Design analysis of a vacuum cleaner using DFMA (boothroyd-dewhurst) method.

Teks penuh

Gambar

Dokumen terkait

and Boothroyd Dewhurst DFMA method were gathered to get a better insight on. how

The idea to come out the mini automatic vacuum cleaner is because current existing design of automatic vacuum cleaner such as Roomba is quite big.. So, in order

To complete this mobile robot its require to design an efficient algorithm to enable smart vacuum clean the whole area... To achieve the goal of this project, research about

The objective of the project is to design and analyze the jigs and fixtures for timing chain cover assembly, which consists of pin ring, sealant and screw assembly.. Design of the

The research will be carrying out and to achieve the following target which is to analyze and compare the B-D DFMA method using manual analysis and software analysis that

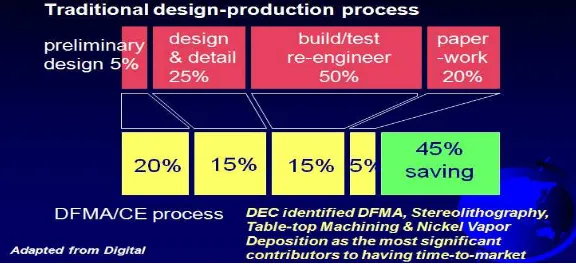

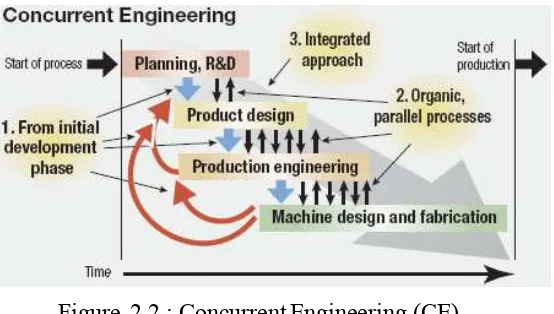

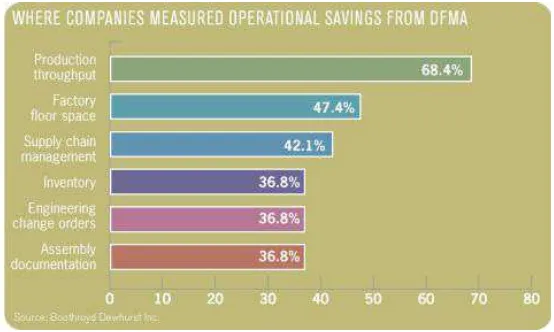

DFA is a kind of design paradigm with which, the engineer use all kinds of methods such as analyze, estimating, planning and simulating to consider all the factors that

In this project, DFMA has been applied in design and development the grass cutting machine. The design also must

Quality Function Deployment (QFD) is a method of product development where the product or process is directed from the Voice of the Customer (VOC) through development