THE QUALITY OF

Pinuspinaster

ArBinennPARTICLEBOARDS USING

NATURAL ADHESIVE MADE OF CORN STARCH,

TANNIN AND CHITOSAN

SONIA SOMADONA

THE GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY

BOGOR

DECLARATION

I declare that this thesisentitled The Quality of

PinuspinasterArBinennParticleboards Using Natural Adhesive Made of Corn Starch, Tannin and Chitosan is my own work with the direction of the supervising committee and has not been submitted in any form for any college except in ENGREF, France (require by Double Degree Program). Information and quotes from journals and books have been acknowledge and mentioned in the thesis where they appear. All complete references are given at the end of the paper.

I understand that my thesis will become part of the collection of Bogor Agricultural University. My signature below give, the copyright of my thesis to Bogor Agricultural University.

Bogor, October 2012

A B S T R A C T

SONIA SOMADONA.The Quality of PinuspinasterArBinenn Particleboards Using Natural Adhesive Made of Corn Starch, Tannin and Chitosan.Under the supervision of SURDIDING RUHENDI and BERTRAND CHARRIER.

The development and optimization of a new, environment-friendly adhesive made from abundant and renewable cornstarch, tannin and chitosan is described in this study. At present, the production of wood composites mainly relies on petrochemical and formaldehyde-based adhesives such as phenol-formaldehyde (PF) resins and urea-phenol-formaldehyde (UF) resins. Natural adhesive is not only environmentally friendly but also less expensive as compared to other exterior binders used in wood composite industry. The objective of this study is to evaluate the quality of adhesive and particleboard produced. This research describes performances of natural adhesive obtained from cornstarch, tannin and chitosan (solid content, viscosity, gel time, pH and bond strength). Results describe physical properties of all particleboard production according to standard EN 323, 2004. Mechanical properties of particleboard did not fulfilled standard EN 312 for IB, MOR and MOE.

SUMMARY

SONIA SOMADONA.The Quality of PinuspinasterArBinenn Particleboards Using Natural Adhesive Made of Corn Starch, Tannin and Chitosan.Under the supervision of SURDIDING RUHENDI and BERTRAND CHARRIER.

Currently, the majority of wood based panels for furniture or construction (particle board, OSB, plywood, LVL, etc.) has used synthetic adhesives such as urea-formaldehyde, melamine formaldehyde, phenol-formaldehyde and resorcinol-formaldehyde are derived from petroleum andnon renewable fossil resource.They contain formaldehyde which is volatile and harmful for human health

Renewable raw materials have several own advantages such as availability, and regeneration. The use of adhesives from renewable raw materials will replace the petroleum based adhesives as they are more environmentally friendly and are able to reduce formaldehyde emissions. These renewable raw materials are corn, tannin and chitosan. These three materials represent an alternative to natural adhesivesin place of synthetic adhesives.

The study was conducted testing the quality of natural adhesives from these three resources and the quality of particleboard using the natural adhesives. Tested the quality of adhesive such as solid content, gel time, pH and viscosity with reference to JIS K 6833-1980) was conducted and for tested quality of particleboard according to standard methods of European Standard EN 310, 317, 319, and 323 for particleboard and fiberboard.

The qualities of natural adhesive are as follows : solid content has value between 30.79% - 31.37 %, viscosity between 30800 cP - 37083.33cP, gel time value about 671.67 second - 980.92 second, pH between 10.66 - 11.91 and bond strength between 2. 29 N/mm2 - 2.98 N/mm2.Based on the results, the solid content value of natural adhesive made of three reneweble raw materials (corn starch, tannin, and chitosan) under the standards set.While the viscosity, gel time and pH do not have the standard. The bond strength of natural adhesive has a value above the standards (≥ 1 N/mm2)

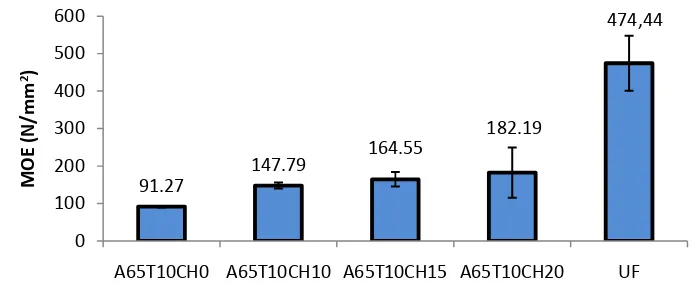

The qualities of particleboard produced in this research are as follows : density has value between 0.39 g/cm3 - 0.43 g/cm3, moisture content between 9.64 % -12.29 %, thickness swelling in 2 h between 21.82 % - 23.22 %, thickness swelling in 24 h between 25.44 % - 28.28 %, internal bond between 0.03 N/mm2 - 0.12 N/mm2, MOR value between 0.93 N/mm2 - 1.73 N/mm2 and MOE between 91.27 N/mm2 - 182.19 N/mm2.The quality of particleboard produced only moisture content and density has a value above the European Standard. Whileinternal bond, thickness swelling, MOE and MOE were lower than beEuropean Standard.

© CopyrightIPB, 2012

Copyright Reserved by Law

Prohibited quoting part or all of this paper without mentioning or citing the sources. Quotation is only for educational purposes, research, writing papers, preparing reports, writing criticism, or review of an issue, and the citations will not harm the interests of IPB

THE QUALITY OF

Pinuspinaster

ArBinenn

PARTICLEBOARDS USING NATURAL ADHESIVE MADE

OF CORN STARCH, TANNIN AND CHITOSAN

Thesis

In partial fulfillment of the requirements for the degree of Master of Science at Department of Forest Product

SONIA SOMADONA

THE GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY

BOGOR

Title : The Quality of PinuspinasterArBinenn Particleboards Using Natural Adhesive Made of Corn Starch, Tannin and Chitosan

Name : Sonia Somadona

NIM : E 251100151

Approvedby : Advisory Committee

Chairman

Prof. Dr. Ir. SurdidingRuhendi

Member

Prof. Dr. Bertrand Charrier

Accepted by:

Chairman of The Department of Forest Product

Prof. Dr. Ir. WayanDarmawan, M.Sc.

Date of Examination :

Dean of The Graduate School

Dr. Ir. DahrulSyah, M.Sc.Agr

ACKNOWLEDGEMENTS

Gratitude to Allah SWT, because of the abundance of his gifts are given the opportunity and health writer so I can complete thesis on the theme "The Quality of PinuspinasterArBinenn Particleboards Using Natural adhesive Made of Corn Starch, Tannin and Chitosan"

First of all, I am very grateful to Prof. Dr. Ir. SurdidingRuhendi and Prof. Dr. BertrandCharrier for his skillful and patient guidance throughout my master study. I also appreciate his work on review and revision of this thesis. His scientific and earnest attitude in research will definitely be beneficial to my future work and life.

I also thanks full to Ministry of National Education and Department of Forest Product Bogor Agricultural University for Double Degree Indonesia-FranceScholarship

Last but not the least, I would like to thank my parents (Alm) Iskandar As and Hj. Husdaliza, SE and my sister Gita Suliska, (Alm) EziRahmadhani for their unselfish love and continuous support for motivation. I would like tothank Raya Syah Putra for love and fidelity to me.

