DOI: 10.12928/TELKOMNIKA.v15i2.6233 584

An Indonesian Standard of Lithium-ion Battery Cell

Ferro Phosphate for Electric Vehicle Alications

Wahyudi Sutopo1, Evizal Abdul Kadir*2 1

Department of Industrial Engineering, Faculty of Engineering, Sebelas Maret University, Surakarta, Indonesia

2

Information Technology Department, Faculty of Engineering, Universitas Islam Riau, Pekanbaru, Riau 28282, Indonesia

*Corresponding author, e-mail: [email protected]

Abstract

In general, the process of developing new standards had problems in early the development process. In particular to identify what steps are necessary to develop new standards. Methodology of writing this article was conducted using the methodology of Framework for Analysis, Comparison and Testing of the Standard (FACTS). The results of this paper are the new standard for the Indonesian National Standard of Lithium-ion Battery Cell Ferro Phosphate for Electric Vehicle Alications. The standard of development data is can be use by automotive industrial and also for the government to decide new policy on electric vehicle especially in Indonesia.

Keywords: standard, cell battery lithium-ion secondary cells, electric vehice and stakeholders

Copyright © 2017 Universitas Ahmad Dahlan. All rights reserved.

1. Introduction

The demands of green technology and environmentall friendly vehicles pose a phenomenon that changes the automotive industry from fossil-fuelled vehicles to electric vehicle (hybrid). This phenomenon is evident with more of 100 kinds of electric vehicles have been develop since 1891 until 2008 [1]. The data of electric vehicles around the world since 1990s until 2008 is shown in Figure 1.

Based on the phenomenon and rapid changes in automotive industry from fossil-fueled vehicles into vehicles with electrical energy, the government launched a national Electric Vehicle (EV) program. The program is intended to allow the State of Indonesian can prepare and participate to take advantage of the phenomenon of change in the automotive industry [2].

To be able doing the research of electric vehicle, required an electric vehicle standards as a reference the research. Standard product can provide assurance to consumer that the product is according to performance, safety or the production process in form of certification or labeling standards of product produced [3]. Standards can be differentiate products in the market, which is a good product or not. However, due to the unavailability of the Indonesian National Standard or technical specifications of the electric vehicles in Indonesia, have an impact on the lack and the quality of the reference in the national electric vehicle research [4].

The number of components that make up an electric vehicle is inve many aspect, making standard of electric vehicles can not be created for the product in all vehicle parts but per vehicle components. This is in accordance with the decision of the government that Indonesia will develop five standard components of electric vehicles since 2015, one of it which is cell Lithium-ion battery Ferro Phosphate Secondarry for Electric Vehicle Alication [5]. Results from this research is expected to develop the standards in accordance with national capabilities and globally accepted [6].

2. Research Method

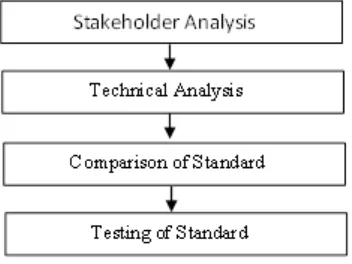

In this research, is using Framework for Analysis, Comparison and Testing Standard (FACTS) method. FACTS is methodology developed by National Institute of Standard and Technology (NIST) U.S. which provides a framework for analyzing, comparing and testing standards [7]. FACTS methodology consist of four main steps are shown on Figure 2.

Figure 2. Process stage in this research

The first step taken is to identify who the stakeholders and collect data and their requirements. This step aims to find out what are the reqiurement of stakeholders cell Lithium-ion battery in Indonesia for electric vehicle alicatLithium-ions. The following list of stakeholders based an different perspective of governent requirement, R&D battery, laboratory of battery, manufacturers of battery, manufacturers of electric vehicle and users of electric vehicle [8]. Data of stakeholder’s requirement are obtained by literature studies. Second step is taken in technical analysis of stakeholder needs. Output of this research is technical data requirement specification of stakeholder cells Lithium-ion battery ferro phosphate for use in electric vehicle alications.

results can be used to create the design of the standard formula. The design of standard formula to use as a questionnaire for material to be distributed to the stakeholders then for verification of national capabilities.

3. Results and Discussion

This research consist of four stages as shown in Figure 2. The following description is stakeholder analysis, technical analysis, comparison of standard and testing of standard. 3.1. Stakeholder Analysis

In this phase, identify who the stakeholders and collect data based on their requirements. Data of stakeholders requirement are obtained by literature studies. Here’s a quick summary of stakeholder requiremets in Table 1.

