Future Prospects of Hydropower Development in Nepal through

diversity and water resources, not even 2% of the total feasible hydropower has been harnessed so far. The run-off river hydropower projects across these regions are not only ceasing the production in dry season, but also suffering from operational and maintenance challenges inducing financial losses. The hydro turbines in these power plants are mostly imported from foreign industries, which do not address the local problems. Turbine Testing Lab, which was established inside the premises of Kathmandu University in 2011, envisions a long term goal of manufacturing the turbines inside Nepal addressing the problems of sediment erosion, by building competences in design and testing facilities within the country. The activities of the lab within the course of 3 years have maintained the energy in terms of mobilizing the resources, technology transfer and capacity enhancement through education and research.This paper presents such past and present activities to reflect the lab endeavors in hydropower development of the country merged with an academic excellence. This paper also proposes several models for future prospects that include Foundation model for creating international standards of turbine design, manufacture and testing, Cooperation model to develop a research culture in industry while developing industrial motivation in academy and Business model for recognizing a turbine manufacturing ecosystem in Nepal through entrepreneurial growth. The models are complemented with a series of future activities captivating the perspectives of national and international institutions, organizations and donors. The ideas presented in this paper can be a good initiation of industrial growth by bridging the gap between academicians and professionals, while maintaining sustainability of the resources.

Keywords: Hydropower, Nepal, Turbine Testing Lab, Models, Sustainability

1. Introduction

was assessed in 1966 from a PhD research work of Dr. Hari Man Shrestha in former USSR[3]. Despite this enormous opportunity, Nepal has not been able to harness even 2% of the total potential power. Any efforts to reduce the 16-hour load-shedding gap in the dry season have proved barely successful. The total peak demand in 2013 was recorded to be 1094.6 MW and is growing at the rate of nearly 10% every year. Whereas, the total supply was only 719.6 MW, out of which 443 MW was generated by NEA, 177.1 MW was produced by independent power projects, with initiations made from 140 MW Upper Seti (Tanahun), 600 MW BudhiGandaki and 530 MW DudhKoshi Storage Development Projects[3]. Nepal Electricity Authority (NEA) is also emphasizing the participation of private sector in the hydropower development by raising the posted power purchase rate. However, developing a hydropower requires a large investment and has longer gestation period compared to other power production. Besides, the import of technologies and manpower from abroad folds the cost by numerous times. The risks and uncertainty factors create economical barrier for further development. Although the history of hydro power generation in Nepal dates back to 104 years at Pharping Hydro Power with capacity of 500 kW, there has not been any steep growth of power production due to the trend of dependency on foreign resources and companies. Similarly, the turbine manufacturing in Nepal started 40 years ago, with the establishment of BalajuYantraShala under the aid of Swiss Government. The manufacturing kicked off with pico size propeller turbines, but since this date, the production trend has neither been modified nor the production size has increased remarkably.

There are several socio-economic and political challenges in Nepal, which limits the construction of power plants. Besides, it faces an inevitable problem of maintenance and operation due to sediment erosion in the run-off-river power plants. Hence, the economic growth of Nepal is trapped between inadequate energy supply from hydropower on one hand and technical challenges in the existing plants on the other. With the increase in independent power producers and local manufacturers, there is increasing demand for turbine quality, performance and reliability. It was realized that competences to exploit water resources for hydropower not only depends on financing, design and management of projects, but also on knowledge generation and local adaptability of technology[4]. Although Nepalese companies are capable of designing, manufacturing and installing micro hydro systems, the lack of performance data about the manufactured turbines is undermining the confidence in local products. Due to that reason, turbines or the design of the turbines are usually imported, which do not take into account the local problems such as erosion.

NORAD regarding financial support for construction of TTL. A total sum of 1.3 million US$ was needed for the construction of the lab, of which NORAD funded 60%, Nepalese industries and institutes supported this endeavor and contributed 20%, whereas remaining 20% was contributed by KU itself. The lab was designed by faculties of KU with support from Norwegian University of Science and Technology (NTNU). NTNU has a similar lab called Waterpower Laboratory, which was established in 1917 and was refurbished and modernized in 2001. Hence, their guidance from the initial design phase of TTL was found to be very useful.

