ContentslistsavailableatSciVerseScienceDirect

Wear

j o ur n a l ho me p a g e :w w w . e l s e v i e r . c o m / l o c a t e / w e a r

Deformation–wear

transition

map

of

DLC

coating

under

cyclic

impact

loading

Mohd

Fadzli

Bin

Abdollah

a,∗, Yuto

Yamaguchi

a, Tsuyoshi

Akao

b, Naruhiko

Inayoshi

c,

Nobuyuki

Miyamoto

c,

Takayuki

Tokoroyama

a,

Noritsugu

Umehara

aaDepartmentofMechanicalScienceandEngineering,GraduateSchoolofEngineering,NagoyaUniversity,Furo-cho,Chikusa-ku,Nagoya464-8603,Japan bTechnologyPlanningDepartment,DENSOCorporation,1-1Showa-cho,Kariya-shi,Aichi448-8661,Japan

cMaterialsEngineeringR&DDepartment,DENSOCorporation,1-1Showa-cho,Kariya-shi,Aichi448-8661,Japan

a

r

t

i

c

l

e

i

n

f

o

Articlehistory:

Received18May2011 Receivedinrevisedform 24November2011 Accepted28November2011

Available online 6 December 2011

Keywords:

Impacttesting DLCcoating

Deformation–weartransitionmap Impactwearmechanisms

a

b

s

t

r

a

c

t

Anewdeformation–weartransitionmapofhydrogen-freeamorphouscarboncoating(commonlyknown asDiamond-LikeCarbon(DLC)coating)ontungstenhighspeedsteel(SKH2)substrateundercyclicimpact loadinghasbeenproposedtoclarifytheinteractionsoftheoperatingparameters,deformationandwear. Thestudywascarriedoutusinganimpacttester,underlubricatedconditionsoverawiderangeofimpact cycles,andappliednormalloads.SKH2discswerecoatedwiththinDLCfilmsusingaPhysicalVapor Deposition(PVD)method.Tungsten(W)wasusedasaninterlayermaterial.TheDLCcoateddiscwas impactedrepeatedlybyachromiummolybdenumsteel(SCM420)pin.Allimpacttestswereconducted atroomtemperature.Ithasbeensuggestedthatthedeformation–weartransitionmapisaneasyway toillustratetheimpactwearmechanismsofDLCcoating,asshownbyitstransitionzones.Initially,the DLCcoatingonlyfollowstheplasticdeformationofthesubstrateuntilseveralimpactcycles.Then,a suppressionofplasticdeformationofthesubstrateistakingplaceduetothedecreasingcontactpressure withimpactcyclestotheyieldpoint.WearoftheDLCcoatingbecomesdominantwhenthecriticallimit ofmaximumnormalimpactloadandimpactcyclesisexceeded.Fromexperimentalobservations,some degradationoftheDLCcoatingoccurswithinthewearzone.

© 2011 Elsevier B.V. All rights reserved.

1. Introduction

DLChasattractedgreatattentionformanyapplicationsdueto itstremendousproperties,suchashighhardness,thermalstability, lowfrictioncoefficient,andgoodchemicalinertness.Furthermore, theDLCfilmshowedanexcellentwearresistanceindryand water-or oil-lubricatedconditions [1].The useof DLCcoating,onthe impactsurfacesofcomponents,provideshighlevelsofprotection againstsurfacedamage.

Theconceptofa‘wearmap’wasfirstdiscussedbyTabor[2], andwasinspiredbythepioneeringworkofFrost[3]on ‘defor-mationmaps’.Thedevelopmentofdeformation–weartransition mapisausefulwaytostudyandpredictthetransitionof deforma-tiontowearofonematerialimpactingagainstanotheratdifferent loadsandcycles.Furthermore,thelocationsofthetransitionzones

∗Correspondingauthor.Tel.:+81527892788;fax:+81527892788.

