THE EFFECT OF ACCELERATED AGING ON THE

CHARACTERISTIC PROPERTIES OF RICE BRAN

LINGGA HERLAMBANG FEBRIANTO

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY BOGOR AGRICULTURAL UNIVERSITY

STATEMENT LETTER OF MANUSCRIPT AND SOURCE OF

INFORMATION*

I declare the truth that this manuscript entitled The Effect of Accelerated Aging on the Characteristic Properties of Rice Bran is my work with guidance of the advisors and has not been submitted in any form at any college, except Bogor Agricultural University and Kasetsart University. Sources of information derived or quoted from published or unpublished works of other authors mentioned in the text and listed in the List of References at the end of this manuscript.

Hereby this statement, I bestow the copyright of my manuscript to the Bogor Agricultural University.

Bogor, January 2015

Lingga Herlambang Febrianto

ABSTRACT

LINGGA HERLAMBANG FEBRIANTO. The Effect of Accelerated Aging on the Characteristic Properties of Rice Bran. Supervised by TJAHJA MUHANDRI and PINTHIP RUMPAGAPORN.

Accelerated aging process using thermal processing has been reported as an alternative way to produce aged rice. Rice bran is a by-product of rice production containing many bioactive compounds, which give beneficial effect to human health. Effect of accelerated aging on functional properties of rice grain and flour has already been discussed. However, the consequence of the accelerated aging technique on the characteristic properties of the rice bran has to be investigated and verified. Moreover, the investigation of accelerated aging on the rice bran is quite limited. The objective of this research is to investigate the effect of accelerated aging using high-temperature fluidized bed drying followed by tempering and ventilation on the dietary fibre (insoluble and soluble dietary fibre), lipid rancidity, and antioxidant activity properties of rice bran. Based on the experimental results it was found that the rice bran properties after accelerated aging process namely, alcohol-soluble and water-soluble acidity, free fatty acids content, total phenolic content, and antioxidant activity significantly affected the aged rice bran properties. The accelerated aging process using high-temperature could decrease acidity and free fatty acids contents of rice bran oil. Moreover, the accelerated aging was found to exhibit decreased of total phenolic content and reducing power of rice bran extracts. The reducing power of rice bran extracts were associated with the total phenolic content. However, the total dietary fibre of rice bran had no significantly different. The accelerated aging could be used to stabilization process for rice bran before further utilization. These process could be produce low acidity and free fatty acid content of rice bran oil production.

Manuscript

submitted as a partial fulfillment of the requirement for degree of Sarjana Teknologi Pertanian

at

Department of Food Science and Technology

THE EFFECT OF ACCELERATED AGING ON THE

CHARACTERISTIC PROPERTIES OF RICE BRAN

DEPARTMENT OF FOOD SCIENCE AND TECHNOLOGY

FACULTY OF AGRICULTURAL ENGINEERING AND TECHNOLOGY BOGOR AGRICULTURAL UNIVERSITY

BOGOR 2015

PREFACE

Praise to ALLAH SWT for the mercy, the graciousness, and the guidance throughout the research and manuscript completion. The research entitled The Effect of Accelerated Aging on the Characteristic Properties of Rice Bran that was carried out in Kasetsart University from May to September 2014.

By completion of this research and manuscript, the author like to express great appreciations and sincere thanks to:

1. My lovely parents, my sister Shafa Nadira, and my big family for their endless loves, cares, prays, and support for me.

2. Dr. Tjahja Muhandri, S.TP., MT, as academic advisor for his time, care, patient, concern, and guidance.

3. Dr. Pinthip Rumpagaporn as advisor for her time, care, patient, knowledge, and valuable suggestion in guiding the author to complete the research in Kasetsart University.

4. Ir. Sutrisno Koswara, M.Si. and Dr. Fahim Muhammad Taqi, DEA, as examiners in my final presentation for their time, valuable suggestion, care, and helps.

5. Dr. Sashitorn Tongchitpakdee and Mr. Phu Thai who take care three of us Indonesian exchange students.

6. All my friends in Rice and Starch laboratory (room 2106), P’Tang,

P’Bunyut, P’Fai Wata, P’Oh, P’Nu, P’Joom, P’Pui, P’Vannack and especially P’Mook, P’Fai, and P’Cin for the helping in my research work and the wonderful time together.

7. Kasetsart exchange student 2014: Dyah Sekar A, Indah Kurniasari, and AIMS students 2014: Gunawan S and Elvan for togetherness, cooperations, and helps during the research in Thailand.

8. BIDIK MISI DIKTI and AIMS program for the scholarship.

9. All Indonesian fellows in Kasetsart University, mas Iwan, mba Dwita, mba Ida, mba Hezti, mas Wildan, mas Aidil, and kak Alfa.

10.All my friends: Agisio Alya, Dicki Aulia R, M. Jaenal Septian, M. Arif Munandar, Bahtiar Mustakim, and all of lovely friends #ITP 47.

Last but not least, hopefully this manuscript is useful for the readers and gives a real contribution in food science development.

Bogor, January 2015

TABLE OF CONTENT

LIST OF TABLE vi

LIST OF FIGURE vi

LIST OF APPENDICES vi

INTRODUCTION 1

Background 1

Research Objective 2

LITERATURE REVIEW 2

Rice Aging 2

Accelerated Aging 3

Rice Bran 3

Rice Bran Oil 4

Antioxidant 4

METHODOLOGY 5

Material 5

Equipment 5

Procedure 5

Method of Analysis 7

RESULT AND DISCUSSION 9

Accelerated Aging of Rice Bran 9

Total, Soluble, and Insoluble Dietary Fibre of Rice Bran 11

Acidity of Rice Bran Oil 13

Free Fatty Acids Content 15

Total Phenolic Content 16

Reducing Power 18

CONCLUSION AND RECOMMENDATION 19

Conclusion 19

Recommendation 19

REFERENCES 19

APPENDICES 23

LIST OF TABLE

1 Schematic model of the aging process in rice (Zhou et al. 2002a) 2 2 Total, soluble, and insoluble dietary fiber of rice bran samples 11

3 Total phenolic content of rice bran sample 17

LIST OF FIGURE

1 Alcohol-soluble acidity of rice bran for several treatment 13 2 Water-soluble acidity of rice bran for several treatment 14 3 Free fatty acid content of rice bran sample 15 4 Antioxidant activity of rice bran by reducing power method 18

LIST OF APPENDICES

1 Scheme of experimental design 23

2 Sample preparation of dry-mill paddy 24

3 Analytical scheme for soluble and insoluble dietary fibre

determination procedure 25

4 Freshly harvested, naturally aged, and accelerated aged rice bran

sample 26

5 The result of iodine test rice bran samples 26 6 The fluidized bed dryer machine and specification 27

7 The rice mill machine 27

8 Data of corrected protein using kjeldahl method for dietary fibre

analysis 28

9 Standard curve of BHT by total phenolic content assay. 28 10 Statistical analysis of total, soluble, and insoluble dietary fibre

rice bran 29

11 Statistical analysis of acidity rice bran oil. 31 12 Statistical analysis of free fatty acid content 32 13 Statistical analysis of total phenolic content rice bran extract 33 14 Statistical analysis of antioxidant activity by reducing power

INTRODUCTION

Background

Rice is a dominant staple food which has been consumed people in many parts of the world, especially in Asia, where it supports approximately one-half of the world population. The cooking quality of rice is one important factors influencing the acceptability of consumers. Cooked rice that is generally preferred and by people in some Asian countries, including Thailand, is that large volume and is non-sticking. The desirable properties of cooked rice are generally obtained by storing paddy for a certain period of time before further processing, the process that is known as aging (Soponronnarit et al. 2008). Aging of rice is a normal step between harvest and consumption. The freshly harvested paddy is less suitable both for processing and consumption, whereas adequate aging brings about the desirable properties (Rayaguru et al. 2011). The physicochemical properties of aged rice is change during storage. The changes of aged rice are caused by changes in lipid, protein, and other subtances produce from enzyme activities and oxygen (Charstil 1994). The changes perhaps altered to physicochemical properties of rice bran. The naturally or conventional aging process is time-consuming, takes a long time, approximately 4-6 months. This aging method also requires much space for storage paddy and high operating cost. It is therefore necessary to explore other techniques that can reduce the aging time and operating cost while, at the same time, can maintain the rice properties such as appearance and texture to be similar to those obtained by the naturally aging process. The accelerated aging of paddy could be used as means to alter the rice characteristics. Accelerated aging process using thermal processing has been reported as an alternative way to produce aged rice.

