GREEN SUPPLY CHAIN MANAGEMENT IN INDONESIAN

CRUMB RUBBER FACTORIES:

DESIGNING STRATEGIES TOWARDS IMPLEMENTATION

TRI SUSANTO

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY BOGOR

DECLARATION OF THESIS, SOURCES OF INFORMATION

AND DELEGATION OF COPYRIGHT

I hereby truthfully stated that all of statement and data in my thesis which

is entitled “Green Supply Chain Management in Indonesian Crumb Rubber

Factories: Designing Strategies towards Implementation” is my original work that

also the results of the study for my thesis under the supervision and advice by the respected advisors committee, except for those which are indicated clearly as literatures cited.This thesis also submitted in Entrepreneurial Commercialization and Innovation Centre, The University of Adelaide, since The Double Degree Program between IPB and The University of Adelaide. Despite of that, this thesis has not been submitted to any tertiaru institution nor published before.

I hereby delegate the copyright of my thesis to the Bogor Agricultural University.

Bogor, July 2015

SUMMARY

Tri Susanto, 2015. Green Supply Chain Management in Indonesian Crumb Rubber Factories: Designing Strategies towards Implementation. ( Marimin, Supervisor and Suprihation, co-supervisor).

Green supply chain management (GSCM) is a new technical innovation that has been touted to improve supply chain performance as well as minimize the environmental impacts. Unfortunately, this concept has not been entirely implemented in Indonesian rubber industries. The primary objective of this research were identify current green practices, to explore influencing factors and formulate green approach as well as select strategies to accelerate GSCM

implementation in Indonesia’s crumb rubber factories (CRFs). The case studies

were conducted in two private CRFs. The data were collected through semi-structure interviews with stakeholders, field observation, and examination of QMS documents. The GSCM model for CRFs was constructed, and the influencing factors were analyzed through thematic analysis through the lens of innovation diffusion theory. The Analytical Hierarchy Process was employed to prioritize the strategies. The findings suggest CRFs have not committed themselves to integrating the environmental management intentionally into the current production system; their motive of green efforts may be more to maximize efficiency and reduce the cost production rather than to be more environmental friendly. The results reveal that technological, organizational and environmental factors may influence the decision on GSCM adoption. In addition, green procurement which emphasizes increasing the quality of raw material from the rubber block supplier and educate farmers or supplier are the prioritized green approach to accelerate GSCM implementation. The practical results of this research provide valuable insights and guidelines for CRFs to integrate the green concepts into operational business strategy.

RINGKASAN

Tri Susanto, 2015. Green Supply Chain Management in Indonesian Crumb Rubber Factories: Designing Strategies towards Implementation. ( Marimin, Ketua Komisi Pembimbing and Suprihation, Anggota Komisi Pembimbing).

Managemen rantai pasok hijau adalah inovasi teknis baru yang telah dipercaya untuk meningkatkan kinerja supply chain serta meminimalkan dampak lingkungan. Sayangnya, konsep ini belum sepenuhnya diterapkan di industri karet Indonesia. Tujuan utama dari penelitian ini adalah mengidentifikasi praktek hijau di rantai pasok saat ini, mengeksplorasi faktor yang mempengaruhi dan merumuskan pendekatan hijau serta memilih strategi untuk mempercepat implementasi rantai pasok hijau di pabrik-pabrik karet remah di Indonesia. Studi kasus dilakukan di dua pabrik karet remah swasta. Data dikumpulkan melalui wawancara semi-struktur dengan para pemangku kepentingan, observasi lapangan, dan pemeriksaan dokumen Sistem Managemen Mutu (ISO 9001:2008). Model Rantai Pasok hijau untuk pabrik karet remah di desain dan disesuaikan, dan faktor-faktor yang mempengaruhi dianalisis melalui analisis tematik melalui lensa teori innovasi difusi. Analytical Hierarchy Process digunakan untuk memprioritaskan strategi. Temuan menunjukkan bahwa pabrik karet remah belum berkomitmen untuk mengintegrasikan pengelolaan lingkungan secara sengaja ke dalam sistem produksi saat ini; Motif mereka mungkin lebih untuk memaksimalkan efisiensi dan mengurangi biaya produksi daripada menjadi lebih ramah lingkungan. Hasil penelitian ini menunjukkan bahwa teknologi, organisasi dan faktor lingkungan dapat mempengaruhi keputusan adopsi konsep rantai pasok hijau. Selain itu, pembelian yang lebih ramah lingkungan yang menekankan peningkatan kualitas bahan baku dari pemasok bokar dan mendidik petani atau pemasok adalah pendekatan yang diprioritaskan untuk mempercepat implementasi rantai pasok hijau. Hasil praktis penelitian ini memberikan wawasan berharga dan pedoman untuk pabrik karet remah untuk mengintegrasikan konsep berwawasan ramah lingkungan ke dalam strategi operasional bisnis

Copyright ©2015 by Bogor Agricultural University

All rights reserved

1. No part or all of this thesis excerpted without inclusion or mentioning the sources

a. Excerption only for research and education use, writing for scientific papers, reporting, critical writing or reviewing of a problem

b. Excerption does not inflict a financial loss in the proper interest of Bogor Agricultural University

A thesis submitted to

Graduate School of Bogor Agricultural University, In partial fulfilment of the requirements for the degree of

Master in Science in Agro industrial Technology

GREEN SUPPLY CHAIN MANAGEMENT IN INDONESIAN

CRUMBR RUBBER FACTORIES:

DESIGNING STRATEGIES TOWARDS IMPLEMENTATION

GRADUATE SCHOOL

BOGOR AGRICULTURAL UNIVERSITY BOGOR

2015

Thesis Tittle : Green Supply Chain Management in Indonesian Crumb Rubber Factories: Designing Strategies towards Implementation.

Nama : Tri Susanto

NRP : F351137111

Approved by Supervisor Comitee

Prof Dr Ir Marimin, MSc Chairman

Prof. Dr. Ir. Suprihatin Member

Acknowledged by

Head of Study Program of Agro Industrial Technology

Prof. Dr. Ir. Machfud, MS

Dean of Graduate School

Dr Ir Dahrul Syah, MScAgr

ACKNOWLEDGEMENTS

Praise and gratitude to Allah SWT, the almighty, the most beneficent and the most merciful, Thanks, Finally, the author could complete this thesis as a partial requirement to get Master Science degree in IPB. In addition, I would also express my gratitude to many people who give support, knowledge, information

and helps during writing this thesis. The title of this thesis is “Green Supply Chain Management in Indonesian Crumb Rubber Factories: Designing Strategies

towards Implementation”.

During this study, Prof. Dr. Ir. Marimin, M.Sc, chairman of supervisor committee has patiently guided and instructed the green supply chain management concept in this thesis, while Prof. Dr. Ir. Suprihation has supported in terms of environmental aspect in the rubber industries. In addition, Dr Barry Elsey has helped in research methodology, particularly on qualitative approach in this research. I would also say many thanks for the insights, valuable information and

also incredible knowledge for Dr. Ron Grill, Dr. Allan O’connor, and Amina

Omarova during the study in The University of Adelaide.

Unforgettable thanks to all of my respondents including two crumb rubber factories in South Sumatera, BPTK, Gapkindo, BIPA, Ministry of Industry, BLH and etc. Working with all of the respondents is such an endless journey, thanks for sharing the knowledge and information. Hopefully, the thesis would be beneficial for the development of crumb rubber industries in Indonesia.

During writing this thesis in Adelaide, Ketut’s Kitchen was also helpful in

supporting my daily life; it was very memorable working with the KK teams. Many thanks also for DD students and Nexus’s community who inspire me in every aspect of the study and life. It is such a golden opportunity to have an academic journey for almost 2 years with all of you guys.

