PROPERTIES OF FIBROUS LIGHTWEIGHT CONCRETE

OF AGAVE SISALANA

Akmaluddin

Civil Engineering Department, Faculty of Engineering – MataramUniversity

Head of Structural Engineering and Construction Material Research Group –

MataramUniversity Jl. Majapahit No. 62 Mataram,

Telp: (0370) 636126

akmal@ftunram.ac.id;

Suryawan Murtiadi Civil Engineering Department, Faculty of Engineering – MataramUniversity

Member of Structural Engineering and Construction Material Research Group –

MataramUniversity Jl. Majapahit No. 62 Mataram,

Telp: (0370) 636126

s.murtiadi@yahoo.co.uk

Suparjo

Civil Engineering Department, Faculty of Engineering – MataramUniversity

Member of Structural Engineering and Construction Material Research Group

Mataram University Jl. Majapahit No. 62 Mataram,

Telp: (0370) 636126

suparjo14867@yahoo.com

Zaedar Gazalba Civil Engineering Department, Faculty of Engineering – MataramUniversity

Member of Structural Engineering and Construction Material Research Group

Mataram University Jl. Majapahit No. 62 Mataram,

Telp: (0370) 636126

zaedargazalba@yahoo.co.id

Abstract

This paper investigates fibrous lightweight concrete containing natural fiber of agave sisalana. The fibers were cut into 60 mm length and put into concrete mixture. Compressive strength and elastic modulus of the concrete mixture were evaluated. Seven set of cylinder specimen were considered. Each set of the specimens consisted of four cylinder specimens containing fiber volume fraction of 0%, 0.5%, 0.75%, 1%, 1.25%, 1.5%, and 2%. The concrete mix was designed to produce a compressive strength of 12 MPa. The test results showed the compressive strength and elastic modulus increase with the increased fiber contents from 0.5% to 1.5%. The maximum compressive strength was achieved at the addition of 1.5% fiber content which produced strength of 17 MPa. All fibrous concrete unit-weights are less than 1850 kg/m3 which is identified as lightweight concrete criterion. In addition, a model to estimate fibrous concrete elastic modulus of sisal fiber was proposed. This model was valid for 0.5% up to 1.5% fiber contents. It is also not recommended to apply sisal fiber content below 1% as gave strength lower than concrete without fiber.

Key Words: lightweight concrete, sisal fiber, compressive strength, elastic modulus

INTRODUCTION

1st International Conference on Infrastructure Development, UMS Surakarta, 1 – 3 Nov 2013 ISBN 978-979-636-154-4

The use of plant fibers in polymer composites provides some advantages such as having a high specific strength, low cost, low density, biodegradable and lightweight (Bismarck et al., 2006; Khoatane et al., 2008). Sisal is one of plant species called Bali Pineapple (agave sisalana weberi) in Indonesia, in which the characteristics of the plants is similar to the pineapple but unfruitful, its leaves are generally sharp, thick, and stiff.

Pumice lightweight concrete is also experiencing growth applications such as for precast wall panels and lightweight structural components. With the advantages of the fibers and the shortcoming of the lightweight concrete (akmaluddin and Murtiadi, 2013) then applying the fibers into the lightweight concrete mixture is a great deal to short it out the lightweight concrete problems. Thus this study aims to discuss the presence of sisal fiber in concrete mixture in terms of its compressive strength, elastic modulus and density.

EXPERIMENTAL PROGRAM

Preparation of Fiber Materials

Figure 1 shows the pineapple plant use in this study and its manually process to obtain sisal fiber. To produce the fibers from the pineapple leaves it can be done by scrapping 60 mm length of the leaves by a simple way using the equipment of bamboo as shown in right side on Figure 1. But this method requires a much time to produce the fibers, thus machines scrap has been manufactured to speed up the process. Once the fibers obtained the drying process was done in room temperature for a day.

To obtain fiber tensile strength a bundle of fibers were made with approximately diameter of 8 mm to facilitate easy gripping in the machine test. Test result showed a maximum tensile strength of sisal of 30

MPa and has a unit weight of 336.6 kg/m3. In addition, the fibers were cut to a length of 60 mm and mixed

with the lightweight concrete mixture. The concrete mixture was set as shown in Table 1 to obtain designed strength of 12 MPa. Fiber volume fractions were specified as 0.5%, 0.75%, 1%, 1.25%, 1.5% and 2%.