Rice bran is a by-product of rice production containing many bioactive compounds, for instance, dietary fibres, antioxidant, essential fatty acids, and phytosterols, which give beneficial effect to human health. It contains 34.1-52.3% carbohydrate, 15-22% lipid, 10-16% protein, 7-11.4% fibre, and 6.6-9.9% ash (Fabian and Ju 2011). Rice bran oil has been extracted and commercialized as high quality of cooking oil, which is high in poly- and mono-unsaturated fatty acids. The naturally aging method can undergo lipid oxidation by lipase activity, if we storing rice in longer time. Heat treatment can deactivate lipase and this can slow down the rate of lipid oxidation (Jaisut et al. 2009). Accelerated aging with heat treatment maybe can protect the rice bran oil functional properties. Moreover, the accelerated aging might be can produce low acidity of rice bran oil.

2

compared to those properties of the sample undergo naturally aging process and freshly harvested of rice bran.

Research Objective

The objective of this research is to investigate the effect of accelerated aging using high-temperature fluidized bed drying followed by tempering and ventilation on the dietary fibre (insoluble and soluble dietary fibre), lipid rancidity, and antioxidant activity properties of rice bran.

LITERATURE REVIEW

Rice Aging

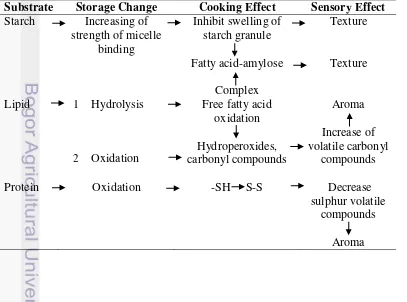

Freshly harvested rice is less preferred by consumer because of poor cooking properties like less kernel elongation and volume expansion with more solids loss and softer gel consistency. Aging brings about progressive desirable changes in the grain (Rayaguru et al. 2011). Aging is natural and spontaneous phenomenon that commences after harvesting and continues as a temperature-, time-, and moisture-dependent index (Likitwattanasade 2009). During the aging or storage, there are physicochemical interaction among starch, lipid, protein, and enzymes reactions, although the overall starch, lipid, and protein content in rice grain remain essentially unchanged. It is apparent that aging is a complicated process involving physical, chemical, and biological change. The model for aging process shows in Table 1. Table 1 Schematic model of the aging process in rice (Zhou et al. 2002a)

3

Aging is one the factors responsible for textural changes in cooked rice and the properties, especially pasting properties of rice flour. The properties of cooked rice become harder and less sticky than freshly harvested rice (Ohno and Ohisa 2005). The aged rice was found to exhibit an increased volume expansion and water absorption during the cooking process. The minimum storage period for major changes to occur in the hardness of cooked rice in conventional aging was 3 months (Katekhong and Charoenrein 2012). The natural aging of rice takes approximately 4-6 months and also requires much more storage for paddy. This can increases operating cost. Moreover, paddy is susceptible to insect damages, as well as microorganisms and rodents during storage (Soponronnarit et al. 2008). It is therefore necessary to explore other techniques that can reduce the aging time and operating cost while, at the same time, can maintain the rice properties such as appearance and texture to be similar to those obtained by the naturally aging process.

Accelerated Aging

The aging process may be accelerated by subjecting the grains to appropriate environmental conditions to bring about the acceptable properties (Rayaguru et al.

2011). Accelerated aging used could be more practical commercially than the naturally aging. The process for accelerated aging could be developed either by dry or wet heat. Dry heat treatment is preferred since its performance is easier and cheaper (Rayaguru et al. 2011). The importance of aging of rice with desired cooking and organoleptic characteristic has attracted considerable attention. Various studies indicated that heat treatment is the major factor responsible for quality changes during aging. Few research workers further reported that the interaction of moisture and temperature along with other factors affect the quality of aged rice. Soponronnarit et al. (2008) investigated the characteristic of accelerated and naturally aged rice using fluidized bed drying followed by tempering and ventilation. The result showed that rice properties; namely elongation ratio, whiteness, volume expansion, water uptake, solid loss, and pasting properties changed in similar way to those of the naturally aged paddy. Nevertheless, the head rice yield of rice undergone accelerated aging process was significant lower than that of the naturally aged paddy (p<0.05). Gujral and Kumar (2003), with accelerated aging process (steaming for 30 min at 22% moisture content), attained improved elongation ratio, water uptake, and lower solid loss for three different rice cultivar. The other study, Rosniyana et al. (2004) conducted experiment on accelerated aging by heating paddy at high temperature of 80-100 oC in a sealed container (1.5 h to 15 h) and compared its cooking properties to those of naturally aged and freshly harvested. During the accelerated aging, elongation was improved and elongation ratio greater than natural aging process. The solid loss and gel properties were also improved.

Rice Bran

4

of the rapid hydrolysis of oil into free fatty acids. The biochemical instability of rice bran occur immediately after milling rice. Furthermore, free fatty acids and lipid hydroperoxides in rice bran increased significantly during storage. However, it is an excellent source of bioactive compounds. Rice bran is rich in natural antioxidant including tocochromanols (tocopherols and tocotrienols) and oryzanol. Since rice bran rich in lipids, it is thus commercially feasible feedstock for oil extraction. Rice bran oil has been extracted and commercialized as high quality cooking oil. Moreover, rice bran has potential source of antioxidant, which beneficial effect in human health.

Rice Bran Oil

Rice lipids are in the aleurone and sub-aleurone layer and germ, while lipases are dormant and localized in the cross-testa layer (Nantiyakul 2012). In intact rice kernel, rice bran lipase is physically separated from lipid. When the rice bran is separated from kernel during milling, lipase and lipid come in contact, which promotes relatively rapid hydrolysis of lipids into free fatty acid, this results in significant loss of triacylglycerols during refining of rice bran oil. The major composition of crude rice bran oil is neutral lipids. Rice bran oil tends contain higher levels of non-triglyceride components. Moreover, the dominant free fatty acids in rice bran oil is oleic and linoleic acids, which are represent more than 80% of the total free fatty acid composition (Nantiyakul 2012). Free fatty acid, monoglycerides and diglycerides in rice bran oil associated with enzymatic hydrolysis. Processing of rice bran oil has some special features compared with other vegetables oils. The rice bran oil processing can be divide into two main parts, extraction of crude rice bran oil and refining process. Rice bran is first stabilized to inactive any lipolytic enzymatic.

Antioxidant

5 activity compare to other fractions, whereas albumin fraction showed the best in reducing activity by FRAP assay (Chanput et al. 2009).

