DESIGNING AN IMPLEMENTATION OF

ENVIRONMENTAL INNOVATION STRATEGY TOWARDS

PROACTIVE ENVIRONMENTAL MANAGEMENT: A CASE

STUDY IN A RIBBED SMOKED SHEET RUBBER FACTORY

IN CENTRAL JAVA PROVINCE, INDONESIA

SYARIFA ARUM KUSUMASTUTI

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY BOGOR

DECLARATION

I hereby declare that the thesis entitled ―Designing an Implementation of Environmental Innovation Strategy towards Proactive Environmental Management: A Case Study in a Ribbed Smoked Sheet Factory in Central Java Province, Indonesia‖ is my original work produced through guidance of my academic advisors and that to the best of my knowledge. This thesis also presented for the award of a degree in The University of Adelaide as a double degree program between Bogor Agricultural University and The University of Adelaide. All of the incorporated materials originated from other published or unpublished papers are stated clearly in the text as well as in the bibliography.

I hereby delegate the copyright of my paper to the Bogor Agricultural University.

Bogor, August 2015

SUMMARY

Syarifa Arum Kusumastuti, 2015. Designing an Implementation of Environmental Innovation Strategy towards Proactive Environmental Management: A Case Study in a Ribbed Smoked Sheet Rubber Factory in Central Java Province, Indonesia. (Suprihatin, Chairman and Nastiti Siswi Indrasti, Member of Advisory Committee).

Ribbed smoked sheet (RSS) is the second largest natural rubber product in Indonesia after crumb rubber. One of the problems associated with natural rubber processing is the environmental problems created by the use of large amounts of water, together with energy and chemicals that pollute the environment. An environmental innovation is considered as a strategy to address the environmental impacts better than the current end-of-pipe treatment by shifting it into more proactive environmental management. This research aims to explore solutions that are more environmentally friendly for the rubber industry. This study uses a qualitative Case Study approach on a small and exploratory scale, with data collected from interviews and observations.

The results show that the environmental issues that are related to the factory’s daily operation are: water usage, accumulation of unprocessed material, the use of ammonia and the use of inorganic fertilizers. The obstacles in the way of environmental management are: financial issue, human resources, communities’ pressure, technological change and communication with environmental experts. Some proactive strategies to overcome these environmental issues are suggested namely: reuse of the wastewater and pollution prevention at sources. The results of this study also suggest conducting cooperation with research institutions or environmental experts especially for skills that cannot be controlled by the manager or employees in the company.

RINGKASAN

Syarifa Arum Kusumastuti, 2015. Perancangan Pelaksanaan Strategi Inovasi Lingkungan menuju Pengelolaan Lingkungan yang Proaktif : Studi Kasus di Industri Karet Ribbed Smoked Sheet di Provinsi Jawa Tengah, Indonesia.

(Suprihatin, Ketua dan Nastiti Siswi Indrasti, Anggota dari Komisi Pembimbing).

Karet asap lembaran atau ribbed smoked sheet (RSS) merupakan produk karet alam terbesar kedua setelah jenis karet remah. Salah satu permasalahan terkait dengan proses pengolahan karet alam adalah masalah lingkungan yang disebabkan penggunaan sejumlah besar air dan bahan kimia yang mencemari lingkungan. Inovasi lingkungan merupakan salah satu strategi untuk mengatasi masalah lingkungan dengan cara mengganti pengolahan limbah di akhir pipa dengan pengelolaan lingkungan yang bersifat lebih proaktif. Penelitian ini bertujuan untuk menggali solusi yang lebih ramah lingkungan untuk industri karet. Penelitian ini menggunakan pendekatan studi kasus kualitatif pada skala kecil dan eksploratif, dengan data yang dikumpulkan melalui wawancara dan pengamatan.

Hasil penelitian ini menunjukkan bahwa masalah lingkungan yang terkait dengan operasional harian di perusahaan meliputi : penggunaan air, penumpukan bahan baku yang belum diproses, penggunaan amoniak, dan penggunaan pupuk buatan. Adapun hambatan yang dialami dalam praktik pengelolaan lingkungan di perusahaan tersebut antara lain: masalah keuangan, sumber daya manusia, tekanan komunitas di sekitar pabrik, perubahan teknologi dan masalah komunikasi dengan pakar lingkungan. Dengan demikian, beberapa strategi proaktif yang dapat disarankan untuk mengatasi permasalahan tersebut yaitu penggunaan kembali air limbah dan pencegahan pencemaran dari sumbernya. Hasil penelitian ini juga memiliki implikasi tentang pentingnya kerjasama dengan lembaga penelitian lingkungan, terutama untuk keahlian yang tidak dapat ditangani baik oleh manajer maupun karyawan di dalam industri.

Kata kunci : karet RSS, strategi pengelolaan lingkungan proaktif, inovasi lingkungan.

Copyright ©2015, by Bogor Agricultural University

All Right Reserved

1. No part or all of this thesis excerpted without inclusion or mentioning the sources

a. Excerption only for research and education use, writing for scientific papers, reporting, critical writing or reviewing of a problem

b. Excerption does not inflict a financial loss in the proper interest of Bogor Agricultural University

Thesis

Submitted to the Graduate School in Partial Fulfillment of Master Of Science

Degree In

Agroindustrial Technology

DESIGNING AN IMPLEMENTATION OF

ENVIRONMENTAL INNOVATION STRATEGY TOWARDS

PROACTIVE ENVIRONMENTAL MANAGEMENT: A CASE

STUDY IN A RIBBED SMOKED SHEET RUBBER FACTORY

IN CENTRAL JAVA PROVINCE, INDONESIA

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY BOGOR

2015

Thesis Title : Designing an Implementation of Environmental Innovation Strategy towards Proactive Environmental Management: A Case Study in a Ribbed Smoked Sheet Rubber Factory in Central Java Province, Indonesia

Name : Syarifa Arum Kusumastuti

Registration Number : F351137201

Study Program : Agroindustrial Technology

Approved

Advisory Committee

Prof Dr-Ing Ir Suprihatin Chairman

Prof Dr Ir Nastiti Siswi Indrasti Member

Agreed

Coordinator of Program Agroindustrial Technology

Prof Dr Ir Machfud, MS

Dean of Graduate School

Dr Ir Dahrul Syah, MScAgr

Examination Date: 9 June 2015

ACKNOWLEDGEMENTS

Praise and gratitude to Allah Subhanahu wa Ta’ala, because of Him, the writer can complete this thesis as a requirement to get a Master Degree in Bogor Agricultural University (IPB). The title of the thesis is Designing an Implementation of Environmental Innovation Strategy towards Proactive Environmental Management: A Case Study in a Ribbed Smoked Sheet Factory in Central Java Province, Indonesia.

The writer want to say thank you, especially for Prof. Suprihatin as a chairman of the advisory committee, Prof. Nastiti S. Indrasti as an advisory committee member, and Dr Ronald Grill as an advisor from University of Adelaide whose gave constructive criticisms and guidance to shape the outlook of this thesis. Special thanks for Dr. Barry Elsey and Ms. Amina Omarova from The University of Adelaide for their guidance in writing this thesis. They teach me how to write the thesis with a good structure. And also I want thank to Charles Clennel who helped me improve the writing of this thesis.

