DESIGNING AN ACTION LEARNING PROCESS TO

PROMOTE INNOVATIVE WASTE MANAGEMENT

PRACTICES IN THE TAPIOCA INDUSTRY IN

LAMPUNG PROVINCE

NUR AINI OKTININGRUM ADINDA

SEKOLAH PASCASARJANA INSTITUT PERTANIAN BOGOR

DECLARATION

I hereby declare that the thesis entitled “Designing an Action Learning Process to Promote Innovative Waste Management Practices in The Tapioca Industry in Lampung Province.” is my original work produced through the guidance of my academic advisors and that to the best of my knowledge. This thesis also presented for the award of a degree in The University of Adelaide as a double degree program between Bogor Agricultural University and The University of Adelaide. All the incorporated material originated from other published or unpublished papers are stated clearly in the text as well as in the bibliography.

I hereby delegate the copyright of my paper to the Bogor Agricultural University.

SUMMARY

NUR AINI OKTININGRUM ADINDA. Designing an Action Learning Process to Promote Innovative Waste Management Practices in The Tapioca Industry in Lampung Province. Supervised by SUPRIHATIN and NASTITI SISWI INDRASTI.

Tapioca industry gives positive impact to the regional economy in Lampung Province. With 66 tapioca factories and 8.059.287 tonnes of tapioca starch production, it makes Lampung Province as the biggest tapioca producer in Indonesia. However, tapioca industry released large amount of waste that can contaminated the environment.

Although there are some ideas and technologies that have been offered by some stakeholders in tapioca industry, poor interaction of stakeholders influences the innovation adoption of technology and regulation compliances.Innovation is an interactive and interdisciplinary phenomenon. Therefore, interactions among stakeholders are critical for accelerating the innovation adoption process in waste management. This research offers action learning as one qualitative method for observe organisations engagement for nurturing ideas of innovation. This study used case studied methodology and followed qualitative research by using field observation and interview for data collection, and interpretive approach for analysing the data.

The initial findings found that the stakeholders have concerned about waste management practices in tapioca industry. However, this research reveals that undefined role of stakeholders, lack of coordination among stakeholders, and financial problem are the burden for innovation adoption process. Based on this situation, the action learning can be arranged. The approach to action learning in this research is developed according to problem analysis in current situation and the stakeholder expectation for future collaboration. Moreover, the government will play a role as a facilitator, while academics and R&D institutions take part as advisor. There are four steps of action learning: planning, action, experience, and understanding. For ensuring sustainable collaboration, agreements among stakeholders are needed.

RINGKASAN

NUR AINI OKTININGRUM ADINDA. Designing an Action Learning Process to Promote Innovative Waste Management Practices in The Tapioca Industry in Lampung Province. Dibimbing oleh SUPRIHATIN dan NASTITI SISWI INDRASTI.

Industri tapioka memberi dampak positif bagi perekonomian Provinsi Lampung. Terdiri dari 66 pabrik tapioka dan produksi pati sebesar 8.059.287 ton/ tahun membuat Provinsi Lampung menjadi penghasil tapioka terbesar di Indonesia. Namun, industri tapioka juga menghasilkan sejumlah limbah yang dapat mengkontaminasi lingkungan. Walaupun beberapa ide dan teknologi telah ditawarkan oleh para stakeholder industri tapioka, kurangnya interaksi antar stakeholder mempengaruhi adopsi inovasi dalam hal teknologi dan pemenuhan regulasi. Inovasi merupakan fenomena interaksi antar disiplin ilmu. Oleh karena itu, interaksi antar stakeholder menjadi penting untuk mempercepat proses adopsi inovasi di manajemen limbah.

Penelitian ini menawarkan action learning sebagai salah satu metode kualitatif untuk mengobservasi hubungan antar organisasi dengan tujuan memunculkan ide inovasi. Studi ini menggunakan metodologi studi kasus dan mengkuti kaidah riset kualitatif dengan menggunakan observasi lapangandan wawancara untuk pengumpulan data, dan pendekatan interpretatif untuk analisa data.

Temuan awal menunjukkan bahwa stakeholder memiliki perhatian terhadap praktek manajemen limbah di industri tapioka. Namun, penelitian ini menemukan bahwa tidak jelasnya peran stakeholder, kurangnya kordinasi antar stakeholder, dan masalah finansial merupakan penghalang dalam proses adopsi inovasi. Berdasarkan situasi tersebut, action learning dapat dirancang. Pendekatan action learning dalam penelitian ini disusun berdasarkan analisa permasalahan dalam situasi saat ini dan ekspektasi stakeholder dalam kolaborasi di masa akan datang. Selain itu, pemerintah akan berperan sebagai fasilitator, sementara akademisi dan lembaga penelitian dan pengembangan berperan sebagai advisor. Terdapat empat langkah dalam action learning: perencanaan, aksi, pengalaman, dan pemahaman. Untuk memastikan keberlanjutan kolaborasi ini, kesepakatan antar stakeholder dibutuhkan.

