SUPERVISOR DECLARATION

" I hereby declare that the quality of the dissertation written is sufficient for the award of Bachelor of Mechanical Engineering (Design & Innovation)"

Signature Supervisor Date

' セ|@

.

: ...

: Siti Nurhaida binti Khalilキセᄋᄋᄋᄋ

ᄋᄋᄋᄋᄋᄋᄋᄋ@

: ...

_ZMNiNANlセNセMセMMMᄋᄋᄋᄋᄋᄋᄋᄋᄋ

ᄋ ᄋ@

DESIGN AND FABRICATION MODULAR PRODUCT WITH THE

INCORPORATION OF DIY ASSEMBLY METHOD: LAZY CHAIR

NUR 'AIN BINTI AZMI

This report is submitted as a partial fulfillment of the requirements for the

award Bachelor of Mechanical Engineering (Design & Innovation)

Faculty of Mechanical Engineering

Universiti Teknikal Malaysia Melaka

DECLARATION

"I hereby declare that the work in this dissertation is my own except for summaries and quotations which have been duly acknowledge"

Signature Author Date

/'

: ...

セ@

... .: Nur 'A in binti Azmi

':l_q Jl!N 2.0\4...

©

Unlverlltl Teknlkal Malaysia MelakllD edicated with love,

To my parents,

Azmi bin Hj. Arshad and Roziah binti Hj. Mustapha,

To my sister,

Nur Asyikin binti Azmi.

To all my friends.

IV

ACKNOWLEDGEMENT

Apart from the efforts of myself, the success of this project depends largely on the encouragement and guidelines of many others. I would like to take this

セーーッイエオョゥエケ@ to express my gratitude to the people who have been helping and

supporting me throughout the successful completion of this project.

First and foremost, I would like to thank my supervisor, Ms. Siti Nurhaida binti Khalil for the valuable guidance and advice right from the beginning of this project until the very end. Her willingness to motivate and encourage me contributed tremendously to my project and without her, this project would not have materialized.

I would like to express my greatest appreciation to my beloved parents, Azmi bin Hj. Arshad and Roziah binti Hj. Mustapha. I cannot thank them enough for their support, faith and loves towards me upon completing my project. They are the reasons for me to complete this project.

Last but not least, special thanks to Marliati Ghazali, Myn Samsuddin, Fariha Azmi, Nik Zubaidi and to all my friends who have been constantly helping and supporting me throughout the completion of this project. I am grateful with their helps and their contributions were vital for this project. Not to forget, thank you for the friendships.

v

ABSTRACT

VI

ABSTRAK

Objektif projek ini adalah untuk mengkaji aktiviti - aktiviti yang direka bentuk yang terlibat didalam proses mereka bentuk konsep modular produk yang baru bagi 'Kerusi Malas' dan fabrikasi sebuah prototaip dengan skala I :2 menggunakan bahan mampan. Modular produk yang baru ini juga harus menggabungkan konsep pemasangan 'DIY' . Projek ini bermula dengan memilih sebuah kerusi malas sebagai penanda aras dan idea-idea untuk reka bentuk konsep yang baru dapat dihasilkan. Carta morfologi digunakan sebagai salah satu kaedah untuk menghasilkan beberapa konsep rekabentuk yang baru. Kaedah pemlihan konsep yang digunakan adalah kaedah Pugh. Konsep reka bentuk yang dipilih akan dianalisis menggunakan kaedah DFMA untuk melakukan perbandingan dengan reka bentuk kerusi malas yang sedia ada. Analisis DFMA adalah salah satu cara atau aplikasi yang digunakan untuk mengurangkan bilangan bahagian atau komponen yang perlu dipasang menjadi satu produk dan meningkatkan kadar pemasangan yang mudah. DIY adalah bahagian yang paling penting dan cara pemasangan yang terbaik akan dipilih menggunakan kaedah pemilihan konsep yang ada di dalam Reka bentuk Kejuruteraan. Kaedah pemasangan DIY diaplikasikan di dalam reka bentuk ini adalah untuk member kesenangan kepasa para pengguna untuk memasang tanpa memerlukan bantuan manual. Hasil daripada projek ini adalah menghasilkan sebuah konsep modular produk yang baru untuk 'Kerusi Malas' bagi mengatasi beberapa masalah yang wujud dengan reka bentuk yang sedia ada.