I also would like to express gratitude to all the respondents who have taken their time to conduct an interview with the author. Special thanks to Mr. Kartono, Mr. Teguh Widodo and Mr. Sunaryo from PT. Perkebunan Nusantara IX, Mr. Arief Yusman and Mrs. Yulma Susanti from Ministry of Industry, Mr. Nasuka and Mr. Krus Haryanto from Center of Industrial Pollution Prevention Technology (CIPPT), and Mr. Dadang Suparto from Rubber Research Institute, Mr. Akhmad Rouf from Getas Rubber Research Center, and also Mr. Slamet Widodo and Mr. Aries Warsito from Central Java’s Environmental Agency who took time to meet me in the middle of his/her work. I also thank Prof Erliza Hambali for her suggestion to reshape my thesis.

In this acknowledgment, I want to thank to my father, mother, brother and sister who continuously to give their support, both in the difficult and good period. Last but not the least, I want to show my gratitude to my friends, namely Karim, Tri, Benny, Andar, Farda, Iwan, Nur Aini, Dwi, Danang, Aditya, Dickie, Ahmad Rudh, Koko, Nuni, Anin, and Yani for their moral support especially when we all lived in Adelaide.

Bogor, August 2015

TABLE OF CONTENT

LIST OF TABLE ... i

LIST OF FIGURE ... i

LIST OF APPENDIX ... i

CHAPTER 1. INTRODUCTION ... 1

1.1. Introduction ... 1

1.2. Statement of Research Problem ... 1

1.3. Purpose of the Study ... 1

1.4. Research Questions ... 2

1.5. Significance of Research ... 2

1.6. Limitations ... 2

1.7. Outline of Research ... 2

CHAPTER 2. LITERATURE REVIEW ... 4

2.1. Overview of the natural rubber industry in Indonesia ... 4

2.2. Environmental Issues of Natural Rubber Processing Sector ... 5

2.3. Rubber industry’s waste management in Indonesia ... 5

2.4. Environmental strategies ... 6

2.5. Environmental Innovation and the Adoption Process ... 7

2.6. Summary ... 9

CHAPTER 3 – RESEARCH METHODOLOGY ... 11

3.1. Conceptual Framework ... 11

3.2. Setting ... 11

3.3. Data Collection ... 12

3.4. Data Analysis ... 12

CHAPTER 4 RESULTS AND DISCUSSION ... 13

4.1. Review on the Environmental management practices in the company . 13 4.2. Obstacles in Environmental Management and Practices ... 16

4.3. Proposed strategies to improve the existing environmental practices ... 18

CHAPTER 5 CONCLUSION AND RECOMMENDATION ... 22

5.1. Conclusion ... 22

5.2. Limitations and Recommendations ... 22

REFERENCES ... 23

LIST OF TABLE

Table 1. Environmental strategies ... 7 Table 2. List of material usage per 31 June 2014 in company X 15 Table 3. Pollution prevention opportunities for Company X ... 20

LIST OF FIGURE

Figure1. The relationship between employees’ involvement on the environmental, operational, as well as overall business performance ... 9 Figure2. Scheme of ribbed smoked sheet production in the Company X ... 14

LIST OF APPENDIX

Appendix 1. Results of observation in the company X 27

Appendix 2. List of Participants 30

Appendix 3. Transcript of interview results 30 Appendix 4. Regulations related to the natural rubber industry and its

environmental management 36

CHAPTER 1. INTRODUCTION

1.1 Introduction

Indonesia is the second largest natural rubber producer in the world after Thailand, approximately 25 % -27 % of the world's natural rubber needs is supplied by Indonesia (ANRPC, 2010). The main types of natural rubber products in Indonesia are: crumb rubber, rubber sheet (Ribbed Smoked Sheet or RSS), concentrated latex, and crepe (Darmawan, Putra & Wiguna 2014). The primary rubber products can also be referred to as intermediate products, because they still require further processing to become finished products such as tires, gloves, shoe soles, etc. (Utomo, Hasanudin & Suroso 2012).

Environmental problems associated with the production of natural rubber in Indonesia are driving the need for implementation of environmental management strategies that have been formulated by the company. One of the strategies is the treatment for waste that is formed at the end of the process. However, several factors such as : the evolvement of environmental issues over time, decreasing the environmental capability to receive the waste that is formed, an increase in consumer awareness of environmentally friendly products and processes, as well as stringent environmental regulations, are pushing the company to review their environmental management performance. Therefore, the existing environmental management such as a wastewater treatment plant is seen as an „end-of-pipe‟ treatment that is uneconomic and cannot anticipate changes in environmental issues in the future (Welford & Gouldson 2002). Moreover, the company as an entrepreneur will need to use innovation as a tool to sustain their business (Drucker 1999). One of those is innovation aiming at environmental impact reduction, or also called environmental innovation (Horbach, Rammer & Rennings 2012). Hence, this research aims to seek innovative strategies for environmental improvement to enhance existing environmental practices in the company, and to encourage company to shift towards proactive environmental management rather than traditional waste management system.

1.2 Statement of Research Problem

Indonesia's natural rubber industries receive a lot of attention with respect to the volume of potential wastewater, solid waste, as well as odour emissions resulting from the production processes (Hasibuan 2012). Even though companies have implemented an end-of-pipe technologies to control the pollution, the type of the waste management is uneconomic and cannot anticipate changes in environmental issues in the future. On the other hand, environmental innovation to overcome the issues and stimulate company to be more environmentally proactive, are not successfully implemented due to the certain factors that include in the existing conditions and obstacles.

1.3 Purpose of the Study

Based on the research problem, the purposes of this study are:

2

2. To identify the obstacles in the way of achieving the implementation of environmental innovations.

3. To suggest improvements for the natural rubber industry through environmental innovations.

1.4 Research Questions

1. What is the current state of the existing environmental management system? 2. What factors hamper the of innovation process on the existing environmental

management?

3. What suitable innovative strategies are needed to improve environmental management performance?

1.5 Significance of Research

This study contributes to the problem-solving strategies based on environmental issues faced in the natural rubber processing industry using the concept of environmental innovation. This innovative strategy is built on the advice of environmental experts by using the approach of preventive environmental processing to replace the existing environmentally unfriendly practices.

1.6 Limitations

The research was conducted in a RSS processing factory in Central Java Province with the following considerations:

a. Identification of process, material and resource uses from the raw material transportation to factory, raw material preparation stage, and manufacturing process until the waste treatment stage in the firm as well as the environment impacts.

b. Overview of employees’ participation and managerial support in environmental activities.

c. Their relationship with local R&D institutions in terms of the innovative environmental aspect.

d. The case study in a single company selected because conditions and environmental management policy in each company are different from each other.

1.7 Outline of Research

This research is divided into five chapters, presented briefly as follows: 1. Introduction,

This chapter describes background and problem in the Ribbed Smoke Sheet (RSS) rubber industry. After the formulation of the problem it proceeds with the formulation of research questions and the expected results of this research. 2. Literature Review

3. Methodology

The research design used a qualitative Case Study approach, this chapter discusses the techniques starting from data collection, research setting, participant selection, and data analysis. The data collection used interviews, site observation, document reviews and literature study. While the for data analysis used explanatory approach that are also supported by a triangulation method to ensure the validity.