Copyright ©2015, by Bogor Agricultural University

All Right Reserved

1. No part or all of this thesis excerpted without inclusion or mentioning the sources

a. Excerption only for research and education use, writing for scientific papers, reporting, critical writing or reviewing of a problem

b. Excerption does not inflict a financial loss in the proper interest of Bogor Agricultural University

Thesis

Submitted to the Graduate School in Partial Fulfillment of Master Of Science

Degree In

Agroindustrial Technology

DESIGNING AN ACTION LEARNING PROCESS TO

PROMOTE INNOVATIVE WASTE MANAGEMENT

PRACTICES IN THE TAPIOCA INDUSTRY IN

LAMPUNG PROVINCE

SEKOLAH PASCASARJANA INSTITUT PERTANIAN BOGOR

BOGOR 2015

Thesis Title : Designing an Action Learning Process to Promote Innovative Waste Management Practices in The Tapioca Industry in Lampung Province

Name : Nur Aini Oktiningrum Adinda

NRP : F351137121

Study Program: Agroindustrial Technology

Approved

Advisory Committee

Prof Dr Ir Suprihatin Chairman

Prof Dr Ir Nastiti Siswi Indrasti Member

Agreed

Coordinator Program of Agroindustrial Technology

Prof Dr Ir Machfud, MS

Dean of Graduate School

Dr Ir Dahrul Syah, MScAgr

ACKNOWLEDGMENTS

Praise and gratitude to Allah Subhanahu wa Ta’ala, because of Him, the writer can complete this thesis as a requirement to get a Master Degree in Bogor Agricultural University (IPB). The title of the thesis is Designing an Action Learning Process to Promote Innovative Waste Management Practices in The Tapioca Industry in Lampung Province.

The author want to say thank you, especially for Prof. Dr. Ir Suprihatin as a chairman of the advisory committee, Prof. Dr. Ir Nastiti Siswi Indrasti as an advisory committee member, and Prof. Noel Lindsay as an advisor from The University of Adelaide whose gave positive criticisms and guidance to shape the outlook of this thesis. Special thanks for Dr. Barry Elsey and Ms. Amina Omarova from The University of Adelaide for their guidance in writing this thesis.

I also would like to express gratitude to all the respondents who have taken their time to conduct an interview with the author. I also thank for Dr. Ir Aji Hermawan, MM for his suggestion to reshape my thesis and Mr. Dahlius and my colleagues in Balai Riset dan Standardisasi Industri Bandar Lampung, Ministry of Industry.

In this acknowledgment, I want to take my time for expressing my love to my husband for his endlessly support. I also want to thank for my parent and sisters in Surabaya and my parent and sister in law in Blitar. Last but not the least, I want to show my gratitude to my friends, namely Karim, Tri, Benny, Andar, Farda, Iwan, Danang, Dwi, Syarifa, Aditya, Dickie, Ahmad Rudh, Koko, Nuni, Anin, and Yani for their moral support especially when in Adelaide.

TABLE OF CONTENTS

RQ1. What problems do the tapioca industry have in adopting innovative

waste management practices in Lampung Province? 4

RQ2. What mechanism of intervention assists the industry toward greater

collaboration? 7

RQ3. What forms of collaboration reveal more immediate influences on

innovation practices in waste management? 9

3 METHODOLOGY 11

RQ1. What problems does a tapioca industry have in adopting innovative waste management practices in Lampung Province? 14 RQ2. What mechanism of intervention assists the industry toward greater

collaboration? 19

RQ3. What forms of collaboration reveal more immediate influences on

innovation practices in waste management? 21

TABLE OF FIGURES

Figure 1 Process in tapioca mills 5

Figure 2 Roger's innovation decision process of technolgy adoption 8

Figure 3 Research flow diagram 11

Figure 4 The collaboration form of innovation adoption in waste mgt. 23

LIST OF TABLE

Table 1 List of respondents 12

Table 2 The intervention of assistance mechanism in innovation adoption of waste management practices in Lampung Province 20 Table 3 The action learning form for innovation adoption in 24

LIST OF APPENDIX

Appendix 1. Glossary of Specific Terms 31

Appendix 2. The List of Interview Questions 32

1

INTRODUCTION

Lampung Province is well-known as the largest tapioca producer in Indonesia with 66 tapioca factories and 8.059.287 tonnes of tapioca starch production (BPS 2014). This industry has a significant positive impact on the regional economy; however, the tapioca industry discharges large amounts of waste from its processing that contributes significantly to environmental degradation. (Mai 2006) identifies the forms of waste that is generated from tapioca starch processing. This includes resource consumption, wastewater, solid waste, and air pollution. Tapioca waste treatment needs a large area for waste processing, and it creates a foul smell that can disturb residents (Thanwised, Wirojanagud & Reungsang 2012).

