77

BAB 6

KESIMPULAN DAN SARAN

6.1.

Kesimpulan

Kesimpulan yang dapat diambil pada Tugas Akhir ini adalah :

a. Total waktu proses produksi dari semula 60 hari dengan urutan pengerjaan

yang diusulkan menjadi 40 hari.

b. Metode SPT

(Shortest Processing Time)

mempunyai waktu total lebih cepat

dibanding metode LPT

(Longest Processing Time).

Pada saat proses

penjadwalan metode LPT terdapat pengecualian yaitu, proses pengerjaan

yang seharusnya dilakukan pada hari sekarang namun karena waktu yang

tidak cukup dikerjakan dihari berikutnya sehingga penjadwalan pada metode

LPT dihasilkan waktu yang lebih lama.

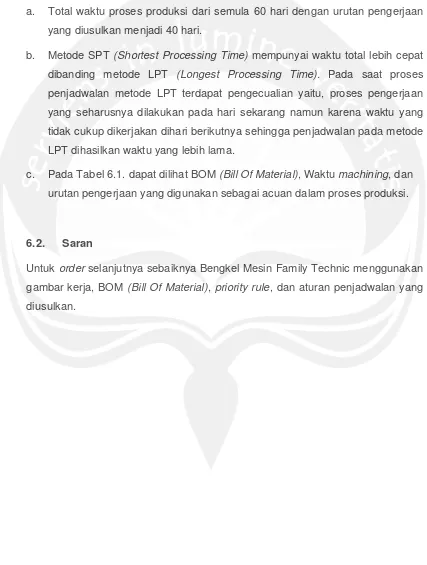

c. Pada Tabel 6.1. dapat dilihat BOM

(Bill Of Material)

, Waktu

machining

, dan

urutan pengerjaan yang digunakan sebagai acuan dalam proses produksi.

6.2.

Saran

[image:1.595.87.514.200.765.2]78

Tabel 6. 1. BOM, Waktu Machining, Urutan Pengerjaan

C u tt in g T u rn in g H a n d G ri n d in g H a n d D ri ll in g W e ld in g D ri ll in g