Vll

TABLE OF CONTENT

CHAPTER CONTENT PAGE

DECLARATION 11

DEDICATION lll

ACKNOWLEDGEMENT lV

ABSTRACT v

ABSTRAK Vl

TABLE OF CONTENT Vll

LIST OFT ABLES Xl

LIST OF FIGURES Xll

LIST OF APPENDICES XlV

CHAPTER l INTRODUCTION l

1.1 Background

1.2 Objective 2

1.3 Scope 2

1.4 Problem Statement 3

1.5 Methodology 3

1.6 Outline of Report 3

1.7 Conclusion Remarks 5

CHAPTER2 LITERATURE REVIEW 6

2. 1 Modular Product 6

2.1.1 Defmitions 7

Vlll

2.1.3

Modular Architectures9

2.1.4

Modular Product Development II2.2

Do It Yourself (DIY) Method12

2.3

Design for Manufacture and Assembly14

(DFMA)2.4

Chair18

2.4.1

History of Chair18

2.4.2

Chair Seats19

2.4.3

Standards and Specifications19

2.4.4

Accessories21

2.5

Materials22

2.5.1

Softwood22

2.5.2

Plywood23

2.5.3

Stainless Steel24

2.5.4

Flexible Polymer Foam26

2.6

Threaded Fasteners28

2.6.1

Screw29

2.6.2

Bolt & Nut30

2.7

Conclusion Remarks31

CHAPTER3

METHODOLOGY

323.1

Introduction32

3.1.1

Benchmark34

3.1.2

Ideas I Sketches35

3.1.3

Generate Concept Design35

3.1.4

Concept Design Selection35

3.1.5

Product Architecture37

3.1.6

Configuration Design38

3. 1.7

Parametric Design38

3.1.8

Detail Design38

3.1.9

Prototype & Testing39

3.2

Flow of Design Process40

3.2.1

Defme Problem41

3.2.2 The House of Quality Configurations

3.2.3 Product Design Specification

3.2.4 Gather Information 3.2. 5 Product Decomposition 3.2.6 Morphological Chart

3.3 Conclusion Remarks

CHAPTER4 CONCEPT GENERATION

4.1 Introduction

4.2 Concept Design 1

4.3 Concept Design 2

4.4 Concept Design 3

4.5 Concept Design for Join Method

4.6 Conclusion Remarks

CHAPTER 5 CONCEPT DESIGN SELECTION

5.1 5.2 5.3

Introduction Pugh M ethod Pugh Method Chart

5.3. 1 Pugh Method: Lazy Chair Design 5.3.2 Pugh Method: Join Method

5.4 Conclusion Remarks

CHAPTER 6 DETAIL DESIGN

6.1 6.2 6.3 Detail Drawing Exploded Drawing Prototype

CHAPTER 7 RESULT & DISCUSSION

7.1 Result

7.1.1 DFA Analysis

7.2

7.3

7.1.1.2. DFA Analysis ofNew Design

7.1.2 DFM Analysis

Discussion

7.2.1 DFAAnalysis Result 7.2.2 Limitations and Strengths

7 .2.3 New Design of Lazy Chair

Conclusion Remarks

CHAPTER 8 CONCLUSION & RECOMMENDATION

8. 1

8.2

Conclusion

Recommendation

REFERENCES

APPENDICES

©

Unlverlltl Teknlkal Malaysia Melakll63

76

77

77

78

79

79

80 80

81

82

85

xu

[image:12.577.102.534.187.752.2]LIST OF FIGURES

Figure 1.1: Current Design ofLazy Chair

Figure 2.1 : Designs of a drawer (Huang 2000) ... ... 7

Figure 2.2: Examples of Modular Product (Holtta-Otto 2005) ... l 0 Figure 2.3: Examples of Integral Product (Holtta-Otto 2005) ... l 0 Figure 2.4: DFMA approach ... 14