Table 1. Stakeholder requirements [9]

Stakeholder Requirement

Goverment Capable of traveling 300 km on a single charge Fast charging and low emission

R & D Baterry

Capacity 42,5 mAH/g, energy density 127,5 wh/kg and tage 3 t

Save energy, Heat resistant, Fast charging

Charge time is 2 hours and capable of traveling 100 km on a single charge

Large capacity, energy saving and durable

Laboratory of Battery

tage stable, ability to pass the over charge test, ability to pass the over discharge test, and able to pass the safety test lithium cells both in performance and abuse test

Manufacturers of Battery

Do not exploded when a short circuit haen, have 3000 cycle and able to survive in temperatures 700C

Long life cycle, do not overheat and fast charging Capable of traveling 300 km on a single charge

Manufacturers of Electric Vehicle

Six-cell batteries ca be used in EV if it has the capacity 200 W, charge time is 5 hours and capable of traveling 150 km on a single charge

Large capacity, have 2000 cycle and 6-8 hours charge time Aged years and capable of traveling 120 km on a single charge Energy 21 KWh and Capable of traveling 100 km on a single charge Able to drive the electric motor 40 V, 20 Nm torque and rotation 500

rpm

Users of Electric Vehicle

Environmentally friendly

The distance travelled long for a single charge and price of EV is less cost

3.2. Technical Analysis

Based on the results of technical analysis, it can be seen that the stakeholders cell Lithium-ion secondary batteries for electric vehicle alications in Indonesia require different types of measurements or tests to ensure that the product has a good quality is: measurment energy density, external short circuit test, heating thermal abuse test, measurment cycle life, energy efficiency measurment, measurment power, storage test, vibration test, test over charge, over discharge test, crush test, impact test, temperature cycling test, altitude test and forced internal short circuit test [11].

Table 2. Technical Analysis [10]

Requirement Technical Analysis Capable of traveling 300 km on a single charge

Fast charging and low emission

Capacity 42,5 mAH/g, energy density 127,5 wh/kg and tage 3 t

Capable of traveling 100 km on a single charge Large capacity

tage stable

Capable of traveling 300 km on a single charge

Six-cell batteries ca be used in EV if it has the capacity 200 W and capable of traveling 150 km on a single charge Large capacity

Capable of traveling 120 km on a single charge

Energy 21 Kwh and Capable of traveling 100 km on a single charge

The distance travelled long for a single charge and price of EV is cheap

Measurment Energy Density

Save energy

Energy saving Measurment Energy Efficiency Able to pass the safety test lithium cells both in storage and

during test Storage Test Environmentally friendly

Measurment Cycle Life Characteristic

Fast charging Charge time is 2 hours

Able to pass the safety test lithium cells both in performance and abuse test

Do not exploded when a short circuit haen fast charging

External Short Circuit Test

Ability to pass the over charge test Over Charge Test Ability to pass the over discharge test Over Discharge Test Able to pass the safety test lithium cells both in performance

and abuse test Vibration test Able to pass the safety test lithium cells both in performance

and abuse test Shock Test Able to pass the safety test lithium cells both in performance

and abuse test Crush Test Able to pass the safety test lithium cells both in performance

and abuse test Impact Test Heat resistant

Able to survive in temperatures 700C Do not overheat

Temperatur Cycling Test

Heat resistant

Able to survive in temperatures 700C Do not overheat

Heating Abuse Test

Able to pass the safety test lithium cells both in performance

and abuse test Altitude Test

IEC 62660-1:2010 is standard for secondary Lithium-ion cells for the propulsion of electric road vehicles part 1 that discusses about performance test [12, 13]. IEC 62660-2:2010 is standard for secondary Lithium-ion cells for the propulsion of electric road vehicle part 2 that discuss sbout realibility and abuse test [14, 15]. IEC 62881:2012 is standard for safety of primary and secondary lithium cells and batteries during transport [16, 17]. Comparison of standar is done by adjusted to the result of technical analysis.

Table 3. Comparison of Standard [18] External short circuit - Sub section 6.3.1 Sub section 6.4.5 Over charge - Sub section 6.3.2 Sub section 6.5.1

Temperature cyling - Sub section 6.2.2 Sub section 6.4.2 Heating abuse - Sub section 6.2.1

Altitude - - Sub section 6.4.1

3.4. Testing of Standard

It this stage, the result of comparison standard can be used to create the design of the standard formula. The design of standard formula then can be used as a questionnaire material to be distributed to stakeholders for verification of national capabilities.

