saya HIDAYATULLAH BIN MUSA

mengaku membenarkan t esis (PSM/ Sarj ana/ Dokt or Fal saf ah) ini disimpan di Perpust akaan Universit i Teknikal Mal aysia Mel aka (UTeM) dengan syarat -syarat kegunaan sepert i berikut :

1. Tesis adal ah hak mil ik Universit i Teknikal Mal aysia Mel aka.

2. Perpust akaan Universit i Teknikal Mal aysia Mel aka dibenarkan membuat sal inan unt uk t uj uan pengaj ian sahaj a.

3. Perpust akaan dibenarkan membuat sal inan t esis ini sebagai bahan pert ukaran ant ara inst it usi pengaj ian t inggi.

4. **Sil a t andakan (√)

SULIT

TERHAD

TIDAK TERHAD

(Mengandungi makl umat yang berdarj ah kesel amat an at au kepent ingan Mal aysia yang t ermakt ub di dal am AKTA RAHSIA RASMI 1972)

(Mengandungi makl umat TERHAD yang t el ah dit ent ukan ol eh organisasi/ badan di mana penyel idikan dij al ankan)

APPROVAL

This thesis submitted to the senate of UTeM and has been accepted as partial fulfillment of the requirements for the degree of Bachelor of Manufacturing Engineering

(Manufacturing Process). The members of the supervisory committee are as follow:

……….

Supervisor

DECLARATION

I hereby, declare this thesis entitled “Study the process of Total Preventive Maintenance (TPM) of Injection Molding Machine Arburg 420C” is the result of my own research

except as cited in the reference.

Signature : ……….

Author Name : ………

Date : ………

ABSTRACT

ABSTRAK

DEDICATION

ACKNOWLEDGEMENTS

Assalamualaikum w.b.t. and warm greeting,

First of all, thank to ALLAH SWT for His blessings and for the strength given to me to finish this Projek Sarjana Muda.

I would like to extend my heartfelt gratitude to all that have been contributed to the success of this Projek Sarjana Muda. I wish to acknowledge and express my gratitude and appreciation to my supervisor, Mr. Mohd Amran b. Md Ali for his supervision, encouragement, suggestion and assistance through the research.

I also would like to convey my biggest thanks to Faculty of Manufacturing Engineering (FKP) especially Professor Dr. Mohd Razali b. Muhamad, Dean of Faculty of Manufacturing Engineering (UTeM) Mr Mohd Hadzley b. Abu Bakar and all the lectures in the faculty.