METHODOLOGY

Material

Rice bran was obtained from Thailand commercial rice cultivar, Chai Nat. The chemical used for the sample preparation and analysis were: Megazyme Total

Dietary Fibre Kit (α-amylase, protease, and amyloglucosidase), 2(N-morpholino) ethanesulfonic acid (MES), tris(hydroxymethyl)aminomethane (TRIS), 0.561 N HCL, 5% HCL, 5% NaOH, 0.1 N KOH, 0.0178 N KOH, ethanol 95%, ethanol 80%, ethanol 78%, methanol 80%, acetone, hexane, petroleum ether, toluene, celite, deionized water, phenolphthalein indicator, 0.2 N folin-ciocalteu, 7.5% sodium carbonat, 0.2 M phosphate buffer (pH 6.6), 1% potassium ferricyanide, 10% trichloroacetic acid, 0.1% ferric chloride, and BHT (butylated hydroxytoluene). All chemical were analytical grade. There were also other chemical reagent needed to perform for protein determination using Kjeldahl assay.

Equipment

The equipment for the research are rice mill machine (NW 1000 Turbo), fluid bed dryer (Sherwood Scientific), tray dryer, sieve (30, 40, and 60 mesh), glassware, crucible, filtering flask, shaking water bath (Memmert), balance, vacuum pump, hot air oven, desiccator, magnetic stirrer and magnetic bar, muffle furnace, pipettes, micropipettes, burette, rotary evaporator, refrigerated centrifuge (Himac CR 20B2), pH meter (Mettler Toledo), spectrophotometer (Thermo Scientific® GENESYS 10 Scanning UV/Visible), can, blender, and equipment for Kjeldahl assay.

Procedure

Sample Preparation

6

soaked paddy. Before start accelerated aging process, paddy was placed in an ambient environment until its temperature was close to the ambient temperature.

Accelerated Aging (Soponronnarit et al. 2008)

The accelerated aging process of paddy is according to the method of Soponronnarit et al. (2008) with some modifications. Approximately 2 kg of rewetted paddy sample (33% d.b initial moisture content) was dried in fluidized bed dryer at temperature 150 oC with superficial velocity of 2.5 m/s for 2 min (minute). The drying process using fluidized bed dryer was divided into several batch, which was approximately 600 g per batch (the maximum capacity of fluidized bed dryer tube was 5 liters). The final moisture contents of paddy after fluidized bed drying process was approximately 22-23% (d.b), because further drying resulted in a decrease of head rice yield (Poomsa-ad et al. 2002). After drying, the paddy grain was tempered in a close container for 120 min. The condition of this tempering stage is normally practiced in rice factories in order to reduce stresses during drying (Soponronnarit et al. 2008). The paddy grain was tempered at same temperature as the grain temperature at the end of fluidized bed drying step. The grain temperature at the end of fluidized bed drying process (after hot air drying) was approximately 77-86 oC, which was approximately the same as gelatinization temperature of rice starch (Soponronnarit et al. 2008). The paddy was subsequently dried by tray dryer at temperature 40 oC with hot air for 4-6 h until the grain moisture content reached approximately 10% (d.b).

Rice Bran Sample Production

The paddy samples were milled using rice mill machine (rice huller with polisher). Rice bran was produced using friction polisher. Before start milling process, paddy samples were placed in an ambient environment until temperature was close to the ambient temperature. The desire moisture content of paddy should approximately 10% (d.b) to avoid rice bran contain starch, because the high moisture content could influencing the polishing of rice grain endosperm. The rice bran samples (composed of pericarp, testa, aleurone, germ, and some endosperm) were passed through 30 mesh sieve and stored under freezer until used further analysis.

Defatting Rice Bran

7 Extraction of Total Antioxidant (Iqbal et al. 2005)

Extraction was carried out following the method reported by Iqbal et al.

(2005) with some modification. Rice bran samples (5.0 g) were ground to passed through 40 sieve mesh and extracted thrice with 25 ml of 80% methanol for 3 hour in a magnetic stirrer at room temperature with shaking occasionally. The residue re-extracted twice with 20 ml of 80% methanol containing 0.15% HCL under the same set condition. The extracts were combined and centrifuged at 3000 rpm for 5 min. The extracts were evaporated by a rotary evaporator (under reduced pressure at 40

oC) and stored at 4 oC until used further analysis.

Method of Analysis

Determination of Total, Soluble, and Insoluble Dietary Fibre (Megazyme Test Kit Total Dietary Fibre Assay Procedure)

The content of total, soluble, and insoluble dietary fibre were analyzed with a Megazyme kit K-TDFR 05/12 Total Dietary Fibre Assay Procedure (based on AOAC Method 991.43 “Total, Soluble, and Insoluble Dietary Fibre in Foods” and AACC Method 32-07.01 “Determination of Soluble, Insoluble, and Total Dietary

Fibre in Foods and Food Products”) (Megazyme, Bray, Ireland, 2012). The rice bran sample should be fat-free and passed through 0.3-0.5 mm sieve mesh. 1 g dried and defatted sample (duplicate) is subjected to sequential enzymatic digestion by heat- stable α-amylase, protease and amyloglucosidase. Sample are incubated at 95-100

oC with heat stable α-amylase to give gelatinization, hydrolysis and

8

BA = blank ash from BR2

BP = blank protein from BR1

Determination of Alcohol-soluble Acidity (AOAC 2000)

The alcohol-soluble acidity of rice bran oil was determined according to the AOAC Official Method 920.92 (AOAC 2000). Rice bran sample was passed through 40 mesh sieve. 10 g of sieved rice bran was mixed with 75 ml 80% ethanol and cover beaker glass with aluminum foil. The mixture was shaking occasionally for 16 h in a magnetic stirrer at room temperature. Then, the mixture was filtered through dry paper (Whatman No. 2) and the filtrate was transferred aliquot (25 ml of filtrate) to erlenmeyer flask. The filtrate was diluted to 100 ml with distilled water and titrated with 0.1 M KOH using phenolphthalein indicator (0.1% m/v). The result was expressed as ml 0.1 M KOH required to neutralize acidity of 100 g bran sample. The assay was carried out in triplicate.

Determination of Water-soluble Acidity (AOAC 2000)

The water-soluble acidity of rice bran oil was determined according to the AOAC Official Method 920.174 (AOAC 2000). Rice bran sample was passed through 40 mesh sieve. 10 g of sieved rice bran was mixed with distilled water in beaker glass and diluted to 200 ml with distilled water. The mixture was covered with aluminum foil and shaking occasionally in a magnetic stirrer at room temperature. Then, the mixture was filtered through dry paper (Whatman No. 2). The acidity was determined in 10 ml by titration with 0.1 M KOH using phenolphthalein as indicator. The result was expressed as CH3COOH (1 ml 0.1 M

KOH = 0.0060 g CH3COOH). The assay was carried out in triplicate.

