The Effect Of Different Cutting Tool Material To The Surface Finish Of D2 Tool Steel In Drilling Process.

Teks penuh

Gambar

Dokumen terkait

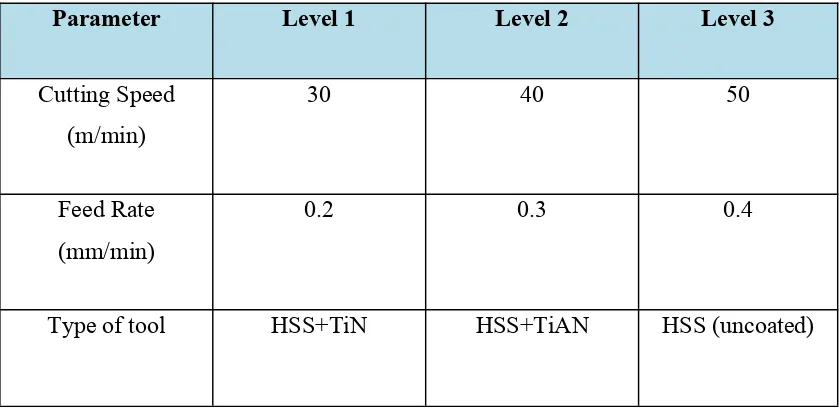

To identify the optimized setting of cutting parameter of feed rate, spindle speed and depth of cut on surface roughness during face milling process of Mild Steel

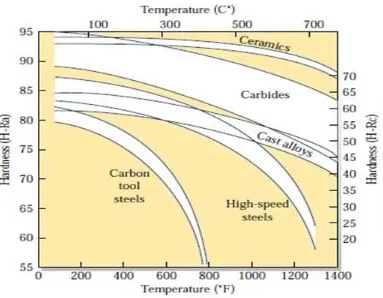

At the end of this study, the High Speed Steel cutting tool efficiency is analyze using test will be conducted by different type of

The aim of this project is to study and compare the tool life of the hardfacing method of tool steel wire using gas metal arc welding with the usual high speed steel cutting tool

The main purpose of this project is to compare surface roughness of tool steel material using zinc coated brass and brass electrode wires and to recommend the

Aluminum alloy LM6 using two different types of cutting tool which are coated high.. speed steel and coated

The result shows that cutting speed was the most significant factor that had affected the surface roughness (Ra) of medium carbon steel (AISI 1040)....

PERTORMANCE OF DIAMOND CUTTING TOOL IN THE TURNING PROSES OF STAINLESS STEEL,COPPf,R AND

Conclusion This paper illustrates the application of the parameter design Taguchi method in the optimization of metal removal rate of AISI 1020 steel in turning operation.. ANOVA is