TABLE OF CONTENT

List of Abbreviations, Symbols and Specialized Nomenclature ...xi

1. INTRODUCTION ...1

2.2 Introduction to Engineering Maintenance………..………..4

2.2.8.2 New Techniques...15

2.2.8.3 Challenges Facing Maintenance Personal...16

2.3Introduction of Total Preventive Maintenance...16

2.3.1 Application of Total Preventive Maintenance...17

2.4 Introduction of Injection Molding...21

2.4.1 Injection Molding Process...21

2.4.2 Injection Molding Machine...22

2.4.3 Types of Injection Molding Machines Components...23

2.4.4 Types of Injection Molding System...26

2.5 Human Error in Engineering Maintenance...28

3. METHODOLOGY ...35

3.1 Introduction ...35

3.2 Project Selection ...37

3.4.1 Selection of machine...37

3.4.1 Selection of experiment method...38

3.3 Discuss detail plan and conduct preliminary research...38

3.4 Study of fundamentals of Total Preventive maintenance...38

3.5 Design and apply the method of Total Preventive Maintenance...39

3.6 Document the Maintenance Procedures (ISO)...40

3.7 Implement of Total Preventive maintenance...41

3.8 Analyze the component that has been maintenance ...42

3.9 Discussion, Conclusion and Recommendations...42

4.FINDING OF TOTAL PREVENTIVE MAINTENANCE……….………..43

4.1 Introduction……….…....43

4.2 Restoration Equipment………...……….43

4.2.1 Procedures to Switch ON the Plastic Injection Molding Machine………….44

4.2.2 Procedures to operate the Plastic Injection Molding Machine………...44

4.2.2.1 Manual Mode………..44

4.2.2.2 Automatic Mode……….45

4.2.3 Procedures to Switch OFF the Plastic Injection Molding Machine…...……45

4.2.4 Safety Precaution………46

4.2.4.1 Safety Instruction Before Operating Injection Molding Machine…..46

4.2.4.2 Safety Instruction While Operating Injection Molding Machine…...47

4.2.4.3 Safety Instruction After Operating Injection Molding Machine……47

4.3 Eliminate Contamination and Stains on Area and Machine………47

4.4 Improve Equipment Accessibility………...51

4.5 Preventive Maintenance for Arburg 420C Injection Molding Machine………….53

4.5.1 Arburg 420C Injection Molding Machines Maintenance Plan Standards…..55

5. DISCUSSION………..62

5.1 Introduction……….…....62

5.2 Quality Improvement...…....62

5.3 Safety Guaranteed………...…………63

5.4 TPM Effectiveness………..64

5. CONCLUSION AND……….……….…...65

5.1 Conclusion ……….……….…....65

5.2 Recommendations...…....66

REFERENCES ...67

APPENDICES

A Gantt chart (PSM 1) B Gantt chart (PSM 2)

C Specification of the Arburg 420C D Maintenance Plan Schedule

LIST OF FIGURES

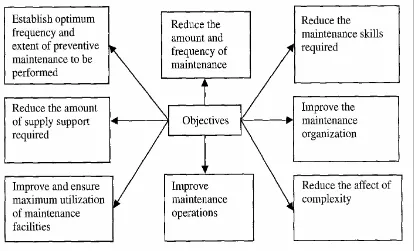

2.1 Important objectives of maintenance engineering...6

2.2 Important benefits of performing preventive maintenance...20

2.3 Injection machine unit...23

2.4 A reciprocating screw, showing the feeding zone, compressing (or transition) zone, and metering zone...24

2.5a Nozzle with barrel in processing position...25

2.5b Nozzle with barrel backed out for purging...25

2.6 The molded system includes a delivery system and molded parts...27

2.7 Some of the important reasons for the human error in maintenance...30

3.1 Process planning of the project...36

3.2 Arburg 420C injection molding machine...37

3.3 Flow chart of documented procedures (ISO) of the project...40

LIST OF TABLES

4.1 Eliminate contamination and stains on area and machine activities………48

4.2 Eliminate contamination and stains on area and machine activities………49

4.3 Eliminate contamination and stains on area and machine activities………50

4.4 Eliminate contamination and stains on area and machine activities………51

4.5 5’S activities……….52

4.6 Machine Maintenance Schedule………...54

4.7 Plastic Injection Plan Maintaining………55

LIST OF ABBREVIATIONS, SYMBOLS, SPECIALIZED

NOMENCLATURE

CAM - Computer Aided Manufacturing CM - Corrective Maintenance CBP - Current Best-Practice

mm - Millimeter

min - Minute

FKP - Faculty of Manufacturing Engineering FMEAs - Failure modes and effects analyses FTM - Fixed-Time Maintenance

PM - Preventive Maintenance

PMT - Post Maintenance Testing rpm - Revolution per minute TPM - Total Preventive Maintenance TQM - Total Quality Management

US - United States

UTeM - Universiti Teknikal Malaysia Melaka

CHAPTER 1

INTRODUCTION

1.1 Background

In this study, it is clearly shown that the conditions of machine are the important term in manufacturing industry. Proper hands-on maintenance techniques provide increased reliability and uptime for our injection molding machines. The common focus of this study is changed from fixing breakdowns machines to preventing them. The benefits of Total Preventive Maintenance (TPM) come when companies transition from a fire-fighting mode of fixing one sudden breakdown after another to preventing those breakdowns.