Table 4. Testing of Standard [19] E : Manufacturers of Electric Vehicle F : Users Electric Vehicle

: Being discussed

4. Conclusion

testing of standard. Based on the results of processing data, it can be concluded that stakeholders cell Lithium-ion battery in Indonesia requires 15 types of measurement / testing, among others: energy density, external short circuit, heating thermal abuse, cycle life, energy efficiency, power, storage charactheristic test, vibration, over charge, over discharge, crush, impact, temperature cycling, altitude and forced internal short circuit.

References

[1] Kumara, Nyoman S, IW Sukareyesa. Tinjauan Perkembangan Kendaraan Listrik Dunia Hingga Sekarang, Jurnal Teknik Elektro. 2009; 8: 78-79.

[2] BSN, Pengembangan Standar Nasional Indonesia Komponen Mobil listrik Jakarta. 2015.

[3] Kementrian Perindustrian Republik Indonesia. Wujudkan Industri Mobil Listrik, Retrieved online: http://kemenperin.go.id/artikel/3741/Wujudkan-Industri-Mobil-Listrik, April 5 2016.

[4] Evizal, T Abdul Rahman, SK Abdul Rahim. Active RFID Technology for Asset Tracking and Management System. TELKOMNIKA. 2013; 11: 137-146.

[5] BSN. Pengembangan SNI Produk Komponen Mobil Berenergi Listrik. Jakarta. 2015.

[6] Evizal Abdul Kadir, Siti Mariyam Shamsuddin, Eko Supriyanto, Wahyudi Sutopo, Sri Listia Rosa, Food Traceability in Suly Chain Based on EPCIS Standard and RFID Technology. TELKOMNIKA Indonesian Journal of Electrical Engineering and Computer Science. 2015; 13(1): 187-194.

[7] NIST, FACTS: A Framework for Analysis, Comparison, and Testing of Standard. U.S. 2013.

[8] D Prianjani. Perancangan Draft Standar Nasional Indonesia Pengujian Sel Ion-Lithium Sekunder Untuk Aplikasi Mobil Listrik, Sebelas Maret University. 2016.

[9] Badan Tenaga Nuklir Nasional, Profil Batan, Retrieved online: http://www.batan.go.id/index.php/id/, March 30 2016.

[10] Lembaga Ilmu Pengetahuan Indonesia. Generasi Baru Marlip LIPI. Retrieved online: http://informatika.lipi.go.id/ipt/index.php?option=com_content&view=article&id=174%3Agenerasi-baru-marlip-lipi&catid=1%3Alatest-news&Itemid=59&lang=in, March 13 2016.

[11] N Atikah. Peningkatan tingkat kesiapan teknologi baterai lithium ion dengan pendekatan tahap kelayakan model komersialisasi goldsmith. Sebelas Maret University. 2015.

[12] Wulandari T. Spesifikasi Produk Sel Ion-Lithium Sekunder SMART UNS, Sebelas Maret University. 2015.

[13] Nipress, Telah Lahir: Baterai Lithium ‘Made In’ Indonesia, Retrieved online: http://www.nipress.com/telah-lahir-baterai-ns-lithium-made-in-indonesia/, March 11 2016.

[14] Nipress, Baterai Mobil Listrik Dasep Dijamin Tidak Overheated, Retrieved online: http://www.nipress.com/baterai-mobil-listrik-dasep-dijamin-tidak overheated/, March 11 2016.

[15] Great Asia Link, Battery Ukuran Kecil Kapasistas Besar, Retrieved online: http://www.grain.co.id/berita/detail/3/battery-ukuran-kecil-kapasitas-besar.html, March 11 2016. [16] Great Asia Link, SUVI Commercial Sport Utility Car, Retrieved

online:http://www.grain.co.id/static/35/suvi.html, April 19 2016.

[17] International Electrotechnical Commission, IEC 62660-1: Secondary Lithium-Ion Cells for The Propulsion of Electric Vehicles – Part 1: Performances Testing. 2010.

[18] International Electrotechnical Commission, IEC 62660-2: Secondary Lithium-Ion Cells for The Propulsion of Electric Vehicles – Part 2: Reliability and Abuse Testing. 2010.

![Figure 1. Number of Electric Vehicles [1]](https://thumb-ap.123doks.com/thumbv2/123dok/238282.502462/1.595.165.431.529.702/figure-number-of-electric-vehicles.webp)

![Table 3. Comparison of Standard [18]](https://thumb-ap.123doks.com/thumbv2/123dok/238282.502462/5.595.146.450.440.683/table-comparison-of-standard.webp)