Some strategies have been developed by key stakeholders (academics/research and development institutions, government, and local firms) to solve these environmental issues. For example, the Indonesian Environmental Compliance Public Disclosure Program (PROPER) was developed by the Government (Meidiana & Gamse 2010) which was informed by research activities from academics and research and development institutions (Mai 2006; Mansourighasri, Muhamad & Sulong 2012). However, the implementation of research innovation and environmental regulation compliance is still low. Based on PROPER assessment results in 2014, there were only 14 of the 66 Lampung Province tapioca processing plants that met the necessary compliances (Ministry of Environment and Forestry 2014).

These failures are the result of a lack of information about environmental regulations and the research results that are available (Meidiana & Gamse 2010). In Lampung Province, there are several parties that have knowledge and information about waste management practices; however, each stakeholder works independently which leads to overlapping roles and inefficiencies in the innovation adoption process and information sharing.

The aim of this research is to analyse initial action that have been undertaken and to develop a learning network framework that will lead to the adoption of innovative methods for the process of waste management. The research focuses on the innovation adoption process in organisations and development of an action learning network among actors for accelerating innovativeness. As part of this process, the study elaborates on theories of innovation adoption and learning networks, then methods of action research and action learning.

Background

Background and need of this study are mentioned as follows: Waste management practices in tapioca industry

2

Innovation adoption process in waste management

Understanding the innovation adoption process while, integrating knowledge and information about R&D results and environmental regulations are needed for accelerating innovation adoption process in waste management.

Action learning process for enhancing interaction among stakeholders

Enhancing interaction among stakeholders through action learning is needed to make them engaged and work together in a term of setting-up a waste some stakeholders in the tapioca industry (Chavalparit & Ongwandee 2009), research and innovation in this field has not been well coordinated. Poor interaction among stakeholders has inhibited the adoption of innovative technologies and regulatory compliance. There are three main problems in the waste management innovation adoption process:

Waste management practices in the tapioca industry

Research indicates that the waste from tapioca processing can be used as renewable energy or raw materials for other products. However, waste management in the tapioca industry is still voluntary since in this type of industry firms are not obliged to follow the environmental national assessment guidelines. Furthermore, some research results are still in the pilot stage and only cover technological issues.

Innovation adoption process in waste management

Research activities by R & D institutions and tapioca processing plants are still uncoordinated. Moreover, enforcement of environment regulations is not well-informed. This means that innovation adoption is not running smoothly.

Action learning process for enhancing interaction among stakeholders Interaction or discussion does not exist. It leads to overlapping roles of stakeholders in tapioca industry.

Purpose of The Study

The purpose of the study is to analyse an innovation adoption process among stakeholders in tapioca industry for developing an action learning process in a waste management system in Lampung Province.

Research Questions

There are three research questions in this study:

What intervention mechanism would assists the industry to move towards greater collaboration?

What forms of collaboration will have the greatest influence on waste management innovative practices?

Significance to The Field

Many stakeholders are involved in the innovation adoption process. Olsson et al. (2010) says that innovation is a complex structure and cannot be possessed by one organisation only. Pedler (2011) offer action learning as a qualitative method for observing organisations and for individual engagement in the nurturing of innovation ideas. Furthermore, innovation is an interactive and interdisciplinary phenomenon. Therefore, interactions among stakeholders are critical for accelerating the innovation adoption process in waste management.

This research contributes to the discipline by providing evidence of innovation initiation of waste management in the Lampung Province tapioca industry. It identifies an interaction network among actors that positively impacts the process of waste management innovation adoption.

Research Scope

4

2

LITERATURE REVIEW

The aim of this study is to address the research questions identified. The literature review examines what other researchers have done as related to the three research questions. The first section addresses the problems and barriers in adopting innovative waste management practices in Lampung Province. The second section presents studies that are related to collaboration and stakeholder roles for facilitating knowledge-based environments to accelerate the innovation adoption process. The last section discusses an action learning process for improving stakeholder collaboration in the innovation adoption process.