E-mailaddresses:[email protected](M.F.B.Abdollah),

[email protected](Y.Yamaguchi),

[email protected](T.Akao),[email protected]

(N.Inayoshi),[email protected](N.Miyamoto),

[email protected](T.Tokoroyama),[email protected]

(N.Umehara).

withintheoperatingparametersareimportant,inordertodesign engineerlesscomponentfailuresoccurringprematurely.

Generally, the construction of transition maps follows two routes[4,5].Oneisempirical:datafromexperimentsareplottedon suitableaxesandidentifiedbywearrateorobservationand bound-ariesaredrawntoseparateclassesofbehavior.Theotherrouteis thatofphysicalmodeling:model-basedequations,describingthe wearratecausedbyeachmechanism,arecombinedtogiveamap showingthetotalrate,andthefieldofdominanceofeach.However, onlytheempiricalapproachisusedinthisstudy.

Theweartransitionmapsspecifictocertainmaterials,suchas ceramics[6],greycastiron[7],magnesiumalloy[8],brassalloy

[9], silicon nitrite [10], have been developed extensively for a decade.Allthetransitionmaps,whichappearintheabovestudies, wereconstructedusingeitheraphysicalmodelingoranempirical approachbasedontheslidingtestdata.However,inthiscentury, thereisstillnodevelopmentofdeformation–weartransitionmap oftheDLCcoatingundercyclicimpactloading.Therefore,theaimof thisstudyistoproposeanewdeformation–weartransitionmapof DLCcoatingbasedonvariationsofmaximumnormalimpactloads andimpactcycles.Afterashortdescriptionoftheimpacttestused inthisstudy,theconstructionofthedeformation–weartransition mapwillbepresentedusingexperimentaldataandobservations. Thetransitionmapof DLCcoating,undercyclicimpactloading,

0043-1648/$–seefrontmatter© 2011 Elsevier B.V. All rights reserved.

tendstofocusonthedescriptionofitsimpactwearmechanisms andthetransitionbetweenthem.

2. Experimentalmethod

2.1. Materials

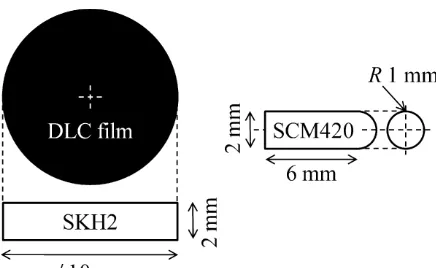

TheSKH2discwasusedasasubstrate,whilstSCM420pinwas usedasanimpactor.Thediameterofthediscandthepinwere 10mmand2mm,respectively(asshowninFig.1).AllDLCfilms weredeposited onto the SKH2 substrate using a PVD method; whereWwasusedasaninterlayermaterial.Thefilmthicknesshc

isapproximately2.97m.TheaveragesurfaceroughnessRaofthe

as-depositedDLCcoatingisapproximately18.63nm,whichwas measuredbyAtomicForceMicroscopy(AFM).Materialproperties arelistedinTable1.

2.2. Impacttesting

Theimpacttestwasperformedusingtwoself-developedimpact testers,asshowninFig.2.Thehorizontalimpacttesterwasused formorethan102impactcycles,withafrequencyof10Hz;anda

drop-weightimpacttesterwasusedforthelowimpactcycles. TheimpacttestrigwasdesignedtoimpactaDLCcoateddisc withaSCM420pinfornumerousimpacts.Priortotheimpacttest, bothdiscandpinwerecleanedusingacetoneinanultrasonicbath. TheDLCcoateddiscwasrepeatedlyimpactedata90◦inclination

atroomtemperature.Severaldifferentmaximumnormalimpact loadswereappliedtotheDLCcoateddiscviaaspringsystemforthe horizontalimpacttester.Meanwhile,themaximumnormalimpact loadofthedrop-weightimpacttestercouldbeincreasedbyadding animpactormassm.Ithasbeenreportedthattheimpactormass doesnotsignificantlyaffectimpactperformances(deformationand wear)[11,12].Theappliedloadwasobservedbyaloadcell.