Finally, proudly, big thanks for my great mother and father who teach me everything; this thesis is dedicated for both of you.

Bogor, July 2015

i

Significance and Contribution to the Field 4

2 LITERATURE REVIEW 5 Innovation Decision Process of GSCM ... 8

Factors influencing the GSCM adoption... 9

3 METHODOLOGY 11 Introduction 11 Setting 11 Participants 11 Measurement Instruments & Data Collection Procedures 12 Data Analysis 13 Validity 13 4 FINDINGS AND DISCUSSION 14 Crumb Rubber Supply Chain 14 Crumb Rubber Industries in South Sumatera ... 14

Crumb Rubber Specification ... 14

Crumb Rubber Processing ... 15

Current Green Practices 16

Best Practices of GSCM Adoption 24 Strategies based on Analytical Hierarchy Process ... 24

ii

Organizational Learning ... 30

Team Project ... 32

5 CONCLUSION AND RECOMMENDATION 33 Conclusion 33 Recommendations 34 Strategic ... 34

Policy-making ... 34

Theory-building ... 34

Future Research Direction ... 34

REFERENCE 35

APPENDICES 39

BIOGRAPHY 66

LIST OF FIGURES

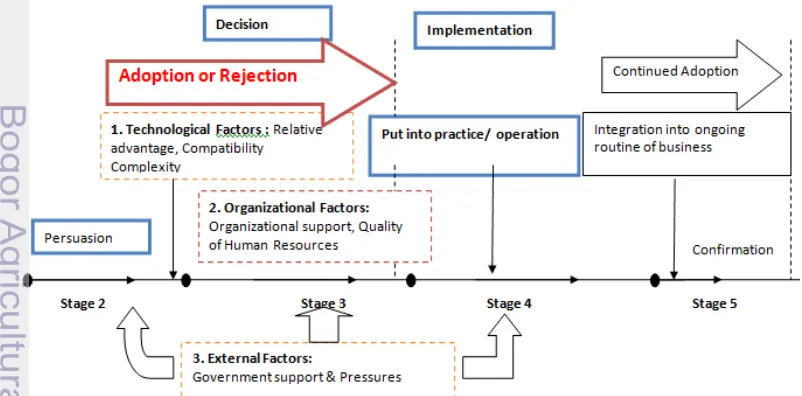

Figure 1. Generalized Supply Chain of Crumb Rubber in Indonesia (Adapted from the studies by (Arifin, 2005; M Arif Darmawan, Wiguna, & Marimin, 2012; M. A. D. Marimin, Muhammad Panji ; Machfud, Bangkit ; Islam Fajar Putra, Bangkit ; Wiguna, Bangkit, 2014; Wibawa, Hendratno, & van Noordwijk, 2005)) 3 Figure 2 Model of GSCM Implementation in CRFs (Adopted from (Elting, 2009; Hervani et al., 2005; Ho, Shalishali, Tseng, & Ang, 2009; M. A. D. Marimin, Muhammad Panji ; Machfud, Bangkit ; Islam Fajar Putra, Bangkit ; Wiguna, Bangkit, 2014; Srivastava, 2007; Zhu, Sarkis, & Lai, 2008) ) 7 Figure 3 Innovation decision process (IDP) towards adoption of green in the

supply chain management (adapted from (Rogers, 2003) 9

Figure 4 Data Collection and Analysis 11

Figure 5 The Production process of Crumb Rubber 16

Figure 6 Influencing factors on GSCM adoption process in CRFs 21

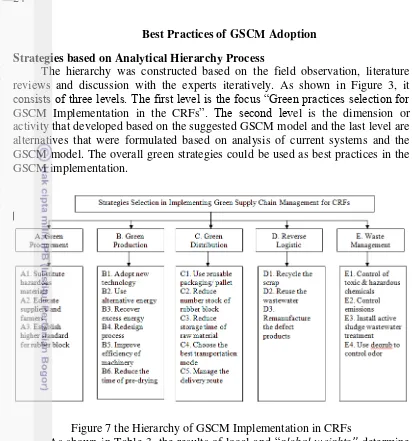

Figure 7 the Hierarchy of GSCM Implementation in CRFs 24

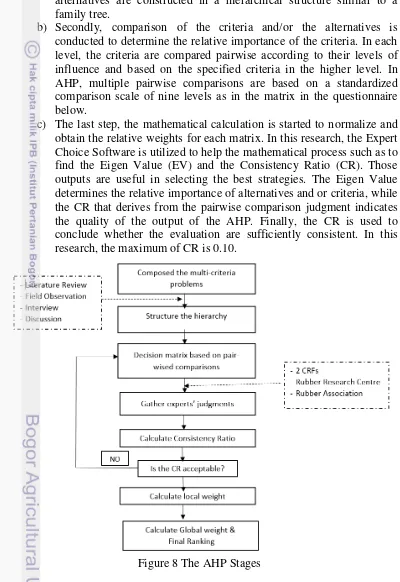

Figure 8 The AHP Stages 42

Figure 9 The influencing factors and IDP Process of GSCM adoption in CRFs 48 Figure 10 Result of Pairwise Comparison from 1st Expert Judgment (Senior Researcher in Indonesian Rubber Research Centre-BPTK Bogor) 58 Figure 11 Result of Pairwise Comparison from 2nd Expert Judgment (Senior Researcher in Indonesian Rubber Research Centre-BPTK Bogor) 59 Figure 12 Result of Pairwise Comparison from 3rd Expert Judgment (Secretary of

Indonesian Rubber Entreprise Association in Palembang) 60

Figure 13 Result of Pairwise Comparison from 4th Expert Judgment (Senior Researcher in Institute for Rubber Research in Sembawa, Palembang) 61 Figure 14 Result of Pairwise Comparison from 5th Expert Judgment (Head of

Factory A) 62

Figure 15 Result of Pairwise Comparison from 6th Expert Judgment (Head of

Factory B) 63

iii

LIST OF TABLES

Table 1 List of Respondents 12

Table 2 Crumb Rubber Specification of Indonesia, Malaysia and Thailand 15

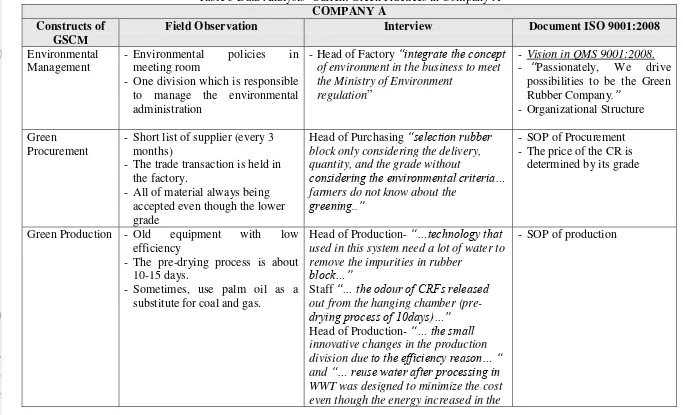

Table 3 Current Green Practices in Each Company 17

Table 4 Ranking of Green Strategies based on AHP 25

Table 5 Data Analysis- Current Green Practices in Company A 44 Table 6 Data Analysis- Current Green Practices in Company B 46 Table 8 Thematic Analysis - Factor Influencing GSCM Adoption 49

LIST OF APPENDICES

Appendix 1- Interview Questions and Framework for Field Observation 39

A. Framework for Field Observation ... 39

B. GSCM Practices (Checking List) ... 39

C. List of Questions During Field Observation ... 40

D. List of Questions (Interview) ... 40

Appendix 2- AHP 41 Analytical Hierarchy Process - Definition ... 41

Appendix 4 – Data Analysis 43 Research Question 1 ... 43

Research Question 2 ... 48

Research Question 3 ... 54

1

1 INTRODUCTION Background

Indonesia is the second largest natural rubber producer in the world, producing about 28% of total production (IRSG, 2014). Approximately 85% of the natural rubber from the plantation is processed as a crumb rubber and exported to other countries like Japan, USA, China, and Australia (Barlow, Jayasuriya, & Tan, 2014). Crumb rubber (CR)1 is a featured export rubber product of Indonesia which has a significant role to play in the national economic development and poverty alleviation. Based on Trade Ministry data, the value of crumb rubber exports was about $9.39 billion USD in 2013, amounting to approximately 7% of

country’s overall exports. Compared to concentrated latex and Ribbed Smoked Sheet (RSS)2, the market demand of CR has increased significantly. The down-stream rubber manufacturers prefer use the CR as their raw material because the easy storability and the physio-chemical and mechanical properties of crumb rubber. Because of this increase, consequently, CRFs have had adverse effects on the environment, particularly due to their waste disposal management.