RQ1. What problems do the tapioca industry have in adopting innovative waste management practices in Lampung Province?

Waste management practices in tapioca industry

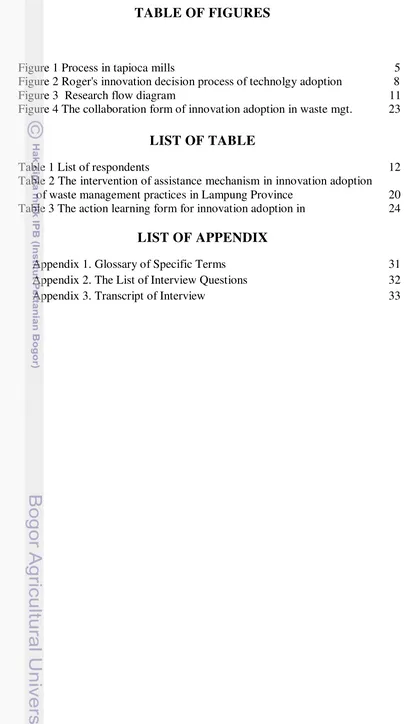

The tapioca processing industry generates a considerable amount of waste and by-products. The environmental impact arises from the processes of cleaning, peeling, and extracting. According to Mol and Dieu (2006), 10m3– 20m3 of waste water that contains high levels of biodegradable organic materials is released per ton of tapioca starch processed. Moreover, Mol and Dieu (2006) analyzed the characteristics of wastewater from tapioca processing with values of 55-200 kilograms of BOD, 130-500 kilograms of COD, 40-140 kilograms of suspended cassava starch extraction process. The tapioca processing stages are shown in Figure 1.

Clean technology implementation

A number of studies have shown that there are “green” waste management actions that can be undertaken to prevent environmental damage from tapioca processing activities. One method that can be used is through the use of “Clean Technology”. The study of clean technology was conducted by Chavalparit and Ongwandee (2009). The purpose of this study is to explore the implementation of clean technology in tapioca starch processing plants in Thailand. Eight tapioca processing plants were selected for an analysis of the clean technology adoption process.

The study variables include the reuse and recycling of water, use of biogas from wastewater, and technology modification for efficiency in the production process. A systematic methodology was adopted to analyse the implementation of cleaner production. The research methodology consists of four steps:

(2) Evaluating and measuring the four key factors by calculating material mass and water mass balances

(3) Selecting an appropriate approach for minimizing the amount of waste generation based on four key factors calculation, and

(4) Designing and implementing potential clean technology options for the tapioca starch plants.

The result of this study show that clean technology implementation in the eight selected tapioca starch processing plants can successfully reduce water consumption and enhance wastewater energy recovery. However, the clean technology approaches that have been offered were only based on material mass and water mass balance calculations. This is more about the technical issues. There were limitations and weakness in this study. For example, the study did not mention the process of clean technology implementation in tapioca starch plants that involves the implementation process and clean technology adoption.

6

Environmental regulation

Another action that exists to improve the implementation of waste management is the presence of environmental regulations and commitments by the Indonesia Government. Meidiana and Gamse (2010) mentioned that the rising number of Clean Development Mechanism (CDM) projects indicates positive attitudes of government towards waste management. The study by Meidiana and Gamse (2010) shows the development of waste management practices in Indonesia. The purpose of the study was to analyse the development of waste management in a particular period to identify the obstacles and the potentials of waste management implementation in the future. The study used a description analysis of the ten indicators by UNEP 2004. The research indicators are based on three periods (before decentralization (before 1999), when UNEP conducted the study (1999-2004), and after enacted by Waste Law No. 18/2008 (2005-2008)). Documents provided by the local governments and waste authorities in Indonesia were analysed by comparing the improvements in every period. This research showed that before 2002, there was no national policy on national waste management concepts. Waste management was under the responsibility of several ministries. It lead to unstructured and weak implementation of laws and weak regulatory enforcement. However, since Presidential Decree No.2/ 2002 was enacted, the Ministry of Environment assumed responsibility for all waste management controls. Nowadays, three institutions have a responsibility for waste management control. These are the Ministry of Environment and Forestry, the Ministry of Settlement and Regional Infrastructure at the national level, and the Local Board of Environmental Impact Management at the regional level (Un-Habitat & Programme 2010). The results indicate that some regulations and monitoring action from Government Institutions occurred after 2002. It shows their concern about waste management issues. However, the inadequate information available about waste management leads to the inefficient planning of waste management implementation in society (Meidiana & Gamse 2010). There were limitations and weaknesses in this study in this regard. For example, this study does not analyse the implementation of regulations in the field and the interaction among institutions.