Figure 2.5: Example of DFM Concurrent Costing Software ... 15

Figure 2.6: Example of Design for Assembly software ... 16

Figure 2. 7: Chair design for comfort ... 20

Figure 2.8: Softwood description ... 22

Figure 2.9: Plywood description ... 23

Figure 2.10: Example's of stainless steel chair ... 24

Figure 2.11: Examples of seats made of flexible polymer foam ... 26

Figure 2.12: Wood screw ... 29

Figure 2.13: Bolt & Nut ... 30

Figure 3.1: Flowchart of Projek Srujana Muda ... 33

Figure 3.2: Existing design of lazy chair as benchmark ... 34

Figure 3.3: Example of Pugh Method selection method for a kettle ... 36

Figure 3.4: An overview of product architecture methodology ... 37

Figure 3.5: CATIA Software ... 39

Figure 3.6: Flow of Design Process (G. E. Dieter 2009) ... 40

Figure 3.7: CES EDUPACK 2011 ... 45

Figure 3.8: Example of Nickel alloys information from CES EduPack ... 46

Figure 3.9: Product Decomposition of existing design of Lazy Chair.. ... 4 7 Figure 4.1: Concept design 1 ... 49

Figure 4.2: Concept design 2 ... 50

Xlll

Figure 5. 1: Concept 2 as the final concept design ... 55 Figure 5.2: Final concept for join method which Concept 2 & Concept 3 ... 56

XIV

LIST OF APPENDICES

Appendix Al: Estimated Handling Time Table ... 86

Appendix A2: Estimated Insertion Time Table ... 87

Appendix A3: Axis of Orientation Chart ... 88

Appendix B 1 : Detail drawing ... 89

Appendix B2: Exploded drawing of Lazy Chair ... 90

Appendix B3: Exploded drawing ofThreaded Fasteners ... 91

Appendix C I : ISO view of Lazy Chair I ... 92

Appendix C2: ISO view of Lazy Chair 2 ... 92

Appendix C3: ISO view of Lazy Chair 3 ... 93

Appendix C4: ISO view of Lazy Chair 4 ... 93

Appendix Dl : Prototype of Lazy Chair 1 ... 94

Appendix D2: Prototype of Lazy Chair 2 ... 94

Appendix D3: Prototype of Lazy Chair 3 ... ... .. 95

Appendix D4: Prototype of Lazy Chair 4 ... ... .. 95

Appendix E l : Flow Chart for PSM I & 2 ... 96

Appendix F l: Gantt Chart for PSM 1 ... 97

CHAPTER I

INTRODUCTION

1.1 Background

Figure 1.1: Current Design of Lazy Chair

Chair is created as furniture that is used to sit on normally by a single person.

Chair has been invented centuries ago and most often the chair is supported by four

legs and has a back. However, the designs are different according to the creativity of

the designers and criteria of the chair itself. There are various types of chair and one

of the chairs is lazy chair or can also be called leisure or relaxing chair. This type of

chair is for relaxing and the person that sits on it can take a nap as the back of the

[image:15.577.103.527.104.744.2]2

chair is inclined and gives comfort to the user. It differs from other chairs because of the slant angle of the back of the chair.

Lazy chair in this project is design to counter several problems from its original design in terms of assemble the product. Using the modular product concept, a new concept design will be produced to overcome the problems. In general, modular product can be defined as an assembly with reduced parts, less complicated and easy to assemble. Modularization is a concept that offers competitive advantage to overcome complexity. Instead of manufacture a product with plenty of parts and mechanical fasteners, design a product using simple blocks which is easy to manufacture and use less joining method. The customers will be more satisfied and pleased with the easiness of assemble the product (Lupton 2006).