1 120 3 120

1 Frame assy 120 wait 3 120

1 frame cor 2 p . . cor 0

2 bearing with housing A 4 p . . . . part standart

3 bearing with housing A kecil 2 p . . . . part standart

4 bearing with housing B 2 p . . . . part standart

5 induction motor 1 p . . . . electical

6 puley karet - B54 3 p . . . . part standart

7 puley pasangan motor 12 " 2 p . . . part standart

8 puley pasangan as penggerak 5" 2 p . . . part standart

9 arm lengan panjang 1 p . . . cor

1 bearing diameter 20 3 p part standart

10 arm lengan pendek 5 p . . . cor

1 bearing dia 20 3 p part standart

11 balancer 2 p . . . cor

1 bush balancer 2 b 10 60 . . . 70 40 2

12 c arm 2 p . . . cor

13 extention universal 8 p . . . part standart

14 shaft 1,5 inch 2 b 20 20 120 . . . . 20 . 180 90 1

15 shaft 1 inch 2 b 20 20 100 . . . . 20 . 160 89 3

16 roda gila (assembly) 2 b . . . 60 . . . assembling 1 60 46 2

1 eksentris 10 . 40 30 assembling 1 80 3 1

1 bush eksentris 2 b 10 60 . 70 1 1

2 blok o 2 b 10 60 40 . 110 2 1

2 bearing diameter 150 2 p . . . part standart 0

3 housing 2 b 10 100 . . . 110 45 2

4 bush roda gila 2 b 10 20 60 . . . 90 44 2

17 baut roda gila panjang 1 b 20 . 40 . . 10 . 70 80 3

18 baut roda gila pendek 1 b 20 . 40 . . 10 . 70 81 3

19 plat extention las 4 b 20 40 . 60 . 30 . . 150 88 1

20 L untuk motor 2 b 20 . . 60 . . 30 10 . 120 86 2

21 plat dudukan motor 2 b 20 . . 60 30 . . 20 . 130 87 1

22 as sensor 1 b 20 . . 60 . . . 80 82 3

23 L dudukan sensor 2 b 10 . . 60 . . 30 20 . 120 85 1

24 as baut for potong 1 b 10 . . 60 . . . 20 . 90 83 3

25 plat servo motor 1 b 10 . 40 60 . . . . 110 84 2

26 L frame 2 b . . . 80 20 assembling 2 100 7 1,2

1 samping panjang 4 b 10 . . 40 . . . . 50 4 2

2 samping pendek 4 b 10 . . 40 . . . . 50 5 2

3 tengah 2 b 10 . . 40 . . . . 50 6 2

2 Penarik assy 60 wait 2

1 karet diameter 60 2 p . . . part standar

2 peer untuk roll p . . . part standar

3 induction motor 1 p . . . electric

4 belt puley 1 p . . . part standar

5 pasangan puley 1 p . . . part standar

6 magnetik 1 p . . . part standar

7 peer adjuster p . . . part standar

8 penyangga roll karet 2 p . . . cor

9 arm panjang 2 p . . . cor

10 arm pendek 2 p . . . cor

11 blok tail 2 p cor

12 karet potongan 5 p . . . part standar

13 as diameter 20,6 mm 2 b 20 20 80 . . . . 10 . 130 64 2

14 as diameter 13 mm 3 b 20 20 120 . . . . 30 . 190 66 1

15 as diameter 1 inch 2 b 20 20 90 . . . . 10 . 140 65 1

16 L for peer 2 b 20 . 40 . . . 20 . 80 63 2

17 pengait megnet 2 b 20 . . 60 . . . 80 62 1

Catatan but uh ope rato r total waktu Urutan pengerj aan SPT dikerja kan pada operat or -P e ra k it a n ( m e n it ) U n it S u b U n it 1 S u b U n it 2 S u b U n it 3 S u b U n it 4 Nama komponen ju m la h p e sa n ( p ) / b u a t (b ) p e rs ia p a n m a te ri a l (m e n it )

Waktu proses (machining) (menit)

79

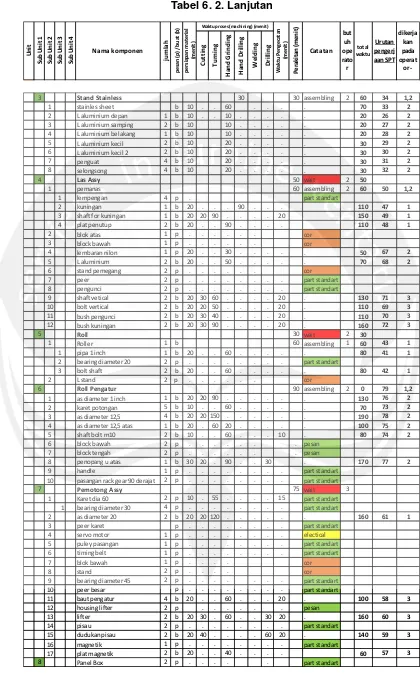

Tabel 6. 2. Lanjutan

C u tt in g T u rn in g H a n d G ri n d in g H a n d D ri ll in g W e ld in g D ri ll in g Catatan but uh ope rato r total waktu Urutan pengerj aan SPT dikerja kan pada operat or -P e ra k it a n ( m e n it ) U n it S u b U n it 1 S u b U n it 2 S u b U n it 3 S u b U n it 4 Nama komponen ju m la h p e sa n ( p ) / b u a t (b ) p e rs ia p a n m a te ri a l (m e n it )

Waktu proses (machining) (menit)

W a k tu P e n g e ca ta n (m e n it )