After the inauguration on November 10, 2011, TTL has been able to carry out several activities within the lab to maintain the dynamicity at high exhilaration. In the course of time, TTL has perceived an ambitious target of becoming a center of excellence for turbine design, manufacturing and testing facilities in Nepal. This paper presents the past and ongoing activities conducted by the lab together with future endeavors to achieve this long term goal. There are various aspects from which the current situation can be observed, this includes development of the lab capacity, motivation of applied research for bridging the gap between industry and university and improving the socio-economic status of the people through employment opportunities. This paper describes each of these individual aspects in the form of three models that TTL is implementing. Some of the fields described in these models are completed, whereas some of the fields are in the stage of development.

2. Turbine Testing Lab – Facilities and Activities

Located at the foothill of Kathmandu University at Dhulikhel, Nepal, the lab operates within the academic environment of the university and collaborates with the industries and private sectors to address technical and societal aspects of hydropower development and turbine-related issues.TTL is the only lab in the world which can perform tests with 30 m natural head. The location and topography of KU has provided the opportunity to place an upper reservoir so as to create a 30 m natural head. The lab has two centrifugal pumps each of 250 kW with variable frequency drive (VFD) for each pump. Each pump canproduce maximum flow of 0.25 m3/s and maximum head of 75 m. The pumps can be connected in series and parallel combination producing a maximum head of 150 m and maximum flow of 0.5 m3/s respectively. TTL has the capacity to perform prototype test up to 300 kW turbines and perform model test for larger turbines. The lab has provision to have four test rigs at a time, along with notches and water volume measurement arrangements for calibration of measuring instruments. Over past few years, the lab has developed and enhanced the competences in performing computational simulations to strengthen the research capacity. It has also acquired state-of-art technologies such as Rapid Prototyping Machine, a 3D printer to produce complicated turbine component models with high accuracy, Particle Image Velocimetry (PIV) setup to study the flow phenomena in turbines, metallurgy microscopes for studying the turbine materials and sediment particles, Rotating Disc Apparatus (RDA) to carry out erosion testing and Borescope as a non-destructive testing for investigating defects or imperfections in inner parts of turbine. Following are some of the achievements of TTL since its establishment.

a. Development of turbines with improved erosion performance

It has been computationally tested that the optimization of hydraulic design of blade profile alone can reduce sediment erosion in Francis runners up to 30%[6]. TTL has also designed and developed a 92 kW Francis model of Jhimruk HP (4 MW), with the conventional and optimized runners to test in the lab. This turbine accounts as the first Francis turbine that was designed and manufactured in Nepal, with the design of TTL and manufactured by one of the 27 manufacturers of Nepal (Nepal Hydro Electric (NHE) Pvt. Ltd.). TTL was funded by RenewableNepal program in a project from 2010-2013, entitled ‘Development of Francis turbines with new Design philosophy addressing the problems of sediment erosion for a sustainable hydropower development in Nepal’, in the course of which, these achievements were made. Another project was funded by NORAD from 2012-2013, in parallel to the above project, entitled ‘Feasibility study for turbine manufacturing and testing facility in Nepal by identifying the erosion potential of sediments in major basins of Nepal’.

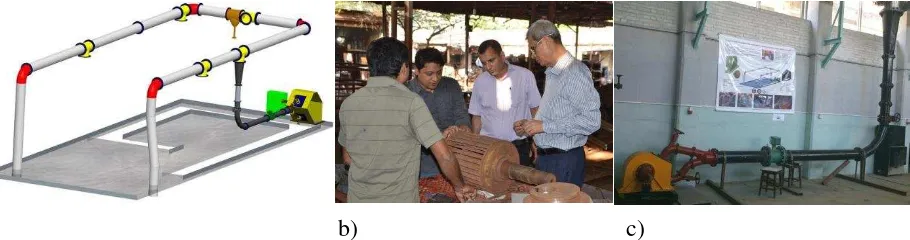

a) b) c)

Figure 1: a) Design of Francis turbine runner blades from computational analysis[7] b) Manufacturing of the 92 kW Francis turbine at NHE c) Installed test rig of the turbine at TTL

b. Research collaboration between industry and university

a) b) c)