Determination Free Fatty Acids Content (Jaisut et al. 2009)

Free fatty acids (FFA) contents of rice bran sample were determined according to the Jaisut et al. (2009). 10 g of ground rice bran sample (passed through 40 mesh sieve) was filled in Whatman No. 1 filter paper. The rice bran sample was extracted with 200 ml of petroleum ether for 16 h with constant stirring at room temperature using magnetic stirrer. Then, the petroleum ether was removed by heating under a fume hood. After the solvent was evaporated, approximately 50 ml of benzene-alcohol-phenolphthalein (a liter of toluene and 95% ethanol with 0.4 g of phenolphthalein indicator) was added into the rice bran oil sample. The sample was titrated with 0.0178 N KOH until the faint pink color and persisted for 1 min. The assay was carried out in triplicate. The FFA contents was expressed as the percentage of oleic acid and calculated by the following equation:

FFA (mg KOH/100 g dry-matter) = ��� ���

− � � � �

Determination of Total Phenolic Content (Iqbal et al. 2005)

9 500 µl of diluted bran extracts (mg/ml), 500 µl of freshly prepared diluted 0.2 M Folin-Ciocalteu reagent and 2 ml of 7.5% (m/v) sodium carbonate solution. The mixtures were kept in dark at ambient condition for 2 h to complete the reaction. The absorbance was observed using UV/Vis spectrophotometer at 765 nm. BHT (butylated hydroxytoluene) solution was used as a standard and total phenolic contents were expressed as milligram of BHT equivalent (mg BHTAE) per 100 g of bran. The assay was carried out in triplicate.

Determination of Reducing Power (Arab et al. 2011)

The determination of reducing power was performed by the method used by Arab et al. (2011) with slightly modified. The 500 µl extracts sample (25 mg/ml) of rice bran was mixed with 2.5 ml of a phosphate buffer (0.2 M, pH 6.6). The diluted sample was then mixed with 2.5 ml of 1% (m/v) potassium ferricyanide solution and incubated at 50 oC for 30 min. About 2.5 ml of 10% (m/v) trichloroacetic acid solution were added for terminated reaction. The mixture was centrifuged at 3000 rpm for 10 min and 2.5 ml of supernatant aliquot mixed with 2.5 ml of distilled water and 0.5 ml of 1% (m/v) ferric chloride solution. The absorbance was observed at 700 nm by UV/Vis spectrophotometer. The assay was carried out in triplicate.

Statistical Analysis

All analysis were carried out in triplicate, and data were presented as means and standard deviation (SD). The significant differences among samples were

determined by analysis of variance and Duncan’s multiple range test using SPSS

program (version 22) at p<0.05.

RESULT AND DISCUSSION

Accelerated Aging of Rice Bran

The accelerated aging of rice bran was followed by Soponronnarit et al.

10

can reduce moisture content of rice grain. Furthermore, the loss of moisture content and high-temperature drying process can deactivate lipase activity on the rice bran. Moreover, the final moisture content of paddy after fluidized bed drying was limited in a small range of 22-23% (d.b) because further drying resulted in a decrease of head rice yield (Poomsa-ad et al. 2005). Furthermore, the tempering step helps release the moisture gradients created during drying process and makes the grain at the temperature near the gelatinization temperature, in the range of 73-80 oC, the

process might result in further starch gelatinization (after drying) (Soponronnarit et al. 2008). The moisture content during tempering process was observed 22.58% (d.b). The moisture content of rice grain should be similar with the final moisture content of rice grain after drying process, if the tempering process in ideal condition. However, the moisture content of rice grain was loss because the close container could not avoid moisture loss. The tempering process might be can change the physicochemical properties of rice bran by the temperature of rice grain near the gelatinization temperature, although the changes mechanism was different with drying process. Moreover, the paddy was dried using tray dryer until the moisture content almost 10% (d.b), because the milling machine has minimum moisture content.

11

Total, Soluble, and Insoluble Dietary Fibre of Rice Bran

The content of total, insoluble, and soluble dietary fibre in all samples were analyzed with a Megazyme Kit Total Dietary Fibre Assay Procedure. According to the definition developed by Philips and Cui (2011) the term dietary fibre refers to

“carbohydrate polymer with ten or more monomer unit, which are not hydrolyzed

by endogenous enzymes in the small intestine of humans”. The dominant dietary

fibre in cereals are cellulose, mixed-linked β-glucans and a range of polysaccharides containing xylans, e.g. arabinoxylans. Dietary fibre can be classified as either soluble or insoluble, based on whether it forms a dispersion when mixed with water (soluble fibre), or not (insoluble fibre). Dietary fibre constituents e.g. arabinoxylan

and β-glucan can be both soluble and insoluble whereas cellulose and lignin are classified as insoluble dietary fibre (Johansson 2012). Dietary fibre of rice bran has beneficial effect to human health.

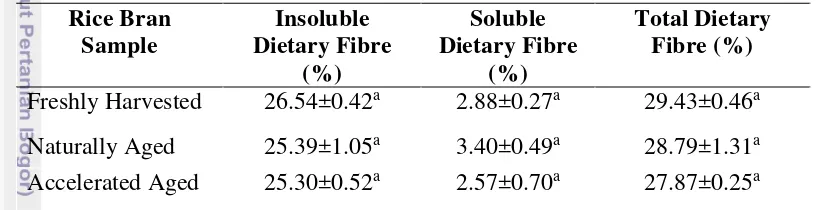

Table 2 Total, soluble, and insoluble dietary fiber of rice bran samples Rice Bran

Freshly Harvested 26.54±0.42a 2.88±0.27a 29.43±0.46a Naturally Aged 25.39±1.05a 3.40±0.49a 28.79±1.31a Accelerated Aged 25.30±0.52a 2.57±0.70a 27.87±0.25a

Result were expressed as mean±SD

a Means within the same column are not significantly different (p>0.05)

12

temperature can be due to fragmentation of polysaccharides because of increased thermal heating (Johansson 2012). These fragments of polysaccharides may not precipitate during treatment with 95% ethanol in the dietary fibre analysis. It was only polysaccharides that precipitate during treatment with 95% ethanol that were detected while smaller fragments and monosaccharides were discarded (Johansson 2012). The TDF can be lost because different solubility properties of polysaccharides in 95% ethanol in the dietary fibre analysis. This could also be the reason for the decrease of TDF with accelerated aging treatment, even though the decrease are not statistical significant.

The insoluble dietary fibre (IDF) of freshly harvested, naturally aged, and accelerated aged rice bran were 26.54%, 25.39%, and 25.30% respectively. The content of IDF from accelerated aged and naturally aged rice bran did not change significantly compared to freshly harvested rice bran as reference. However, they differ from the results observed by Johansson (2012) that the content of insoluble dietary fibre decrease with increasing temperature for the wheat bran sample. Moreover, Benitez at al. (2011) was reported that insoluble dietary fibre of onion by-product, on applying sterilization process there was decrease. According to Benitez et al. (2011) reductions in IDF content could be attributed to partial degradation of cellulose and hemicelluloses into simple carbohydrates as a consequence of heat treatment. The different result from the literature could probably be due to the accelerated aging process could not structural modification affecting to these polymers during the drying process. Because of the temperature and drying time process or thermal heating to the grain were not enough for degradation polymers. So, insoluble dietary fibre content of accelerated aged rice bran still has beneficial effect to human consumption, because of the structure of IDF did not change during fluidized bed drying process.