3 Stand Stainless 30 30 assembling 2 60 34 1,2

1 stainles sheet b 10 . . 60 . . . . 70 33 2

2 L aluminium depan 1 b 10 . . 10 . . . 20 26 2

3 L aluminium samping 2 b 10 10 . . . 20 27 2

4 L aluminium belakang 1 b 10 10 . . . 20 28 2

5 L aluminium kecil 2 b 10 20 . . . 30 29 2

6 L aluminium kecil 2 2 b 10 20 . . . 30 30 2

7 penguat 4 b 10 20 . . . 30 31 2

8 selongsong 4 b 10 20 . . . 30 32 2

4 Las Assy 50 wait 2 50

1 pemanas 60 assembling 2 60 50 1,2

1 lempengan 4 p . part standart

2 kuningan 1 b 20 . . . 90 . . . 110 47 1

3 shaft for kuningan 1 b 20 20 90 . . . . 20 150 49 1

4 plat penutup 2 b 20 . . 90 . . . . 110 48 1

2 blok atas 1 p . . . cor

3 block bawah 1 p . . . cor

4 lembaran nilon 1 p 20 . . 30 . . . 50 67 2

5 L aluminium 2 b 20 . . 50 . . . 70 68 2

6 stand pemegang 2 p . . . cor

7 peer 2 p . . . part standart

8 pengunci 2 p . . . part standart

9 shaft vetical 2 b 20 30 60 . . . . 20 . 130 71 3

10 bolt vertical 2 b 20 20 50 . . . . 20 . 110 69 3

11 bush pengunci 2 b 20 30 40 . . . . 20 . 110 70 3

12 bush kuningan 2 b 20 30 90 . . . . 20 . 160 72 3

5 Roll 30 wait 2 30

1 Roller 1 b 60 assembling 1 60 43 1

1 pipa 1 inch 1 b 20 . . 60 . . . 80 41 1

2 bearing diameter 20 2 p . . . part standart

3 bolt shaft 2 b 20 . . 60 . . . 80 42 1

2 L stand 2 p . . . cor

6 Roll Pengatur 90 assembling 2 0 79 1,2

1 as diameter 1 inch 1 b 20 20 90 . . . 130 76 2

2 karet potongan 5 b 10 . . 60 . . . 70 73 2

3 as diameter 12,5 4 b 20 20 150 . . . 190 78 2

4 as diameter 12,5 atas 1 b 20 . 60 20 . . . 100 75 2

5 shaft bolt m10 2 b 10 . . 60 . . . 10 . 80 74 2

6 block bawah 2 p . . . pesan

7 block tengah 2 p . . . pesan

8 penopang u atas 1 b 30 20 . 90 . . 30 . 170 77 2

9 handle 1 p . . . part standart

10 pasangan rack gear 90 derajat 2 p . . . part standart

7 Pemotong Assy 75 wait 3

1 Karet dia 60 2 p 10 . 55 . . . . 15 part standart

1 bearing diameter 30 4 p . . . part standart

2 as diameter 20 2 b 20 20 120 . . . 160 61 1

3 peer karet p . . . part standart

4 servo motor 1 p . . . electical

5 puley pasangan 1 p . . . part standart

6 timing belt 1 p . . . part standart

7 blok bawah 1 p . . . . cor

8 stand 2 p . . . . cor

9 bearing diameter 45 2 p . . . part standart

10 peer besar p . . . part standart

11 baut pengatur 4 b 20 . . 60 . . . 20 . 100 58 3

12 housing lifter 2 p . . . pesan

13 lifter 2 b 20 30 . 60 . . 30 20 . 160 60 3

14 pisau 2 p . . . part standart

15 dudukan pisau 2 b 20 40 . . . . 60 20 . 140 59 3

16 magnetik 1 p . . . part standart

17 plat magnetik 2 b 20 . . 40 . . . . 60 57 3

80

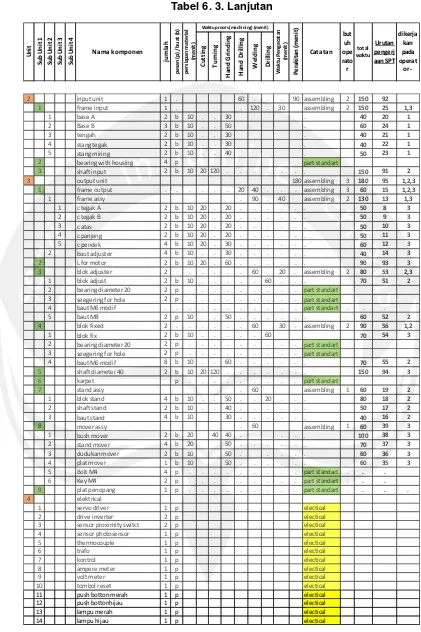

Tabel 6. 3. Lanjutan

C u tt in g T u rn in g H a n d G ri n d in g H a n d D ri ll in g W e ld in g D ri ll in g Catatan but uh ope rato r total waktu Urutan pengerj aan SPT dikerja kan pada operat or -P e ra k it a n ( m e n it ) U n it S u b U n it 1 S u b U n it 2 S u b U n it 3 S u b U n it 4 Nama komponen ju m la h p e sa n ( p ) / b u a t (b ) p e rs ia p a n m a te ri a l (m e n it )