Figure 1.Pineapple Plant and Process Obtaining Fiber Manually

Table 1

Concrete Mixture Proportions

Type ofconcrete

Target strength

f’c, MPa

Mixture proportion

w/c Cement kg/m3

Sand kg/m3

Pumice kg/m3

Lightweight 12 0.94 367 473 378

Specimens Preparation

Figure 4.Fibrous Concrete Specimen Preparation Instrumentation and Test Procedure

A compression test machine available in the Laboratory of Structure and Material Faculty of Engineering University of Mataram was used. The machine has loading capacity about 300 kN and can store data using computer data acquisition system automatically. Test results for both compressive strength and modulus of elasticity of the specimen obtained straightforward from once testing process. Figure 5 shows set-up specimen in terms of testing both concrete compressive strength and its elastic modulus.

Figure 5.Set-up Compression and Modulus of Elasticity Test

TEST RESULTS AND DISCUSSION

Concrete Compressive Strength

Experimental data for compressive strength of concrete is obtained from testing concrete cylinders destructively. Typical stress-strain relationship of the cylinder test specimens is shown in Figure 6.

From the figure it can be obtained maximum compressive strength of the specimen which is shown as a peak point in the graph. Using the graph it can be sorted out the value of elastic modulus of concrete experimentally by applying Eq. (1).

2 1

2 0 00005

c

S S

E

.

ε

− =

−

(1)

where: S2 is compressive strength at the stress level of 0.4 f’c. S1 is the compressive strength at the strain of

0.00005. 2 is the strain reading on the compressive strength value of S2.

Modulus of elasticity of lightweight concrete without fibers can be calculated theoretically using Eq. (2) below.

0 65 4700

'c c

1st International Conference on Infrastructure Development, UMS Surakarta, 1 – 3 Nov 2013 ISBN 978-979-636-154-4

Figure 6.Typical Cylinder Specimen Test Results

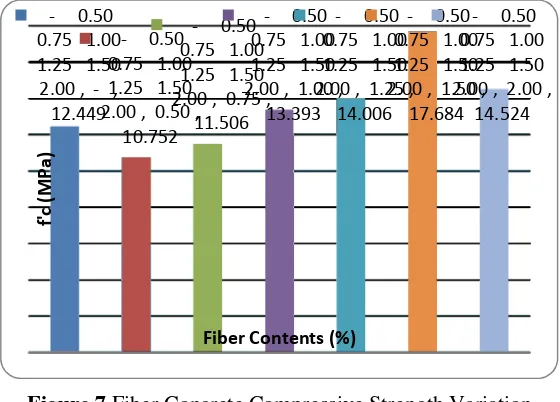

The compressive strength test results for varieties fiber contents in the lightweight concrete mixture are presented in Figure 7. It can be seen in the figure that from 0.5% to 1.5% fibers content the concrete strength increased gradually from about 10 MPa to 17 MPa. However it can be clear noticed from the figure that additional fiber of 0.5% and 0.75% has lower strength than that of the concrete without containing fiber (0%). This phenomenon is suspected due to the fiber contents in the concrete mixture undistributed uniformly throughout the concrete matrix.

Figure 7.Fiber Concrete Compressive Strength Variation

Additional fiber higher than 1.5% volume fraction in the concrete mixture did not produce strength better than that of concrete with 1.5% as shown in the figure. It is predicted because of pretty much fiber contents may hinder the movement of cement paste to fill the empty spaces in the concrete matrix. This lead to brittle concrete due to void on pumice aggregate did not fill in by cement paste properly.

With reference to Figure 7 it also found that only one type of fiber concrete that meets the criteria as a structural concrete as the concrete compressive strength reaches values over 17 MPa (ASTM C330-89). Thus the lightweight concrete with fiber volume fraction of 1.5% may represent structural fibrous lightweight concrete.

