Comparison of machinability aluminium alloy LM6 when using coated and uncoated carbide cutting tool.

Teks penuh

Gambar

Dokumen terkait

At the end of this study, the High Speed Steel cutting tool efficiency is analyze using test will be conducted by different type of

I hereby, declared this report entitled “Performance of CVD Coated Carbide Tool By Optimizing Machining Parameters During Turning of Titanium Alloy Ti-6Al-4V ELI in Flooded

The machining parameters evaluated are cutting speed, feed rate and depth of cut. The cutting speed and feed rate will be various while depth of cut will

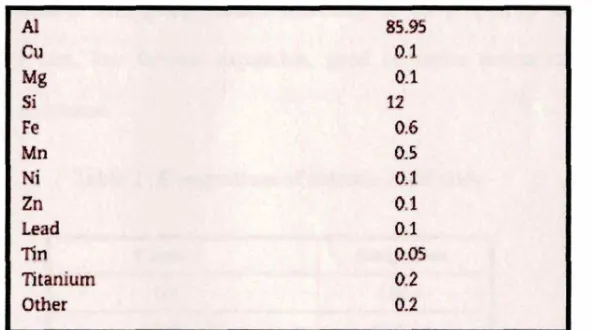

Milling process is important to produce a flat shape such as flat bar, vise and many more (Joardar 2011). Therefore the study of milling aluminium LM6 tends to investigate

Milling process is important to produce a flat shape such as flat bar, vise and many more (Joardar 2011). Therefore the study of milling aluminium LM6 tends to investigate

1, 20223 Medan Estate, Indonesia Abstract Objective of study reported in this paper is finding the optimum cutting condition respected to surface roughness Ra, flank wear VB and tool

Dhar, et al [8] has conducted experiment on cutting temperature, surface roughness, tool wear, and dimensional deviation in cryogenic machining The present work shows the experimental