Bogor, October 2012

TABLE OF CONTENTS

Objectives of Research 2

LITERATURE REVIEW 3

Particleboard 3

Tannin 4

CornStarch 5

Chitosan 5

MATERIAL AND METHOD 7

Time and Place of Research 7

Materials and Research Equipment 7

Experimental Design 7

Adhesive Preparation 7

ParticleboardPreparation 8

Testing of Adhesive 9

Solid Content 9

Viscosity 9

Gel Time 10

pH 10

Bond Strength of Adhesive 10

Testing of Particleboard 11

Density 11

Moisture Content 11

Thickness Swelling 12

Internal Bond 12

MOR and MOE 13

Quality of Adhesive 15

Solid Content 15

Viscosity 15

Gel time and pH 16

Bond Strength 17

Quality of Particleboard 18

Density 18

Moisture Content 19

Thickness Swelling 20

Internal Bond 21

MOR and MOE 21

CONCLUSIONS 23

REFERENCES 25

LIST OF FIGURES

No Page

1. Particleboard 3

2. Condensed tannin and Hydrolyzable tannin 4

3. Glucose molecule 5

4. Chitosan 6

5. Process of the particleboardpreparation 8

6. Cutting diagram particleboard 9

7. Test of adhesion of adhesive 11

8. Testing Internal Bond 12

9. Way of testing the MOR and MOE 13

10. The Average Value of the Solid Content of Natural Adhesive 15 for Different Concentration of Chitosan

11. The Average Value of the Viscosity of Natural Adhesive 16 for Different Concentration of Chitosan

12. The Average Value of the Gel Time of Natural Adhesive 17 for Different Concentration of Chitosan

13. The Average Value of the pH of Natural Adhesive 17 for Different Concentration of Chitosan

14. The Average Value of the Bond Strength of Natural Adhesive 18 for Different Concentration of Chitosan

15. The Average Value of theDensityof Particleboard 18 for Different Concentration of Chitosan

16. The Average Value of theMoisture Contentof Particleboard 19 for Different Concentration of Chitosan

17. The Average Value of theThickness Swelling2h and 24h 20 of Particleboard for Different Concentration of Chitosan

18. The Average Value of theInternal Bondof Particleboard 21 for Different Concentration of Chitosan

LIST OF APPENDIX

1. The Average Value of Qualityof Natural Adhesive 27 for Different Concentration of Chitosan

INTRODUCTION

Background

Currently, the majority of wood based panels for furniture or construction (particle board, OSB, plywood, LVL, etc.) has used synthetic adhesives such as urea-formaldehyde, melamine formaldehyde, phenol-formaldehyde and resorcinol-formaldehyde .These adhesive are derived from petroleum, which is non renewablefossil resource. They contain formaldehyde which is volatile product during both the manufacturing process and after the implementation. The emission of formaldehyde is harmful for human health(Vick, 1999). Moreover, oil prices are not stable, affected the price of products that use petroleum-based adhesives (urea-formaldehyde, melamine formaldehyde, phenol-formaldehyde and resorcinol-formaldehyde, etc).

Renewable raw materials have several own advantages such as availability, and regeneration. The use of adhesives from renewable raw materials will replace the petroleum based adhesives as they are more environmentally friendly and are able to reduce formaldehyde emissions.

Corn (Zea mays L.) is a commodity of global agriculture. It is an important source of carbohydrates and protein. Starch is used as an adhesive in a range of products such as binders, materials, glues and pastes (Imam et al. 1999, Yazaki and Collins 1997).

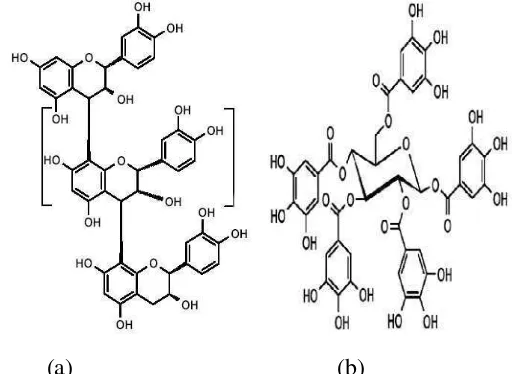

Tannins are formed of glycosides or organic polymers which contained in various plants. Tannins are divided into two groups: condensed tannins and hydrolyzable tannins. Hydrolyzable tannins are polyphenolic compounds based complexes of digallic acid and D-gluchilose. While condensed tannins are composed of units from flavonoids and are used to replace the phenolic compounds as well as the UF and MUF synthesis in wood-based panels. They do not emission formaldehyde when used as an adhesive (Pizzi 2006).

These three materials represent an alternative to natural adhesivesin place of synthetic adhesives. Therefore, it is important to conduct studies on the performance of natural adhesivesfrom these three resources and the quality of particleboard using the natural adhesives.

Objectives of Research The objectives of this research are:

1. To use renewable raw materials to replace synthetic products (especially if they are hazardous products).

2. Essential that these glues have physical and mechanical properties at least similar to synthetic materials (in this case Urea formaldehyde).

LITERATURE REVIEW

Particleboard

According to Bowyer et al. (2003) and Tsoumis (1991), particleboard is a panel product manufactured by embedding the particles together (such as small pieces of wood or other lignocellulosic material), with wood as a primary resource. Dumanauw (1990) states that the advantages of particle boards compared with solid wood are free from knots and checks, size and density can be adjusted, thickness and density are uniform, more isotropic, quality or surface appearance can be adjusted according to market or costumer desire. Particleboard typically has two face layers made from fine wood furnish (external layer) and one core layer made from coarse wood furnish. Generally particleboard is less expensive than solid wood. However, compared to solid wood, particleboard has a lower dimensional stability, lower in screw holding and strength. Particleboard is mainly used for furniture and kitchen cabinets products.

Approximately 95 % of the lignocellulosic material used for particleboardproduction is wood, but other agro-based residues have not been frequently utilized. Annual plant wastes, such as flax and hemp shives, bagasse, cotton stalks, small grain straw (including rice straw), peanut husks, rice husks, grape stalks, and palm stalks are inexpensive and valuable raw materials for lignocellulosic board production (Kozlowski et al. 1994).

Tannins

Tannin is a general term for a widely occurring group of substances that comes from the plants with varying proportions. Tannins are polyphenolic compounds which are able to interact with other macromolecules such as proteins and carbohydrates. Moreover tannin are an excellent renewable resource which can be used for replacing petroleum-derived phenolic compounds.

Different types of tannins have been used for a long time in the production of adhesives (Godwin and Mercier. 1983). Hydrolyzable tannin are derivatives of gallic acid (3,4-5 trihydroxyl benzoic acid). Gallic acid which is esterifies to a core polyol, and the galloylgroups may be further esterifies or oxidativelycross linked to yield more complex hydrolyzable tannins. Hydrolyzable tannin can be decomposed in water, which can react to form other useful substances such as gallic acid, pyrotocatechic acid and sugar. While condensed tannins, constituting more than 90% of the total world production of commercial tannins, are both chemically and economically more interesting for the preparation of resin adhesive (Pizzi and Mittal. 2003). Condensed tannins have a complex chemistry. It is a group of phenolic polymers which are widely distributed in the plant kingdom particularly with woody growth habit. These compounds consist of flavan-3-ol units linked together through C4-C6 or C4-C8 bonds (Rahim and Kassim.2008).

(a) (b)

Corn Starch

Starch is a renewable resource available in abundant quantities at a very low cost. Starch is a carbohydrate food reserve in plants and the major energy resource for non-photosynthetic organisms. Starch granules are composed primarily from different chemically biopolymers (amylase and amylopectine). The proportions of amylase and amylopectin depend on the variety of corn. Amylase is

essentially a linear molecule which consists of α-glucopyranosyl residues linked

via (1-4) glycosides bonds. While amylopectin molecules, on the other hand, are

highly branched, with α-glucopyranosyl residues linked by (1-4) glycosides

linkages and by α-(1-6) bonds at branch points. Ratio and proportion of amylase

ranged from 20% to 25%, and 75% to 80% for amylopectin respectively

The size of a starch granule also depends on the source, and the potato starch granules are the largest granules from all sources. When heated, in the presence of excess water, starch granules lose their crystalline, absorb large amounts of water, and leach amylase out, which impart viscosity to the starch/water system (Imam et al. 1999).

Figure 3. Glucose molecule(erzagenatrika.blogspot.com)

Chitosan

industries for high quality adhesive, purification of drinking water (having a coagulation power), increasing the dye industry in paper, textile and pulp (Alamsyah. 2001). Suptijah P (2006) found that chitosan has a specific shape, containing amine groups in the carbon chain and positively charged as opposed to other polysaccharides.

Chitosan is a naturally occurring biopolymer thin sheet-shaped, has no odor, white in color and the most abundant biomaterial. Chitosan is considered to be a random copolymer comprised primarily of repeat sugar units with the structure of a (1-4)-linked 2-amino-2- deoxy-b-D-glucopyranose and comprised also of some units of (1-4)-linked 2-acetamido-2-deoxy-b- D-glucopyranose (Wong et al. 2006).

MATERIAL AND METHOD

Time and Place of Research

This researchwas conducted in Laboratory of Physical Chemistry, University of Pau and Pays de l’Adour, France. This research was carried out from January 2012 to July 2012.

Materials and Research Equipment

The material used in this research was particle Pinuspinaster from particleboard industry in Mont de Marsan with moisture content ≤ 5 %. Fine particles with a size of 10 mesh and coarse particles with a thickness of 5 mm, length 50 mm and width 4-5 mm were used.Corn starch was obtained from Fisher scientific while quebracho tannin was obtained from Silva team, chitosan with molecular weight 600.000-800.000, hexamine, NaOH and aquadest.