The research of this study involved the fundamentals of maintenance of Arburg 420C injection machine and the process which are related to the TPM concept. The main focus of this study is focuses on TPM of Arburg 420C injection molding machine. The propose of this research is on the aspect need on maintenance of injection molding machine such as daily maintenance, weekly maintenance, monthly maintenance and annually maintenance.

theirself with observation and guide by technician. Students from first years till last year were use the injection molding machines in their course, so the frequency of use this machine is very high. In this situation, the maintenance action is very important to avoid the breakdown problem from happened to the machine. There have Preventive Maintenance, Breakdown Maintenance and Corrective Maintenance had been implement in this lab, but the shown the poor result of maintenance and not implement systematic. So the solution is to implement of TPM programme to the Arburg 420C injection molding machine at casting laboratory. This project will define TPM in some detail, evaluate its strengths and weaknesses as a maintenance philosophy, and discuss implementation procedures. Examples of successfully implemented programs will be presented.

1.2 Problem Statement

Nowadays many of injection companies do not have proper scheduling of maintenance on their factories. This situation will lead cost of maintenance system of injection machine will be increase. Some of company have maintenance system but do not document properly the maintenance documentation. Maintenance of related equipment such as cruncher, water cooling machine and material feeding also will increase the maintenance cost.

Today, with competition in industry at an all time high, TPM may be the only thing that stands between success and total failure for some companies. It has been proven to be a program that works. It can be adapted to work not only in industrial plants, but in construction, building maintenance, transportation, and in a variety of other situations.

1.3 Objective

The aim of this project was to study the process of Total Preventive Maintenance (TPM) of injection machine Arburg 420C. The main objectives were:

1. To find out the proper way of Total Preventive Maintenance (TPM) on Arburg 420C injection machine.

2. To documented a daily, weekly, monthly and annually maintenance. 3. To investigate before, during and after operation maintenance.

1.4 Scope

This study focuses on the concept of Total Preventive Maintenance of Arburg 420C injection machine. Besides that, this project also will study what aspect need on maintenance of injection machine. The aspect of maintenance such as a daily maintenance, weekly maintenance, monthly maintenance and annually maintenance will be investigated.

CHAPTER 2

LITERATURE REVIEW

2.1 Introduction

This literature review discusses thoroughly on the issue that is related with the Total Preventive Maintenance in manufacturing industry. The legal requirement regarding the Total preventive Maintenance is stated in this part and explains further on what is the preventive maintenance how important the factor to be controlled the maintenance process in machining operation. The other related topic is about the maintenance overview, injection molding machine and the others factor that related the maintenance operation. Here in this literature review also review the other method and techniques which used in the preventive maintenance and also the development and the challenge of the preventive maintenance in industry nowadays.

2.2 Introduction to Engineering Maintenance

In the future engineering equipment will be even more computerized and complex. Further computerization of equipment will increase the importance of software maintenance significantly, approaching, if not equaling hardware maintenance. In addition, factors such as increased computerization and complexity will result in greater emphasis on maintenance activities with respect to areas such as cost effectiveness, quality, safety, and human factors [2]. In the future creative thinking and new strategies will definitely be required to realize all potential benefits and turn them into profitability.

2.2.1 History of Maintenance

Although humans have felt the need to maintain their equipment since the beginning of time, the beginning of modern engineering maintenance may be regarded as the development of the steam engine by James Watt (1736-1819) in 1769 in Great Britain [4]. In the United States the magazine Factory first appeared in 1882 and has played a pivotal role in the development of the maintenance field [3]. In 1886 a book on maintenance of railways was published [5].

2.2.2 Maintenance Engineering Objectives

There are many objectives of maintenance engineering. Some of the important ones as shown in Figure 2.1 [7].