Barriers in innovation adoption

1. Usage barrier

The usage barrier is associated with the utilization of innovation. These barriers arise when an innovation is not well-matched with customer requirements, in term of habits or practices.

2. Value barrier

The value barrier is related to comparing performance with price. It occurs when an innovation does not show great performance-to-price compared with other products.

3. Risk barrier

Uncertainty is always attached with innovation; therefore, risk cannot be avoided by customers. The risk barrier refers to the consequences that customers may be exposed to should they accept an innovation (Laukkanen et al. 2007).

4. Tradition barrier

The tradition barrier occurs when innovation gives effect in daily routines. Consumers may be reluctant with an innovation because it changes their daily lives. Therefore, not all consumers have an interest with a new innovation. 5. Image barrier

The image barrier is linked with stereotyped thinking, it can be brand or certain identity of the product.

By using this framework, (Laukkanen et al. 2007) suggests that the value barrier is the most significant barrier to mobile banking adoption for both elderly and younger users. However, the elderly have higher degrees of risk barriers to the use of mobile banking. This is due to more mature people not trying an innovation because it is complicated to use. Hence, banks need to develop promotional campaigns for demonstrating the advantages of mobile banking compared with conventional financial services.

RQ2. What mechanism of intervention assists the industry toward greater collaboration?

Innovation adoption process in waste management

Like the growth of a knowledge-based economy, innovation is a precious asset to an organization. It helps organizations to survive in a competitive market. The Oslo-Manual of the OECD 1997 divided innovation into process, product, and organizational innovation (Rennings & Rammer 2011): (1) Process innovation occurs when a given amount of output can be produced with less input; (2) Product innovation requires improvement to existing goods or the development of new goods; and (3) Organizational innovation includes new forms of management.

8

that a potential adopter passes through before making a decision to use a new product, service, or idea (Frambach & Schillewaert 2002). Rogers (2010) explains the adoption process as “the process through which an individual or other decision-making unit passes from first knowledge of an innovation, to forming an attitude toward the innovation, to a decision to adopt or reject, to implementation of the new idea, and to confirmation of this decision.” During the process, there are two main stages to consider: Initiation and implementation (Frambach & Schillewaert 2002). Between these two stages, the adoption decision occurs. The initiation stage is the path when an organization becomes aware of the innovation and starts to evaluate the product. The implementation stage is the process when an organization makes a decision to use and purchase the innovation. The innovation adoption process is shown in Figure 2.

Figure 2 Roger's innovation decision process of technology adoption (Rogers 2010)

Mechanism of intervention

Innovation can be considered as an interactive and interdisciplinary phenomenon (Olsson et al. 2010). It makes interaction among parties important in terms of information sharing. A proper approach can be created to produce valuable learning and collaboration development through reflective actions. Revans (2011) proposed seven phenomena as manifestations of action learning: self-directed teams, coaching, focus groups, action research, seminars, problem-based learning and experiential learning.

1. Self-directed teams

2. Coaching

Simpson and Bourner (2007) describes coaching as a one-to-one relationship between the coach and the ‘coachee’. The coach role is as guide or facilitator for the ‘coachee’- to explore his/her potential and aspirations. Methods of coaching include instruction, questioning and challenge. However, the coaching approach can be non-reflective because the coach may provide instruction as an expert.

3. Focus groups

Generally, focus groups include discussion by a group of people on a particular topic. A focus group consists of 8 to 12 people with a moderator. This approach looks for feedback or evaluation on a specific topic by exploring people’s insights and feelings.

4. Action research

Action research is based on a problem with a purpose to make a contribution in knowledge sharing. This approach can be done collaboratively or participatively by following a learning cycle process: Planning, acting, observing, and reflecting.

5. Seminars

(Revans 2011) describes seminar as tutor-led sessions with aim to learn through discussion and to develop critical thinking by asking questions. Subject expert led a small-group interaction to develop questions.

6. Problem-based learning

Problem based learning is inspired by open-ended and problems. This mechanism involves cross-disciplinary learning. It is not restricted with traditional subject boundaries. Small collaborative groups and facilitators are used to support this process.

7. Experiential learning

Experiential learning means learning from experience. These concepts include interaction of experience and reflection (Revans 2011).

RQ3. What forms of collaboration reveal more immediate influences on innovation practices in waste management?

Action learning process and interaction among stakeholders

10

depend on them (Pedler 2011). The essence of action learning based is, “there can be no learning without action and no action without learning”. Revans’ equation holds that:

L = P + Q

… where learning (L) is a combination of P (programmed knowledge, or the content of traditional instruction), and Q (Questioning insight, derived from fresh questions and critical reflection).