Figure 2: a) MS by Research on failure analysis of Pelton runner for Khimti HP [8] b) Design of IEC standard Francis and Pelton test rigs at TTL from Master students of NTNU

c) Design and computational analysis of a bifurcation for DaraundiKhola HP

c. Leading the research activities into next level

TTL has also been conducting several other research activities focusing on the sustainable and renewable energy technology in the context of Nepal. One of such activities includes identification of the technical feasibility and conditions of use of Reversible Pump Turbines (RPT) in Nepal and designing such an RPT for a feasible site condition[7]. This was the second project funded by Renewable Nepal program in 2013-2014. This project had Chilime HP as the industrial partner and the site feasibility was also done in the premises of Chilime and Bhotekoshi River. A local industry called D-Matrix Pvt. Ltd. was the manufacturing partner for manufacturing the scale down model of the designed turbine, as a demonstration unit at TTL. There have also been some other research activities done in the lab such as wind turbine rotor design and analysis through computations and experiments, use of PIV techniques for fluid and particle behavior in the turbine and advanced computational techniques, in order to build higher competences in research and taking the research level of Nepalese institutions to next level.

a) b) c) d)

Figure 3: a) RPT designed by TTL and manufactured in a local company

b) Wind turbine blade printed in the 3-D printer for testing purpose c) PIV in a Pelton Bucket

c) CFD analysis of a Pelton turbine conducted in a MS by Research work[9]

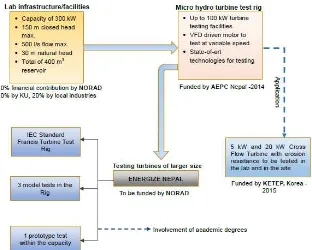

d. Contributions in uplifting the Micro Hydro Status of Nepal

Nepal. There are more than 27 micro hydro turbine manufacturers and more than 2500 Micro Hydro Projects (MHP) in the country. In future these micro hydro turbine projects and manufacturers are expected to increase; and continue its contribution significantly for electrifying Nepal. Thus, R&D to promote MHP in Nepal has been crucial.With a mission to make renewable energy mainstream resource to rural areas of Nepal, AEPC is providing subsidy to micro hydropower projects. Cross flow turbine is widely used in micro hydropower plants. Although standard for Micro Hydro exists and is put into practice, it is rather simple. Hydraulic efficiency is not measured, but is calculated from the empirical relation of generator. For a micro hydropower plant, only the electrical output is of major concern. So to obtain design output at lower turbine efficiency has led to oversizing of micro hydro turbines. Annually millions of rupees are being wasted by the use of larger turbine than needed. Pertaining to the need of standardizing micro hydro turbines and testing facilities for these turbines, AEPC has granted fund for the project (2014-2015) of establishing micro hydro turbine test rigs at TTL so as to uplift the status of micro hydro in Nepal. Testing standards and testing procedures relevant to present context of Nepal will be developed in this project.

In course of completion of the project funded by AEPC,Korea Institute of Energy Technology Evaluation and Planning (KETEP) has also paid a great interest in motivating the research culture in micro hydro sector of Nepal. In 2015, KU in collaboration with KMOU (Korea Maritime Ocean University) has received a fund for developing 5 kW and 20 kW cross flow turbine in a feasible site of Nepal, with design optimization in regard to the erosion effect. The 3 year project will include a PhD enrollment and all the design, testing and analysis works will be carried out in the lab, whereas the manufacturing will be done in Korea. It is also planned to manufacture the turbines alternatively in Nepal so that the design competences in Nepal can be enhanced.

a) b) c)

Figure 4: a) Test rig layout design b) Manufacturing at Krishna Grill c) Pelton turbine rig installed at TTL

3. Models for enhancement of R&D activities of TTL a. Foundation Model

testing laboratory involves enhancing the laboratory facility for design verification and model test certification.The University aims in enhancing the capability of TTL to serve as a center for sustainable development of hydropower in Nepal and in the region. The capacity of TTL will be developed for research, design verification and model test certification to provide technical solutions and intellectual support related to mechanical equipment of hydropower, focusing on turbines.