Waktu proses (machining) (menit)

W a k tu P e n g e ca ta n (m e n it )

2 input unit 1 . 60 . . . 90 assembling 2 150 92

1 frame input 1 . . 120 . 30 assembling 2 150 25 1,3

1 base A 2 b 10 . . 30 . 40 20 1

2 Base B 3 b 10 . . 50 . 60 24 1

3 tengah 2 b 10 . . 30 . 40 21 1

4 stang tegak 2 b 10 . . 30 . 40 22 1

5 stang miring 2 b 10 . . 40 . 50 23 1

2 bearing with housing 4 p part standart

3 shaft input 2 b 10 20 120 . . . 150 91 2

3 output unit 180 assembling 3 180 95 1,2,3

1 frame output . . . 20 40 . . . assembling 3 60 15 1,2,3

1 frame assy . 90 . 40 assembling 2 130 13 1,3

1 c tegak A 2 b 10 20 . 20 . . . 50 8 3

2 c tegak B 2 b 10 20 . 20 . . . 50 9 3

3 c atas 2 b 10 20 . 20 . . . 50 10 3

4 c panjang 2 b 10 20 . 20 . . . 50 11 3

5 c pendek 4 b 10 20 . 30 . . . 60 12 3

2 baut adjuster 4 b 10 . . 30 . . . 40 14 3

2 L for motor 2 b 10 20 . 60 . . . 90 93 3

3 blok adjuster 2 . . . 60 20 . assembling 2 80 53 2,3

1 blok adjust 2 b 10 . . . 60 . . . 70 51 2

2 bearing diameter 20 2 p . . . part standart

3 seegering for hole 2 p . . . part standart

4 baut M6 modif . . . . .. . . part standart . . .

5 baut M8 2 p 10 . . 50 . . . 60 52 2

4 blok fixed 2 . . . 60 30 . assembling 2 90 56 1,2

1 blok fix 2 b 10 . . . 60 . 70 54 3

2 bearing diameter 20 2 p . . . part standart

3 seegering for hole 2 p . . . part standart

4 baut M6 modif 8 b 10 . . 60 . . . 70 55 2

5 shaft diameter 40 2 b 10 20 120 . . . 150 94 3

6 karpet p . . . part standart

7 stand assy . 60 assembling 1 60 19 2

1 blok stand 4 b 10 . . 50 . . 20 . . . 80 18 2

2 shaft stand 2 b 10 . . 40 . . . 50 17 2

3 baut stand 4 b 10 30 . . . 40 16 2

8 mover assy . 60 assembling 1 60 39 3

1 bush mover 2 b 20 40 40 . . . . 100 38 3

2 stand mover 4 b 20 50 . . . 70 37 3

3 dudukan mover 2 b 10 50 . . . 60 36 3

4 plat mover 1 b 10 50 . . . 60 35 3

5 Bolt M4 4 p . . . part standart . . .

6 Key M4 2 p . . . part standart . . .

9 plat penopang 1 p . . . part standart . . . .

4 elektrical

1 servo driver 1 p electical

2 drive inverter 2 p electical

3 sensor proximity switct 2 p electical

4 sensor photosensor 1 p electical

5 thermocouple 1 p electical

6 trafo 1 p electical

7 kontrol 1 p electical

8 ampere meter 1 p electical

9 volt meter 1 p electical

10 tombol reset 1 p electical

11 push botton merah 1 p electical

12 push bottonhijau 1 p electical

13 lampu merah 1 p electical

81

DAFTAR PUSTAKA

Alpriesta (2013). Metode

Lot Splitting

dan

Earliest Dua Date

(EDD) dalam

pembuatan prosedur penjadwalan guna meminimasi keterlambatan

pada PT Bejana Mas Perkasa, Nanggulan- Kulon Progo, Yogyakarta

(Skripsi). Fakultas Teknologi Industri, Universitas Atma Jaya

Yogyakarta, Yogyakarta.