Several equipments are used in this study such as: water bath, oven, rotary mixer,rotary blender, pressing machine, universal testing machine, pH meter, caliper, viscometer and precision balance.

Experimental Design

The experiments in completely randomized design with three replicates with different solution concentration of chitosan are (0, 10, 15, and 20 %).The results obtained were subjected to an analysis of variance (ANOVA) used software Minitab 15 to identify the effect of the chitosan concentration of chitosan for quality a of adhesive and properties particle board. Duncan test was applied to compare treatment means.

AdhesivePreparation

ml. The hexamine was dissolved in aquadest to give a solution of concentration equal to 30% before being added to the solution of corn starch-tannin-chitosan. The solution was mixed and then 125 ml of sodium hydroxide (33%) were added.

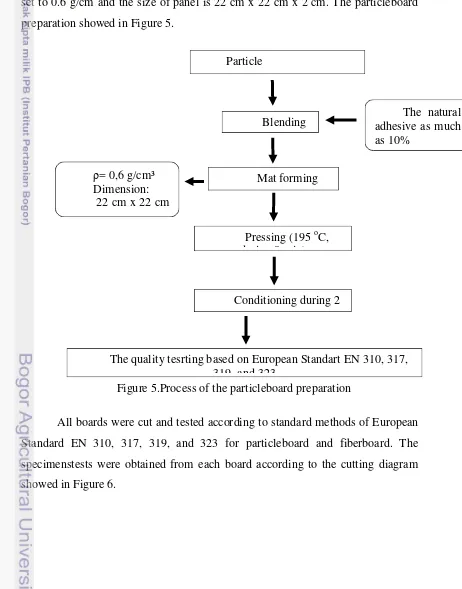

Particleboard Preparation

Particleboard was made by three layers, face, core, and back. Ratio between face/back and core is 30:70 based on weight strands. Target of density is set to 0.6 g/cm3and the size of panel is 22 cm x 22 cm x 2 cm. The particleboard preparation showed in Figure 5.

Figure 5.Process of the particleboard preparation

All boards were cut and tested according to standard methods of European Standard EN 310, 317, 319, and 323 for particleboard and fiberboard. The specimenstests were obtained from each board according to the cutting diagram showed in Figure 6.

Particle

Blending

Mat forming

ρ= 0,6 g/cm³ Dimension: 22 cm x 22 cm

Pressing (195 oC, d i 8 i )

The natural adhesive as much as 10%

Conditioning during 2

22 cm

22 cm

Figure 6. Cutting diagram of particleboard Notes :

1. MOE and MOR (20 cm x 5 cm)

2. Density and Moisture content (15 cm x 5 cm) 3. Internal bond (5 cm x 5 cm)

4. Thickness swelling (5 cm x 5 cm)

Testing of Adhesive

Test the quality of adhesive, the studysolid content, gel time, pH and viscosity with reference to JIS K 6833-1980) was conducted.

Solid Content

Solid Content is ratio between the weight of sample before and after heating at a given temperature until weight constant. Method of determination the solids content :

1. Sample of adhesive (1.5 gram was placed in to petridish (W1)

2. The adhesive in the petridish was dried in an oven at 105 ± 2 oC for 1 hour 3. Petridish was put in a desiccator for 10 minutes, then weighed

4. Drying and measuremass were performed until constant weight (W2). Solid content is determined by the formula:

The principle of measuring the viscosity is a measure of internal friction induced by the cohesion of the molecules in the adhesive. The viscosities of the natural adhesive were determined using a Brookfield Viscometer at 20 rpm using spindle number S07 and expressed in cP. The viscosity was measured in triplicate at 25 ± 1 °C.

Gel Time

Gelation is defined as the point where the resin ceases to be a viscous liquid and becomes soft, elastic, solid rubber (Pizzi and Stephanou. 1993). Five gram of adhesive was placed in a test tube and heated in boiling water or in water bath at temperatures above 100 °C under continuous mixing. The reactivity of a mixture is defined as the time measured from the beginning of heating until gelation occurred.

pH

The pH measurement is a measure of the concentration of H + ions in a solution. The method for determining the pH of the adhesive using a pH meter is as follows:

1. The samples of adhesive are poured into a 200 ml beaker and the acidity was measured at 25 °C using a pH meter.

2. Before pH measurement, a calibration of the pH meter is first performed with buffer solutions of pH equal to 4 and 7 at a temperature of 25 oC.

Bond Strength of Adhesive

Bonding quality was evaluated from the percentage of wood failure at the bonding area and bond strength of each specimen. The description of the procedure in Figure 7 is below:

Figure 7. Test of adhesion of adhesive Testing of Particleboard

Density

Density of a particleboard were determined according were determined according to the European Standard method (EN 323) on specimens with dimensions 200 mm x 50 mm x 20 mm. The density is the average of the measured densities on the test specimens of each panel. This density is the ratio of the mass of each specimen and volume.

Where :

Ρ : density

M : mass of the sample V : volume of the sample

Moisture Content

European Standard (EN 323) was using to determine moisture content. It corresponds to the mass loss from the sample after drying in an oven at 103 ± 2 °C to constant weight. Denoted by H, the water content is expressed as a percentage by weight and is equal to:

H : moisture content (%)

M1 : mass of the sample before drying in an oven (g).

M2 : mass of the sample after drying in an oven until constant weight (g). Thickness Swelling

Thickness swelling was determined according to the European Standard method (EN 317). To determine thickness swelling properties, particleboards were cut into 50 mm × 50 mm and soaked in water at room temperature (20 ± 2 °C) for both 2 hour (h) and 24 hour (h). The thickness and weight of the particleboard samples were measured before and immediately after soaking. Thickness swelling were calculated as ratios of absorbed water and increased thickness to the values before soaking, respectively, and expressed as percentages.

Where :

t1 : thickness of sample before immersion (mm) t2 : thickness of sample after immersion (mm)

Internal Bond

Size of sample 50 mm x 50 mm x 20 mm were attached to two aluminum blocks with polypropylene adhesive and left to dry. Two blocks drawn perpendicular to the surface of the specimen until the maximum load. Internal bond values calculated using the formula:

where:

IB : internal bond (N/mm2)

Pmax : maximum compressive load (N) A : surface area the sample (mm2)

Direction of the load

Direction of the load Figure 8. Testing Internal Bond

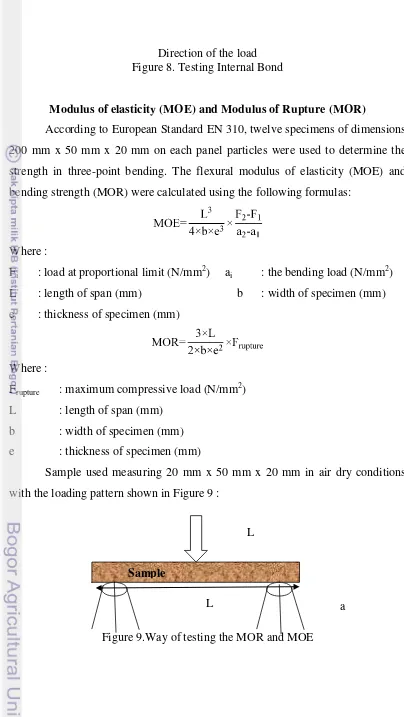

Modulus of elasticity (MOE) and Modulus of Rupture (MOR)

According to European Standard EN 310, twelve specimens of dimensions 200 mm x 50 mm x 20 mm on each panel particles were used to determine the strength in three-point bending. The flexural modulus of elasticity (MOE) and bending strength (MOR) were calculated using the following formulas:

Where :

Fi : load at proportional limit (N/mm2) ai : the bending load (N/mm2) L : length of span (mm) b : width of specimen (mm) e : thickness of specimen (mm)

Where :

Frupture : maximum compressive load (N/mm2) L : length of span (mm)

b : width of specimen (mm) e : thickness of specimen (mm)

Sample used measuring 20 mm x 50 mm x 20 mm in air dry conditions with the loading pattern shown in Figure 9 :

Figure 9.Way of testing the MOR and MOE Sample

L

RESULTS AND DISCUSSION

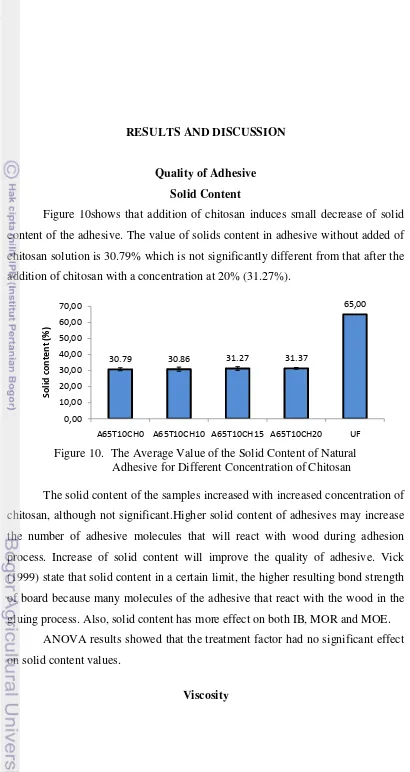

Quality of Adhesive Solid Content

Figure 10shows that addition of chitosan induces small decrease of solid content of the adhesive. The value of solids content in adhesive without added of chitosan solution is 30.79% which is not significantly different from that after the addition of chitosan with a concentration at 20% (31.27%).