Based on the last annual assessment result by the Ministry of Environment, about 28 of 150 CRFs are categorized as “red label performers” and 45 of 150 CRFs are in “blue level performers” (Ministry_of_Environment, 2014). Red label means that the management of hazardous and toxic material, wastewater, solid waste, and gas emission in CRFs is well below the green level of government regulation standards and are being threatened with closure as a result. Meanwhile, the blue is a level between red and green levels. This under-performed environmental performance has caused serious ecological problems such as water contamination, air pollution, and bad odours surrounding the CRFs. It seems that the environmental performance in mostly Indonesian CRFs is still under-performed. An empirical study by Arifin (2005) reports that the low efficiency of the supply chain mechanism, and low product quality of the CR is caused by the complexity of the marketing channel from plantation to CR processing. This low economic performance also leads to deteriorate the environmental condition along the supply chain.

Many researchers have made recommendations to overcome the environmental issues in CRFs. For instance, Utomo, Hasanuddin, and Suroso (2010) suggest re-designing the production process in order to minimize the amount of wastewater. Another research by (Muhammad Arif Darmawan et al., 2014) mentions that the best strategy for green productivity improvement in natural rubber processing is production optimization. This optimization primarily focuses on adopting new technology to reuse water that leads to improve the

1

Crumb rubber (CR) is a typical rubber product from coagulated latex that is processed by washing, drying, heating and pressing without additional chemicals. Crumb rubber is an intermediate rubber product for other rubber industries like tires, balls, engine mountings, gaskets, etc. Every rubber producer has their quality standard such as SIR (Standard Indonesian Rubber) and STR (Standard Thailand Rubber). The CR specification of each country is different in some parameters, but the standards are accepted as export requirements(Muhammad Arif Darmawan, Putra, Wiguna, & Marimin, 2014).

2

production efficiency as well as obtain higher environmental performance. However, the studies only focused on the upstream practices in RSS and natural rubber factories rather than the CRFs. In addition, previous studies only emphasized the processing plant and the production technology, while the researchers have not yet considered the entire supply chain activities of natural rubber because the concept of greening the supply chain is relatively new in Indonesian rubber industries.

The issue of environmental pollution accompanying industrial development ought to be addressed by the supply chain management that considers the material and information flows as well as the networking of certain industries to be environmentally friendly. Green Supply Chain Management (GSCM) is the merging of environmental and supply chain management concepts. This concept could be useful to improve the effectiveness of the supply chain (economic profit) and also reduce negative environmental impacts (Srivastava, 2007). The other purpose of GSCM is environmental consciousness in each step of the supply chain through efficiently using materials and energy and minimizing waste. Many industrial sectors like manufacturing, logistics, electronic and assembling in some countries have initiated to adopt the GSCM in their business strategy. For instance, Taiwan (Chien & Shih, 2007), India (Diabat & Govindan, 2011), China (Chien & Shih, 2007) and Brazil (McCormack, Bronzo Ladeira, & Paulo Valadares de Oliveira, 2008). Nevertheless, the GSCM implementation in agricultural based industries has not been explored widely owing to the supply chain mechanism of agricultural products being complex and highly uncertain compared to manufacturing products. This complexity is because the agro-product characteristics are perishable, seasonal and bulky and also the chain has many tiers (as shown in Figure 1).

Bearing in mind the importance of CRFs for the Indonesian economy and the environmental deterioration, there is a growing need to determine a more effective way of solving the environmental problems as well as to improve the CR competitiveness in the global market. However, the GSCM adoption in CRFs has not been widely explored, and the practices have not yet developed in Indonesian rubber industries. Therefore, there is an urgent need to design a strategy that will accelerate innovation diffusion of GSCM in CRFs to address the ecological issues, while at the same time improving the CR competitiveness in the global market.

Statement of the Problem

3

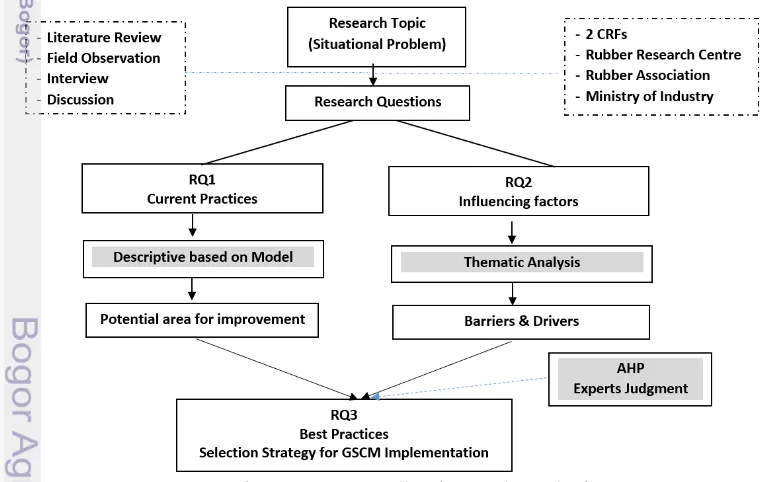

Research Questions The problem areas lead to main research questions:

RQ1: What are the current practices of GSCM in CRFs? How effective are they in minimizing the environmental impact on CRF activities?

RQ2: What are the factors that may influence the adoption of innovative green concepts into the existing crumb rubber supply chain?

RQ3: What kind of green supply chain activities may enhance the implementation of GSCM? What best practices may be useful (simply implemented in CRFs)?

Figure 1. Generalized Supply Chain of Crumb Rubber in Indonesia (Adapted from the studies by (Arifin, 2005; M Arif Darmawan, Wiguna, & Marimin, 2012; M. A. D. Marimin, Muhammad Panji ; Machfud, Bangkit ; Islam Fajar Putra, Bangkit ; Wiguna, Bangkit, 2014; Wibawa, Hendratno, & van Noordwijk, 2005))

Purpose of The Study

The purpose of this research is to identify the current GSCM practices and to explore factors influencing GSCM adoption as well as formulate strategies to improve the GSCM implementation among CRFs in Indonesia.

4

Significance and Contribution to the Field

Previous studies only focused on the upstream area of the supply chain, comprising the plantation, RSS, and rubber block3 (M. A. D. Marimin, Muhammad Panji ; Machfud, Bangkit ; Islam Fajar Putra, Bangkit ; Wiguna, Bangkit, 2014; Wibawa et al., 2005). The studies in innovation adoption of GSCM in a context of the Indonesian CRFs have not been broadly developed yet, and the implications regarding the diffusion of the various GSCM practices are not well understood by stakeholders. Unfortunately, the evidence of GSCM implementation and the operational best practices for CRFs is very limited. Thus, the specific research that focuses on how innovation adoption of GSCM in CRFs is critical.