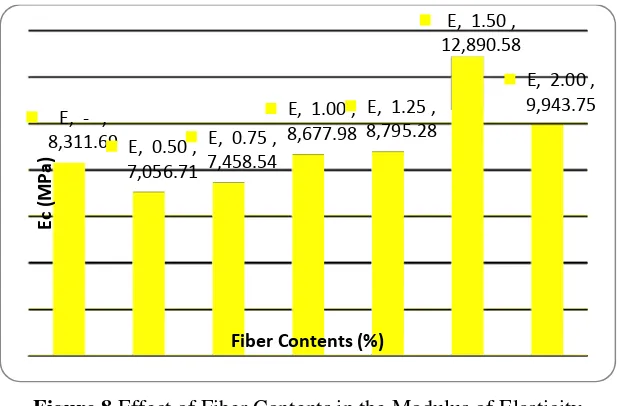

Using Eq.(1), the elastic modulus of fibrous lightweight concrete experimentally was obtained as presented in Figure 8. Results showed that the values were varied between 6000 and 12000 MPa with the trend identical to the compressive strength test results. When applying Eq. (2) then elastic modulus of elasticity was obtained of 10500 MPa for lightweight concrete without fiber. This gives experimental elastic modulus value about 0.76 or 8000/10500 of the theoretical value. This can be argued as the theoretical model was developed in general for the lightweight concrete without specifically considering pumice aggregate.

- 0.50 0.75 1.00 1.25 1.50 2.00 , - ,

12.449

- 0.50 0.75 1.00 1.25 1.50 2.00 , 0.50 ,

10.752

- 0.50 0.75 1.00 1.25 1.50 2.00 , 0.75 ,

11.506

- 0.50 0.75 1.00 1.25 1.50 2.00 , 1.00 ,

13.393

- 0.50 0.75 1.00 1.25 1.50 2.00 , 1.25 ,

14.006

- 0.50 0.75 1.00 1.25 1.50 2.00 , 1.50 ,

17.684

- 0.50 0.75 1.00 1.25 1.50 2.00 , 2.00 ,

14.524

f'

c

(M

P

a

)

Figure 8.Effect of Fiber Contents in the Modulus of Elasticity

All the specimens are also measured its density. Average density values for all cylindrical specimens are presented in Figure 9 below. From the figure it is clear that the density value of all the specimens below the

density maximum value of 1850 kg/m3 (ACI, 2005) as shown by dash line for lightweight concrete

categories. Thus all the specimens are classified as lightweight concrete.

Figure 9.Density Variation of Fibrous Concrete

Referring to Eq.(2) it is clear that modulus of elasticity has a linier relationship with compressive strength. The equation model agrees with the test results as shown in Figure 10 below. It is clear from the figure that with the increasing compressive strength elastic modulus of the concrete are also increased.

1st International Conference on Infrastructure Development, UMS Surakarta, 1 – 3 Nov 2013 ISBN 978-979-636-154-4

To account for the effect of fiber content in the concrete mixture it is necessary to develop mathematical model for the relationship between the modulus of elasticity and compressive strength. Thus, using available data in this study then the data were manipulated and presented in terms of Ec(1+v) in the y-axis and f'c in the x-axis as shown in Figure 11, where v is the representation of fiber contents (%).

Figure 11.Determining the Relationship of Ec and f'c

When a linier regression is applied in the data gives R2 = 0985. This means that the relationship is strong

with less than 2 % deviate data occur. This relationship can be worked out to produce a mathematical model as given in Eq. (3) below.

where: v = volume fraction of fibers in concrete (%).

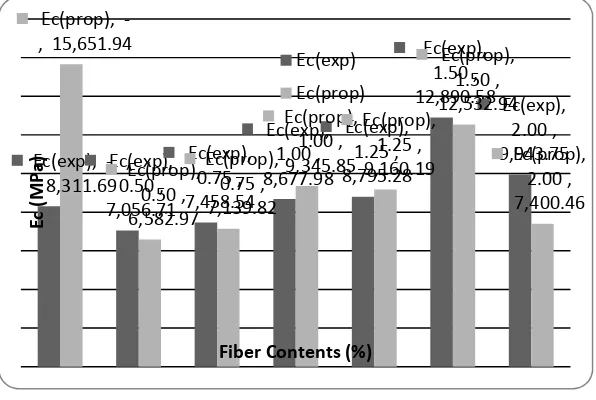

To compare an experimental and predicted elastic modulus thus Eq. (1) and Eq. (3) are applied respectively. The results of comparison are presented in Figure 12. It is clear from the figure that all the predicted value almost agrees with the experimental value for fiber contents from 0.5 % to 1.5%. At a volume fraction of 2%, predicted value lower than that of the experimental value with differentiate about 2000 MPa. Thus Eq. (3) valid only for predicting fibrous lightweight concrete with fiber content between 0.5% and 1.5%.