Olsson et al. (2010) analyzed the action learning method for increased innovation capability in organizations. The purpose of their study was to describe and discuss the learning network frameworks used in a current action Swedish learning project, InnoPlant. Their study elaborates the theory of innovation capability and learning networks, and the methods of action research, experiential learning, and action learning. The research participants included two county councils that represent the public healthcare system, three companies that represented the medical technology, and two universities and one research centre which represented academia. There were three different approaches tested: (i) Action learning network; (ii) local empirical action research studies and feedback discussion; and (iii) local driven innovation fostering projects. The results indicated that action learning is suitable for enhancing the innovation capability of organisations. However, the findings found that a code of contracts is essential for a binding commitment among participants. Furthermore, there were limitations in this study as the role of each participant was not explicitly described.

3

METHODOLOGY

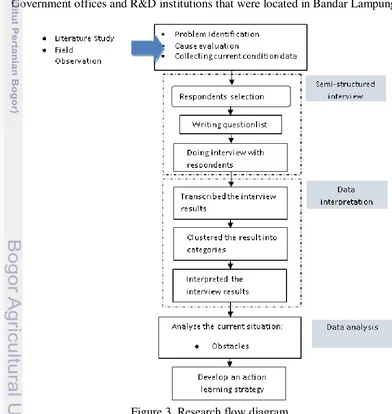

The objective of this study is to identify a suitable innovation adoption process among actors in the Lampung Province tapioca industry for creating an action learning process in waste management. This study used a case studied methodology approach and followed qualitative research guidelines by using field observations and interviews for data collection, and an interpretive approach for analysing the data. The flow diagram of research design is shown in Figure 3.

Settings

This research takes place in Lampung Province. The research was conducted during the period, July 2014 – June 2015. The research was divided into the data collection stage over a period of six months; the literature review and data analysis occurred over another six months. The research location is in Lampung Province. The respondents are located in various cities in Lampung Province: There were three tapioca factories in three different cities, and Government offices and R&D institutions that were located in Bandar Lampung.

12

Participants

Total participants for this study are eight (8) respondents, which represents stakeholders in tapioca industry (business, government, and academics).

Sampling.

The sampling procedure used is purposive sampling. The participants represent a group of actors (academics, business and government) in the tapioca industry that have knowledge and experience about the research topic.

Participant description.

There were three different groups interviewed. Three tapioca processing plants represented business, two research institutions and one university represented academics, and two province councils represented government. In the next chapter, individual actors are identified by following codes: Tpp1-Tpp3 for tapioca processing plants, Aca1-Aca3 for academics, and Gov1-Gov2 for a government. Details of the respondents appear in Table 1.

Table 1 List of respondents

Institution Information

Manager of tapioca processing industry from three different factories.

General process production in tapioca processing and waste management practices in tapioca industry.

Two representatives from regional environmental monitoring agency (BPLH Prov. Lampung)

The role of institution related to regulatory monitoring activities. Lecturer/ Researcher of R&D

institutions from three different organizations.

Research and development activities related to waste management and environmental issues.

Intervention and Materials

This study adopted a case study methodology. Data was collected from each stakeholder groups in tapioca industry. Semi-structured interviews were arranged with non-participant observation, supported by internal documents where possible. The semi-structured interview began with broad and open questions while exploring each respondent’s story to get more insight into the topic. Interview questions only used to check problem areas that have been covered. Non-participant observation was needed to understand networking behavior among actors.

Data Collection

interview. An interpretive approach was used to measure actor statements about waste management in the tapioca industry.

Procedure

This study used field observations and interviews for the data collection process. Field observation was conducted by visiting the tapioca processing plants to understand the natural process production of tapioca. Then, individual explorative interviews with a representative from the actor groups were arranged for identifying major themes. An interview guide was prepared based on the main research questions and keeping the interviews on track. A total of eight (8) interviews were organized, recorded, and transcribed. Each lasted between 45-60 minutes. Secondary data from institution internal documents was also collected to support the findings.

Data Analysis

The collected data was transcribed and organized based on research questions and themes. Standard techniques for a case study were followed Yin (2013). First, the interviews were transcribed with the Indonesian language, to get more understanding and minimize misperceptions. Second, data was clustered to produce more general codes and to identify themes. A coding method was used to organize interview data into a limited number of issues around the questions. Data from the field observations are also compared with the data from the interview. The transcript of interviews shows in Appendix 3. Third, data are divided into specific themes, in a term to capture different perspectives and interpretations. Therefore, it can answer the research questions. Fourth, the data analysis involved translated the interviews into English.