Figure 10. The Average Value of the Solid Content of Natural Adhesive for Different Concentration of Chitosan

The solid content of the samples increased with increased concentration of chitosan, although not significant.Higher solid content of adhesives may increase the number of adhesive molecules that will react with wood during adhesion process. Increase of solid content will improve the quality of adhesive. Vick (1999) state that solid content in a certain limit, the higher resulting bond strength of board because many molecules of the adhesive that react with the wood in the gluing process. Also, solid content has more effect on both IB, MOR and MOE.

ANOVA results showed that the treatment factor had no significant effect on solid content values.

Viscosity

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

The viscosity values of resins made from different additions of chitosan solution; 65:10:0, 65:10:10, 65:10:15 and 65:10:20 (corn starch:quebrachotannin:chitosan solution, weight ratios) were tested. The results of viscosity test are shown in Figure 11.

Figure 11. The Average Value of the Viscosity of Natural Adhesive for Different Concentration of Chitosan

The viscosity of the samples increased with increased concentration of chitosan. The increase in viscosity may be due to protein unfolding in accordance with Angleimer and Montgomery (1976) who stated that an increase in intrinsic viscosity is one of the effects of protein denaturation. The higher viscosity of adhesive, the more difficult the adhesive flows on the wood surface because penetrating the medium and glue line very slowly then caused difficulty to applying adhesive (Corn Products International. 2006).

ANOVA results showed that treatment factor had significant effect on viscosity. The advanced test, Duncan test, showed that the concentration of chitosan 20% were significantly different with concentration of chitosan 0%, 10%, and 15%.

Gel Time and pH

Gel time is defined as the point at which polycondensates formed by the reaction of a cornstarch-quebrachotannin-chitosan solution become an elastic, rubbery solid. Gel time is highly dependent on the pH of the adhesive: the gel time generally decreases when the pH of the adhesive is increases, but does not in this study, where the gel time increases when pH increases. This is because the properties of corn starch when first heated melted, and then thickens. The results

30800 (a) 31333.33 (a) 33200 (a)

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

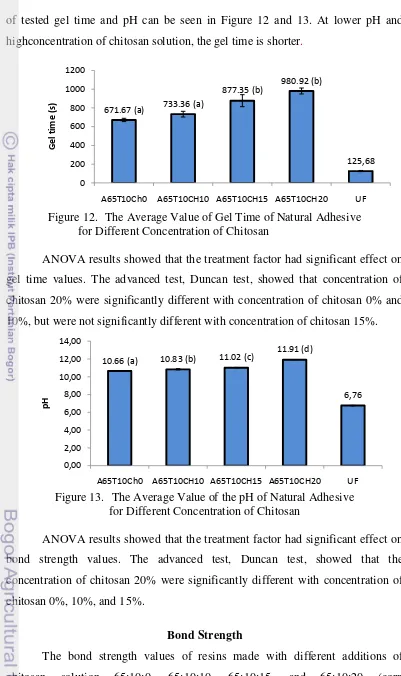

of tested gel time and pH can be seen in Figure 12 and 13. At lower pH and highconcentration of chitosan solution, the gel time is shorter.

Figure 12. The Average Value of Gel Time of Natural Adhesive for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had significant effect on gel time values. The advanced test, Duncan test, showed that concentration of chitosan 20% were significantly different with concentration of chitosan 0% and 10%, but were not significantly different with concentration of chitosan 15%.

Figure 13. The Average Value of the pH of Natural Adhesive for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had significant effect on bond strength values. The advanced test, Duncan test, showed that the concentration of chitosan 20% were significantly different with concentration of chitosan 0%, 10%, and 15%.

Bond Strength

The bond strength values of resins made with different additions of chitosan solution 65:10:0, 65:10:10, 65:10:15, and 65:10:20 (corn

671.67 (a) 733.36 (a)

A65T10Ch0 A65T10CH10 A65T10CH15 A65T10CH20 UF

G

A65T10Ch0 A65T10CH10 A65T10CH15 A65T10CH20 UF

p

starch:quebrachotannin:chitosan solution, weight ratios) were tested. The results of the effect of substitution level of chitosan solution on the bond strength are shown in Figure 14. The increase of chitosan solution substitution level, bond strength is relatively affected by the presence of chitosan solution up to 15% (65:10:15). The bond then decrease due to the presence of chitosan solution of 20% (65:10:20). It is interesting to observe, when the substitution level is higher than 15%, resin showed small tendency reductions in bond strength values. Thus it can be concluded that substitution level of 15% is optimal for the preparation of (corn starch-quebracho tannin-chitosan solution, weight ratios) wood adhesives.

Figure 14. The Average Value of the Bond Strength of Natural Adhesive for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had no significant effect on bond strength values.

Quality of Particleboard Density

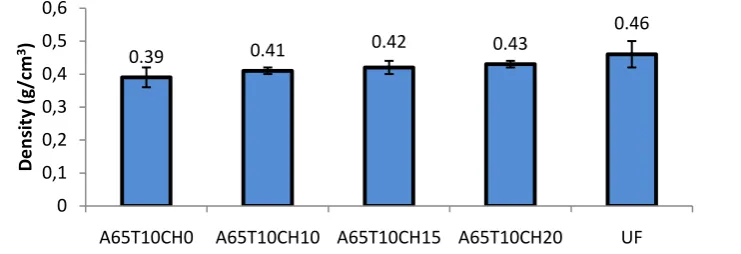

Figure 15 shows the density of the particleboard by the using of corn starch-quebrachotanin-chitosan solution adhesives. The average values of density are 0.39-0.46 g/cm3.

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

Figure 15.The Average Value of the Density of Particleboard for Different Concentration of Chitosan

These results pointed out that the density of particleboard produced is categorized as medium density. This category is adopted from the classification according to Maloney (1993) that divides the particleboard into a low density particleboard that is less than 0.40 g/cm3, medium density that is between 0.40-0.80 g/cm3, and a high density for more than 0.80 g/cm3. For overall, not all of the particle boards achieved the density target of 0.6 g/cm3. Can be caused by moisture content on particleboard that adapted the ambient temperature while conditioning process. In addition, other factor that may affect the density of board were evaporation of water when pressing process, the lost of particle during pressing process and the end of pressing process and measurement process of dimensions which is not in all parts of particleboard thus there is a possibility of non compact side of particleboard was not measured.

ANOVA results showed that the treatment factor had no significant effect on density.

Moisture Content

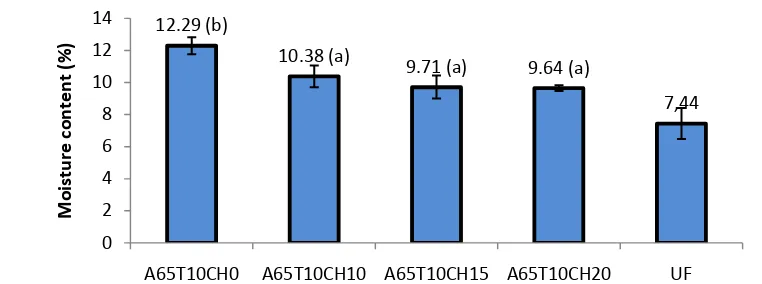

The result of moisture content of particleboard made of natural adhesive (corn starch-quebrachotannin-chitosan solution) and UF are between 7.44%-12.29%. The moisture content of the particleboards is based on European Standard EN 323 which suggests 5% to 13%. High moisture content may affect the quality of the particle board. According to Kollmanet al. (1975),moisture content is one of the factors that affect the quality of adhesion.The moisture content of particleboards are shown in Figure 16.