The framework of the foundation model is explained in Figure 5. The goal of establishing a Francis turbine IEC 60193 standard test rig at TTL has been put forward as a proposal to Energize Nepal program, which is expected to start in early 2016. The outputs of the project are indicated below:

1. IEC standard hydro turbine test rig installed and turbine performance testing procedure established at TTL

2. 3 set of models of Francis runners are fabricated according to new design concept concerning better sediment handling and tested in the IEC standard test rig

3. Development of competent human resources in the field of hydro turbines and electric power engineering by involving 29 academic graduates (Master and PhD) in the research activities in the field of turbine design and hydropower

4. Experience sharing from the acquired knowledge among the stakeholders of the field through dissemination programs and publications

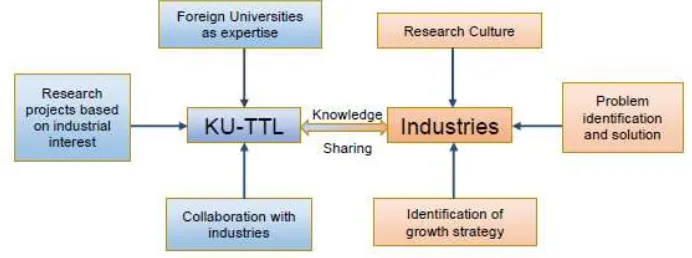

Figure 5: Foundation Model b. Cooperation model

The higher education provided in Universities and the challenges of industries are highly inter-dependent. The education should impose research activities which could address the problems of local industries. One of the objectives of the lab is to stimulate collaborative research with national and international Universities and industries. This has been done so far by conducting some research and student projects initiated by industry. The Renewable-Nepal program at KU [10]was initiated in 2009 with the purpose of building applied research capacity at Nepalese Universities and research institutions that can serve Nepalese energy industry in developing high quality products. TTL has so far, hosted 2 out of 21 projects that are funded by this program which were discussed above. In both the projects, TTL has maintained a close collaboration with Nepalese industries, NHE and D-Matrix Engineering Pvt. Ltd. for manufacturing the turbines designed as an outcome of systematic research in the context of Nepalese scenario. In the first project, TTL also collaborated with NTNU for guiding an MS by Research student throughout the project.

computational simulations.

Even with all these efforts, it has been observed that there is a definite mismatch in the perspectives of Universities and industries. The research outcomes, in a way do not lie under the low-hanging-fruit of industries, for they always seek for immediate and reliable results. A cooperation model has been proposed in Figure 6, which presents an idea of how the research culture should be developed in the industries, while emphasizing on industrial applications/interests in the research performed at TTL. The knowledge sharing is a give and take process, which can be stimulated through regular seminars and workshops. The research could strengthen the quality of education, but to benefit the industries, the research outcome should be able to provoke the industrial growth in a short time. The collaboration can also be in the form of student projects and internships for undergraduate and graduate level students.

Figure 6: Cooperation model

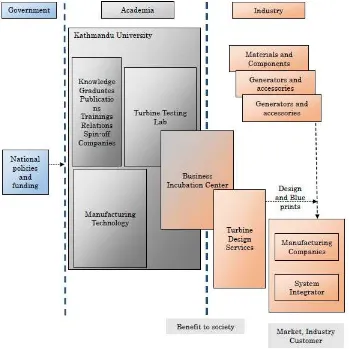

c. Business model

The ultimate goal of TTL and KU is to raise the socio-economic standard of the country. This goal is directly related with the societal benefits, including the sufficient supply of electricity and employment opportunities. In 2014, KU launched a Business Incubation Center (BIC) as a semi-autonomous body under KU, which provides a platform for innovators and experts from academia, the private, technical and development sectors, to work together to transform innovative ideas from Nepali citizens across the world into socially-conscious successful businesses. In the long run, TTL has also incepted a vision to commercialize the research outcomes in the form of a company. With the target of developing reliable turbines inside Nepal for all levels (small, medium and large), Turbine Design Services (TDS) has been conceived as a spin-off company of TTL under the framework of BIC. The primary goal of TDS is to impart knowledge based service that includes design and blue prints, testing and best practices needed for project specific activities. TDS will collaborate with researchers/departments/research labs within the University and with manufacturing companies and vendors to deliver a complete solution for hydropower clients.

related to potential Conflict-Of-Interest and Conflict-Of-Commitment in the future. For that reason, TDS will operate at arm’s length from KU with transparent rules and procedures. The purpose of this approach is to leverage the core competences of KU and the individual researchers towards innovation and sustainable development in Nepal, without jeopardizing the integrity of the University and the academics. TDS will make this knowledge base available on commercial terms to the hydroelectric power industry, in the form of consulting support, customized turbine design and/or licenses to commercially use its technology.