13

Acidity of Rice Bran Oil

The acidity of rice bran oil was determined according to Silva et al. (2006). The value of acidity rice bran oil was measured by alcohol-soluble and water-soluble acidity according to AOAC Official Method. These method was chosen because more practical and quick to know acidity of rice bran oil compared to other method. The alcohol-soluble and water-soluble acidity were rapid method to determined acidity of rice bran oil. The degree acidity of rice bran oil is an important indicator of oil quality. The acidity is expressed as the amount of KOH (in mg) necessary to neutralize free fatty acids contained in 1 g of oil. The value of acidity is correlated with rancidity of rice bran oil, which is develop of any amount of free fatty acid (FFA). The high value of acidity is correlated with high amount of FFA on the rice bran oil. The problem of rancidity in rice bran oil caused by lipases. The hydrolytic rancidity contributes to the acidity increase.

a-b Mean within the same letter are not significantly different (p>0.05)

Figure 1 Alcohol-soluble acidity of rice bran for several treatment

Figure 1 shows the results for alcohol-soluble acidity of rice bran samples. The content of alcohol-soluble acidity freshly harvested, naturally aged, and accelerated aged rice bran were 0.69 mg KOH/g bran, 0.94 mg KOH/g bran, and 0.79 mg KOH/g bran, respectively. The alcohol-soluble acidity content of accelerated aged did not change significantly compared with freshly harvested rice bran. The accelerated aging using high-temperature fluidized bed drying was effective reducing the alcohol-soluble acidity compared with natural aged rice bran. Silva et al. (2006) was reported thermal treatment capable to reduce oxidative reaction of rancidity on rice bran contributed to higher lipolytic enzyme inhibition. This fact could probably be the accelerated aging using high-temperature can deactivate lipase activity on the rice grain and slow down the rate of lipid oxidation. The lipase inactivation caused by denaturation of lipase protein. The high-temperature during accelerated aging can cause denaturation process of lipase. So,

14

lipase will loss of biological activity. Furthermore, the alcohol-soluble acidity of naturally aged rice bran was highly significant than those of the other rice bran samples. The high content of alcohol-soluble acidity was correlated with free fatty acid on rice bran oil. The decomposition of lipids (triacylglycerols) into free fatty acids was occurred by endogenous and microbial lipase during storage (Zhou et al.

2002b).

a-c Mean within the same letter are not significantly different (p>0.05)

Figure 2 Water-soluble acidity of rice bran for several treatment

Figure 2 shows the result of water-soluble acidity of rice bran samples. The content of water-soluble acidity of freshly harvested, naturally aged, and accelerated aged rice bran were 10.32%, 9.06%, and 8.12%, respectively. Accelerated aged rice bran presented lowest significantly water-soluble acidity than those of the other rice bran samples. The similar result was reported on the alcohol-soluble acidity content. The low value of water-alcohol-soluble and alcohol-alcohol-soluble acidity was correlated with low acidity of rice bran oil (low FFA content). Silva et al.

(2006) showed the toasting process with heat treatment effective in reducing the water-soluble acidity of polished rice bran. On the other hand, the contrast result presented on the freshly harvested rice bran. The content of water-soluble acidity of freshly harvested highly significant than those of the other rice bran samples. This fact could probably be correlated with solubility of free fatty acid in the water and alcohol solution, which was used to determination of water-soluble and alcohol-soluble acidity. Probably, the length of hydrocarbon chain from free fatty acid affected the solubility in the water. The solubility of FFA in the water was affected by the number of carbon atoms building blocks of the fatty acids. The short chain fatty acids are more soluble than long chain fatty acids. Moreover, the short chain of free fatty acid and organic acids would be more soluble in the water. Freshly harvested rice bran could probably be has higher organic acids than the other sample. In addition, increase in water-soluble acidity probably due to formation of organic acids other than fatty acids. Furthermore, the decrease in water soluble acidity in the accelerated aged caused by high-temperature treatment, which was decarboxylated or volatilized of organic acid by high-temperature.

15

Free Fatty Acids Content

Free fatty acids (FFA) content of rice bran oil was determined according to Jaisut et al. (2009). These method to make sure the results of alcohol-soluble and water-soluble acidity methods and to determined rice bran oil quality. The rice bran oil was extracted with petroleum ether, which was all FFA on the rice bran oil could be analyzed. When bran layers are removed from the endosperm during the milling process, the lipids in rice bran come into contact with highly reactive lipases. The lipases, which are endogenously enzyme, cause hydrolysis of neutral bran oil to FFA and leading to development rancidity (Kim et al. 2014). In addition, FFA is highly susceptible to oxidation which usually occurs by the action by the action of lipoxygenase. Furthermore, the FFA undergoes further oxidation decomposition with the generation rancid off-flavors of rice bran (Kim et al. 2014). The bran oil with an excess 10% FFA is unsuitable for human consumption or the economical extraction of edible oil especially high refining loss (Ramezanzadeh et al. 1999). Inactivation of lipases activity could be prevent hydrolytic rancidity in the rice bran

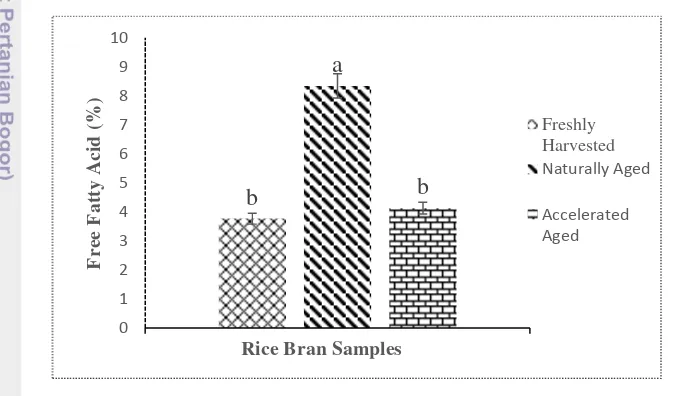

a-b Mean within the same letter are not significantly different (p>0.05)

Figure 3 Free fatty acid content of rice bran sample

Free fatty acids content of accelerated aged rice bran was not significantly different compared with freshly harvested rice bran (Figure 3). These result was similar with alcohol-soluble acidity result on the acidity determination. The acidity value (alcohol-soluble and water soluble acidity) of rice bran oil was correlated with FFA content, which was high acidity value described high FFA content. The FFA levels of naturally aged rice bran presented highly significantly than those other samples. Figure 3 shows the levels FFA of freshly harvested, naturally aged, and accelerated aged rice bran were 3.77%, 8.34%, and 4.12% respectively. The accelerated aged rice bran was presented low of FFA level. The high-temperature treatment affected inactivation of lipases activity and removing water required for

16

lipase activity (hydrolysis lipid). Heat treatment can cause protein denaturation. Protein denaturation would cause change of physicochemical properties of protein (irreversible) and loss of the biological activity as enzyme due to the modification of secondary, tertiary, and quaternary protein structure. However, Tao et al. (1993) was reported that the heating process on the rice bran above 100 oC needed to inactivate of lipase activity (denaturation of lipase enzyme), so that rice bran more resistant to hydrolytic rancidity. The treatment during accelerated aging process was enough to denatured and inactivate lipase activity because the heating process using high temperature (150 oC) for 2 min. Furthermore, high-temperature treatment affected the removing water required for lipase activity (hydrolysis of lipid) and this can slow down the rate of lipase activity to produce FFA through lipid hydrolysis of lipid. Jaisut et al. (2009) reported that FFA level of jasmine brown rice was lower than those untreated sample after drying process with high-temperature. The similar result reported by Shaker et al. (2013) that the heating of rice grains at 100 oC could decreased FFA content compared with untreated rice grains during storage for four weeks. The content of FFA was positively related to the activity of lipases. On the other hand, naturally aged rice bran presented higher levels FFA than those of the other samples. This fact could probably be the activity of endogenous and microbial lipase during aging process (Zhou et al. 2002b). The accelerated aged rice bran was better to utilize than those of naturally aged rice bran. Therefore, the accelerated aged rice bran oil was still suitable for human consumption, but the bran oil with over 5% FFA is considered unsuitable for human consumption (Shaker et al. 2013). The accelerated aging process using high-temperature fluidized bed drying could probably be used to stabilization process for rice bran before further utilization. These process could be produce low acidity (low FFA content) of rice bran oil production. The heating of rice bran during accelerated aging process were to retard the increase of FFA content, lipase activity, and oil oxidation.