Validity

14

4 FINDINGS AND DISCUSSION

RQ1. What problems does a tapioca industry have in adopting innovative waste management practices in Lampung Province?

Current waste management practices

From the data analysis, the main topic that occurs is the nature of waste management practices in the tapioca industry. According to the interviews with the key tapioca industry actors, simple waste management practices have been implemented in a tapioca processing plant, especially with reuse and recycling activities for solid waste. According to Sriroth et al. (2000), the cassava slurry contains a high starch content (about 68% based on dry weight) and fiber (about 27% based on dry weight). Because of this high starch concentration, an animal feeder industry uses cassava slurry as a raw material. Another development in solid waste treatment is the utilization of cassava peel as biofertilizer. Cassava peel consists of two elements, an outer covering brown layer and an inner covering of parenchymatous. Both are lignocellulolytic components (Ogbo 2010). By using a particular fermentation process, the tapioca industry can produce biofertilizer from cassava peel. These following statements support the reuse and recycling practices in solid waste management:

“It is true that the tapioca industry produces some waste from the process production. But, they can sell their solid waste to the market. Usually, cassava peels are used as raw materials for animal feed or compost, and the acid citrate industry needs cassava slurry as their primary material.” (Gov1)

“20% of our cassava slurry production has been used as feed for waste water treatment, and we have sold the rest to the market. Another factory need cassava slurry as a material for traditional sauce, and cassava peel as a material for animal feed.” (Tpp1)

While solid waste treatment provides a positive trend, a different situation emerges in waste water treatment in the tapioca industry. The Majority of actors in the Lampung Province tapioca industry persist with conventional lagoon treatments, rather than using applied biogas reactors for further benefits. According to Gov1, only 10-20 tapioca processing plants from 66 factories are going further with new technology by converting methane from wastewater into biogas (a renewable energy resource).

“Most of them (tapioca processing plants) are using conventional lagoons like a big pond with long time detention, at least 3-5 months for processing treatment.” (Aca1).

“Nowadays, lagoon treatment is used in our factory. But, we have modified this treatment with a mixing tank reactor.” (Tpp1)

“Before 2012, we were using lagoon treatment for our waste water. But since 2012, a biogas plant is now effectively used in our factory.” (Tpp2) The study found that Tpp2 not only implementing waste management practices but also innovation in waste management with sustainability concept. Macnaghan et.al. (1995) explains that sustainability is the movement from current unsatisfactory state to a satisfactory state related with environmental, economic and social needs. Hanss and Bohm (2011) categorized sustainability into five dimensions: (i) an environmental dimension (e.g. preservation of natural resources); (ii) a social dimension (e.g. improving the living conditions of the of the world’s poor and promoting equal opportunities); (iii) an economic dimension (e.g. economic viability and economic growth that secure human well-being); (iv) a temporal dimension (in that the needs of current and future generations are considered); and (v) a developmental dimension (e.g. technological innovation or changes in lifestyles and political priorities).

Tpp2 factory has implemented three elements of sustainability in waste management: economic, environmental, and social called 30-40-50 Program. This programs are:

- 30: reduce fossil fuel consumption by 30% and replace with renewable energy. - 40: reduce pesticide and chemical fertilizer by 40%.

- 50: increase yield by 50%.

Some innovative waste management practices have been done to accomplish 30-40-50 Program. In energy management program, waste water has been converted and utilized as a biogas for energy. This effort can be used to generate energy in the production process accounted for about 75% of the required energy(Thanwised, Wirojanagud, Reungsang 2012). Solid waste from production processes such as slurry and peel are used for waste water treatment plant (WWTP) feeding. Solid waste also been utilized as an organic fertilizers, especially compost and liquid biofertilizer. However, there are several things that should be considered in biofertilizer making such as microbes growth profile, types and optimum condition of an organism, and formulation of inoculum (Mohammadi and Sohrabi 2012). This factory is continually formulated the best composition for biofertilizer from their solid waste by adding bamboo and other materials. Another innovative approach that has been arranged is in water sustainability by reducing water consumption in cassava washing. For all of these efforts, this factory gets international recognition and awards.

Factors driving for innovation

16

Based on the study conducted by Jabbour et al. (2014), there are “three levels of characteristics” which determine an innovation process in environmental management: Reactive, preventive, and proactive. The interview results reveal several factors that determine the waste management innovation in the Lampung Province tapioca industry.