4. In chapter Findings and Discussion, the results of the data collection are presented in accordance with research questions, which consist of the overview of current environmental management and the barriers that are encountered by this industry. Afterwards formulate improvement solutions based on findings on the obstacles and the existing practices.

5. Conclusion

4

CHAPTER 2. LITERATURE REVIEW

The agricultural sector is one of the main contributors to the economic development in Indonesia and the natural rubber industry plays a crucial role in meeting the country’s industrial and export demands. Rubber production and demand increases from year to year (Damanik 2012), that spur competitiveness both in terms of quantity and quality. One thing that has emerged in the production process is the environmental issue. Industrial activity leads to the use of natural resources as raw materials. By-product outputs that are generated from this activity are called waste, and usually discharged into the environment.

Environmental management approaches that are end-of-pipe treatment aimed at the fulfilment of the rules or standards of effluent alone are considered not to be sufficient to anticipate environmental issues that evolve over time. The importance of the organization's response to environmental issues either from industrial activities undertaken, as well as pressure from outside the company should be able to drive continual improvement of the business' operations and management of the environment. One way to improve environmental management is find new ways to reduce the environmental impact. This change requires environmental innovation. As suggested by Warhurst and Bridge (1996), the environmental management performance can be improved through innovation.

Previous studies on environmental management improvement strategies were predominantly directed to crumb rubber industry rather than the ribbed smoke sheet (RSS) industry. While research in the context of the RSS rubber industry is about increasing productivity, product quality, as well as about the techniques in the plantation. On the other hand, the search for innovative environmental strategy within the scope of research cooperation between research centres and industry with environmental centres are still limited.

Therefore, this section will discuss an overview of natural rubber industry in Indonesia and the related environmental issues, environmental management strategies, environmental management innovation, process innovation adoption and implementation which are related to environmental management in the company's performance.

2.1 Overview of the natural rubber industry in Indonesia

Indonesia is the second largest natural rubber producer in the world after Thailand, and approximately 25 % -27 % of the world's natural rubber needs is supplied by Indonesia (ANRPC, 2010). The world rubber needs in 2009 amounted to 9,277 million tons, in 2010 rose to 10.664 million tons of crude rubber production but only 10.219 million tons could be met. Indonesian production of rubber has increased steadily, although in 2012 the production decreased slightly then rose again until 2013. There has been an upward trend on Indonesian rubber export, it is calculated that about 85% rubber produced is exported to many countries such as USA, China, Japan, Singapore and Brazil and about 15% fulfils domestic demands. There is also a domestic demand for some rubber goods factories such as tire production, automotive rubber goods production, glove industry etc. (―Rubber (Natural)‖, 2015, para7).

(Darmawan, Putra & Wiguna 2014). Classification of those types of rubber products based on some criteria include the form of raw materials, type of production processes, and the characteristics of the resulting products (Utomo, Hasanudin & Suroso 2012).

2.2 Environmental Issues of Natural Rubber Processing Sector

Environmental pollution problems in Indonesia are related to the existence of three things: 1. the future trends of industrialization, 2. the growth of the industry sector in urban areas and 3.The rapid growth of Indonesia’s economy. These will have a negative impact on the environment by combining industrial pollution with the pollution from human activities, the increasing utilization of natural resources, ecosystem degradation, and threats to human health (UNEP 2003).

As one of the main commodities of the agricultural sector, Indonesia's natural rubber industries receive attentions with respect to the magnitude of potential wastewater, solid waste, as well as odour emissions resulting from the production processes chain (Hasibuan 2012). That was because the processing of rubber which is converted from latex into rubber primary product such as crumb rubber or concentrated latex requires a large amount of water, chemicals and energy. The natural rubber processing sector consumes large volumes of water and energy and uses large amount of chemicals as well as other utilities. Consequently, those primary stages create large quantities of wastes discharged to environment (Nguyen & Luong 2012; Wouapi & Maimo 2007). The uses of auxiliary raw materials such as chemicals at this stage of raw material handling and coagulation, as well as a large amount of water at the dilution phase, have potential of wastewater generation. While the smoking process and by-products can cause air pollution and odour (Jawjit, Kroeze & Rattanapan 2010).

Some characteristics of the waste or pollution associated with the processing of the intermediate products of natural rubber, are: 1) high concentration of biochemical oxygen demand (BOD), chemical oxygen demand (COD) and suspended solids (SS) in the wastewater, 2) acidic effluent, 3) high concentration of ammonia and nitrogen compounds, 4) high level sulphate, and 5) high level of odour (Van et al. 2007). The untreated wastewater from natural rubber production can contaminates ground water and surface water (Girish 2014). In addition to water pollution, environmental impact is also caused by air pollution, for the example, odour and smoke particles from the production process of the RSS rubber (Tekasakul & Tekasakul 2006). In addition to air pollution from the production process, air pollution also comes from anaerobic wastewater treatment system due to the release of methane as a greenhouse gas (Jawjit, Kroeze & Rattanapan 2010).

2.3 Rubber industry’s waste management in Indonesia

6

processing performance will be monitored annually by the Environmental Agency at the provincial level. The result of this monitoring gives industry a color-coded score based on their pollution management. The ratings run from black for no pollution control to green for significant pollution prevention efforts to the top score of gold for facilities that keep emission levels near zero (Esty & Winston 2009). If the environmental management is not able to meet the compliance, it will impact not only on the environment, but also on the financial performance of the company in the form of amounts of money as liability settlement (Esty & Winston 2009). However, the implementation of Environmental Management System (EMS) in a company should not only to comply the regulations, but also able to facilitate the adoption and encourage innovation in the industry user (Carruthers & Vanclay 2012).

Most of the rubber industry in Central Java, using the approach of the end-of-pipe treatment which consists of aerobic or anaerobic treatment system for wastewater or wet scrubber which is installed in the chimney. For example, in conventional wastewater treatment, this requires a large area of land to provide the anaerobic ponds, because anaerobic reactions run for a very long time depending on the waste load (Spellman, 2003). The change of the external environment outside the organization such as rising market demand and consumer demand for products made with environmentally friendly processes will certainly make the company review the existing management as well as the operations. In other words, they also have to make innovations and improvements in response and in anticipation of risks that will occur in the future.

2.4 Environmental strategies

Many companies are implementing environmental management systems and aim to comply with standards applicable environmental regulations in their country (Theyel 2000). Because environmental issues are evolving over time (Esty & Winston 2009), it would not enough if the company is applying this system only with the aim to meet the standards set by the environmental agency only.

Since there are some differences in the condition and type of environmental impact in each company (Banerjee, S 2001), those factors lead to differences in approach to environmental management. Some environmental approaches include: (1) the end-of-pipe approach, (2) pollution prevention or total quality management (TQM), (3) product stewardship, and (4) sustainable development (Hart, 1995 in Buysse & Verbeke, 2003). Meanwhile, according to Lawrence, Andrews and France (1998), various environmental strategies include waste management, materials minimization, energy conservation, design for environment, product take-back, and communication. Based on Banerjee, SB, Iyer and Kashyap (2003) about corporate environmentalism, Čater, Prašnikar and Čater (2009) outlines environmental strategies into sections as shown in Table 1.