ThesurfacemorphologyoftheaffectedareaontheDLC coat-ing,aswellasonthecounterpartmaterial,wasobservedbyAFM, FieldEmissionScanningElectronMicroscopy(FE-SEM),andEnergy DispersiveX-raySpectroscopy(EDS).Inaddition,theFocusedIon

Fig.1. DimensionsoftheDLCcoateddiscandtheSCM420pin.

Table1

MaterialpropertiesoftheDLC,SKH2substrateandSCM420pin.

Properties DLC SKH2 SCM420

Youngmodulus,E(GPa) 251 378 295

Poisson’sratio,v 0.3 0.3 0.3

Hardness,H(GPa)a 17.14 9.80 7.43

Yieldstrength,Y(GPa)b 6.12 3.50 2.65

aFromthenanoindentationtest. b Y=H/2.8.

Fig.2. Schematicillustrationoftheimpacttester:(a)horizontalimpacttesterand (b)drop-weightimpacttester.

Beam(FIB)wasusedtomillthetestedsample,inordertoexamine thecrosssectionoftheDLCcoatingontheSKH2substrate.

2.3. Residualimpactcratervolume/depth

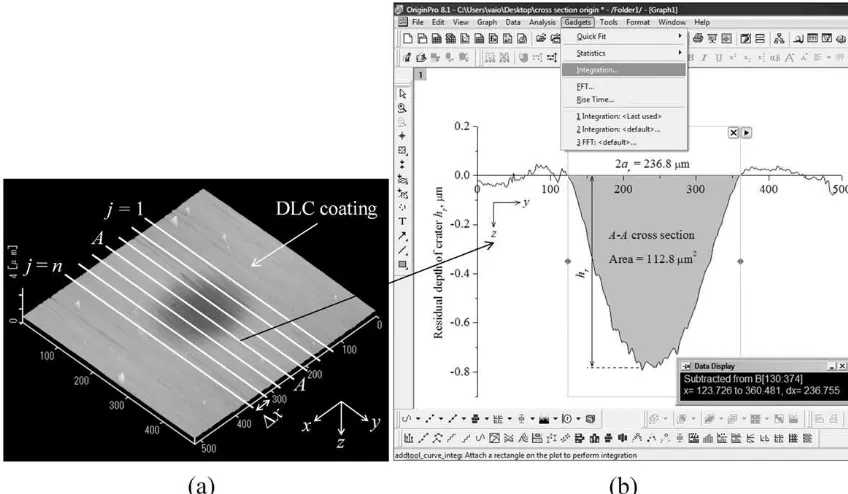

Therawdatacollectedincludedthemeasurementsofthe resid-ualimpactcratervolumeanditsdepth/radius.Thedepthhrand radiusaroftheresidualimpactcrateroftheDLCcoatingwere mea-sureddirectlyfromacross-sectionalAFMtopographyimage.The cross-sectionalimage,paralleltothey-axis,wastakenatthecenter ofimpactcrater,asshowninFig.3.Inordertocalculatetheresidual impactcratervolume,rawdatafromtheAFMwasexportedto Orig-inPro8.1.Anillustrationofhowtheresidualimpactcratervolume wascalculatedisshowninFig.3.Therawdataofx-axiswere dis-cretetoncross-sectionswiththethicknessofx.ThesurfaceareaA

ofeachcross-sectionwasdeterminedusingtheintegrationmethod functioninOriginPro8.1.TheresidualimpactcratervolumeVris determinedusingthefollowingequation:

Vr= n−1

j=1

(A×x)j (1)

2.4. Transitionofcontactpressure

Fig.3.(a)Discretionsofx-axisofanimpactcratertoncrosssections,withthethicknessofxand(b)determinationofeachsurfacearea(A–Acrosssection)usingthe integrationfunctioninOriginPro8.1.

(a)Contactconditionisassumedtobepointcontact.

(b) Themajor(y)axisandminor(x)axisoftheresidualcontact radius,obtainedexperimentallyfromeachimpactcycle,isused.

Meancontactpressurepmeanforiimpactcyclesiscalculatedby usingthefollowingequation[14]:

pmean,i= Fz

arxary

i(2)

whereFzisthemaximumnormalimpactload,aryandarxarethe residualradiiofthemajorandminoraxes,respectively.