When the customers assemble the product themselves, the terms used for that act is Do It Yourself (DIY) method. DIY is an act of building or modifying without the help of any expertise and instead do it independently. Usually products with DIY assembly method will provide a manual for the customers to follow and DIY products are easy to assemble and use low cost tools (Howell2010).

1.2 Objective

To study the activities in designed involved in designing of a new modular product concept for " Lazy Chair" and fabrication of a prototype of scale l :2 using sustainable material. The modular product also has to incorporate "DIY" assembly method.

1.3 Scope

l. To propose few concept designs of modular product.

3

1.4 Problem Statement

The existing design of lazy chair does not imply the DIY concept. The chair already builds and joints completely and the buyers have to bring the chair in one piece. The chair inclination level can be adjusted according to the user's wish. The tricky part is that both of the rum rest must be moved simultaneously in order to change the inclination level. New modular conceptual design of lazy chair with the incorporation of DIY method will be produced at the end of this project to overcome problems of existing design.

1.5 Methodology

Methodology generally is a guideline for solving problems. In this project, there are several methods used to complete the design of new product. From the frrst steps until the end, the methods are represents in flow chart to make it easy to understand.

1.6 Outline of Report

Chapter 1 - Introduction

This chapter contains the background, objectives, scope and problem statement of the project. This chapter also reviews generally about the methods used in this project.

Chapter 2 - Literature Review

This chapter reviews the details of subjects cover in this project. The frrst subject is modular product and followed by DIY assembly method, DFMA, chair, materials and Screw, Bolt and Nut.

4

Chapter 3 - Methodology

This chapter contains the methods used in completing the project. The flow chart of this project is included in this phase and the details of each methods used is discussed.

Chapter 4 - Concept Generation

This chapter shows several of the concept designs generated from the previous morphological chart (In Chapter 3). The descriptions of each concept designs are also stated in this chapter.

Chapter 5 - Concept Design Selection

This chapter reviews the method used in selecting the best concept design. There are several methods that can be used, but in this project, the author chose Pugh Method as the concept design selection method.

Chapter 6 - Detail Design

5 Chapter 7 - Result & Discussion

This chapter discussed in details the results from the DFA and DFM analysis done manuaJly and the outcomes of this project.

Chapter 8 - Conclusion

This chapter will conclude all the results and fmdings that have been completed.

1. 7 Conclusion Remarks

In this chapter, the author reviews about the objectives, problem statements and scopes of this project. The author also reviews the outline of this report in general which consists of 8 chapters including this chapter. The background and history of the lazy chair are also discussed in this chapter generally as the details will be further discussed in the next chapter.

CHAPTER2

LITERATURE REVIEW

This chapter will discuss further on the project. The first subject to be discussed is modular product. The topics covered are the defmitions and advantages of modularity. This chapter also will discuss about the Do It Yourself assembly method, Design for Manufacture and Assembly and about the chair itself

2.1 Modular Product

[image:20.577.92.531.61.382.2]7

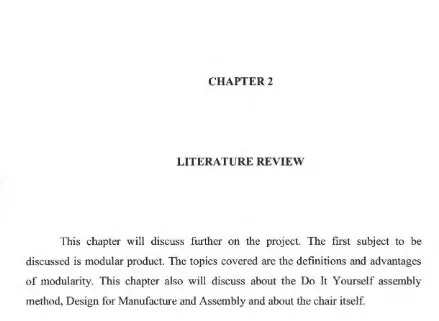

(a) (b)

[image:21.577.136.503.51.319.2]4 modules are used

7 blocks are used

Figure 2.1: Designs of a drawer (Huang 2000)