Figure 12.Ec Values at Various Fiber Contents

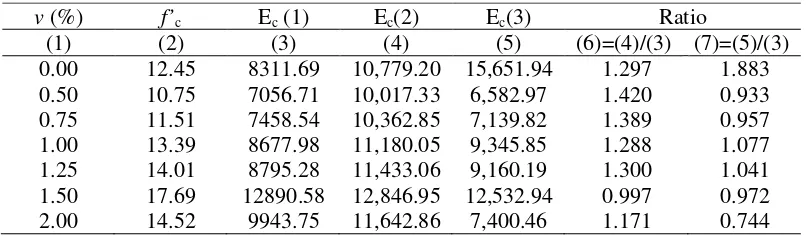

Table 2 provide more detail comparison of existing model, Eq.(2), and proposed model, Eq.(3) to the experimental model, Eq.(1) as given in column (6) and (7) of Table 2 respectively.

modulus of elasticity.

Table 2 Comparison of Ec

v (%) f’c Ec (1) Ec(2) Ec(3) Ratio

(1) (2) (3) (4) (5) (6)=(4)/(3) (7)=(5)/(3)

0.00 12.45 8311.69 10,779.20 15,651.94 1.297 1.883

0.50 10.75 7056.71 10,017.33 6,582.97 1.420 0.933

0.75 11.51 7458.54 10,362.85 7,139.82 1.389 0.957

1.00 13.39 8677.98 11,180.05 9,345.85 1.288 1.077

1.25 14.01 8795.28 11,433.06 9,160.19 1.300 1.041

1.50 17.69 12890.58 12,846.95 12,532.94 0.997 0.972

2.00 14.52 9943.75 11,642.86 7,400.46 1.171 0.744

CONCLUSIONS

From this research, several conclusions can be drawn as follow:

1. The addition of sisal fibers into the concrete mixture significantly affects the compressive strength and elastic modulus of fibrous lightweight concrete.

2. Fibrous lightweight concrete containing less than 1% sisal fiber produce compressive strength less than strength of the normal lightweight concrete (0%).

3. Maximum compressive strength of 17 MPa was achieved at the fibrous lightweight concrete with 1.5% fiber contents.

4. Unit-weight of fibrous lightweight concretes were less than 1850 kg/m3 which is identified as

lightweight concrete criterion.

5. The empirical formula to calculate the elastic modulus of fibrous lightweight concrete of sisal fiber was proposed.

ACKNOWLEDGEMENT

Grateful acknowledgement is addressed to the Director of Directorate Research and Community Service for the financial support through the National Strategy Research Scheme under Directorate General of Higher Education, Ministry of National Education and Culture, Republic of Indonesia.

REFERENCES

ACI-Committee-544. 1996. State-of-the-art report on fiber reinforced concrete. Michigan: Farmington

Hills.

Akmaluddin and Murtiadi, S. 2013. Hybrid Precast Concrete Column and Sandwich Concrete Beam under Static Loading.Procedia Engineering V54 pp. 286 – 298 Elsevier Ltd.

ASTM-C192.Standard Practice for Making and Curing Concrete Test Specimens in the Laboratory. ASTM ASTM-C330, 1989.Specification for Lightweight Aggregates for Structural Concrete.ASTM.

Bismarck, A., Baltazar, Y.J. & Sarlkakis, K. 2006.Green Composites as Panacea?Socio- Economic Aspects of Green Materials.V.8 (3). pp. 445–463.

John, K., & Naidu, S. 2004. Tensile Properties of Unsaturated Polyester-Based Sisal Fiber– Glass Fiber Hybrid Composites.V23, 1815 p.

Khoatane, M. C. Vorster, O. C., & Sadiku, E. 2008. Hemp Fiber-Reinforced Pentene/Polypropylene

Copolymer: The Effect of Fiber Loading on the Mechanical and Thermal Characteristics of the Composites. Journal of Reinforced Plastics and Composites. V27. 1533 p.

Poon, C.S. Shui ZH and Lam, L. 2004.Compressive behavior of fiber reinforced high-performance concrete subjected to elevated temperatures. Cement Concrete Res; V34 pp. 2215–2222.

Suhaendi, S.L. and Horiguchi, T. 2006. Effect of short fibers on residual permeability and mechanical