Total Phenolic Content

17 Table 3 Total phenolic content of rice bran sample

Rice bran Freshly

a-b Mean value in the same row with the same letter are not significantly

different (p>0.05)

Table 3 shows the result of total phenolic content of rice bran extracted using 80% methanol. Among all rice bran extracts, the highest phenolic content was found in freshly harvested rice bran extract significantly. The total phenolic content of naturally and accelerated aged rice bran extracts were not significantly different. In grains, phenolic compounds exist both free and covalent bound forms. The bound phenolic compounds, representing 80-95% of the total amount, are ester linked to cell wall polymer (Serpen et al. 2008). The free form of phenolic compounds was easier extractable than those bound form phenolic compounds. The freshly harvested rice bran extract might be contained a large amount of free form phenolic compounds. Moreover, extraction phenolic compounds of rice bran was used methanol 80% (v/v). Serpen et al. (2008) was reported that the use of water and ethanol produced markedly higher total antioxidant capacity values with respect to those obtained using only ethanol. This fact due to the high content of water soluble antioxidant. Furthermore, the total phenolic compounds of naturally aged rice bran extract was lower than those freshly harvested rice bran extract. The naturally aged paddy had to be stored for one years. Storage of rice grain results a decrease of phenolic content (Shen et al. 2009).

18

Reducing Power

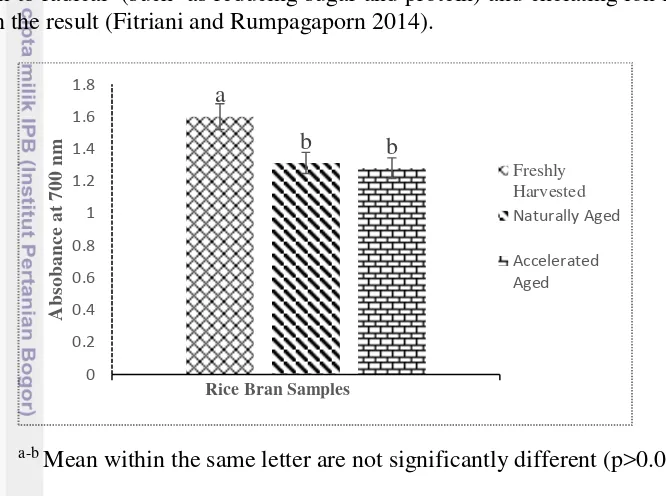

The reducing power of rice bran extracts was determined according to Arab

et al. (2011). Literature reports (Arab et al. 2011; Iqbal et al. 2005) are evident that reducing power of bioactive compounds is associated with antioxidant activity. Thus, a relation should be located between reducing power and antioxidant effect. Reducing power has also been used to evaluate the ability of natural antioxidant to donate electrons. The power of certain antioxidants is associated with their reducing power (Kim et al. 2006). Since this method measured the ability of substrate to reduce Fe3+ to Fe2+, the presence of any molecules that rapidly donate a hydrogen atom to radical (such as reducing sugar and protein) and chelating ion interfered with the result (Fitriani and Rumpagaporn 2014).

a-b Mean within the same letter are not significantly different (p>0.05)

Figure 4 Antioxidant activity of rice bran by reducing power method

Figure 4 shows the reducing power activity of all methanol extract rice bran samples with higher absorbance values depicting higher reducing activity. Under the same concentration, the highest absorbance value (at 700 nm) was found in the freshly harvested rice bran extract. The absorbance values of naturally aged and accelerated aged rice bran extract were not significantly different. However, the absorbance values of freshly harvested, naturally aged, and accelerated aged rice bran extract were 1.600, 1.313, and 1.280, respectively. The reducing power activities of rice bran extracts were associated with the total phenolic compounds. These similar result with other studies conducted by Iqbal et al. (2005) and Arab et al. (2011). The results demonstrate that some compounds of rice bran extracts such as tocopherol were electron donor to free radicals to terminate or stabilize radical chain reaction. The high-temperature fluidized bed drying was affected the reducing power of accelerated aged rice bran extract. This fact could probably be due to the high-temperature drying process destroy the antioxidant compounds. Iqbal et al.

19

CONCLUSION AND RECOMMENDATION

Conclusion

According to the results of this study, it could be conclude that the accelerated aging was affected characteristic properties of rice bran. The total, soluble, and insoluble dietary fibre of all rice bran samples had no significant different. The accelerated aging treatment with high-temperature drying process could not change and affect the dietary fibre content. The high-temperature treatment of accelerated aging process could decrease acidity and free fatty acids content of rice bran oil. Heat treatment of high-temperature drying process could be inactivate endogenous lipases activity. Moreover, the accelerated aging could decrease of total phenolic content and reducing power rice bran extracts. The reducing power of rice bran extracts was assosciated with the total phenolic compounds. The accelerated aging process using high-temperature fluidized bed drying could be used to stabilization process for rice bran before further utilization. These process could be produce low acidity and free fatty acid content of rice bran oil production.

Recommendation

Further research was needed to investigate the effect accelerated aging on the various paddy variety (waxy and non-waxy rice) and effect of accelerated aging using other method such as wet heat. There was needed to know the effect of accelerated aging on the stabilization of rice bran during storage.

REFERENCES

Amissah JGN, Ellis WO, Oduro I, Manful JT. 2003. Nutrient composition of bran from new rice varieties under study in Ghana. Food Control. 14: 21–24. [AOAC] Association of Offical Analytical Chemists. 2000. Official Method of

Analysis of AOAC International. Washington DC (US): AOAC.

Arab F, Alemzadeh I, Maghsoudi V. 2011. Determination of antioxidant component and activity of rice bran extract. Chemistry and Chemical Engineering. 18(6): 1402-1406.

Benitez V, Molla E, Martin-Cabrejas MA, Aguilera Y, Lopez-Andreu FJ, Esteban RM. 2011. Effect of sterilisation on dietary fibre and physicochemical properties of onion by-products. Food Chemistry. 127: 501-507. doi:10.1016/j.foodchem.2011.01.031.

20

Charstil J. 1994. Effect of storage on the physicochemical properties and quality factors of rice. In E. W. Marshall & I. W James (Eds), Rice Science and Technology (1st ed., pp. 49-75(. Louisiana, USA: Marcel Dekker Inc.

Dar BN, Sharma S. 2011. Total phenolic content of cereal brans using conventional and microwave assisted extraction. American Journal of Food Technology.

6(12): 1045-1053.doi:10.3923/ajft.2011.1045/1053.

Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H. 2011. Dietary fibre and fibre-rich by-product of food processing: Characterisation, technological functionality and commercial applications: A review. Journal of Food Chemistry. 124: 411-421.

Esposito F, Arlotti G, Bonifati AM, Napolitano A, Vitale D, Fogliano V. 2005. Antioxidant activity and dietary fibre in durum wheat bran by-products.

Journal of Food Research International.

Fabian C, Ju YH. 2011. A review on rice bran protein: its properties and extraction methods. Critical reviews in food science and nutrition. 51(9): 816-827. Fitriani D, Rumpagaporn P. 2014. Antioxidant activity of enzymatically treated

extract from commercially defatted rice bran. In: Kasetsart University, editor.

52 Kasetsart University Annual Conference. 2014 Feb 4-7; Bangkok, Thailand. Bangkok (TH): Kasetsart University. p 435-442.