Table1. Environmental strategies

Corporate environmental strategy 1. Companies’ new business decision 2. Choice of technology

3. Selection of plant location 4. Investment on research and

development

Functional environmental strategy 1. Purchasing environmental strategy 2. Production environmental strategy 3. Marketing environmental strategy 4. Personnel environmental strategy

(Čater, Prašnikar & Čater 2009)

2.5 Environmental Innovation and the Adoption Process

Compliance with environmental laws in a country is one of the factors driving innovation opportunities within a company. It is intended to encourage the company and all its elements to use the technology, materials and processes that are more environmentally friendly (Nidumolu, Prahalad & Rangaswami 2009).

Horbach, Rammer and Rennings (2012), state that environmental innovation is the innovation of the product, process, marketing or organization that leads to reduced environmental impact. Based approaches are used; environmental innovations can be categorized into two types i.e. reactive and preventive strategies (Lam, Hills & Welford 2005). The reactive environmental innovation is used to address environmental problems that cannot be avoided when pollution has occurred. The reactive measures include: waste treatment technologies and disposal in an environmentally friendly manner.On the contrary, the preventive measures carried out by preventing pollution at the source. And for the effective and efficient implementation of both strategies, they also should be supported by environmental policies (Wouapi & Maimo 2007). Moreover, according to Hasibuan (2011), identification of the critical success factors of environmental management in the rubber company needs to be done because it determines the direction of the policy strategy for better environmental management. As suggested by Halila (2007), supporting the diffusion of eco-innovations has two benefits; from environmental point of view and economic point of view.

8

describes the relationship between eco-innovations, demand and cost or regulation. This model is used to analyse the conduciveness of environmental innovation adoption, as well as a test of the performance of the company's environmental innovation. However, the use of this model demonstrates that the determinant factors of eco-innovations differ depending on firms' strategic profiles. Moreover, according to (Damanpour & Gopalakrishnan 2001), the innovation adoption speed in an organization shows the duration of the organization to adopt and implement it since the first introduction. The speed of innovation adoption also implies the firm’s capability to innovate (Subramanian & Nilakanta 1996).

In addition, many research that determine the factors and barriers to the implementation of environmental management and innovation, indicate the importance of exploring these things in the formulation and successful implementation of environmental improvement strategies.

Determinant factors towards firms’ proactive environmental management

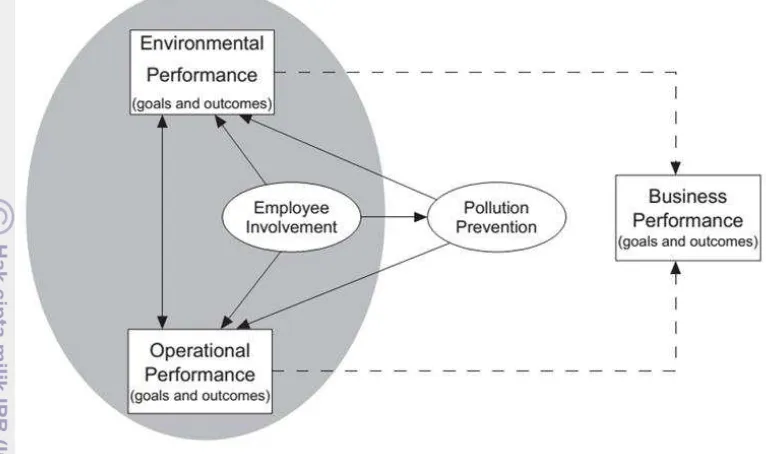

Figure1. The relationship between employees’ involvement on the environmental, operational, as well as overall business performance

(Hanna, Rocky Newman & Johnson 2000)

Besides determinant factors of implementation of proactive environmental management, there are also barriers that inhibit the rate of adoption and implementation. Post and Altman (1994) classified the barrier into two main categories namely industrial and organizational barriers. The industrial barriers consist of high investment cost, competitiveness, government regulations, technical information, and uncertainty of the results. While the organizational barriers, consist of employees, top management leadership, communications, and past experience.

2.6 Summary

10

study will explore the obstacles and significant source of pollutions to formulate environmental innovation opportunities towards proactive management.

CHAPTER 3

–

RESEARCH METHODOLOGY

3.1. Conceptual Framework

In seeking the innovative environmental strategies, according to (Rickmann 1992) it is necessary to conduct the identification and prioritization of key environmental issues for the determination of the resources and actions required. After that, a more detailed examination of the status and performance of environmental management are required. Thus, to determine the areas and corrective actions, it is necessary to review the existing environmental management system in the company. This review may consist of the amount of natural resources used during production processes, and the amount of waste that is formed along with the potential environmental impacts that may result.

Hence, research on innovative strategies and opportunities for environmental improvement will be done in a natural sheet rubber processing factory using the fumigation method. A case study research approach was used to understand the findings (Bossink 2007; Yin 1994). Therefore, this study consists of five phases namely:

a. Focussing on providing the justifications for the selection of the company where the case study will be conducted. Those reasons are based on: the identification of the innovative environmental strategies and the company’ relationship with research institute and local environmental agency.

b. Field observations at the selected company.

c. Interviews with the experts to identify any obstacles to the achievement of improvement experienced environmental management performance.

d. Analysis on the environmental impact and the possible innovative solutions from the interview and observations results.

e. Establish actions and strategies to accelerate the adoption process of environmental innovation and improvement based on the perception of practitioners. province. The company manufactures quality rubber products such as RSS (ribbed smoked sheet) and cutting (pieces of rubber from the sorting process). This company employs 1,447 employees. Ribbed smoked sheet (RSS) is one of the processed products made from rubber plantations in Indonesia. RSS occupies the second largest rubber products after crumb rubber or SIR (Standard Indonesian Rubber). The process of RSS rubber through smoking is more complicated than the manufacturing of crumb rubber that consist of nine stages (Utomo, Hasanudin & Suroso 2012). The stages in the RSS production from field latex are:

1) Raw material handling before arrive at factory 2) reception of latex in the factory

12

By studying data from books, journals, research report, publications and documents that are relevant for this study. The documents that were studied include environmental regulations, the company's monthly production reports, and job training reports.

b. Interview

The interview aims at generating primary data from source persons, who are selected through purposive method sampling (Palys 2008). The interview method is deployed to acquire the point of view of source persons in terms of environmental aspects in accordance with the context of this study. The total participants are 11 that consist of:

1) Two representatives from Ministry of Industry who handle agricultural industry and green industry policy.

2) Two representatives from environmental agency at the provincial level 3) Two representatives from R & D Agency pollution prevention

4) Two representatives from R & D Agency of natural rubber 5) Selected factory (director, technical manager, and employees)

The interview is a semi-structured interview, in which the main research questions were explored and combined with derivative questions from primary research questions, following the context of this study and the roles of the participants. The interviews with experts were held for thirty to sixty minutes which then recorded and transcribed.

c. Observation

This stage focused on the performance of existing environmental management, to identify sources of pollution and their causes. Direct observation was performed at every stage of the production process to identify the practices that are inefficient and potentially cause environmental impacts in the company. At this stage a checklist was used during the observation process, which consists of the data about raw material consumptions; production process, numbers of employees, waste management system; and additional qualitative information as needed.

3.4. Data Analysis

CHAPTER 4 RESULTS AND DISCUSSION

From the results of data collection, obtained a review of existing environmental management practices in company X, the obstacles encountered in the implementation of environmental practices and innovations, as well as strategies to overcome those problems.