0.39 0.41 0.42 0.43

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

Figure 16. The Average Value of the Moisture Content of Particleboard for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had significant effect on moisture content. The advanced test, Duncan test, showed that the concentration of chitosan 0% were significantly different with concentration of chitosan 10%, 15%, and 20%.

Thickness Swelling

Based on EN Standards, particleboard should have a maximum thickness swelling (TS) value of 8% for 2h immersion. In addition, the maximum TS for 24 h requirement EN312 (2004) is 15%. Average TS of the specimens ranged from 10.24% to 23.22% and 11.41% to 28.28% for 2 h and 24h immersion, respectively. Panel which used natural adhesive (corn starch 65% and tannin 10%) gave the highest TS of 23.22 and 28.28% after soaking for 2 h and 24h, respectively. Springback of the panels as they are soaked in water is transferred in less-dimensional stability which is a common behavior of any wood composite

(Kalaycıogluand Nemli. 2006). In general, panels did not satisfy the thickness

swelling requirement for general uses. This is probably because of no utilization wax (hydrophobic substance) in particleboard manufacturing.

Bond quality and adhesive properties affected the thickness swelling (Sauter, 1996). The high thickness swelling of particleboard because using natural adhesive made of corn starch, tannin and chitosan so water was able to penetrate easily into the weakly bonded particleboard. Also,raw materials natural adhesive had the carbohydrate content, making it rich in hydroxy groups.

12.29 (b)

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

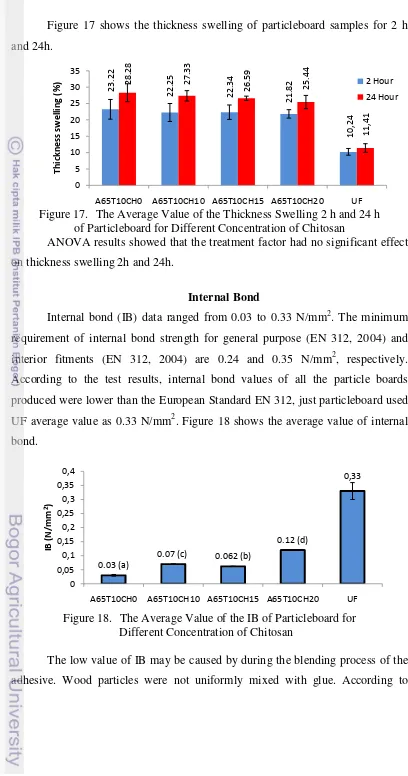

Figure 17 shows the thickness swelling of particleboard samples for 2 h and 24h.

Figure 17. The Average Value of the Thickness Swelling 2 h and 24 h of Particleboard for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had no significant effect on thickness swelling 2h and 24h.

Internal Bond

Internal bond (IB) data ranged from 0.03 to 0.33 N/mm2. The minimum requirement of internal bond strength for general purpose (EN 312, 2004) and interior fitments (EN 312, 2004) are 0.24 and 0.35 N/mm2, respectively. According to the test results, internal bond values of all the particle boards produced were lower than the European Standard EN 312, just particleboard used UF average value as 0.33 N/mm2. Figure 18 shows the average value of internal bond.

Figure 18. The Average Value of the IB of Particleboard for Different Concentration of Chitosan

The low value of IB may be caused by during the blending process of the adhesive. Wood particles were not uniformly mixed with glue. According to

23.

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

T

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

IB

(

N/m

m

Cavdaret al.(2008) internal bond strength is very sensitive to resin distribution on the strands and vertical density profiles of the panels.

ANOVA results showed that the treatment factor had significant effect on internal bond. The advanced test, Duncan test, showed that the treatment is significantly different on each treatment.

MOR and MOE

Based on EN Standards 11.5 and 1500 N/mm2 are the minimum requirements for respectively MOR and MOE of particleboard panels for interior fitments including furniture manufacturing application (EN 312, 2004). Average MOR and MOE of the specimens ranged from 0.93 to 2.97 N/mm2 for MOR and 91.27 to 474.44 N/mm2 for MOE.

All panels made with natural adhesive and UF had the lower values compared to other types of specimens and exceed the EN Standards for MOR and MOE for interior fitments including furniture manufacturing application. This may be caused by during the blending process of the adhesive and the wood particles which are not well mixed so that the particleboard does not coherent enough with the glue. The high level of viscosity is probably at the origin of theses low performances. Figure 19 and 20 shows the average value MOR and MOE.

Figure 19. The Average Value of the MOR of Particleboard for Different Concentration of Chitosan

0.93

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

Figure 20. The Average Value of the MOE of Particleboard for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had no significant effect on MOR and MOE.

CONCLUSIONS

1. The resulting natural adhesive qualities are as follows: solid content has value between 30.79% - 31.37 %, viscosity between 30800 cP - 37083.33cP, gel time value about 671.67 second - 980.92 second, pH between 10.66 - 11.91 and bond strength between 2. 29 N/mm2- 2.98 N/mm2.

2. The qualities of particleboard produced in this research are as follows: density has value between 0.39 g/cm3- 0.43 g/cm3, moisture content between 9.64 % -12.29 %, thickness swelling in 2 h between 21.82 % - 23.22 %, thickness swelling in 24 h between 25.44 % - 28.28 %, internal bond between 0.03 N/mm2- 0.12 N/mm2, MOR value between 0.93 N/mm2- 1.73 N/mm2 and MOE between 91.27 N/mm2- 182.19 N/mm2.

3. The factors that affect the quality of adhesive such as: quality of raw materials, characteristics of the raw materials. While The factors that affect the quality of particleboard are adhesive viscosity and solid content of adhesive, and process preparation of particleboard.

4. If compared to the adhesive quality of UF and particle board using UF,the natural adhesive is far below the standard, thus affecting the quality of the particleboard.

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

REFERENCES

Angleimer, A.F., Montgomery, M.W. 1976. Amino Acids, Peptides and Proteins.In: Fenema, O.R. (Ed.), Food Chem. Marcel Dekker. New York, NY. 205-284.

Alamsyah R. 2001.

KarakteristikdanPenerapanKhitindanKhitosan.JurnalTeknologiIndustri. II (2).61-68.

Bowyer, J.L. Shmulsky, R. Haygreen, J.G. 2003. Forest Product and Wood Science An Introdution 4th Ed. USA : Iowa State Press A Blackwell Publ. Corn Products International, Inc. 2006.Corrugating Starch Adhesives Manual.

USA. 9-10.

DepartemenKehutanandan Perkebunan.1999.PanduanKehutanan

Indonesia.DepartemenKehutanandan Perkebunan Republik Indonesia.Jakarta.

Dumanauw, J. F. 1990. Mengenal Kayu. Pendidikan Industri Kayu Atas.Semarang.

European Standard EN 312. 2003. Particleboards - Specifications. EuropeanCommittee for Standardization. Brussels. Belgium.

European Standard EN 317. 1993. Particleboards and Fiberboards Determinationof Swelling in Thickness After Immersion in Water. European Committee for Standardization. Brussels. Belgium.

European Standard EN 319. 1993. Particleboards and FiberboardsDeterminationof Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization. Brussels. Belgium.

European Standard EN 323. 1993. Wood-based Panels Determination of Density.European Committee for Standardization. Brussels. Belgium. Foley,W. J.,Iason, G. R. and Mcarthur, C. 1999. Role of Secondary Metabolites In

the Nutritional Ecology of Mammalian Herbivores: How Far Have We Come In 25 Years In: Nutritional Ecology of Herbivores, H.-J.G. Jung and G. C. Fahey Jr, (Eds) American Society of Animal Science, Illinois. 130– 209.

Godwin, T.W.; and Mercier, E.I. 1983. Introduction to Plant Biochemistry, 2nd ed. Pergamon Press. Oxford, UK.

Imam, S.H., Mao, L., Chen, L., Greene, R.V. 1999. Wood Adhesive FromCrosslinkedpoly(Vinyl Alcohol) And Partially Gelatinized Starch: Preparation and Properties. Starch/Stärke.51 (6).225–229.

Japanese Industrial Standard. 1980. General Testing Methods for Adhesive. JIS K 6833-1980. Japanese Standard Associations. Japan.

Kalaycioglu H., Nemli, G. 2006. Producing Composite Particleboard FromKenaf (Hibiscus Cannabinus L.) Stalks, Industrial Crops And Products.24. 177– 180.

Kollmann, F.F.P., E.W. Kuenzi and A.J. Stamn. 1975. Principle of Wood Science and Technology. Vol. 11. Springer–Verlag, Berlin. Heildelberg. New York.