Garau MC, Simal S, Rossello C, Femenia A. 2007. Effect of air-drying temperature on physico-chemical properties of dietary fibre and antioxidant capacity of orange (Citrus aurantium v. Canoneta) by-products. Food Chemistry. 104: 1014-1024.doi:10.1016/j.foodchem.2007.01.009.

Gujral HS, Kumar V. 2003. Effect of accelerated aging on the physicochemoical and textural properties of brown and milled rice. Journal of Food Engineering. 59: 117-121. doi:10.1016/S0260-8774(02)00438-7.

Irakli MN, Samanidou VF, Biliaderis CG, Papadoyannis IN. 2012. Development and validation of an HPLC-method for determination of free and bound phenolic acids in cereals after solid-phase extraction. Food Chem. 134: 1624-1632.

Iqbal S, Bhanger MI, Anwar F. 2005. Antioxidant properties and components of some commercially available varieties of rice bran in Pakistan. Food Chemistry.

93: 265-272. doi:10.1016/j.foodchem.2004.09.024.

Jaisut D, Prachayawarakorn S, Varanyanond W, Tungtrakul P, Soponronnarit S. 2009. Accelerated aging of jasmine brown rice by high-temperature fluidization technique. Food Research International. 42: 674-681. doi:10.1016/j.foodres.2009.02.011.

Jeong SM, Kim SY, Kim DR, Jo SC, Nam KC, Ahn DU, Lee SC. 2004. Effect of heat treatment on the antioxidant activity of extracts from citrus peels. J. Agric. Food Chem. 52: 3389-3393. doi:10.1021/jf049899k.

Johansson M. 2012. Dietary fibre composition and sensory analysis of heat treated wheat and rye bran [thesis]. Sweden (SE): Swedish University of Agricultural Science.

21 Kim SM, Chung HJ, Lim ST. 2014. Effect of various heat treatment on rancidity and some bioactive compounds of rice bran. Journal of Cereal Science. 60: 243-248. doi:10.1016/j.jcs.2014.04.001.

Kim SY, Jeong SM, Park WP, Nam KC, Ahn DU, Lee SC. 2006. Effect of heating conditions of grape seeds on the antioxidant activity of grape seed extracts.

Food Chemistry. 97: 472-479. doi:10.1016/j.foodchem.2005.05.027.

Likitwattanasade T. 2009. Effect of accelerated aging on functional properties of rice grain and flour [thesis]. Thailand (TH): Kasetsart University.

Nantiyakul N. 2012. Processing rice bran to yield added –value oil based extrats [disertation]. England (GB): University of Nottingham.

Ohno T, Ohisa N. 2005. Studies on textural and chemical changes in aged rice grains. Food Sci. Technol. Res. 11:385-389.

Philips GO, Cui SW. 2011. An introduction: Evolution and finalization of the regulatory definition of dietary fibre. Journal of Food Hydrocolloids. 25: 139:143.

Pisithkul K, Jongkaewwattana S, Wongpornchai S, Tulyathan V, Meechoui S. 2010. Partial characterization of rice (Oryza sativa L.) cv. khao dawk mali 105 as affected by accelerated-aging factors. J. Nat. Sci. 9(2): 305-317.

Poomsa-ad N, Soponronnarit S, Prachayawarakorn S, Terdyothin A. 2002. Effect of tempering on subsequent drying of paddy using fluidisation technique.

Journal of Drying Technology. 20: 195-210.

Ramezanzadeh FM, Rao RM, Windhauser M, Prinyawiwatkul W, Tullry R, Marshall WE. 1999. Prevention of hydrolytic rancidity in rice bran during storage. J. Agric. Food Chem. 47: 3050-3052. doi:10.1021/jf981335r.

Rayaguru K, Pandey JP, Routray W. 2011. Optimization of process variables for accelerated aging of basmati rice. Journal of Food Quality. 34: 56-63. doi:10.1111/j.1745-4557.2010.00366.x.

Rosniyana A, Hashifah MA, Shariffah NSA. 2004. Effect of heat treatment (accelerated ageing) on the physicochemical and cooking properties of rice at different moisture contents. J. Trop. Agric. and Fd. Sc. 32(2): 155-162. Saad N, Esa NM, Ithnin H, Shafie NH. 2011. Optimization of optimum condition

for phytic acid extraction from rice bran. Afr. J. Plant Sci. 5: 168-176.

Serpen A, Gokmen V, Pellegrini N, Fogliano V. 2008. Direct measurement of the total antioxidant capacity of cereal products. Journal of Cereal Science. 43: 816-820. doi:10.1016/j.jcs.2008.06.002.

Shaker MA, Amany MB, Mahmoud AMA. 2013. Production of low acidity rice bran oil by heating process. Journal of Food Science and Technology. 1(2): 13-18.

Shen Y, Jin L, Xiao P, Lu Y, Bao J. 2009. Total phenolics, flavonoids, antioxidant capacity in rice grain and their relations to grain color, size and weight. Journal of Cereal Science. 49: 106-111. doi:10.1016/j.jcs.2008.07.010.

Silva MA, Sanches C, Amante ER. 2006. Prevention of hydrolytic rancidity in rice bran. Journal of Food Engineering. 75: 487-491. doi:10.1016/j.jfoodeng.2005.03.066.

22

Stratil P, Klejdus B, Kuban V. 2007. Determination of phenolic compounds and their antioxidant activity in fruits and cereals. Talanta. 71: 1741-1751. doi:10.1016/j.talanta.2006.08.012.

Tao J, Rao R, Liuzzo J. 1993. Microwave heating for rice bran stabilization. J Microw Power Electromag Energy. 28(3): 156-164.

Zhou Z, Robards K, Helliwell S, Blachard C. 2002a. Ageing of stored rice: changes in chemical and physical attributes. Journal of Cereal Science. 35: 65-78. doi:10.1006/jcrs.2001.0418.

23

APPENDICES

24

25

Appendix 3 Analytical scheme for soluble and insoluble dietary fibre determination procedure

26

Appendix 4 Freshly harvested, naturally aged, and accelerated aged rice bran sample

Note:

1 Freshly harvested rice bran 2 Naturally aged Rice bran 3 Accelerated aged rice bran

Appendix 5 The result of iodine test rice bran samples

Before Iodine Test After Iodine Test

Note:

1 Naturally aged rice bran 2 Freshly harvested rice bran 3 Accelerated aged rice bran 1 4 Accelerated aged rice bran 2

1 2 3

3

1 2 3 4

2 3 4

27 Appendix 6 The fluidized bed dryer machine and specification

Specification of Fluidized Bed Dryer Machine: Fluid Bed Dyer (Vertical Hot Air Flow)

Serial No. 07952 Date 9643 Voltage 230 Volt/AC 50 Hz 3 kW Weight 18.5 kg Tube capacity: 5 liters

Sherwood Scientific, Cambridge Science Park, Cambridge, English Appendix 7 The rice mill machine

Model: NB 1000 TURBO (www.natrawee.co.th) Mill both white and brown rice effectively High milling capacity with 50 - 70 kg/hour

Separate rice bran, chaff, and broken-milled rice automatically Adjust the whitening level easily

Made from high quality material Installed strong wheels for relocating Motor 1 HP 220 V

Weight: 96 kg

28

Appendix 8 Data of corrected protein using kjeldahl method for dietary fibre analysis

Rice Bran Sample Dietary Fibre Replication Protein Weight (g)

Freshly Harvested

Appendix 9 Standard curve of BHT by total phenolic content assay.

29 Appendix 10 Statistical analysis of total, soluble, and insoluble dietary fibre rice

bran

Tests of Between-Subjects Effects

Dependent Variable: Total Dietary Fiber

Source

Type III Sum

of Squares df Mean Square F Sig.