2.1.1 Definitions

[image:21.577.116.517.308.744.2]Modularity is a common but unexplored thread among all areas of life-cycle engineering. It has become very famous in studies recent years though it has existed for at least 30 years. Modular products tend to have fewer components for assembly and therefore cheaper to assemble. Modularity has no specific definitions and in fact according to (Gershenson 2003), there is no agreement on the definition of modularity. Modular product can be defined in many ways and shown below in Table 2.1 are some examples of the definitions:

Table 2. 1: Definitions of Modular Product Authors

Pabl and Beitz

Ulrich and Tung

Definitions

Modular products refer to products, assemblies and components that fulfill varwus functions through the combination of distinct building blocks (Pahl 1988)

Defme modularity m terms of two characteristics of product design (Ulrich

Erixson and Kusiak

Chun Che Huang

1991):

1. Similarity between the physical

and functional architecture of the

design.

2. Minimization of incidental

interactions between physical

components.

Define modularity as a tool to decrease

assembly and manufacturing costs in

product families and manufacturing

systems (Erixson 1996).

The terms modularity in products is used

to describe the use of common units to

create product variants (Huang 2000).

8

In general, modular product is an assembly with reduced parts, less

complicated and easy to assemble. Due to the functional independence it creates,

modularization has been called the goal of good design (John K. Gershenson 1999).

2.1.2 Advantages of Modular Product

Modularity has a lot of advantages and benefits, as an example, modularity

allow the designer to control the degree to which changes in processes or

requirements affect the product. According to Ulrich and Tung (Ulrich 1991 ), they

described the benefits of modularity as:

l. Greater product variety. A modular product design can be partitioned

technically and variations in functional components can be substitutes

into modular architecture to create product variations based on

different combinations (Eggen 2003).

2. Economies of scale. Since each module will usually be produced in a

9

3. Ease of product updating. A modular product is decomposed into

modules; only certain modules need to be replaced. And for same

reason, upgrades, updates, maintenance and disposal are simpler.

4. Increased product variety. The use of modules means that a great

product variety can be achieved using different combination of

modules.

5. Reduced order lead-time. Since modules are manufactured in

relatively large scale, the production can be organized so as to reduce

manufacturing lead time.

6. Ease of design and testing. As the component is produced in modules,

the design is simple and for testing purpose, the components can be

tested individually.

Designing a modular product can gives the result of product cost and

development time higher or lower. If the designs are simple needs simpler

manufacturing process, the cost can be low but if the designs are complicated and

needs a lot interfaces between the modules, the cost may be higher. The development

time is often lower once the design is split into modules, where the design teams can

work in parallel on the different modules.

2.1.3 Modular Architectures

There are two types of product architecture; modular architecture and integral

architecture. An integral architecture includes a complex mapping from functional

elements to physical components (John K. Gershenson 1997). In the other hand,

modular architecture has a one-to-one mapping. Modular architecture allows a design

change to be made to one module without requiring a change to other modules for

the product function properly (Eggen 2003).

10

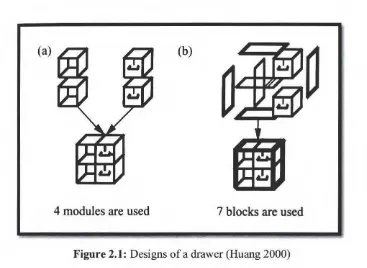

Typical examples for modular architecture which is close to one to one mapping between functions are mechanical pencil, personal desktop computer and pocket knife. The examples shown in Figure 2.2 below.

Figure 2.2: Examples of Modular Product (Ho ltUi-Otto 2005)

In the other hand, typical examples of integral architecture where it is hard to determine what part of a product performs which function are an old fashioned pencil, a laptop and a hunting knife. The examples shown in Figure 2.3 below.

[image:24.577.107.527.56.361.2] [image:24.577.111.523.413.602.2]<I

- '"1u0