Lopez, C. dan P. Shanley. 2004. Kekayaan Hutan Asia. PT Gramedia PustakaUtama, Anggota IKAPI. Jakarta.

Nemli, G., Gezer, E.D., Yildiz, S., Temiz, A., Aydın, A. 2006. Evaluation of

theMechanical, Physical Properties and Decay Resistance of Particleboard MadeFrom Particles Impregnated With Pinus Brutia Bark Extractives. Bioresour.Technol. 97 (16). 2059–2064.

Peshkova, S., K. Li. 2003. Investigation Of Chitosan-Phenolics Systems As Wood Adhesives. Journal of Biotechnology. 102. 199-207.

Pizzi, A., K. L. Mittal. 2003. Handbook Of Adhesive Technology Second Edition, Revised And Expanded. Marcel Dekker Inc . New York. 568-582 Pizzi, A. 2006. Recent Developments In Eco-Efficient Bio-Based Adhesives for

Wood Bonding: Opportunities and Issues. J. Adhesion Science Technology. 20 (8).829–846.

Rahim, A and Kassim, J. 2008.Recent Development of Vegetal Tannins in Corresion Protection of Iron and Steel.Recent Patent on Materials Sciences. 1. 223-231.

Sauter, S.L. 1996. Developing Composites From Wheat Straw. In: Proceedings of The 30th International Symposium of Washington State University on Particleboard/Composite Materials. 197-214.

Singh, N., K. S. Sandhu, and M. Kaur. 2005. Physicochemical Properties Including Granular Morphology, Amylase Content, Swelling and Solubility, Thermal and Pasting Properties of Starches From Normal, Waxy, High Amylase and Sugary Corn. Progress InFood Biopolymer Research. 1. 43-55.

Sugita P, T Wukirsari, ASjahriza, D Wahyono. 2009. KitosanSebagaiSumber Biomaterial MasaDepan. IPB Press. Bogor.

SuptijahP.

2006.DeskripsiKarakteristikFungsionaldanAplikasiKitindanKitosan.Dala m:Prosiding Seminar NasionalKitin-Kitosan2006 ; Bogor, 16 Maret 2006. DepartemenTeknologiHasilPerairan, FakultasPerikanandanIlmuKelautan IPB. Bogor. 14-24.

Sutigno.2004. MutuPapanpartikel.http:// mofrinet.cbn.ne.id/ informasi/setjen/ pustan/info-v.htm.[13April 2010].

Tsoumis G. 1991. Science and Technology of Wood. Van Nostrand Reinhold. New York.

Vick, C.B. 1999. Wood Handbook: Wood as an Engineering Material. Southern Forest Products Association. Wisconsin.

Yamada, K., T. Chen., G. Kumar., O. Vesnovsky., L. D. Timmie., and G. F. Payne. 2000. Chitosan Based Water-Resistant Adhesive. Analogy to Mussel Glue. Journal: Biomacromolecules. 1. 252-258.

Yazaki Y, Collins PJ. 1997. Uses of Wattle Extract: Tannin Based Adhesives. Rural Industries Research and Development Corporation.RIRDC Publication No. 97/72.Chapter 15.127-143.

29 APPENDIX

Appendix 1.The Average Value of Qualityof Natural Adhesive for Different Concentration of Chitosan

Appendix 2.The Average Value of Qualityof Particleboard for Different Concentration of Chitosan

Quality of ParticleBoard Tipe of Adhesive

Natural Synthet

ic

0% 10% 15% 20% UF

A B S T R A C T

SONIA SOMADONA.The Quality of PinuspinasterArBinenn Particleboards Using Natural Adhesive Made of Corn Starch, Tannin and Chitosan.Under the supervision of SURDIDING RUHENDI and BERTRAND CHARRIER.

The development and optimization of a new, environment-friendly adhesive made from abundant and renewable cornstarch, tannin and chitosan is described in this study. At present, the production of wood composites mainly relies on petrochemical and formaldehyde-based adhesives such as phenol-formaldehyde (PF) resins and urea-phenol-formaldehyde (UF) resins. Natural adhesive is not only environmentally friendly but also less expensive as compared to other exterior binders used in wood composite industry. The objective of this study is to evaluate the quality of adhesive and particleboard produced. This research describes performances of natural adhesive obtained from cornstarch, tannin and chitosan (solid content, viscosity, gel time, pH and bond strength). Results describe physical properties of all particleboard production according to standard EN 323, 2004. Mechanical properties of particleboard did not fulfilled standard EN 312 for IB, MOR and MOE.

SUMMARY

SONIA SOMADONA.The Quality of PinuspinasterArBinenn Particleboards Using Natural Adhesive Made of Corn Starch, Tannin and Chitosan.Under the supervision of SURDIDING RUHENDI and BERTRAND CHARRIER.

Currently, the majority of wood based panels for furniture or construction (particle board, OSB, plywood, LVL, etc.) has used synthetic adhesives such as urea-formaldehyde, melamine formaldehyde, phenol-formaldehyde and resorcinol-formaldehyde are derived from petroleum andnon renewable fossil resource.They contain formaldehyde which is volatile and harmful for human health

Renewable raw materials have several own advantages such as availability, and regeneration. The use of adhesives from renewable raw materials will replace the petroleum based adhesives as they are more environmentally friendly and are able to reduce formaldehyde emissions. These renewable raw materials are corn, tannin and chitosan. These three materials represent an alternative to natural adhesivesin place of synthetic adhesives.

The study was conducted testing the quality of natural adhesives from these three resources and the quality of particleboard using the natural adhesives. Tested the quality of adhesive such as solid content, gel time, pH and viscosity with reference to JIS K 6833-1980) was conducted and for tested quality of particleboard according to standard methods of European Standard EN 310, 317, 319, and 323 for particleboard and fiberboard.

The qualities of natural adhesive are as follows : solid content has value between 30.79% - 31.37 %, viscosity between 30800 cP - 37083.33cP, gel time value about 671.67 second - 980.92 second, pH between 10.66 - 11.91 and bond strength between 2. 29 N/mm2 - 2.98 N/mm2.Based on the results, the solid content value of natural adhesive made of three reneweble raw materials (corn starch, tannin, and chitosan) under the standards set.While the viscosity, gel time and pH do not have the standard. The bond strength of natural adhesive has a value above the standards (≥ 1 N/mm2)

The qualities of particleboard produced in this research are as follows : density has value between 0.39 g/cm3 - 0.43 g/cm3, moisture content between 9.64 % -12.29 %, thickness swelling in 2 h between 21.82 % - 23.22 %, thickness swelling in 24 h between 25.44 % - 28.28 %, internal bond between 0.03 N/mm2 - 0.12 N/mm2, MOR value between 0.93 N/mm2 - 1.73 N/mm2 and MOE between 91.27 N/mm2 - 182.19 N/mm2.The quality of particleboard produced only moisture content and density has a value above the European Standard. Whileinternal bond, thickness swelling, MOE and MOE were lower than beEuropean Standard.

INTRODUCTION

Background

Currently, the majority of wood based panels for furniture or construction (particle board, OSB, plywood, LVL, etc.) has used synthetic adhesives such as urea-formaldehyde, melamine formaldehyde, phenol-formaldehyde and resorcinol-formaldehyde .These adhesive are derived from petroleum, which is non renewablefossil resource. They contain formaldehyde which is volatile product during both the manufacturing process and after the implementation. The emission of formaldehyde is harmful for human health(Vick, 1999). Moreover, oil prices are not stable, affected the price of products that use petroleum-based adhesives (urea-formaldehyde, melamine formaldehyde, phenol-formaldehyde and resorcinol-formaldehyde, etc).

Renewable raw materials have several own advantages such as availability, and regeneration. The use of adhesives from renewable raw materials will replace the petroleum based adhesives as they are more environmentally friendly and are able to reduce formaldehyde emissions.

Corn (Zea mays L.) is a commodity of global agriculture. It is an important source of carbohydrates and protein. Starch is used as an adhesive in a range of products such as binders, materials, glues and pastes (Imam et al. 1999, Yazaki and Collins 1997).

Tannins are formed of glycosides or organic polymers which contained in various plants. Tannins are divided into two groups: condensed tannins and hydrolyzable tannins. Hydrolyzable tannins are polyphenolic compounds based complexes of digallic acid and D-gluchilose. While condensed tannins are composed of units from flavonoids and are used to replace the phenolic compounds as well as the UF and MUF synthesis in wood-based panels. They do not emission formaldehyde when used as an adhesive (Pizzi 2006).