Figure 2.1: Important objectives of maintenance engineering.

2.2.3 Facts Related to Engineering Maintenance

Some of the facts and figures concerning engineering maintenance are as follows:

2. It is estimated that the cost of maintaining a military jet aircraft is approximately $1.6 million per year, and about 11% of the operating cost for an aircraft accounts for maintenance activities [9].

3. Over the years the size of a plant maintenance group in a manufacturing organization has varied from 5 to 10% of the total operating force [10] — 1 to 17 persons in 1969 and 1 to 12 persons in 1981 [10].

4. For fiscal year 1997, the request of the U.S. Department of Defense for their operation and maintenance budget was $79 billion [11].

5. In 1970 a British Ministry of Technology Working Party document reported that the United Kingdom annual maintenance cost was around 3000 million pounds [12,13]. 6. The U.S. Department of Defense spends approximately $12 billion annually on

depot maintenance of weapon systems and equipment [14].

2.2.4 Safety in Maintenance

Safety in maintenance is becoming an important issue, as accidents occurring during maintenance work or concerning maintenance are increasing significantly. For example, in 1994 around 13.61% of all accidents in the U.S. mining industry occurred during maintenance work and they have been increasing at a significant rate annually since 1990 [15,16].

Some of the main reasons for safety problems in maintenance are poor safety standards and tools, poor equipment design, poor training of maintenance personnel, insufficient time to perform required maintenance tasks, poorly written maintenance instructions and procedures, poor management, poor work environments, and inadequate work tools[16].

When the need for maintenance cannot be avoided, designers should follow guidelines such as those listed below for improving safety in maintenance [17]:

1. Eradicate the need for performing maintenance and adjustments close to hazardous operating parts or equipment.

2. Keep design as simple as possible, because complexity usually adds to maintenance problems.

3. Aim to eliminate the requirement for special tools or equipment.

4. Provide appropriate guards against moving articles or parts and interlocks for blocking accesses to hazardous locations.

5. Incorporate appropriate fail-safe designs for preventing injury and damage if a failure occurs.

6. Design for easy accessibility so that items requiring maintenance can easily be checked, removed, replaced, or serviced.

7. Develop designs or procedures that minimize the occurrence of maintenance errors.

8. Develop the design in a manner that reduces the probability of maintenance personnel being injured by escaping high-pressure gas, electric shock, contact with a hot surface, and so on.

9. Incorporate appropriate devices or other measures for early prediction and detection of all potential failures so that the required maintenance can be performed prior to failure with somewhat reduced risk of hazard.

2.2.5 Quality in Maintenance

1. In 1986 the space shuttle Challenger exploded and all seven crew members lost their lives [18,19]. A subsequent investigation identified the cause of the disaster as the failure of the pressure seal in the aft field joint of the right solid rocket motor. Furthermore, the investigation concluded that a high-quality maintenance program would have successfully tracked and discovered the cause of the disaster.

2. In 1990 10 people died as the result of a serious steam leak in the fire room on the U.S.S. Iwo Jima (LPH2), a U.S. Navy ship [20]. Failure of the service turbine generator root-valve bonnet fastener was identified as the main cause of this tragedy. Further investigation revealed that ship’s personnel furnished the replacement fasteners without properly verifying if the requirements of the technical manual and drawings were fully satisfied.

3. In 1963 the US.S. Thresher, a U.S. Navy nuclear submarine, was lost at sea because of flooding in its engine room [18,20]. An investigation identified a piping failure in one of the salt water systems as the most likely cause for the disaster. Consequently, many changes were recommended in the submarine design and maintenance processes.

Past experiences indicate that Post Maintenance Testing (PMT) is quite useful for increasing the quality of maintenance. Its three main objectives are

a. To ensure that no new deficiencies have been introduced.

b. To ensure that the original deficiency has been eradicated properly. c. To ensure that the item in question is ready to carry out its stated mission