2.5. Wearmeasurements

InordertodeterminetheweardepthoftheDLCcoating,its crosssectionontheSKH2substratewaspreparedusingaFIBand observedbyFE-SEM,asshowninFig.4.Thetestedsamplewas milledalongthecentreoftheimpactcraterofthemajoraxis.From

Fig.5,itisassumedthattheweardepthhw(measuredfromthe FIB-milledcross-sectionalimage)isconstantthroughoutthecontact surface,andthus

hp=hr−hw (3)

wherehp istheplasticdeformationdepthandhristheresidual depthofimpactcrater.

Fig.4.FE-SEMcross-sectionalviewoftheFIB-milledDLCcoatingontheSKH2substrate(tiltedat60◦),whereh60c1isthenon-impactedfilmthickness,andh60c2isthe

Fig.5.Schematicillustrationoftheweardepthhw.

2.6. Constructionofthedeformation–weartransitionmap

Inthisstudy,theconstructionofthedeformation–wear transi-tionmapisacombinationofproceduresbyAshbyandLim[5]and ShuandShen[6].

Nouniversaldeformation–weartransitionmapexists,because thecontrollingvariables differfrom mechanism tomechanism. Therefore,suitableaxesofthemaphavetobedecided.Inthisstudy, theappropriateaxesaredeterminedtobethemaximumnormal impactloadFzandtheimpactcyclesN.Thesevariableswere cho-senfortworeasons:firstly,theydirectlydeterminetheresidual impactcratervolumeandsecondly,theyareunderthecontrolof theoperator,andeasilymeasured.

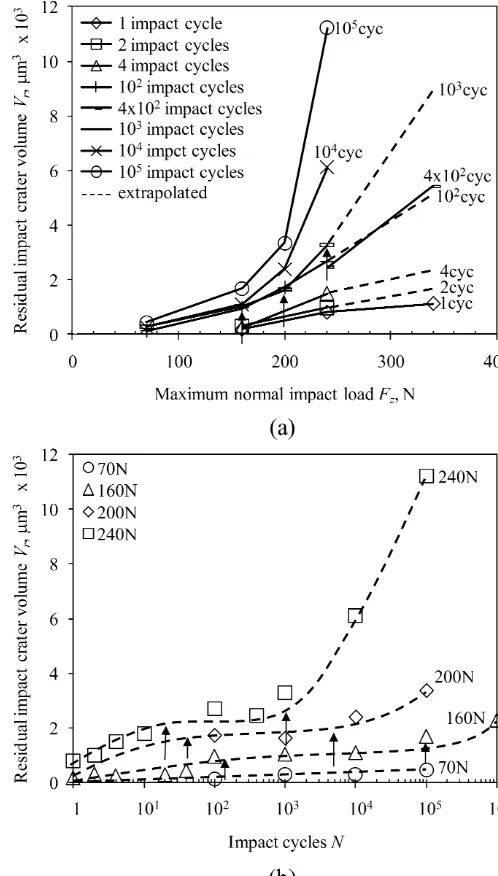

Alldata points of the residual impact crater volume Vr are plottedasfunctionsofFz andN,asshowninFig.6.Some

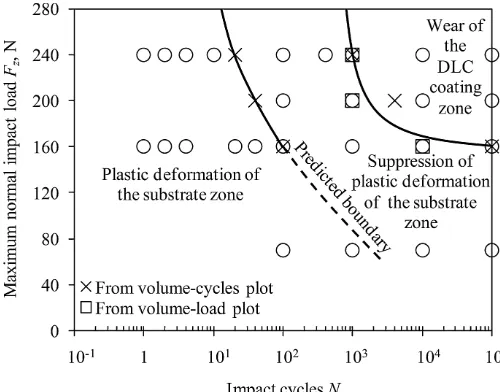

inter-polations and extrapolations are needed to obtain an evenly distributeddataset.Then,thelocationsofbothload-andimpact cycle-dependentdeformation–weartransitions,areidentifiedby experimentalobservationsanddatatrendanalysis.Arrowsindicate theonsetofthesevariable-dependentdeformation–wear transi-tions.Thebestfittingcurvesconnectingallofthetransitionpoints arethentracedandillustratedinthegraphofFzvs.N,asshown inFig.7.Thesecurvesrepresentthedeformation–weartransition boundaryoftheimpactedDLCcoating.