This current study contributes to green practitioners and stakeholders by providing evidence of GSCM implementation in Indonesia CRFs. The research would not contribute new knowledge to the GSCM theory rather it would offer a relevant and suitable model of GSCM implementation for CRFs. The other research findings include the factors influencing GSCM adoption which would be useful for the stakeholders in designing the greening action and strategies towards the implementation. In addition, the outcome of this research may provide new and practical guidance for applying the constructed model of GSCM in the real world. The contribution of this research probably would give a definite advantage to the process of GSCM innovation diffusion among agro-based industries in Indonesia.

3

5

2 LITERATURE REVIEW

Previous researchers have approached GSCM from many different disciplines such as management, EMS, logistics, network analysis, human resources, and GSCM performance measurement. Meanwhile, there has been little research focus on the GSCM innovation diffusion. In order to implement GSCM entirely, the adopters who implement the concept should know what GSCM is. Therefore, the literature review starts with a GSCM definition and its importance for factories, and then follows by the justification of GSCM model that is relevant to CRFs condition in Indonesia. Furthermore, the literature review also addresses the innovation-decision process of GSCM adoption.

Green Supply Chain Management GSCM definition

Green issues have been popular due to the pressures from regulation, market, NGO, and suppliers. Therefore, adoption of ecological mindset into the business activities has become a crucial part of corporate strategies in sustaining the competitiveness in the global market (Zhu, Sarkis, & Geng, 2005). GSCM is an incredible concept to instil environmental thinking in traditional supply chain (Beamon, 1999). Compared to the traditional supply chain, the GSCM allows collaboration among the members non-linearly to share information and materials (Srivastava, 2007). This collaboration leads supply chain members to work effectively to achieve higher level of greenness (Beamon, 1999; Bhetja, Babbar, Singh, & Sachdeva, 2011; Walton, Handfield, & Melnyk, 1998). In the context of CRFs, the green adoption primarily stresses in using materials and energy efficiently while minimizing waste in each step of CR production.

Importance of GSCM

GSCM is necessary because it supports the saving of resources and energy, cutting down costs as well as providing profitable pollution prevention (Diabat & Govindan, 2011; Rao, 2007; Srivastava, 2007). The external drivers such as customer demand, NGO, business partners, neighbors, government regulation and investors have a significant impact on how companies see how critical GSCM adoption is in their operational and strategic business management. For instance, green image and eco-label have influenced the customers’ decision to buy products. Furthermore, NGOs, WWF and Green Peace have campaigned greening industries to society by exposing companies that are potentially harming the environment. These phenomena could affect the customer’s behavior. A strong internal driver is the willingness to improve risk management due to potential interruptions in the supply chain. Another internal driver is the collaboration with suppliers or other stakeholders to find alternative materials, technology, and equipment in order to minimize environmental impacts more efficiently (Johansson & Winroth, 2009).

6

follows (Eltayeb, Zailani, & Ramayah, 2011; Johansson & Winroth, 2009; Srivastava, 2007):

a) reducing the production cost,

b) enhancing the product value to customer, c) increasing the sales,

d) obtaining positive media attention, e) improving operational efficiencies,

f) Increasing the ratings from investment firms.

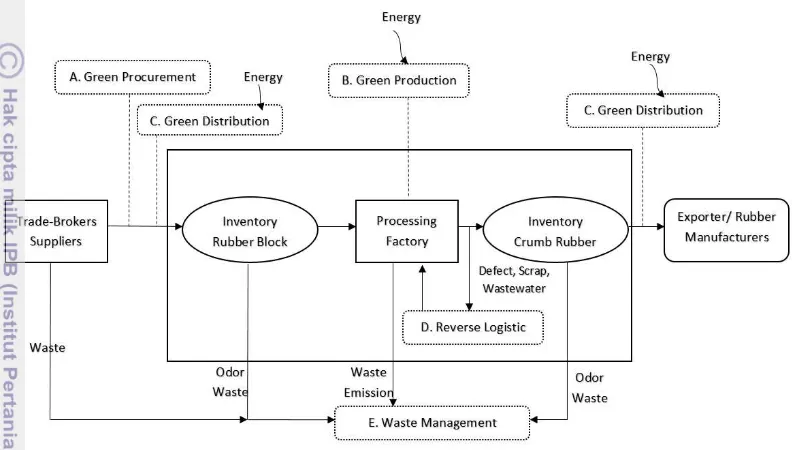

GSCM Model for CRFs

Various models of GSCM are typically fitted with certain industries or products (Andiç, Yurt, & Baltacıoğlu, 2012; Henriques & Sadorsky, 2007; Srivastava, 2007). For instance, Hervani, Helms, and Sarkis (2005) define GSCM in manufacturing companies as a sequence of activities from green purchasing, green manufacturing / material management, green distribution / marketing, and reverse logistic. In addition, Srivastava (2007) suggests the green product design should be in the model. Meanwhile, Zhu et al. (2005) emphasize the concept of

“closing the loop” in the GSCM implementation, which means the green should be integrated integration from suppliers until the end-customers or buyers.

In this research, the GSCM model is tailored based on the CRFs production system. The suggested GSCM model for CRFs is a series of procurement, production, distribution, reverse logistics, and waste management (as shown in Figure 2); the model excludes product design. The government and buyers establish the specification of crumb rubber so that the companies do not need develop the product specifications. Moreover, based on the CR supply chain mechanism, the marketing and relationship with the end customer is not included

in CRFs scope. Thus, the concepts of “closing the loop” and green marketing are excluded in the GSCM model in CRFs.

a. Green Procurement

The concept green indicates that purchasing should involve reuse, reduction, and recycling activities in the business while the purchasing materials need to have less impact over the whole life cycle (Salam, 2008). Moreover, substituting hazardous materials, establishing environmental standards for suppliers, and improving the quality of raw material are essential practices for green adoption (Min & Galle, 2001; Walton et al., 1998). Traditional companies consider the procurement of raw material or services as supporting activities in achieving profits. Indeed, in CRF, the purchasing of rubber block from suppliers either farmers or middlemen is the vital activity because the quality of raw material influences the production process, and the amount of supply relates closely to lead time for order fulfillment.

b. Green Production

7

chain costs. In the production process of crumb rubber, the primary processes are down-sizing and cleaning the rubber block. Consequently, CRFs consume large quantities of energy and water as well as generate amount of wastewater. In this context, green production in CRFs should be concerned about the amount of energy and water utilization, the quantity of hazardous waste, type of energy sources, and typical technology for the production system.

Figure 2 Model of GSCM Implementation in CRFs (Adopted from (Elting, 2009; Hervani et al., 2005; Ho, Shalishali, Tseng, & Ang, 2009; M. A. D. Marimin, Muhammad Panji ; Machfud, Bangkit ; Islam Fajar Putra, Bangkit ; Wiguna, Bangkit, 2014; Srivastava, 2007; Zhu, Sarkis, & Lai, 2008) )

c. Green Distribution

According to Ho et al. (2009), green distribution could be defined as green packaging and green logistics. Recently, the issue of increasing amounts of solid waste due to the dumping of packaging material has led to the emergence the green packaging concept in the supply chain. The greening packaging can be approached by using green materials, recycling and reusing packaging and coordination with vendors or customers to standardize the packaging to be more environmentally friendly (Dekker, Bloemhof, & Mallidis, 2012; Ninlawan, Seksan, Tossapol, & Pilada, 2010). While the green logistics for raw material and finished goods includes the reduction in energy usage for logistic activities and waste during the process. The current condition of rubber logistics is less organized between stakeholders. In order to implement an interconnected system between government, public and corporate sectors which integrates material and information management of transportation, storage, and delivery, it is necessary to consider an efficient distribution route (Sheu, Chou, & Hu, 2005). In CRF, the distribution activities like warehousing and transporting cause air pollution and odors4 from manufacturing. Therefore, the inventory system in the factory needs