4.1. Review on the Environmental management practices in the company

This section will explain about the condition of the company. Conditions related to environmental issues and its management is composed of picture production process which involves a series of process stages, the raw materials used, the types of waste treatment, as well as the environmental impacts that may arise from the operations of the company.

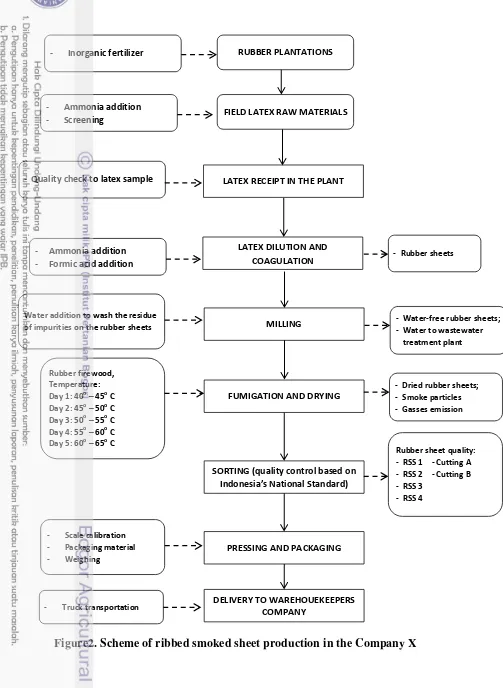

a. The process of making RSS rubber in company X

The fresh from plantation is delivered to factory using truck that is equipped by a colleting tank. Then the latex volume was measured to determine the ammonia volume that is needed. After that, the latex is filtered to flow into the bulking tank. Furthermore, an amount of sample was taken from latex to measure the dry rubber content. The measurement is aimed to determine the amount of water, formic acid, and the numbers of dilution tanks. During the dilution stage, the latex that has been mixed with water and formic acid, then stirred carefully to maintain the quality of the latex. Afterwards, the next process is the freezing of latex for about 2 hours. After latex was coagulated and becomes the form of sheets, then the sheets are washed to remove the remaining chemicals. Afterwards, latex are moved into a grinding machine using water flowed conveyor for easy transportation in addition to material, as well as washing latex of chemicals and other impurities. After that, the rubber sheet is transported to the curing chamber using the new monorail operated since 2013 to streamline the time and effort. In the smoking chamber, the rubber sheets are smoked with different levels of temperature for five days. Fumigation is completed by burning the rubber firewood with conditioning the temperature, ventilation and the amount of smoke for the optimum process. The purpose of smoking is to prevent the rubber sheets' spoilage due to the activity of microorganisms. From the smoke chamber, rubber sheets are then grouped by level of quality, namely, RSS-1, RSS-2, RSS-3, and cutting. After sortation, the product is then packaged and stored in a warehouse for shipment.

14

Figure2. Scheme of ribbed smoked sheet production in the Company X - Ammonia addition

- Screening

-Quality check to latex sample

- Ammonia addition - Formic acid addition

Water addition to wash the residue of impurities on the rubber sheets

Rubber firewood,

LATEX RECEIPT IN THE PLANT

SORTING (quality control based on

Indonesia’s National Standard) FUMIGATION AND DRYING

b. Identification of environmental pollution

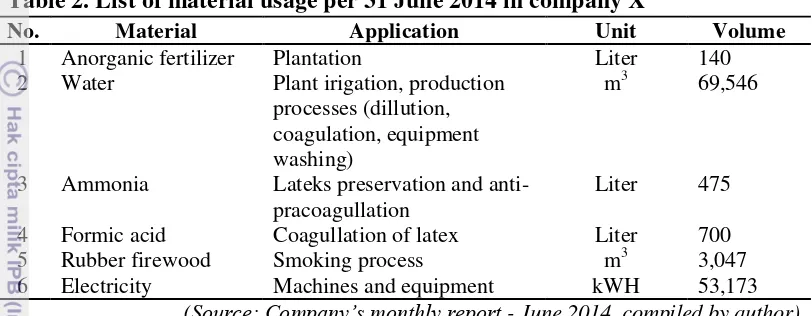

The environmental review aimed to take into the environmental effects associated with firm’s activities in order to identify the most significant ones (Hillary 1997). The following is the list of material used for production per 31 June 2014 in the company.

Table 2. List of material usage per 31 June 2014 in company X

No. Material Application Unit Volume

1 Anorganic fertilizer Plantation Liter 140 2 Water Plant irigation, production

processes (dillution, coagulation, equipment washing)

m3 69,546

3 Ammonia Lateks preservation and anti-pracoagullation

Liter 475

4 Formic acid Coagullation of latex Liter 700 5 Rubber firewood Smoking process m3 3,047 6 Electricity Machines and equipment kWH 53,173

(Source: Company‟s monthly report - June 2014, compiled by author)

From observations and interviews, the followings are the potential environmental effects that can be identified in this rubber company:

1) Pollution by wastewater resulting from the production process that uses large amounts of water.

2) Air pollution that comes from burning wood to the rubber latex curing process. According to Tekasakul and Tekasakul (2006), burning the rubber firewood can cause smoke particles pollution if there are no proper ventilation system. It also has effect to the local residents. However, this concern is not significant because from the air monitoring results, it shows that the air quality still meet the regulatory standards.

3) Bad smell due to the accumulation of raw material that has not been processed yet in the secondary product unit.

4) The use of ammonia. Ammonia is used to prevent coagulation latex at the time of collecting the latex, and prevent contamination of the latex. (Afreen, Haque & Huda 2013). Ammonia has a pungent odor, toxic, and corrosive to some materials (Pahlevi 2007). With these characteristics, ammonia will impact on the health of the respiratory system of workers (Tekasakul & Tekasakul 2006).

5) The use of inorganic fertilizers contributes to greenhouse gases. This is due to two reasons: 1). the process of making artificial fertilizers which is energy intensive, and 2) The application of fertilizer will release the gas N2O (Jawjit, Kroeze & Rattanapan 2010).

16

rubber products (RSS) and by-products (brown crepe rubber) in the company X, waste that were generated are wastewater and solid waste. The liquid wastes are generated from water residue and washing equipment. While the solid waste consist of solid rubber and wood chips. Rubber processing wastewater containing nitrogen and ammonia which when exceeded the quality standard, will pollute the river and the surrounding environment. The wastewater is flowed towards first waste reservoir that is called a rubber trap. The rubber trap functions to trap solid particles that do not flow towards the end of the waste tank. Meanwhile, the collected solid wastes will be sold to the third party for further processing.

In addition to solid waste originating from the tub rubber trapper, solid waste also comes from latex that undergoes pre coagulation but still can be utilized as the primary raw material for Brown Crepe processing that still has economic value. On the word of the technical manager of this company, the untreated solid waste from the wastewater treatment unit were traded to a third party, which then refer to in the report as miscellaneous income.

While according to Provincial Environmental Agency, the environmental problems associated with the processing of this rubber is water pollution. “Environmental pollution resulting from the production of natural rubber is greatest magnitude of the amount of wastewater that is discharged into the environment. This wastewater pollution was caused by the huge amount of water that was used in production processes such as for freezing latex, latex laundering and equipment.”