3. Resultsanddiscussion

3.1. Deformation–weartransitionmap

Themaximumnormalimpactloadandimpactcyclesareboth importantparametersandeithervariablecaninduceatransition from deformation to wear of DLC coating, as shown in Fig. 6. Therefore,adeformation–weartransitionmapwasgeneratedby simultaneouslyvarying the maximum normal impact load and impactcycles,whichrevealedthistransitionverywell.

Besides,theimpactwearmechanismsoftheDLCcoatingcan easilybeshownbyitstransitionzonesonthedeformation–wear transitionmap,asshowninFig.7.Threezoneswereidentified:

(a)Theplasticdeformationofthesubstratezone,wherethe resid-ualimpactcratervolumechangeswiththemaximumnormal impactloadandimpactcycles.Asdemonstratedinprevious experiment[12],thedeformationofanelastic-perfectplastic substrateshouldnotbealteredbythepresenceofathinfilm, whichitselfsimplyfollowsthedeformationofthesubstrateat theinterface.Thestraininthefilmisgovernedbythesurface strainofthesubstrate.Furthermore,Fig.8clearlyshowsthat almostnowearisobservedat70and160Nofthemaximum normalimpactload.Inaddition,theweardepthisalmostzero

Fig.6.ResidualimpactcratervolumeoftheimpactedDLCcoating,plottedasa functionof(a)maximumnormalimpactloadand(b)impactcycles.(Arrowsindicate theonsetofload/cycle-dependentdeformation–weartransitions.)

at200and240Nunderlowimpactcycles.Thisthereforereveals thatonlyplasticdeformationofthesubstratehasoccurred. (b)Suppressionofplasticdeformationofthesubstratezone,where

theresidualimpactcratervolumeremainsconstantwiththe impactcycles. Thisisduetothedecreasingcontactpressure withimpactcyclestotheyieldpoint,asshowninFig.9.Asthe numberofimpactcyclesisincreased,thecontactareaspreads. Additionally, thisexperiment wasunder theconstant maxi-mumnormalimpactloadforeachimpactcycle,andtherefore, thecontactpressureisdecreased.Inthiszone,thedeformation ofsubstrateismostlikelytoundergoanelasticdeformation ifthecontactpressure isalmostorbelowitsyieldpoint.By increasingthemaximumnormalimpactload,thesuppression ofplasticdeformationofthesubstratetakingplace,isfaster.At 240Nofmaximumnormalimpactload,theplasticdeformation ofthesubstrateissuppressedafter101impactcycles,because

Fig.7. Deformation–weartransitionmapofDLCcoatingundercyclicimpact load-ing.Theillustrationofthepredictedboundaryisbasedonthecontactpressure approachingtheyieldpoint.

Fig.8.Comparisonoftheresidualdepthoftheimpactcraterhrandtheplastic deformationdepthhpasafunctionoftheimpactcycles.Thedifferencebetween bothcurves(patternedinverticallines)givestheapproximateweardepthofthe DLCcoating.

Fig.9. Relationshipbetweenmeancontactpressureandimpactcycles.