4

8

to be managed deliberately because these activities are primarily odor sources that could cause a serious environmental problem for humans near the location.

d. Reverse Logistics

The reverse logistics concept includes the process of planning, implementing and controlling the using of raw materials so that the value or disposal from the products could be recaptured (Wang, Lai, & Shi, 2011). The other definition of reverse logistic is the systematic process of taking their distributed products for possible recycling, remanufacturing, or disposal. In this research, the reverse logistics focus is on the internal area of the CRFs because crumb rubber is an intermediate product. In addition, collecting product returns from the customers is unlikely as buyers generally accept the product (possibly reducing the price if the quality is poor).

e. Waste Management

The primary goals of waste management are minimizing the amount of disposed material, source reduction, pollution prevention and disposal. Thus, controlling the solid waste, wastewater, and gas emissions as well as handling raw material, products, and defect products are essential to succeed in this goal (Andiç et al., 2012; Rothenberg & Zyglidopoulos, 2007). The waste should be maintained according to the process: reduction, reuse, recycling, energy recovery and finally disposal of the unusable part of the materials (Andiç et al., 2012). In CRFs, the waste management concept would be included in each step of CR processing.

Studies of GSCM practices have been developed for particular industries such as electronic industries in Taiwan (Chen, Shih, Shyur, & Wu, 2012); textile industries in India (Baskaran, Nachiappan, & Rahman, 2012); Chemical and cosmetic sectors in Brazil(de Sousa Jabbour, 2015). Their studies result in different approaches in order to implement the GSCM so that the best practices have been developed based on the nature of the industries and the final product. To illustrate, Andiç et al. (2012) identify waste management as the starting point to adopt green concepts in electrical, electronic equipment industries. Meanwhile, waste minimization plays a crucial role in GSCM implementation in Indian Pharmaceutical Industries (Gangele & Verma, 2011). On the other hand, the result of GSCM adoption observation in 341 Chinese manufacturers implied that internal environmental management and green purchasing should have multifaceted application in GSCM implementation (Zhu et al., 2008). Therefore, the prioritization of GSCM activities and formulating strategies for each activity along the crumb rubber supply chain are necessary to accelerate GSCM adoption in CRFs.

Innovation Diffusion of GSCM Innovation Decision Process of GSCM

9

it is indirectly related to the basic work activities, but more closely to management. While technical innovation pertains to products, services, and production process technology. Adopting green practices involves implementing new or modified processes, techniques and systems to be more environmentally friendly, this adoption behaviour can be said to be a technical innovation process (Henriques & Sadorsky, 2007).

Diffusion is the “process by which innovation is communicated through certain channels over time among the members of a social system” (Rogers, 2003, p. 5). According to Rogers (2010) the four major elements in the diffusion of new ideas are innovation, communication channels, time and context (the social system). GSCM should show five perceived innovation characteristics that determine its rate of adoption; these factors will be explained as the influencing factors in the next section. The third element, time, is involved in the innovation-decision process (IDP). IDP is defined as “the mental process through which an individual (or other decision-making unit) passes from first knowledge of an innovation to forming an attitude toward the innovation, to a decision to adopt or reject, to implementation of the new idea, and to confirmation of this decision” (Rogers, 2010, p. 163). Figure 3 illustrates the process of how innovations are implemented in an organization. As the GSCM concept is fairly new for Indonesian industries, the IDP would be beneficial as framework in diffuse the GSCM among stakeholders. The essential stages in IDP are the knowledge and decision, mainly in which organization considers to adopt or reject the innovation. The last element of innovation diffusion is the social system. This element varies from individuals, informal groups, organizations, and or subsystems. The pattern of the connection and information networking influence how quickly an innovation is diffused and the time of adoption (Valente, 1995).

Figure 3 Innovation decision process (IDP) towards adoption of green in the supply chain management (adapted from (Rogers, 2003)

Factors influencing the GSCM adoption

Many studies have been conducted to analyse the factors affecting green practice adoption in the supply chain. For instance, Chau and Tam (1997) highlighted understanding the factors is valuable for practitioners to implement green practices quickly. Therefore, in this study, influencing factors are explored and analysed to formulate appropriate best practice for implementing GSCM.

10

green manufacturing practices in Taiwan electronic industries. However, the studies are limited to logistic and electronics industries, which is different from processing factories.

Henriques and Sadorsky (2007) Clarifies the changes in organization due to the technical innovation process of adopting the green concepts would not be flow smoothly. GSCM, a new technical innovation, should show the perceived characteristics. This becomes important consideration in the decision stage whether to adopt or to reject the GSCM adoption. However, other possible factors that may affect the decision were also explored in this study. The explanations of GSCM characteristics are described as follows:

1) Relative advantage. Companies are more likely to adopt a new technology that can provide better performance and higher profit than the old technologies (Lin & Ho, 2011).

2) Compatibility. How the whole of GSCM concept fits with the capability that a company already possesses. GSCM should be synchronized with the current production system in CRFs in order for its adoption to succeed. 3) Complexity. Many studies reveal that the complexity of green practices

has negative influences on green adoption for many industries.

4) Trialability. The easier it is to trial, the less uncertainty for companies in adopting the green concept.

11

3 METHODOLOGY Introduction

It is noteworthy that most previous studies conducted on GSCM implementation in various industries has been carried out through the case study methodology. Yin (2011) mentions that a case study methodology enables the use of multifaceted sources of evidence such as document, reports, and especially interviews. Even though the researcher could not control the case, the case would result in deep exploration in a particular case. This study adopted a similar research method with the qualitative approach, using two cases from CRFs in South Sumatera, Indonesia. The study was purposively conducted in two cases studies in two different companies that are the oldest companies (have been operating for about 60 years), but still need improvement in environmental performance. Companies A and B have slight differences in production capacity, processing technology and the number of employees while based on the environmental assessment those companies are in the same level of perceived environmental friendliness. Figure 4 shows how the data were collected and analyzed.

Setting

The research was in South Sumatera province, the highest crumb rubber producer in Indonesia. The data collected from December 2013 until March 2015.

Figure 4 Data Collection and Analysis

Participants

12

employees in the factory. Both companies have implemented the Quality Management System (QMS) based on ISO 9001:2008 since 2004. They are classed in the blue level performance of environmental assessment5. The

document of ISO 9001:2008 is not related to environmental management system, but the reports in controlling the quality of product is documented based on this standard.

Table 1 List of Respondents

No Institution and Respondents Data Collection

1 Company A (heads of the factory, head division of procurement, production, inventory, logistic, environment and quality assurance)

Field observation for 4days (Observation list is in Appendix 1).

Interview @ 60-90 minutes with head of each division.

2 Company B ditto

3 Research Centre for Rubber in Bogor ( 2 researchers)

Semi-structured interview with open ended questions, each respondent is about 60 minutes 4 Research Centre for Rubber in South

Sumatera

(Head office and 1 researcher ) 5 Ministry of Industry (MoI)

(Head Section in Assessment Centre for Green Industry and Environment & Head of Sub-directorate for Agro Industry)

6 Rubber Association South Sumatera, Gabungan Pengusaha Karet Indonesia, GAPKINDO (Secretary). 1 secretary 7 Product Certification Body (BIPA)

(Head office, 2 auditors and 1 researcher)

8 Environmental Agency in South Sumatera

(1 Inspector for CRFs) 9 2 Farmers Musi Banyuasin

Measurement Instruments & Data Collection Procedures

The questionnaire and list of interview questions were formulated based on some literature reviews of GSCM implementation and the condition of CRFs in Indonesia. Academics and experts discussed the content of interview question to improve the precision of some questions. An interview script that had open-ended questions was used; the guideline is in Appendix 1. The semi-structured

13

interviews were personally conducted and recorded, mostly about 30-60 minutes for each respondent; a series of notes was made during the interviews. The interviews were in Indonesian, being the mother language of researchers and respondents; it gives more benefits to the sharing of ideas. In addition, field observation is also helpful in overcoming discrepancies between the interview and the actual condition; this might help uncover behavior of which the participants themselves may not be aware.