These three materials represent an alternative to natural adhesivesin place of synthetic adhesives. Therefore, it is important to conduct studies on the performance of natural adhesivesfrom these three resources and the quality of particleboard using the natural adhesives.

Objectives of Research The objectives of this research are:

1. To use renewable raw materials to replace synthetic products (especially if they are hazardous products).

2. Essential that these glues have physical and mechanical properties at least similar to synthetic materials (in this case Urea formaldehyde).

LITERATURE REVIEW

Particleboard

According to Bowyer et al. (2003) and Tsoumis (1991), particleboard is a panel product manufactured by embedding the particles together (such as small pieces of wood or other lignocellulosic material), with wood as a primary resource. Dumanauw (1990) states that the advantages of particle boards compared with solid wood are free from knots and checks, size and density can be adjusted, thickness and density are uniform, more isotropic, quality or surface appearance can be adjusted according to market or costumer desire. Particleboard typically has two face layers made from fine wood furnish (external layer) and one core layer made from coarse wood furnish. Generally particleboard is less expensive than solid wood. However, compared to solid wood, particleboard has a lower dimensional stability, lower in screw holding and strength. Particleboard is mainly used for furniture and kitchen cabinets products.

Approximately 95 % of the lignocellulosic material used for particleboardproduction is wood, but other agro-based residues have not been frequently utilized. Annual plant wastes, such as flax and hemp shives, bagasse, cotton stalks, small grain straw (including rice straw), peanut husks, rice husks, grape stalks, and palm stalks are inexpensive and valuable raw materials for lignocellulosic board production (Kozlowski et al. 1994).

Tannins

Tannin is a general term for a widely occurring group of substances that comes from the plants with varying proportions. Tannins are polyphenolic compounds which are able to interact with other macromolecules such as proteins and carbohydrates. Moreover tannin are an excellent renewable resource which can be used for replacing petroleum-derived phenolic compounds.

Different types of tannins have been used for a long time in the production of adhesives (Godwin and Mercier. 1983). Hydrolyzable tannin are derivatives of gallic acid (3,4-5 trihydroxyl benzoic acid). Gallic acid which is esterifies to a core polyol, and the galloylgroups may be further esterifies or oxidativelycross linked to yield more complex hydrolyzable tannins. Hydrolyzable tannin can be decomposed in water, which can react to form other useful substances such as gallic acid, pyrotocatechic acid and sugar. While condensed tannins, constituting more than 90% of the total world production of commercial tannins, are both chemically and economically more interesting for the preparation of resin adhesive (Pizzi and Mittal. 2003). Condensed tannins have a complex chemistry. It is a group of phenolic polymers which are widely distributed in the plant kingdom particularly with woody growth habit. These compounds consist of flavan-3-ol units linked together through C4-C6 or C4-C8 bonds (Rahim and Kassim.2008).

(a) (b)

Corn Starch

Starch is a renewable resource available in abundant quantities at a very low cost. Starch is a carbohydrate food reserve in plants and the major energy resource for non-photosynthetic organisms. Starch granules are composed primarily from different chemically biopolymers (amylase and amylopectine). The proportions of amylase and amylopectin depend on the variety of corn. Amylase is

essentially a linear molecule which consists of α-glucopyranosyl residues linked

via (1-4) glycosides bonds. While amylopectin molecules, on the other hand, are

highly branched, with α-glucopyranosyl residues linked by (1-4) glycosides

linkages and by α-(1-6) bonds at branch points. Ratio and proportion of amylase

ranged from 20% to 25%, and 75% to 80% for amylopectin respectively

The size of a starch granule also depends on the source, and the potato starch granules are the largest granules from all sources. When heated, in the presence of excess water, starch granules lose their crystalline, absorb large amounts of water, and leach amylase out, which impart viscosity to the starch/water system (Imam et al. 1999).

Figure 3. Glucose molecule(erzagenatrika.blogspot.com)

Chitosan

industries for high quality adhesive, purification of drinking water (having a coagulation power), increasing the dye industry in paper, textile and pulp (Alamsyah. 2001). Suptijah P (2006) found that chitosan has a specific shape, containing amine groups in the carbon chain and positively charged as opposed to other polysaccharides.

Chitosan is a naturally occurring biopolymer thin sheet-shaped, has no odor, white in color and the most abundant biomaterial. Chitosan is considered to be a random copolymer comprised primarily of repeat sugar units with the structure of a (1-4)-linked 2-amino-2- deoxy-b-D-glucopyranose and comprised also of some units of (1-4)-linked 2-acetamido-2-deoxy-b- D-glucopyranose (Wong et al. 2006).

MATERIAL AND METHOD

Time and Place of Research

This researchwas conducted in Laboratory of Physical Chemistry, University of Pau and Pays de l’Adour, France. This research was carried out from January 2012 to July 2012.

Materials and Research Equipment

The material used in this research was particle Pinuspinaster from particleboard industry in Mont de Marsan with moisture content ≤ 5 %. Fine particles with a size of 10 mesh and coarse particles with a thickness of 5 mm, length 50 mm and width 4-5 mm were used.Corn starch was obtained from Fisher scientific while quebracho tannin was obtained from Silva team, chitosan with molecular weight 600.000-800.000, hexamine, NaOH and aquadest.

Several equipments are used in this study such as: water bath, oven, rotary mixer,rotary blender, pressing machine, universal testing machine, pH meter, caliper, viscometer and precision balance.

Experimental Design

The experiments in completely randomized design with three replicates with different solution concentration of chitosan are (0, 10, 15, and 20 %).The results obtained were subjected to an analysis of variance (ANOVA) used software Minitab 15 to identify the effect of the chitosan concentration of chitosan for quality a of adhesive and properties particle board. Duncan test was applied to compare treatment means.

AdhesivePreparation

ml. The hexamine was dissolved in aquadest to give a solution of concentration equal to 30% before being added to the solution of corn starch-tannin-chitosan. The solution was mixed and then 125 ml of sodium hydroxide (33%) were added.

Particleboard Preparation

Particleboard was made by three layers, face, core, and back. Ratio between face/back and core is 30:70 based on weight strands. Target of density is set to 0.6 g/cm3and the size of panel is 22 cm x 22 cm x 2 cm. The particleboard preparation showed in Figure 5.

Figure 5.Process of the particleboard preparation

All boards were cut and tested according to standard methods of European Standard EN 310, 317, 319, and 323 for particleboard and fiberboard. The specimenstests were obtained from each board according to the cutting diagram showed in Figure 6.

Particle

Blending

Mat forming

ρ= 0,6 g/cm³ Dimension: 22 cm x 22 cm

Pressing (195 oC, d i 8 i )

The natural adhesive as much as 10%

Conditioning during 2

22 cm

22 cm

Figure 6. Cutting diagram of particleboard Notes :

1. MOE and MOR (20 cm x 5 cm)

2. Density and Moisture content (15 cm x 5 cm) 3. Internal bond (5 cm x 5 cm)

4. Thickness swelling (5 cm x 5 cm)

Testing of Adhesive

Test the quality of adhesive, the studysolid content, gel time, pH and viscosity with reference to JIS K 6833-1980) was conducted.

Solid Content

Solid Content is ratio between the weight of sample before and after heating at a given temperature until weight constant. Method of determination the solids content :

1. Sample of adhesive (1.5 gram was placed in to petridish (W1)

2. The adhesive in the petridish was dried in an oven at 105 ± 2 oC for 1 hour 3. Petridish was put in a desiccator for 10 minutes, then weighed

4. Drying and measuremass were performed until constant weight (W2). Solid content is determined by the formula:

The principle of measuring the viscosity is a measure of internal friction induced by the cohesion of the molecules in the adhesive. The viscosities of the natural adhesive were determined using a Brookfield Viscometer at 20 rpm using spindle number S07 and expressed in cP. The viscosity was measured in triplicate at 25 ± 1 °C.

Gel Time

Gelation is defined as the point where the resin ceases to be a viscous liquid and becomes soft, elastic, solid rubber (Pizzi and Stephanou. 1993). Five gram of adhesive was placed in a test tube and heated in boiling water or in water bath at temperatures above 100 °C under continuous mixing. The reactivity of a mixture is defined as the time measured from the beginning of heating until gelation occurred.

pH

The pH measurement is a measure of the concentration of H + ions in a solution. The method for determining the pH of the adhesive using a pH meter is as follows:

1. The samples of adhesive are poured into a 200 ml beaker and the acidity was measured at 25 °C using a pH meter.

2. Before pH measurement, a calibration of the pH meter is first performed with buffer solutions of pH equal to 4 and 7 at a temperature of 25 oC.