reason.Thepredictedboundary,showninFig.7,isillustrated basedonthecontactpressureapproachingtheyieldpoint. (c)WearoftheDLCcoatingzone,wheretheresidualimpactcrater

volumeincreasesrapidly/radicallywiththemaximumnormal impact loadand impact cycles. A critical maximum normal impactloadandacriticalimpactcycleexiststhatwill precipi-tatetheweartransitionoftheDLCcoating.Moreover,atthose criticalimpactloadsand impactcycles,weargraduallyrises asmaterialiswornaway.Fig.8showsthatnowearoccursif themaximumnormal impactloadisvery small,buta wear transitionoccurs(duetotheimpactcycles)whenthe maxi-mumnormalimpactloadreachesabove160N.Generally,the presenceofatransferlayeronthecounterpartmaterialafter repeatedimpactsmodifiesthetribologicalcontactfromthatof SCM420/DLCtoDLC/DLC;anda significanttemperaturemay resultatthecontactpointduetothelowthermal conductiv-ityofDLC,thuspromotinggraphitization.Inaddition,interface failurescanbefound,wherethecoatinglosesadhesiontothe substrateduetobothshearandtensilestress[15].Cracksmay startfromdefectsattheinterfaceandsometimescause catas-trophic failure withdelamination of ratherbig flakesof the coating.Iftheloadishighenough,cohesivefailuresandfatigue can alsobefound[15].The cohesivefailuresnormally con-sistofacontinuousremovalofthecoating,startingfromthe middleofthesphericalcalotte.Thefatigueoccursdueto peri-odicalstressloadsandshowsmicro-crackswithinthecoating. Consequently,theincreaseinwear,asthemaximumnormal impactloadandimpactcyclesisincreased,maybeduetothe combinationofgraphitizationandcrackingfromcyclicimpact loading.Thisisinagreementwiththisstudy,wheresome degra-dationoftheDLCcoating,suchascrackpropagationofthefilm, phasetransformation,andatribochemicalreactionofthewear debris/transferlayer,wasobserved.Inaddition,theformation ofatransferlayerontheaffectedareaofthecounterpart mate-rialwasalsoobservedexperimentallyinthiszone.Detailsabout thiswearwillbebrieflydiscussedinSection3.2.

3.2. DegradationofDLCcoatingwithinthewearzone

3.2.1. Crackpropagation

Asthethinhardcoatingfullytransmitstheimpactgenerated stressfieldtotheductilesubstrate,thesubstrateundergoesalarge

Fig.11.FE-SEMmicrographoftheweardebristakenfromtheedgeofimpactcrater. Thetop-leftmicrographisanimpactcrater.

plasticdeformation(largeindentdepth)thatthecoatingcannot accommodateotherthanbydevelopinganetworkofcracks.Radial crackscan therefore beobserved in theDLCfilm, as shown in

Fig.10.Thismicrographhasbeentakenafter104 impactcycles

at240N,usingFE-SEM.Radialcrackingisobservedinthecoating belowtheimpaction,which initiatesfromthecoating/substrate interface and propagates upwards into the coating. The main reason for this is the low yield stress of the substrate, which allowedplastic strainunder theimpactor; which the hard and oftenbrittlecoatingcouldnotfollow.Toreducethestressinthe coating,itstartstobuildaradialcrackinsidethecoating.Theradial cracksobservedinthisstudyhavealsobeenidentifiedinastudy onindentationandscratching[16].Tensilestressconcentrationsat

Fig.12.Ramanspectrumoftheweardebrisandtransferlayerafter104and105

impactcyclesat240N.TheRamanspectrumoftheas-receivedSCM420pinandthe as-depositedDLCcoatingareforcomparison.

thecoating/substrateinterfaceduringloadinghavebeenidentified asadrivingforcethatcausesthistypeofcrack[17,18].

3.2.2. Phasetransformationandtribochemicalreactionofwear debrisandtransferlayer

TheweardebrisoftheimpactedDLCcoatingwereonlyobserved ontheedgeoftheimpactcraters,asshowninFig.11.Inthecaseof acontinuouspresenceofoillubricant,thegenerateddebris com-binedwithoil,andremovedprogressivelybyitsevacuationoutside oftheimpactcraters.However,someoftheweardebristransferred tothecounterpartmaterial,asatransferlayer.Thegraphitization ofweardebris,aswellasthetransferlayer,isconfirmedbythe

Ramanspectroscopystudy[19].FromFig.12,theGpeakofthewear debrisshiftedtoahigherfrequencycomparedtotheas-deposited DLCcoating.Therefore,thismeansthatthesp2 bondingfraction

increases,partialtetrahedralbondshavebeenbroken,andhave transformedintotrigonalbonds[20].ThedecreaseintheFWHMG

indicatedtheremovalofabondangledisorderandthe increas-ingdominanceofcrystallites[20].Fromtheanalysisabove,thesp2

coordinatedcarbonbecomesgraduallydominantandcausesphase transformationfromsp3tosp2,whichwouldinducegraphitization.