Data Analysis

All interviews were audio recorded on tape, and interviews are listened to repeatedly and continually coded as proposed by Creswell (2013). The collected data were organized and coded based on the research questions, and then analysed through thematic analysis. After the coding of the material, some nodes were created and categorized following the already established framework from the literature review. The generated nodes were again refined, and subcategories formed. Data from the field observations and document of ISO 9001:2008 were also used to compare with the results of the interviews. After that, the result was translated into English. The process of data analysis is in Appendix 4.

Selection strategies for GSCM implementation is a complex decision for the organizations. Therefore, Analytical Hierarchy Process (AHP) would be used to prioritize the beneficial strategy that result in a significant impact for CRFs. The AHP was employed by using Expert Choice Software. The hierarchy structure was constructed through the study of the most cited journals, analysing the current system of CRFs, and discussion with experts. The experts are two doctors who are the senior researchers in rubber technology, the head of rubber Research Centre, the secretary of the rubber association in Palembang, and two directors CRF. The pair-wise comparison matrix was judged by six experts. A Consistency Index (CI) which is generated through the calculation in the software was used to control the consistency of experts’ opinion. The description of AHP is in Appendix 2.

Validity

The units of analysis used in this study were two large companies, their current use of GSCM practices and the implementation phase of GSCM practices in the past. Due to the openness and interactivity, interview outcomes might suffer from low reliability, as every interview is different (Creswell, 2013). This research adopts an inductive process that only observed small numbers of samples. The context-bound theory that emerges after or during the research is most likely just valid in these particular circumstances (Creswell, 2013).

14

4 FINDINGS AND DISCUSSION

The participants were asked through semi-structured interviews, and additional data were also collected during field observation. Their responses, which depend on knowledge, experience and insights, were valuable to present the GSCM implementation in CRFs. The result of field observation and check-up ISO 9001:2008 document were useful to find the consistency of the data collected; this was also helpful to get the validity of the research. This chapter presents the findings along with the interpretation and discussion.

Crumb Rubber Supply Chain Crumb Rubber Industries in South Sumatera

Natural rubber industry in Indonesia can be divided into two different type based on owner namely state owned and private owned factories. All state owned industry have their own rubber tree plantation for latex supply, but private owned industry usually buy rubber block from farmers as raw material in crumb rubber production. Hence, the crumb rubber supply chain is like a mutual symbiosis between CRFs and farmers. The detail explanation is shown in Figure 1.

South Sumatera is the highest producer of natural rubber in Indonesia. The plantation area is about 658.812 ha and it produces approximately 470.000 ton rubber annually. The production tends to grow every year (IRSG, 2014). It is about 30 private crumb rubber factories are operated. Most of the CRFs produce technical specification of crumb rubber namely Standard Indonesian Rubber (SIR) 20 and SIR 10. In addition, respondents also stated that CRFs also produce crumb rubber based on customer requirements which has a different quality from SIR 10 or SIR 20.

Crumb Rubber Specification

15

suggested to only accept the high purity and clean rubber block from farmers in order to get the higher specification of crumb rubber.

Table 2 Crumb Rubber Specification of Indonesia, Malaysia and Thailand

Parameters Grades

a) TSR’s specified by ISO under ISO -2000 b)

Standard Indonesian Rubber (SIR), SNI 1903-2000 c)

Standard Malaysian Rubber (SMR) d)

Standard Thailand Rubber (STR)

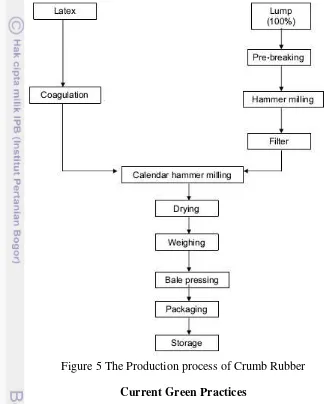

Crumb Rubber Processing

Crumb rubber is dry rubber production process of the cleaning stage and size reduction, milling, shredding, drying, and compression from the raw material (rubber block) to produce a dry rubber lumps. Dry rubber wrapped neatly in subsequent polyethylene plastic. Crumb rubber raw material can be either fresh rubber latex field that further processed into high quality crumb rubber that is SIR 3, while raw materials in form of rubber block, such as slab, lump, and ojol, was processed into low grade crumb rubber of SIR 10 or 20, which are the domain product of the factories.

Based on the respondents, there are some benefits of crumb rubber processing such as the process is faster, the product is more clean and uniform, and the appearance is more interesting and easy handling. Generally, raw materials used for making crumb rubber can be field latex or low quality lump. In those factories, the raw material used is lump or rubber block, the step is started by soaking and/or washing the lump, and then followed by hammer milling, crepe formation, milling, drying, and bale pressing, and packing. The flow diagram of crumb rubber processing is presented in Figure 5.

Manufacture of crumb rubber with this pattern use of water resources and electrical energy in large quantities, among others caused by solid coagulated rubber latex (bokar) as raw material in dirty conditions and poor quality that

16

by microorganisms (Utomo, et. Al, 2010). Respondents stated that those condition became problem for crumb rubber industry which is generally located in urban areas and near settlements. Generally speaking, they experience an obstacle for crumb rubber industry in Indonesia who had to produce as efficiently as possible in order to remain competitive with natural rubber produced by other countries (Malaysia and Thailand).

Figure 5 The Production process of Crumb Rubber

Current Green Practices

17

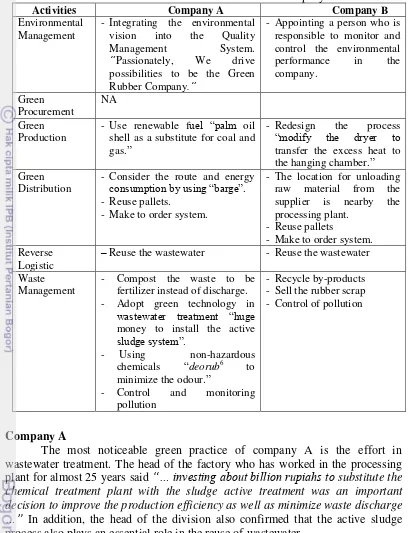

Table 3 Current Green Practices in Each Company

Activities Company A Company B

Environmental Management

- Integrating the environmental vision into the Quality

Management System.

“Passionately, We drive possibilities to be the Green Rubber Company.”

- Appointing a person who is responsible to monitor and shell as a substitute for coal and gas.”

Reuse the wastewater - Reuse the wastewater

Waste wastewater treatment. The head of the factory who has worked in the processing plant for almost 25 years said “… investing about billion rupiahs to substitute the chemical treatment plant with the sludge active treatment was an important decision to improve the production efficiency as well as minimize waste discharge …” In addition, the head of the division also confirmed that the active sludge process also plays an essential role in the reuse of wastewater.

The second practice that has a significant influence is the commitment from the management to be more environmentally friendly. They put the environmental management system (EMS) content into the quality manual of ISO 9001:2008, even though, the company has not implemented the EMS officially. As a result, the management representative (MR) has responsibility for

6

18

implementing the EMS in a similar way as the QMS. Hence, MR has tried to integrate some environmental procedures in the QMS document.