Corrected Model 3.670a 2 1.835 2.758 .141

Intercept 7413.240 1 7413.240 11141.471 .000

Sample 3.670 2 1.835 2.758 .141

Error 3.992 6 .665

Total 7420.902 9

Corrected Total 7.662 8

a. R Squared = .479 (Adjusted R Squared = .305)

Total Dietary Fiber

Duncana,b

Rice Bran N

Subset

1

Accelerated

Aged 3 27.8738

Naturally Aged 3 28.7975

New Harvest 3 29.4288

Sig. .065

a. Uses Harmonic Mean Sample Size = 3.000.

b. Alpha = .05.

Tests of Between-Subjects Effects

Dependent Variable: Insoluble Dietary Fiber

Source

Type III Sum

of Squares df Mean Square F Sig.

Corrected Model 2.884a 2 1.442 2.775 .140

Intercept 5966.012 1 5966.012 11483.073 .000

Sample 2.884 2 1.442 2.775 .140

Error 3.117 6 .520

Total 5972.013 9

Corrected Total 6.001 8

30

Insoluble Dietary Fiber

Duncana,b

Rice Bran N

Subset

1

Accelerated Aged 3 25.3009

Naturally Aged 3 25.3937

New Harvest 3 26.5454

Sig. .087

a. Uses Harmonic Mean Sample Size = 3.000.

b. Alpha = .05.

Tests of Between-Subjects Effects

Dependent Variable: Soluble Dietary Fiber

Source

Type III Sum

of Squares df Mean Square F Sig.

Corrected Model 1.058a 2 .529 1.976 .219

Intercept 78.503 1 78.503 293.352 .000

Sample 1.058 2 .529 1.976 .219

Error 1.606 6 .268

Total 81.166 9

Corrected Total 2.663 8

a. R Squared = .397 (Adjusted R Squared = .196)

Soluble Dietary Fiber

Duncana,b

Rice Bran N

Subset

1

Accelerated Aged 3 2.5730

New Harvest 3 2.8834

Naturally Aged 3 3.4038

Sig. .106

a. Uses Harmonic Mean Sample Size = 3.000.

31 Appendix 11 Statistical analysis of acidity rice bran oil.

Tests of Between-Subjects Effects

Dependent Variable: Alcohol Soluble Acidity (mg KOH/g bran)

Source

Type III Sum

of Squares df Mean Square F Sig.

Corrected Model .097a 2 .049 46.385 .000

Intercept 5.641 1 5.641 5385.417 .000

Sample .097 2 .049 46.385 .000

Error .006 6 .001

Total 5.744 9

Corrected Total .103 8

a. R Squared = .939 (Adjusted R Squared = .919)

Alcohol Soluble Acidity (mg KOH/g bran)

Duncana,b

Rice Bran N

Subset

1 2

New Harvest 3 .691949

Accelerated Aged 3 .748111

Naturally Aged 3 .935021

Sig. .078 1.000

a. Uses Harmonic Mean Sample Size = 3.000.

b. Alpha = .05.

Tests of Between-Subjects Effects

Dependent Variable: Water Soluble Acidity (%)

Source

Type III Sum

of Squares df Mean Square F Sig.

Corrected Model 12.563a 2 6.281 16.559 .000

Intercept 1264.086 1 1264.086 3332.506 .000

Smple 12.563 2 6.281 16.559 .000

Error 4.552 12 .379

Total 1281.200 15

Corrected Total 17.114 14

32

Water Soluble Acidity (%)

Duncana,b

Rice Bran Sample N

Subset

1 2 3

Accelerated Aged 5 8.1240

Naturally Aged 5 9.0600

Freshly Harvested 5 10.3560

Sig. 1.000 1.000 1.000

a. Uses Harmonic Mean Sample Size = 5.000. b. Alpha = .05.

Appendix 12 Statistical analysis of free fatty acid content

Tests of Between-Subjects Effects

Dependent Variable: Free Fatty Acid (%)

Source

Type III Sum

of Squares df Mean Square F Sig.

Corrected Model 25.882a 2 12.941 77.484 .003

Intercept 175.790 1 175.790 1052.553 .000

Sample 25.882 2 12.941 77.484 .003

Error .501 3 .167

Total 202.173 6

Corrected Total 26.383 5

a. R Squared = .981 (Adjusted R Squared = .968)

Free Fatty Acid (%)

Duncana,b

Rice Bran N

Subset

1 2

Freshly Harvested 2 3.7660

Accelerated Aged 2 4.1299

Naturally Aged 2 8.3425

Sig. .439 1.000

33 Appendix 13 Statistical analysis of total phenolic content rice bran extract

Tests of Between-Subjects Effects

Dependent Variable: Total Phenolic Content (mg BHT equivalent/100 g)

Source

Type III Sum

of Squares df Mean Square F Sig.

Corrected Model 201.058a 2 100.529 9.075 .015

Intercept 47238.832 1 47238.832 4264.179 .000

Sample 201.058 2 100.529 9.075 .015

Error 66.468 6 11.078

Total 47506.358 9

Corrected Total 267.526 8

a. R Squared = .752 (Adjusted R Squared = .669)

Total Phenolic Content (mg BHT equivalent/100 g)

Duncana,b

Rice Bran N

Subset

1 2

Accelerated

Aging 3 68.4690

Naturally Aged 3 69.7868

New Harvest 3 79.0891

Sig. .645 1.000

34

Appendix 14 Statistical analysis of antioxidant activity by reducing power method

Tests of Between-Subjects Effects

Dependent Variable: Reducing Power (Absorbance at 700 nm)

Source

Type III Sum

of Squares df Mean Square F Sig.

Corrected Model .186a 2 .093 31.654 .001

Intercept 17.589 1 17.589 5995.618 .000

Sample .186 2 .093 31.654 .001

Error .018 6 .003

Total 17.792 9

Corrected Total .203 8

a. R Squared = .913 (Adjusted R Squared = .885)

Reducing Power (Absorbance at 700 nm)

Duncana,b

Rice Bran N

Subset

1 2

Accelerated

Aging 3 1.28050

Naturally Aged 3 1.31317

New Harvest 3 1.60025

Sig. .488 1.000

35

AUTHOR BIOGRAPHY

Lingga Herlambang Febrianto was born on 2nd February in Ponorogo, East Java, Indonesia. He is eldest child of Mr. Bambang Setyadi and Mrs. Hermin Purwaningsih. He finished his elementary school, junior high school, and senior high school in SDN 1 Kesugihan (1999-2004), SMPN 6 Ponorogo (2004-2007), and SMAN 1 Ponorogo (2007-2010). In 2010, the author continued his study in Bogor Agricultural University. He was accepted as a Food Science and Technology in the Faculty of Agricultural Engineering and Technology.

During his study, the author granted the scholarship from BIDIK MISI DIKTI (2010-2014). Besides, he joined some organizations, such as OMDA Ponorogo and Telisik Pangan. The author joined some committee actively, such as SUKSESI HIMITEPA, HACCP-PLASMA 2012, BAUR 2012, I-FOODAY, LCTIP XX, and ORDE KRAMAT 2014. Gratefully, he was granted a partial scholarship in AIMS (ASEAN International Mobility for Student) program to do research on Department of Food Science and Technology, Faculty of Agro-Industry, Kasetsart University, Thailand, for 4 months. In May 2014, he started his research entitled “The Effect of Accelerated Aging on the Characteristic Properties of Rice

Bran” with Pinthip Rumpagaporn, Ph.D as advisor in Kasetsart University and Dr.