In an ecosystem development for turbine manufacturing in Nepal, the role of TDS is described in different spectrum of hydropower development. Initially in the sector of micro-hydropower projects, TDS will provide an automated service where turbine manufacturers can obtain recommendations and blue-prints for a standard turbine design based on input parameters. In the case of larger power plants, TDS will provide a consultant-type of professional services, providing optimized turbine designs that meet the special needs of individual flows in sediment-rich environments.

KU has also recently (2014) established a Technical Training Center (TTC) with the financial aid from KOICA-Korea, where the manufacturing capacities are built. Synergic effects of TTL, TTC and TDS under the framework of BIC will be the strongest element to develop and implement technical knowhow needed for turbine manufacturing.

4. Conclusion

The national and foreign investment in the sector of hydropower in Asia is likely to grow in near future. However, it is still a topic of debate when a sustainability of the hydropower development is raised as an inevitable issue. The hydropower sector of Nepal lacks collaboration between industries and academic institutions. There needs to be such learning environment, where students and researchers can address the growing problems of hydropower and industries need to have the research motivation. In order to overcome this gap between the two areas, Turbine Testing Lab was established under Kathmandu University, which has created and seized numerous opportunities to have academic and industrial cooperation. The second criterion is to have the complete foundation inside the lab, so that the testing can be done in full phase and certification can be provided with internationally recognized standards. The third criterion is to create societal benefits by commercializing the services and bringing employment opportunities.

In this paper, three models have been presented which are needed to enhance the R&D activities in the lab. With an aim of becoming a center of excellence for turbine design, manufacturing and testing facilities in Nepal, TTL has been implementing these models in one way or other, in its past, present and future activities.

5. Bibliography

[1] I. f. I. D. S. (IIDS), "Nepal Economic Outlook 2013/2014," IIDS, Kathmandu, 2014.

[2] T. W. Bank, "The World Bank," [Online]. Available: http://www.worldbank.org/en/country/nepal. [Accessed 12 February 2015].

[3] R. Jha, "Total Run-of-River type Hydropower Potential of Nepal," Hydro Nepal, no. 7, pp. 8-13, 2010.

[4] N. E. A. (NEA), "A Year in Review, Fiscal Year 2011/2012," NEA, 2012.

[5] B. Thapa and O. G. Dahlhaug, "Turbine Testing Laboratory and its Role in Hydropower," Hydro Nepal, no. 5, pp. 66-70, 2009.

[6] B. S. Thapa, B. Thapa and O. G. Dahlhaug, "Current research in hydraulic turbines for handling sediment," Journal of Energy, vol. 47, no. 1, pp. 62-69, 2012.

[7] S. Chitrakar, M. Cervantes and B. S. Thapa, "Fully coupled FSI analysis of Francis turbines exposed to sediment erosion," International Journal of Fluid Machinery and Systems (IJFMS), vol. 7, no. 3, pp. 101-109, 2014.

[8] A. Panthee, H. P. Neopane and B. Thapa, " CFD Analysis of Pelton Runner," International Journal of Scientific and Research Publications (IJSRP), vol. 4, no. 8, 2014.

[9] N. Maharjan, S. Chitrakar and R. Koirala, "Design of Reversible Pump Turbine for its prospective application in Nepal," International Journal of Scientific and Research Publications (IJSRP), vol. 4, no. 7, 2014.

![Figure 1: a) Design of Francis turbine runner blades from computational analysis[7]](https://thumb-ap.123doks.com/thumbv2/123dok/405689.125703/4.612.69.539.263.391/figure-design-francis-turbine-runner-blades-computational-analysis.webp)

![Figure 2: a) MS by Research on failure analysis of Pelton runner for Khimti HP [8]](https://thumb-ap.123doks.com/thumbv2/123dok/405689.125703/5.612.95.522.456.605/figure-ms-research-failure-analysis-pelton-runner-khimti.webp)