The third green practice is the “make to order system”. The head of the production division in both companies implied that the production process and inventory control is managed by the planning team in the head company, not in processing plant. This system is primarily considered as a business strategy to minimize product stock in the storage warehouse rather than reduce the odor of the crumb rubber. The head of company clarified that the company only start producing once the purchase order from head office including quantity, specification, and shipment schedule is received. It infers that this strategy is not mainly for the sake of the environment but lowers costs and production efficiency.

A further ecological practice is energy efficiency through alternative fuel and mode of transportation based on route planning. The company also tries to remanufacture the solid waste from the waste and defect product to become fertilizer. The respondent said: “…converting lump into fertilizer is useful to treat solid waste. We usually discharge the waste and defect product in the edge of the river, but now we could make money by selling the fertilizer to farmers…” Another effort to be more environmentally friendly is the using of non-hazardous chemicals such as liquid smoke (deorub) to make the rubber odorless.

Company B

Different from company A, the obvious green practice in Company B is energy consumption efficiency. The different strategy is reflected in the innovation of process production like modifying the machinery in the heating and pressing stage. The head of the production division replied “…the excess heat from the machine makes workers uncomfortable, in order to minimize it, we modified the heat pipe by transferring the heat into the hanging chamber…”. This initiative resulted in reducing the time of drying in the hanging shed without decreasing the quality of the crumb rubber.

Company B appointed a team in the environmental division to monitor and control the environmental performances, particularly to make trimester reports to the Environmental Agency in South Sumatera and the Ministry of Environment (MoE). To minimize the transportation cost of rubber block, company B selected the location of the warehouse and processing plant to be close to each other. This is also helpful in reducing the odor that is released by the CR while in the warehouse.

19

The companies are aware of the environmental problems and have adopted some approaches that can benefit them economically and environmentally. For instance, using alternative energy and waste management have been used as initial points to adopt GSCM practices. This is a common starting point for GSCM as stated by Andiç et al. (2012). While, management commitment like in company A also plays an important role in integrating green concepts into existing production system (de Sousa Jabbour, 2015; Zhu & Sarkis, 2004; Zhu, Sarkis, & Lai, 2007). Johansson and Winroth (2009) mention that re-designing process could be used as a fundamental initiation to implement GSCM, this statement confirms the finding in both CRFs. Similarly, substituting deorub for hazardous chemicals has been done in both companies. This is just as shown by Holt and Ghobadian (2009) in greening the textile industries. In both companies, waste management has improved due to basic practices to address the excess material, wastewater, and some solid waste (e.g. composting, resell, reuse of scrap etc.). This concept of reduce, reuse, and recycle in waste management approach has been implemented widely for many industries in order to minimize the environmental impacts (Atlas & Florida, 1998; Ninlawan et al., 2010; Srivastava, 2007).

With regard to their motivation for greening the CRFs, it could be said that they have not considered the ecological aspect into their business goals. As Head of factory A said: “My real job is decreasing the cost of the production, and even minimize the failure in factory. Regarding the waste, I used to eliminate or reduce it just to comply with the government regulation. So, being aware of many aspects like, economics is what makes it. It is no use being very green, if we go out of business.” Furthermore, the head of factory also implied that efforts become green are costly and laborious. For instance, the head of factory for company B stated:

“…as long as the efforts do not lead to decreasing the profit, perhaps we are still able to use the strategies, but by being green does not mean generating more profit…” Based on the efforts as shown in Table 2, all of the practices could initiate GSCM adoption. It seems that all of the plans emphasize maximizing the efficiency and optimizing the cost of production rather than adopting the environmental management strategies to be green consciously.

In terms of appraising the effectiveness of the current GSCM implementation in both CRFs, it seems that their current efforts, responsiveness and enthusiasm of greening the crumb rubber supply chain are less adequate to improving their environmental performance. The indication of this less active green adoption need to be explored in order to formulate the better way to shift this condition to be proactively adopting GSCM in the current production system. Therefore, the reason and factors affecting the green adoption will be determined in the next session. The factors will be useful as consideration in synchronizing the current practices with the green concepts to accelerate the GSCM implementation in CRFs.

Factors Influencing GSCM adoption

20

the two observed CRFs namely technological, organizational and environmental factors.

In terms of adopting GSCM in CRFs, the stage 3 which is decision is the second important point to diffuse the GSCM approach in organization. In this research, the knowledge and persuasion stages are counted as fundamental knowledge for CRFs. It is evidence that CRFs have known and understood well about the concept of greening supply chain. Therefore, in this study, the influencing factors are examined in the stage decision to reject or adopt the GSCM. The next stage is the implementation, after CRFs decide to adopt the GSCM, it is useful to formulate guidance operation or best practice. Considering the emerged factors and examine it carefully with the current condition of GSCM application in CRFs, the best practice is formulated in the next section of this paper. Figure 5 shows the holistic model of GSCM implementation and illustrates the emerged factors that may influence the decision to adopt or reject the greening supply chain in CRFs.

Technological Factors

Technology in this term is the GSCM as an innovative system that will be diffused into the organization in CRFs. The results show that the relative

advantage, compatibility, and complexity of GSCM influence CRFs’ decision

whether adopt or reject the GSCM. This finding confirms the statement of Rogers (2003). He describes those three factors have consistently influenced in adoption behaviour of technical innovation.

Relative Advantage

According to respondents, the green practices have to be able to provide more relevant benefits for companies such as profit, satisfaction, and reputation rather than the existing production system. In addition, a return on investment (ROI) and efficiency are critical factors in decision making in adopting new green technology that need high-cost investment. To illustrate, company A invested a lot of money to install new wastewater (active sludge system) treatment due to its logistic companies. Therefore, to advance green practice adoption, the technology provider or stakeholders who are concern about greening the industry should put more effort into convincing them of the profitability of green adoption.

Compatibility

21

whereas this approach was not compatible with company B. Other evidence is the redesigning of the dryer system in company B, and this innovative strategy emerged due to their experiences of maintaining the machinery in the processing plant. Thus, it can be accepted consistently in the current production system. Accordingly, these findings confirmed the previous research that how the green approach fits in with the current operational knowledge is an essential determinant of the adoption of technical innovation(Andiç et al., 2012; Eltayeb et al., 2011; Lin & Ho, 2011; Zhu et al., 2008). Consequently, the best practices of GSCM should be designed and developed by synchronizing the green approach with the current system.

Complexity

GSCM is a technical innovation that incorporates tacit and explicit knowledge (de Sousa Jabbour, 2015; Hazen, Cegielski, & Hanna, 2011; Srivastava, 2007). In order to succeed in green practices, the adopter requires laborious efforts to learn and diffuse that learning within the organization (Etzion, 2007; Hazen et al., 2011). Regarding the GSCM implementation, the organization needs a high innovative capability to succeed the GSCM implementation. Both companies stated that lack of clarity of GSCM practices make the adoption more difficult for them to understand. Their responses indicate that their knowledge and skill of GSCM are still lacking because GSCM was assumed to be a complex innovation. Based on the field observation, there are only a few green approaches that adopted in CRFs. These findings are in accordance with the results of research on how the complexity of environmental innovation adoption negatively influences the decision process (Hazen et al., 2011; Henriques & Sadorsky, 2007; Rothenberg & Zyglidopoulos, 2007). Therefore, increasing the clarity of GSCM is valuable for CRFs to internalize the knowledge, and also enhances the compatibility of some green approaches. Consequently, the structured information may gives opportunities for CRFs to be able to select ecological approaches that are more consistent with their existing system.

22

Organizational factors

In the implementation of technical innovation like GSCM, the company needs to invest in enough technical resources to make the adoption process succeed.