While the Section Head of Environmental Biotechnology says that: "The wastewater from the production of natural rubber is organic. So that in the processing of wastes using biological techniques like using aeration pond. One problem is the electricity expenditure to be incurred to operate the aerator‖. In this case, company X is using a three-stage aerobic biological treatment technique using with water hyacinth plants before the treated wastewater discharged into receiving water bodies. Thus the practice of including in pollution management practices in end-of-pipe treatment.

During this time we are always monitoring the quality of wastewater and air emissions. We send samples of wastewater to one testing laboratory, as well as the testing of the emissions and ambient air quality every year. From the certificate issued by the agency, the results of testing waste water and air quality otherwise still meet the requirements of environmental regulations.

4.2. Obstacles in Environmental Management and Practices

From the results of data collection, the findings of obstacles experienced include human resources, infrastructure, technological change, community pressure, communication with external stakeholder. The followings are description of identified obstacles:

a. Financial issues

another benefit consideration is when they were offered by an external expert to use the wastewater recycling technology. The company said that the profits earned by applying new environmentally friendly technologies are difficult to be measured. As the manager said that there is the potential for recycling of waste water, but once calculated, the cost is enormous. They are very optimistic to provide the money to invest in the environmental technologies. But the concern is that, as entrepreneurs, the investments that they put in for technology and innovation in all our production chain should provide benefits that can be measured. Whether based on how long it will take for the capital back or the value of benefits to obtain. According to the manager, the environmental advantages it difficult to measure to determine the criterion of such advantages. From those problems, it shows the necessity of a model that can measure environmental costs (Post & Altma 1994), to convince them to apply more environmentally friendly technologies. Post and Altma (1994), adds that to deal with the lack of capital costs for an environmental management improvement project, carrying out the innovations in marketing can add capital financing. Correspondingly, environmental marketing strategies formulated by Čater, Prašnikar and Čater (2009) using the competitive advantage of buyers who require environmentally friendly products.

b. Communication with external stakeholders

The location of a business that is close to other institutions (in this case the environmental expert or environmental research agency), will be beneficial for the adoption process of more proactive environmental management (Carruthers & Vanclay 2012). Nevertheless, the distant location of the plant to the city centre and the competent environmental agencies considerably hampers to the smooth process of communication and consultation for solving problems related to environmental management in the company. The manager considered it is time-inefficient. That is because face-to-face communication is considered by the company as effective way to communicate their environmental issue to the experts (Moore 2010). Although direct communication is necessary, it must also be ensured that the expected output from communication can be useful, especially when faced with particular problems. To that end, it is important to develop a communication channel to the external environment experts, although sometimes necessary also direct meetings. This communication channel is expected as one of the lines consultations to address environmental problems that are happening in the company if the two parties are not the opportunity for a direct meeting (Polonsky 1995).

c. Human resources

18

awareness of workers is important to achieve successful implementation. Besides, the focus of employees and the company is still dominated by production problems. Therefore the engineering manager is open and welcomes any suggestions from environmental experts that can be applied in the factory to minimize environmental impact.

d. Communities pressure

Although the company has fulfilled the requirements of wastewater disposal, if there is dissatisfaction from the public to the pollution situation, the community's pressure will be expected to continue (Wang 2000). In this case, the company had received a complaint from surrounding community due to their sewerage. The weak understanding of the community about the provision of wastewater reuse also worsened the complaint issue. Basically the result of waste treatment is not intended for irrigation of farmland without the certain conditions according to the applied law. Previously, the company had semi-open sewage for their effluent. The community that are majority farmers used the effluent to irrigate their fields. However, there was an inevitable occurrence befall their crops. Even though the cause could be not only from the company’s wastewater, the representatives of residents who felt aggrieved demanded for corporate’s responsibility. To overcome the problems with the residents, the company entered into a dialogue with us to find a solution. In addition, the company is asking for input from the nearest environment agency to overcome this. In order to achieve a mutual benefit and prevent future conflict between the local communities and the company, the results of the discussion which was also attended by representatives of various elements, reached an agreement that states that the risk of the use of the output of the wastewater treatment facilities will not be covered by the company. As a result of the negotiations, until this point, nobody has using the company's effluent for irrigation so the company has not been receiving complaint about the issue.

e. Technological change consideration

The director of company X informed that when they conducted a study visit to Thailand and Malaysia. There they saw that in terms of production, they are more use of machinery. The diffusion of new technologies is often constrained by social and technical considerations (Cantono & Silverberg 2009). If the company’s management decide to use more machines then they fear that this will impact on the number of employees. Besides, the installation of new clean technologies is costly

4.3. Proposed strategies to improve the existing environmental practices

"I'm usually looking for information on the Internet. Besides the network of friends of the consultant or from other units of other companies that are still under the umbrella of the same entity. In addition, each year, innovation competitions are held, followed by all units of the company. The contest winner will be announced and given a reward".

In these competitions, the unit that became the winner can present the innovation success they have achieved. Afterward, the other units that are still in a holding company can copy the innovation success into their units. The competition can motivate other groups to innovate, or adopt innovations made by the unit that became the winner. Also, based on interviews with several experts, in general, there are three types’ improvements that are needed. The improvements include process development, proper handling of raw materials, as well as improvements to the wastewater treatment system. Therefore, some alternative solutions to these problems can be described as follows:

a. Reuse of wastewater

The quality of treated wastewater effluent that meets the Quality Standard according to the Ministry of Environment's Decree No. 51/1995 has opportunities to be reused. However, the use of the treated wastewater is not intended for the production, especially for water that has direct contact with latex. It will have an impact on the quality of the resulting rubber sheet. Therefore, the possible re-use of reclaimed wastewater is for irrigation. Such as the practice of wastewater re-use of for irrigation in the various rubber plantation, and rice field in Thailand through preliminary experiment followed by a feasibility study (Chaiprapat & Sdoodee 2007). That is because of the consideration of economic and organic nutritional value contained in the treated wastewater.

As the company has implemented an environmental management system, company X must consider the quality of effluent that still meets with the requirements for irrigation water quality standards according to Ministry of Environment’s Decree No. 51/1995. Moreover, in the context of Indonesia, the output of effluent reuse for irrigation must meet certain statutory requirements as stipulated in Government Regulation No. 82/2001 on Water Management and Water Pollution Control. The highlights of the requirements in the regulations include: Study the effects on fish, animals, and plants, quality of soil and groundwater, as well as public health. Afterwards, the study results need to be submitted to the regent or mayor to obtain written consent to its application. Thus, prior to its implementation, it is necessary for testing of the effect to the control plants for a year.

b. Efficiency in water usage

Because to the large amount of water used, the company should conduct efficiency for water use. In this case it does not mean reducing the amount of water usage, but examining the efficiency of its use. This is in line with the manager's technique which is for example to warn employees to turn off the water taps when not needed. Although the boss is still a very necessary role in the supervision of its implementation, the employees show a cooperative attitude to implement management directives.

c. Raw material substitution

20

smoke is an alternative as a latex coagulant to replace ammonia. Liquid smoke is considered more environmentally friendly because it is made from a biomass through a pyrolysis process. The company has such resources given they own the rubber plantation and can utilize parts of rubber trees that have not grown to make liquid smoke.

d. Good housekeeping

According to Hill (2010), good housekeeping is considered as a cost effective way to reduce pollution. Its implementation requires commitment and active participation of managers and employees. This practice is considered to save costs of waste treatment because of the potential efficiency of resource use (Hillary 1996).