Asforthetransferlayer,thegraphitizationisexpectedtooccur sinceitmainlycomesfromtheweardebris.Thisisconfirmedasthe Gpeakisshiftedtohigherfrequencythanthatoftheas-deposited DLCcoating,asshown in Fig.12.However,the wideningofits FWHMG,after105impactcyclesat240N,suggeststhatthesize

ofthelargersp2clustersisreducedduetothemechanicalcrushof

thelargersp2clusters.

Inaddition,thetribochemicalreactiontotheenvironment dur-ingimpactoccurredatthematingmaterialwherethetransferlayer adhered;aswellasintheweardebris[19].Thiswasduetothe oxi-dationofferrum(Fe)tomagnetite(Fe3O4)andhematite(␣-Fe2O3)

phaseswithapredominantpeakatapproximately680cm−1and

1317cm−1.Thebroadpeakatabout1350cm−1,whichis

proba-blyduetothedisorderedgraphite(Dpeak),overlappedwiththe

␣-Fe2O3peak.Thus,theDpeakisnotclearlyvisibleinFig.12.

3.2.3. Formationofthetransferlayer

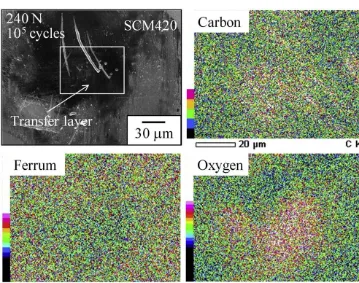

Undertribologicalconditions,thesofterofthetwomaterials willusuallybeworn.InthecaseofDLC,thissituationmaybe dif-ferentsincethewearofDLC,whichhasagraphiticnature,canbe depositedontothepartnersurface,formingtheso-calledtransfer layer.TheDLCthencontactsagainstitsowntransferlayerandeven thoughitisthehardersurface,onlytheDLCiswornataverylow wearrate,whereasthesofterpartnersurfacewillnotbeworn.The EDSmaps(asshowninFig.13)confirmthattheDLCcoating trans-ferredtothecounterpartmaterialofSCM420pinafter105impact

cyclesat240N.

4. Conclusions

Anewdeformation–wear transitionmap ofDLCcoating has beenproposedusingthetest resultstostudyofhowindividual impact parameters suchas maximum normal impactload and impactcyclesinfluencethistransition.

TheimpactwearmechanismsoftheDLCcoatingcaneasilybe shownbyitstransitionzonesonthedeformation–weartransition map.Threezoneshavebeenidentifiedasfollows:

(a)The plastic deformation of the substrate zone:the residual impact cratervolume increases with the maximum normal impactloadandimpactcycles.Onlythesubstrateisplastically deformed.Inaddition,wearhasnotbeenobservedinthiszone. (b)Suppression of plastic deformation of the substrate zone: theresidualimpactcratervolumeremainsconstantwiththe impactcyclesandplasticdeformationofthesubstratenolonger appears.Thisisduetothedecreasingcontactpressure with impactcyclestotheyieldpoint.

(c)WearoftheDLCcoatingzone:theresidualimpactcratervolume increasesrapidly/radicallywiththemaximumnormalimpact loadandimpactcycles,duetomaterialloss.TheDLCcoating appearstoapproachahighdegreeofwearwhenthecritical limit of maximumnormal impactloadand impactcyclesis exceeded.Thiswearisassociatedwithsomedegradationofthe DLCcoating,suchasthepropagationofradialcracksintheDLC film,phasetransformationoftheweardebris/transferlayer,and itstribochemicalreactionwiththeenvironment.Inaddition, formationofatransferlayeronthecounterpartmaterialhas alsobeenobservedexperimentallyinthiszone.