Bond Strength of Adhesive

Bonding quality was evaluated from the percentage of wood failure at the bonding area and bond strength of each specimen. The description of the procedure in Figure 7 is below:

Figure 7. Test of adhesion of adhesive Testing of Particleboard

Density

Density of a particleboard were determined according were determined according to the European Standard method (EN 323) on specimens with dimensions 200 mm x 50 mm x 20 mm. The density is the average of the measured densities on the test specimens of each panel. This density is the ratio of the mass of each specimen and volume.

Where :

Ρ : density

M : mass of the sample V : volume of the sample

Moisture Content

European Standard (EN 323) was using to determine moisture content. It corresponds to the mass loss from the sample after drying in an oven at 103 ± 2 °C to constant weight. Denoted by H, the water content is expressed as a percentage by weight and is equal to:

H : moisture content (%)

M1 : mass of the sample before drying in an oven (g).

M2 : mass of the sample after drying in an oven until constant weight (g). Thickness Swelling

Thickness swelling was determined according to the European Standard method (EN 317). To determine thickness swelling properties, particleboards were cut into 50 mm × 50 mm and soaked in water at room temperature (20 ± 2 °C) for both 2 hour (h) and 24 hour (h). The thickness and weight of the particleboard samples were measured before and immediately after soaking. Thickness swelling were calculated as ratios of absorbed water and increased thickness to the values before soaking, respectively, and expressed as percentages.

Where :

t1 : thickness of sample before immersion (mm) t2 : thickness of sample after immersion (mm)

Internal Bond

Size of sample 50 mm x 50 mm x 20 mm were attached to two aluminum blocks with polypropylene adhesive and left to dry. Two blocks drawn perpendicular to the surface of the specimen until the maximum load. Internal bond values calculated using the formula:

where:

IB : internal bond (N/mm2)

Pmax : maximum compressive load (N) A : surface area the sample (mm2)

Direction of the load

Direction of the load Figure 8. Testing Internal Bond

Modulus of elasticity (MOE) and Modulus of Rupture (MOR)

According to European Standard EN 310, twelve specimens of dimensions 200 mm x 50 mm x 20 mm on each panel particles were used to determine the strength in three-point bending. The flexural modulus of elasticity (MOE) and bending strength (MOR) were calculated using the following formulas:

Where :

Fi : load at proportional limit (N/mm2) ai : the bending load (N/mm2) L : length of span (mm) b : width of specimen (mm) e : thickness of specimen (mm)

Where :

Frupture : maximum compressive load (N/mm2) L : length of span (mm)

b : width of specimen (mm) e : thickness of specimen (mm)

Sample used measuring 20 mm x 50 mm x 20 mm in air dry conditions with the loading pattern shown in Figure 9 :

Figure 9.Way of testing the MOR and MOE Sample

L

RESULTS AND DISCUSSION

Quality of Adhesive Solid Content

Figure 10shows that addition of chitosan induces small decrease of solid content of the adhesive. The value of solids content in adhesive without added of chitosan solution is 30.79% which is not significantly different from that after the addition of chitosan with a concentration at 20% (31.27%).

Figure 10. The Average Value of the Solid Content of Natural Adhesive for Different Concentration of Chitosan

The solid content of the samples increased with increased concentration of chitosan, although not significant.Higher solid content of adhesives may increase the number of adhesive molecules that will react with wood during adhesion process. Increase of solid content will improve the quality of adhesive. Vick (1999) state that solid content in a certain limit, the higher resulting bond strength of board because many molecules of the adhesive that react with the wood in the gluing process. Also, solid content has more effect on both IB, MOR and MOE.

ANOVA results showed that the treatment factor had no significant effect on solid content values.

Viscosity

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

The viscosity values of resins made from different additions of chitosan solution; 65:10:0, 65:10:10, 65:10:15 and 65:10:20 (corn starch:quebrachotannin:chitosan solution, weight ratios) were tested. The results of viscosity test are shown in Figure 11.

Figure 11. The Average Value of the Viscosity of Natural Adhesive for Different Concentration of Chitosan

The viscosity of the samples increased with increased concentration of chitosan. The increase in viscosity may be due to protein unfolding in accordance with Angleimer and Montgomery (1976) who stated that an increase in intrinsic viscosity is one of the effects of protein denaturation. The higher viscosity of adhesive, the more difficult the adhesive flows on the wood surface because penetrating the medium and glue line very slowly then caused difficulty to applying adhesive (Corn Products International. 2006).

ANOVA results showed that treatment factor had significant effect on viscosity. The advanced test, Duncan test, showed that the concentration of chitosan 20% were significantly different with concentration of chitosan 0%, 10%, and 15%.

Gel Time and pH

Gel time is defined as the point at which polycondensates formed by the reaction of a cornstarch-quebrachotannin-chitosan solution become an elastic, rubbery solid. Gel time is highly dependent on the pH of the adhesive: the gel time generally decreases when the pH of the adhesive is increases, but does not in this study, where the gel time increases when pH increases. This is because the properties of corn starch when first heated melted, and then thickens. The results

30800 (a) 31333.33 (a) 33200 (a)

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

of tested gel time and pH can be seen in Figure 12 and 13. At lower pH and highconcentration of chitosan solution, the gel time is shorter.

Figure 12. The Average Value of Gel Time of Natural Adhesive for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had significant effect on gel time values. The advanced test, Duncan test, showed that concentration of chitosan 20% were significantly different with concentration of chitosan 0% and 10%, but were not significantly different with concentration of chitosan 15%.

Figure 13. The Average Value of the pH of Natural Adhesive for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had significant effect on bond strength values. The advanced test, Duncan test, showed that the concentration of chitosan 20% were significantly different with concentration of chitosan 0%, 10%, and 15%.

Bond Strength

The bond strength values of resins made with different additions of chitosan solution 65:10:0, 65:10:10, 65:10:15, and 65:10:20 (corn

671.67 (a) 733.36 (a)

A65T10Ch0 A65T10CH10 A65T10CH15 A65T10CH20 UF

G

A65T10Ch0 A65T10CH10 A65T10CH15 A65T10CH20 UF

p

starch:quebrachotannin:chitosan solution, weight ratios) were tested. The results of the effect of substitution level of chitosan solution on the bond strength are shown in Figure 14. The increase of chitosan solution substitution level, bond strength is relatively affected by the presence of chitosan solution up to 15% (65:10:15). The bond then decrease due to the presence of chitosan solution of 20% (65:10:20). It is interesting to observe, when the substitution level is higher than 15%, resin showed small tendency reductions in bond strength values. Thus it can be concluded that substitution level of 15% is optimal for the preparation of (corn starch-quebracho tannin-chitosan solution, weight ratios) wood adhesives.

Figure 14. The Average Value of the Bond Strength of Natural Adhesive for Different Concentration of Chitosan

ANOVA results showed that the treatment factor had no significant effect on bond strength values.

Quality of Particleboard Density

Figure 15 shows the density of the particleboard by the using of corn starch-quebrachotanin-chitosan solution adhesives. The average values of density are 0.39-0.46 g/cm3.

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF

Figure 15.The Average Value of the Density of Particleboard for Different Concentration of Chitosan

These results pointed out that the density of particleboard produced is categorized as medium density. This category is adopted from the classification according to Maloney (1993) that divides the particleboard into a low density particleboard that is less than 0.40 g/cm3, medium density that is between 0.40-0.80 g/cm3, and a high density for more than 0.80 g/cm3. For overall, not all of the particle boards achieved the density target of 0.6 g/cm3. Can be caused by moisture content on particleboard that adapted the ambient temperature while conditioning process. In addition, other factor that may affect the density of board were evaporation of water when pressing process, the lost of particle during pressing process and the end of pressing process and measurement process of dimensions which is not in all parts of particleboard thus there is a possibility of non compact side of particleboard was not measured.

ANOVA results showed that the treatment factor had no significant effect on density.

Moisture Content

The result of moisture content of particleboard made of natural adhesive (corn starch-quebrachotannin-chitosan solution) and UF are between 7.44%-12.29%. The moisture content of the particleboards is based on European Standard EN 323 which suggests 5% to 13%. High moisture content may affect the quality of the particle board. According to Kollmanet al. (1975),moisture content is one of the factors that affect the quality of adhesion.The moisture content of particleboards are shown in Figure 16.

0.39 0.41 0.42 0.43

A65T10CH0 A65T10CH10 A65T10CH15 A65T10CH20 UF