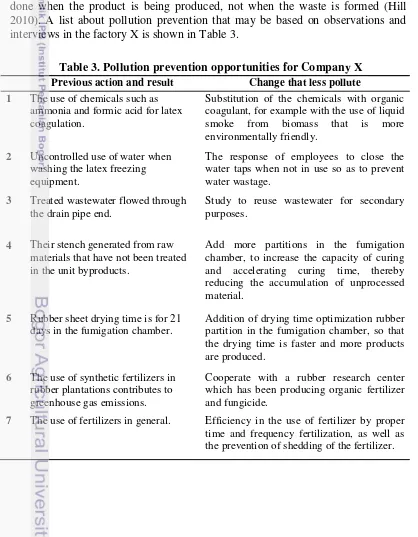

e. Pollution prevention

To reduce and eliminate contaminants that are formed, one of the approaches that can be used is the prevention of pollution. Pollution prevention is done when the product is being produced, not when the waste is formed (Hill 2010). A list about pollution prevention that may be based on observations and interviews in the factory X is shown in Table 3.

Table 3. Pollution prevention opportunities for Company X

Previous action and result Change that less pollute 1 The use of chemicals such as

ammonia and formic acid for latex coagulation.

Substitution of the chemicals with organic coagulant, for example with the use of liquid smoke from biomass that is more environmentally friendly.

2 Uncontrolled use of water when washing the latex freezing equipment.

The response of employees to close the water taps when not in use so as to prevent water wastage.

3 Treated wastewater flowed through the drain pipe end.

Study to reuse wastewater for secondary purposes.

4 Their stench generated from raw materials that have not been treated in the unit byproducts.

Add more partitions in the fumigation chamber, to increase the capacity of curing and accelerating curing time, thereby reducing the accumulation of unprocessed material.

5 Rubber sheet drying time is for 21 days in the fumigation chamber.

Addition of drying time optimization rubber partition in the fumigation chamber, so that the drying time is faster and more products are produced.

6 The use of synthetic fertilizers in rubber plantations contributes to greenhouse gas emissions.

Cooperate with a rubber research center which has been producing organic fertilizer and fungicide.

f. Personnel environmental strategy

This strategy relates to human resources constraint. Recognizing the importance of employees’ participation in the environmental activities in the company, the company could implement personnel environmental strategy that is also enabled by management supports (Čater, Prašnikar & Čater 2009). The methods are by facilitating employees' training and building awareness about environmental issues. It is expected that the active role of workers and managers' support to be more proactive in the environmental management practices (Hanna, Rocky Newman & Johnson 2000).

g. R&D cooperation strategy

22

CHAPTER 5 CONCLUSION AND RECOMMENDATION

5.1. Conclusion

This study explores and identifies the factors that have the greatest environmental impact in a production chain of natural rubber processing. The purpose of identifying the source of contamination as well as the barriers faced is used to explore new opportunities to improve the environmental management system that is neither effective nor efficient. The review shows that the pollution caused by: water usage, accumulation of unprocessed material, the use of ammonia and the use of inorganic fertilizer. While some obstacles encountered by companies to be more environmentally friendly include the financial considerations, human resources, community pressure, technological change as well as communication with the institutional environment. Based on the situation and the obstacles, some strategies that are proposed to overcome the issues are study on the wastewater reuse and pollution prevention. The prevention at the source consists of efficiency in water usage, raw material substitution, good housekeeping, and increasing production capacity. Besides, a personnel environmental strategy is beneficial to overcome barriers in human resources. In addition, collaboration with experts is one of good ways to overcome the lack of expertise and knowledge about environmental management.

5.2. Limitations and Recommendations

This study aims to explore strategies for the improvement of environmental practices that has existed in a company. These environmental improvement strategies cannot be generalized beyond the company where the conditions and characteristics differ by region. However, this design is an appropriate template for a broader based study. In addition, future research also needed to evaluate the effectiveness if the application of these strategies is implemented by the organization. The results of this research highlight the practical implications by optimizing employees’ participation for environmental friendly practices. As the strategic implications, this research also assists the company’s management in environmental decision making by conducting a feasibility study on an environmental project towards implementation. These results also suggest policy makers to assist industries in the environmental management and provide the industries with technical guide. For theory building, the obstacles could the basis for theory building of environmental innovation strategy.

REFERENCES

Association of Rubber Producing Countries (ANRPC). (2010). Retrieved 4 April 2014 from www.anrpc.org

Afreen, S, Haque, K & Huda, M 2013, 'Troubleshooting for the observed problems in processing latex concentrate from natural resource', in IOP

Conference Series: Earth and Environmental Science, IOP Publishing, vol. 16, p. 012007.

Banerjee, S 2001, 'Corporate environmental strategies and actions', Management Decision, vol. 39, no. 1, pp. 36-44.

Banerjee, SB, Iyer, ES & Kashyap, RK 2003, 'Corporate environmentalism: antecedents and influence of industry type', Journal of Marketing, vol. 67, no. 2, pp. 106-122.

Becker, W & Dietz, J 2004, 'R&D cooperation and innovation activities of firms—evidence for the German manufacturing industry', Research Policy, vol. 33, no. 2, pp. 209-223.

Bossink, BA 2007, 'The interorganizational innovation processes of sustainable building: a Dutch case of joint building innovation in sustainability', Building and Environment, vol. 42, no. 12, pp. 4086-4092.

Buysse, K & Verbeke, A 2003, 'Proactive environmental strategies: a stakeholder management perspective', Strategic management journal, vol. 24, no. 5, pp. 453-470.

Cantono, S & Silverberg, G 2009, 'A percolation model of eco-innovation diffusion: the relationship between diffusion, learning economies and subsidies', Technological Forecasting and Social Change, vol. 76, no. 4, pp. 487-496.

Carruthers, G & Vanclay, F 2012, 'The intrinsic features of Environmental Management Systems that facilitate adoption and encourage innovation in

primary industries', Journal of Environmental Management, vol. 110, pp. 125-134. Čater, T, Prašnikar, J & Čater, B 2009, 'Environmental strategies and their

motives and results in Slovenian business practice', Economic and Business Review, vol. 11, no. 1, pp. 55-74.

Chaiprapat, S & Sdoodee, S 2007, 'Effects of wastewater recycling from natural rubber smoked sheet production on economic crops in southern Thailand', Resources, conservation and recycling, vol. 51, no. 3, pp. 577-590.

Damanik, S 2012, 'Pengembangan Karet (Havea brasiliensis) berkelanjutan di Indonesia', Perpektif, vol. 11, no. 1, June 2012, p. 12.

Damanpour, F & Gopalakrishnan, S 2001, 'The dynamics of the adoption of

24

Darmawan, MA, Putra, MPIF & Wiguna, B 2014, 'Value chain analysis for green productivity improvement in the natural rubber supply chain: a case study', Journal of Cleaner Production, vol. 85, pp. 201-211.

De Marchi, V 2012, 'Environmental innovation and R&D cooperation: Empirical evidence from Spanish manufacturing firms', Research Policy, vol. 41, no. 3, pp. 614-623.