Baker, K.R, (1974).

Introduction to Sequenching and Scheduling

, John wiley &

Son, New York.

Baker, Kennenth R., Trietsch. (2009).

Principles of Sequencing and Scheduling.

America : John Wiley & Sons, Inc.

Bedworth, David D., Bailey, James E. (1987

). Integrated Production Control

Systems

. Singapore: John Wiley and Sons Inc.

Bedworth, David D. & Cao, Jing. (2002).

Flow Shop Scheduling in Serial

MultiProduct Processes With Transfer and set-up Times

. USA:

Department of Industrial Engineering, Arizona State University.

Conway, Richard W., Maxwell, William L., Miller, Louis W. (2001).

Theory of

Scheduling.

America : Addison-Wesley Publishing Company

.

Educooling.

(2015).

BOM

(Bill

Of

Material).

27

Mei

2016.

educooling.com/2016/01/12/bill-of-material-bom/

Fauzie (2011). Penjadwalan Proses Persiapan Tenun di Departemen Weaving PT

Kusumahadi Santosa Surakarta (Skripsi). Fakultas Teknologi Industri,

Universitas Atma Jaya Yogyakarta, Yogyakarta.

Ginting, R. (2009). Penjadwalan Mesin. Grahailmu: Jogjakarta.

Hery, (2015). Gambar Teknik Kupas Tuntas Dasar Pengertian dan Fungsinya, 27

Mei 2016,

www.ilmucad.com/2015/12/gambar-teknik-pengertian-dan-fungsinya.html

Kamnisky, P., dan Kaya, O. (2008).

Scheduling and Due-date Quotation in a

Make-to-Order Supply Chain

. Naval Research Logistic 55, 444-458.

Morton, Thomas E., Pentico, David W. (2001).

Heuristic Scheduling Systems.

82

Nahmias, S. ,(1997).

Production and Operation Analysis

. New York, McGraw-Hill.

Pinedo, M & Chao, (1999).

“Operation Scheduling with Applications in

Manufacturing and Services”, McGraw-Hill, New York.

Rudyanto dan Arifin (2010). Penerapan Metode Earliest Due Date pada

Penjadwalan Produksi Paving pada CV. Eko Joyo (Jurnal). Jurusan

Sistem Informasi, Sekolah Tinggi Managemen Informatika dan Teknik

Komputer Surabaya.

Sandianto (2014). Analisis Penjadwalan Produksi di Bengkel Knapot AMAN

Purbalingga (Skripsi). Fakultas Teknologi Industri, Universitas Atma

Jaya Yogyakarta, Yogyakarta.

77

0

11

30

Drawn by

:

Robertus David P.

Reg. Nr.

:

141608109

Date

:

19-05-2016

Checked by :

Scale :

1:10

Unit :

mm

Material :

Sign :

Operation

Dwg. Nr.

SN. NS.

Rep. by.

Rep.

Origin.

Output Unit

A3

1200

Drawn by

: Robertus David P.

Reg. Nr.

: 141608109

Date

: 19-05-2016

Checked by :

Scale : 1:10

Unit : mm

Material :

Sign :

Operation

Dwg. Nr.

SN. NS.

Rep. by.

Rep.

Origin.

Input Unit

A4

Pieces

Description

Item

Material

Dimension

Remarks

Frame Input

Bearing with Housing

Shaft Input

Hollow 50x50x2,3

Purchased

-850

40

0

58

Drawn by

:

Robertus David P.

Reg. Nr.

:

141608109

Date

:

19-05-2016

Checked by :

Scale :

1:20

Unit :

mm

Material :

Sign :

Operation

Dwg. Nr.

SN. NS.

Rep. by.

Rep.

Origin.

Proses Unit

A3

Pieces

Description

Item

Material

Dimension

Remarks

20

75

1212

15

Drawn by

:

Robertus David P.

Reg. Nr.

:

141608109

Date

:

19-05-2016

Checked by :

Scale :

1:20

Unit :

mm

Material :

Sign :

Operation

Dwg. Nr.

SN. NS.

Rep. by.

Rep.

Origin.

Mesin Las Potong Plastik

A3

Pieces

Description

Item

Material

Dimension

Remarks

12

10

3200

15