Acknowledgments

TheauthorMohdFadzliBinAbdollahgratefullyacknowledges thescholarshipfromUniversitiTeknikalMalaysiaMelaka(UTeM) forhisDoctoralstudy.

References

[1]K.Holmberg,H.Ronkainen,A.Matthews,Tribologyofthincoatings,Ceram.Int. 26(2000)787–795.

[2]D.Tabor,Statusanddirectionoftribologyasascienceinthe80s:understanding andprediction,in:Proc.Int.Conf.Tribol.80s,vol.1,1984,pp.1–17. [3]H.J.Frost, M.F. Ashby,DeformationMechanism Maps: ThePlasticityand

CreepofMetalsandCeramics,firsted.,PergamonPress,Oxford,NewYork, 1982.

[4] S.C.Lim,M.F.Ashby,Wear-mechanismmaps,ActaMetall.35(1987)1–24. [5]M.F. Ashby, S.C. Lim, Wear-mechanism maps, Scripta Metall.24 (1990)

805–810.

[6]S.M.Hsu,M.C.Shen,Ceramicwearmaps,Wear200(1996)154–175. [7] A.R.Riahi,A.T.Alpas,Wearmapforgreycastiron,Wear255(2003)401–409. [8]H.Chen,A.T.Alpas,SlidingwearmapforthemagnesiumalloyMg–9Al–0.9Zn

(AZ91),Wear246(2000)106–116.

[9]K.Elleuch,R.Elleuch,R.Mnif,V.Fridrici,P.Kapsa,Slidingweartransitionfor theCW614brassalloy,Tribol.Int.39(2006)290–296.

[10] J.R.Gomes,A.S.Miranda,J.M.Vieira,R.F.Silva,Slidingspeed-temperaturewear transitionmapsforSi3N4/ironalloycouples,Wear250(2001)293–298.

[11]P.Robinson,G.A.O.Davies,Impactormassandspecimengeometryeffectsin lowvelocityimpactoflaminatedcomposites,Int.J.Eng.12(1992)189–207. [12] M.F.B.Abdollah,Y.Yamaguchi,T.Akao,N.Inayoshi,T.Tokoroyama,N.

Ume-hara,Theeffectofmaximumnormalimpactload,absorbedenergy,andcontact impulseontheimpactcratervolume/depthofDLCcoating,Tribol.Online6 (2011)257–264.

[13] T.Yoshimi,S.Matsumoto,Y.Tozaki,T.Yoshida,H.Sonobe,T.Nishide,Work hardeningandchangeincontactconditionofrollingcontactsurfacewith plas-ticdeformation,Tribol.Online4(2009)1–5.

[14] K.L.Johnson,ContactMechanics,firsted.,CambridgeUniversityPress, Cam-bridge,1985.

[15]C.P.O. Treutler, Industrial use of plasma deposited coatings for compo-nentsofautomotivefuelinjectionsystems,Surf.Coat.Technol.200(2005) 1969–1975.

[16]Z.H.Xie,R.Singh,A.Bendavid,P.J.Martin,P.R.Munroe,M.Hoffman,Contact damageevolutioninadiamond-likecarbon(DLC)coatingonastainlesssteel substrate,ThinSolidFilms515(2007)3196–3201.

[17]A.C.Fischer-Cripps,B.R.Lawn,A.Pajares,L.Wei,Stressanalysisofelastic-plastic contactdamageinceramiccoatingsonmetalsubstrates,J.Am.Ceram.Soc.79 (1996)2619–2625.

[18]A.Abdul-Baqi,E.VanderGiessen,Numericalanalysisofindentation-induced crackingofbrittlecoatingsonductilesubstrates,Int.J.SolidStruct.39(2002) 1427–1442.

[19]M.F.B.Abdollah,Y.Yamaguchi,T.Akao,N.Inayoshi,N.Umehara,T.Tokoroyama, Phasetransformationstudiesonthea-Ccoatingunderrepetitiveimpacts,Surf. Coat.Technol.205(2010)625–631.