Drucker, PF 1999, Innovation and entrepreneurship : practice and principles, [2nd rev. ed.] edn, Butterworth-Heinemann, Oxford.

Elman, C 2005, 'Explanatory typologies in qualitative studies of international politics', International organization, vol. 59, no. 02, pp. 293-326.

Esty, D & Winston, A 2009, Green to gold: How smart companies use

environmental strategy to innovate, create value, and build competitive advantage, John Wiley & Sons.

Fischer, K & Schot, J 1993, Environmental strategies for industry; international perspectives on research needs and policy implications.

Girish, K 2014, 'Effect of Carbon Sources on the Biomass Build-Up and Degradation of Rubber Processing Industry Effluent', International Journal of Applied Sciences and Biotechnology, vol. 2, no. 4, pp. 579-584.

Hanna, MD, Rocky Newman, W & Johnson, P 2000, 'Linking operational and environmental improvement through employee involvement', International Journal of Operations & Production Management, vol. 20, no. 2, pp. 148-165.

Hasibuan, S 2011, 'Dimensi sistem manajemen lingkungan yang dominan

terhadap upaya produksi bersih perusahaan (Studi kasus industri pengolahan karet remah)', JURNAL TEKNOLOGI LINGKUNGAN, vol. 6, no. 1.

Hasibuan, S 2012, 'Pengembangan sistem penunjang manajemen audit produksi bersih pada agroindustri karet remah', Agroindustrial Technology, Disertation thesis, Graduate School thesis, Bogor Agricultural University, Bogor.

Hill, MK 2010, Understanding environmental pollution, Cambridge University Press.

Hillary, R 1996, Environmental management systems and cleaner production, ed. R Hillary, Wiley, Chichester New York.

Hillary, R 1997, 'Environmental management systems and cleaner production'. Horbach, J, Rammer, C & Rennings, K 2012, 'Determinants of eco-innovations by type of environmental impact—The role of regulatory push/pull, technology push and market pull', Ecological Economics, vol. 78, pp. 112-122.

Khanna, M, Deltas, G & Harrington, DR 2009, 'Adoption of pollution prevention techniques: the role of management systems and regulatory pressures',

Environmental and Resource Economics, vol. 44, no. 1, pp. 85-106.

Lam, J, Hills, P & Welford, R 2005, 'Ecological modernisation, environmental innovation and competitiveness: the case of public transport in Hong Kong', International Journal of Innovation and Sustainable Development, vol. 1, no. 1, pp. 103-126.

Lawrence, L, Andrews, D & France, C 1998, 'Alignment and deployment of environmental strategy through total quality management', The TQM Magazine, vol. 10, no. 4, pp. 238-245.

Moore, SA 2010, 'The effect of knowledge sharing on the environmental performance of proactive environmental organisations', PhD thesis, Southern Cross University, Lismore, NSW.

Nadel, S 2012, 'The determinants of eco innovative performance according to firms' strategic profiles: The case of French Industrial Firms'.

Nguyen, HN & Luong, TT 2012, 'Situation of wastewater treatment of natural rubber latex processing in the Southeastern region, Vietnam', Journal of Vietnamese Environment, vol. 2, no. 2, pp. 58-64.

Nidumolu, R, Prahalad, CK & Rangaswami, M 2009, 'Why sustainability is now the key driver of innovation', Harvard business review, vol. 87, no. 9, pp. 56-64. Pahlevi, D 2007, 'Penghilangan Emisi Gas Bau Dari Tempat Penumpukan Leum Industri Karet Remah Dengan Menggunakan Teknik Biofilter'.

Palys, T 2008, 'Purposive sampling', The Sage encyclopedia of qualitative research methods, vol. 2, pp. 697-698.

Pannell, DJ, Marshall, GR, Barr, N, Curtis, A, Vanclay, F & Wilkinson, R 2006, 'Understanding and promoting adoption of conservation practices by rural landholders', Animal Production Science, vol. 46, no. 11, pp. 1407-1424.

Pfafflin, JR, Baham, P & Gill, FS 1996, Dictionary of environmental science and engineering, Taylor & Francis.

Polonsky, MJ 1995, 'A stakeholder theory approach to designing environmental marketing strategy', Journal of Business & Industrial Marketing, vol. 10, no. 3, pp. 29-46.

Post, JE & Altma, BW 1994, 'Managing the environmental change process:

barriers and opportunities', Journal of Organizational Change Management, vol. 7, no. 4, pp. 64-81.

Rickmann, A 1992, 'Developing environmental management strategies', European Environment, vol. 2, no. 1, pp. 15-18.

26

Subramanian, A & Nilakanta, S 1996, 'Organizational innovativeness: exploring the relationship between organizational determinants of innovation, types of innovations, and measures of organizational performance', Omega, vol. 24, no. 6, pp. 631-647.

Tekasakul, P & Tekasakul, S 2006, 'Environmental problems related to natural rubber production in Thailand', Journal of Aerosol Research, vol. 21, no. 2, pp. 122-129.

Theyel, G 2000, 'Management practices for environmental innovation and performance', International Journal of Operations & Production Management, vol. 20, no. 2, pp. 249-266.

UNEP 2003, 'Sustainable Use of Natural Resources in the Context of Trade Liberalization and Export Growth in Indonesia : A Study on the Use of Economic Instruments in the Pulp and Paper Industry'.

Utomo, TP, Hasanudin, U & Suroso, E 2012, Agroindustri karet Indonesia : Petani karet dan kelembagaan, proses pengolahan dan kinerjanya, dan selayang pandang karet sintetis, 1 edn, Sarana Tutorial Nurani Sejahtera, Bandung.

Van, HNT, Duong, DTT, Thanh, NTM, Trang, THTT, Dinuriah, I, Sharmin, S, Khai, HM & Huy, TNQ 2007, 'Waste Abatement and Management in Natural Rubber Processing Sector', Asian Institute of Technology

Wang, H 2000, 'Pollution charges, community pressure, and abatement cost of industrial pollution in China', World Bank Policy Research Working Paper, no. 2337.

Warhurst, A & Bridge, G 1996, 'Improving environmental performance through innovation: recent trends in the mining industry', Minerals Engineering, vol. 9, no. 9, pp. 907-921.

Welford, R & Gouldson, A 2002, Environmental management and business strategy, Pitman, London.

Wouapi, N & Maimo, T 2007, 'Towards a comprehensive analysis of cleaner technology potentials to address industrial pollution arising from natural rubber processing industry: A case study of Cameroon Development Corporation-Rubber Factories'.

Appendix 1

–

Results of observation in the company X

1. Company’s profile

NO ELEMENTS VALUE UNITS DESCRIPTION 1 INPUT

a. Total raw material 161,711 Kg b. Auxiliary

- Formic acid 700 Liter Coagulation of latex - Ammonia Liter Latex preservation and

anti-pre-coagulation - Inorganic fertilizer 140 Liter Rubber plantations c. Utility

- Water 69,546 M3 Production and washing - Electricity 53,173 kWH Equipment

- Rubber firewood 3,047 M3 Smoking process d. Human resources (based

on level)

- Managers 10 Person - Implementers 418 Person - Freelancers 1019 Person e. Human resources

development

Pre-planting training. Internal training External training

2 OUTPUT