Organizational support

Technological factors relate closely to capital, financial, human resources, skill, and expertise. The organization should provide these needs to accelerate adopting green practices (Henriques & Sadorsky, 2007; Hong, Kwon, & Jungbae Roh, 2009; Rothenberg & Zyglidopoulos, 2007). As mentioned earlier, the process of greening the company needs some changes in production technology, production systems and the organizational culture. It is found that capital and human resources are needed by CRFs, particularly to buy the technology, install new equipment and train employee to operate the new machines. According to the respondents, top management commitment to advancing green practice adoption is very necessary, particularly in term of collaboration between divisions. The green adoption leads to change the system of interaction between divisions and is a multidisciplinary process in the company. For that reason, top management would need to commit to planning the availability of the resources and finances to improve the innovative capability of the organization. In addition, respondent B emphasized that motivation, incentives and policies were also helpful to enhance the green practice adoption behaviour. These findings are in accordance with the statement that management support and organizational learning have positive influences on GSCM adoption by Zhu, Sarkis, and Lai (2012).

Quality of Human Resources

23

External Factors

The Ministry of the Environment has controlled and monitored the CRFs’ environmental performance due to their significance as vital industry sector for the Indonesian economy. Therefore, the government has established regulation and policies on greening the industry. Fortunately, many government action plans were also programmed to support the CRFs in succeeding in the green industry campaign. In addition, pressure from stakeholders such as NGO, government and local population are considerable as significant drivers for GSCM implementation.

Customer demand

The end tiers of CR supply chain are other rubber product manufacturers. The CR is an intermediate product that has to be processed before used by the end of the consumers. It is found that the Company A exports the CR to tire factories like Japan, USA and China. In this case, each customer establishes their specification and requirement before shipping. Respondent A said – “the exporters do not verbalize a preference for an environmentally sound product”. In addition, respondent B highlighted that the customers only require the certificate of crumb rubber quality from independent Product Certification Body. The statements signpost customer pressure may not influence the decision on green adoption. However, this finding contrasts with research conducted by Diabat and Govindan (2011). The reason for this phenomenon might be because CR is only the intermediate product that is not bought by the end customer, but the rubber manufacturers. Terms of eco-label together with the products are required to most consumer goods, not the factories or manufacturers.

Government support

24

Best Practices of GSCM Adoption Strategies based on Analytical Hierarchy Process

The hierarchy was constructed based on the field observation, literature reviews and discussion with the experts iteratively. As shown in Figure 3, it

consists of three levels. The first level is the focus “Green practices selection for

GSCM Implementation in the CRFs”. The second level is the dimension or activity that developed based on the suggested GSCM model and the last level are alternatives that were formulated based on analysis of current systems and the GSCM model. The overall green strategies could be used as best practices in the GSCM implementation.

Figure 7 the Hierarchy of GSCM Implementation in CRFs

As shown in Table 3, the results of local and “global weights” determine the relative importance of main activities and green strategies respectively. In addition, ranking indicates the priority of practices on which organizations should commit and work throughout the process of GSCM implementation. The local weight is derived from judgment with respect to single criterion while the global weight is derived from multiplication the local weight of each alternative by the weight of the main activities (category). The consistency index for each pairwise comparison matrix ranges between 0.0034 – 0.0104 which can be used as reliability indicator for decision makers.

Based on the AHP result (the local weight), it is evident that green procurement (0.347), green production (0.266), and waste management (0.183) are the three most critical activities to start implementing GSCM. Furthermore, considering the global weights in Table 4, it is suggested that the five prioritized strategies to accelerate GSCM adoption follow this order:

a) Establish higher standard for rubber block, b) Educate suppliers and farmers,

c) Reuse the wastewater, d) Recover excess energy, and

25

Table 4 Ranking of Green Strategies based on AHP

Activities

A1. Substitute hazardous material 0.082 0.028454 14 A2. Educate suppliers and farmers 0.354 0.122838 2 A3. Establish higher standard for rubber

block 0.564 0.195708 1

B. Green

Production 0.266

B1. Adopt new technology 0.147 0.039102 10 B2. Use alternative energy 0.151 0.040166 9 B3.Recover excess energy 0.253 0.067298 4

B4. Redesign process 0.165 0.04389 8

B5. Improve efficiency of machinery 0.076 0.020216 16 B6. Reduce the time of pre-drying

process 0.208 0.055328 6

C. Green

Distribution 0.106

C1. Use reusable packaging/ pallet 0.085 0.00901 21 C2. Reduce stock rubber block 0.234 0.024804 15 C3. Reduce storage time of rubber

block 0.348 0.036888 13

C4. Choose the best transportation

mode 0.158 0.016748 19

C5. Manage the delivery route 0.175 0.01855 18

D. Reverse

Logistic 0.098

D1. Recycle the scrap 0.205 0.02009 17

D2. Reuse the wastewater 0.687 0.067326 3 D3. Remanufacture the defect product 0.108 0.010584 20

E. Waste

Management 0.183

E1. Control of toxic & hazardous

chemicals 0.204 0.037332 11 procurement activities is the crucial factor in implementing GSCM, followed by green production and waste management. To get better understanding of these results, the interpretation of the interviews will be elaborated with the evidence of AHP in the next subsection.

Green Procurement

26

quality of the rubber block based on its amount of impurities, coagulant agent, and dried content: namely type A (the best quality), B, C, and D (the lowest quality). Both of the respondents suggested that the rubber block (raw materials) from farmers and collectors may be the source of waste problems. It indicates that the waste generation is primary from the low grade of the rubber block. This is because during the production process there is only physical processing such as down-sizing, grinding, drying, heating and pressing, with no chemical addition. It is inferred that the lower the grade of rubber block causes higher water and electricity consumption during the production process, and this leads to generate more wastewater and solid waste. The production process of rubber block type D causes the increasing of operational cost. It is calculated that the production cost is about as twice as much as type A, and the waste discharge is approximately four times more than the good grade (Utomo et al., 2010). Since the excessive of water consumption in processing the low grade of rubber block, it is suggested to reuse the wastewater. Fortunately, both companies have started to treat the wastewater and reuse it in the washing stage of the crumb rubber processing. However, the CRFs have limited capacity to treat all of the wastewater to become reusable water, thus, increasing its capacity would be a beneficial strategy to greening the process. This strategy is also suggested on AHP.

It is found that farmers tend to add impurities such as sand, soil, old scrap rubber (e.g. tires) or other materials to increase the weight of the rubber block (Utomo et al., 2010; Wibawa et al., 2005). The reason is the farmers only receive a very low profit from selling rubber block since the complex supply chain activities of the crumb rubber (as Figured in Fig. 1). Even though, the companies have established strict supplier selection for rubber block which is based on quality, delivery and consistency, the low-grade rubber block from suppliers or farmers is still being accepted. This phenomenon happens because the companies experience a lack of rubber block supply in some seasons. In addition, CRFs may have chance to buy the lowest price of rubber block when the quality is very bad; in this condition, the suppliers or farmers do not have any good bargaining position. Therefore, in order to successfully implement GSCM, CRFs need to be persistent in only accepting good quality rubber block or establish higher standard such as putting environmental criteria in the supplier selection. These findings support the result of the highest ranking strategy based on AHP. As common result, green procurement including the environmentally supplier relationship also could result in vital starting point in GSCM implementation (Gollagher et al., 2010; Hong et al., 2009; Salam, 2008).

In crumb rubber industries, farmers are critical supply chain members who produce the first raw materials for other rubber manufacturers. Respondent A stated “if farmers stop cheating and willing to improve the quality of the rubber block, we could buy it with a higher price and waste from this factory could be minimized”. Hence, the need of environmental partnership with farmers may become a highlighted point in the procurement activities. Respondent B agreed that the farmers do not experience a strong enough pressure to produce the better quality from any stakeholders even government or the CRFs themselves. It could

be seen that farmers’ awareness of being environmental friendly is still low so that