Reactive. The reaction of management to fines and other penalties enforced by public authorities (Jabbour et al. 2014). Some studies have identified environmental regulation as a main factor driving innovation, well-known as the “regulatory push/ pull effect” (Rennings & Rammer 2011). In Lampung Province, the waste quality standard is mentioned in Government Regulation No.7/2010. Another pressure comes from the Indonesian Environmental Compliance Public Disclosure Program (PROPER) Program by the Ministry of Environment and Forestry. There are penalties that are imposed by the government if the industry does not comply with regulations. These range from written warnings to revocation of business permits. The interviewees affirm, “The enforcement of environmental regulations has influenced innovation activities in the tapioca industry”.

“ Environmental regulations are stringent day by day. It forces us to the last decade, coal and fuel prices have risen significantly. Hence, the tapioca industry has started using their waste as an alternative energy source. These include the implementation of cleaner technology by generating biogas from waste water for the drying process, or water recycling in the production process to minimize production costs.

“The coal and fuel prices in the market are very high now, that’s why we are looking for another option for energy, and one of the options is using our waste from the production process.” (Tpp1)

Proactive. Known as the “strategic environmental management stage”, management are aware that waste management is the pillar of their competitive advantage (Jabbour et al. 2014). There are some proactive factors that emerge in waste management in the tapioca industry;

- Positive reputation and credibility in the market.

“They (the tapioca industry) have to implement ISO 14001 or ISO 9001 if they want to export their products.” (Aca1)

- Environmental awareness.

Some in the tapioca industry have realized that they have to participate actively in good environmental management practices. As a mentioned by Gov1, if the tapioca industry implements proper waste management, it can get funding from the “carbon market policy”.

Impediments in innovation adoption process

Rogers (2010) assumes that all innovations are accepted and adopted by users. However, innovation means change for users, and this could result in resistance as a response to change before the adoption process begins. The tapioca industry actors may have their reasons for resisting innovation for their products. Based on innovation resistance theory (Ram & Sheth 1989), some factors are identified as potential impediments to Lampung Province innovation adoption of waste management:

Usage barriers

The usage barrier commonly relates to service utilization and consumer requirements. From the interviewee feedback, it seems that usage barriers are not the main obstacle to adopting good waste management practices. All the stakeholders have an interest in implementing new technology.

“Now, we use conventional lagoons for our wastewater treatment, but since we have heard of the success stories from another factory, we decided to install a biogas converter.” (Tpp1)

On the other hand, the respondents may have found difficulty in the first implementation of new waste management practices.

“when the first time we tried the biogas reactor, there were so many trial and error experiences. We are a little bit afraid of using this technology.” (Tpp3)

Value barriers

18

suggests that some respondents felt that high investment in waste management implementation is the main issue against innovation adoption.

“Basically, they (the tapioca processing plants) understand the advantages of good waste management practices, but we cannot deny that the investment for new technology in waste management is expensive.” (Aca2)

Risk barriers

The risk barrier refers to the risk that users are exposed to when using innovative technologies. Laukkanen et al. (2007) mentioned that inventors should notice that risk is a user perception rather than a product characteristic. Some tapioca processing plants fear that they might make mistakes when applying new technology for the first time, especially for SMEs. Sometimes SMEs do not have the financial or technical resources to adopt innovation (Johnson 2010). For an SME tapioca processing plant, human resources are a key problem in the innovation adoption process. These firms have high dependencies with the owners for adopting new innovations.

“as an owner, I have to know everything about this factory. This includes knowledge about how to manage our waste. I come to a workshop or supervised the innovation adoption transfer from their thoughts to their workers. However, these risks can be minimized by employing a consultant or having a discussion with experts. In the big tapioca processing plants, innovation adoption runs more smoothly and there is less risk because the larger firms have better infrastructures and human resources.

Tradition barriers

Image barriers

The image barrier refers to stereotyped thinking that can hamper innovation adoption. The image barrier in waste management practices emerges from waste management behaviours. On the one hand, the tapioca processing plant operators perceive the implementation of waste management to be too complicated to apply because they have to change their organizational habits. On the other side, the adoption of waste management practices will lead to good reputations for the company since the awareness of environmental issues has risen recently.

“Before we have our kick start in new waste management next year, we have to change our installation system, habits, and perspectives. It is not an easy job, big homework for the company.” (Tpp1)

Other than five barriers based on innovation resistance theory, this research has found other obstacles to the adoption of waste management practices. From the interviews, the researcher noticed that there was an emerging problem related to joint research activities among stakeholders. As regards funding issues, the R&D institutions point out disagreement about the ownership of intellectual property. Aca1 says: “There may be disagreements occurring over the ownership of an innovation product that has been produced from research activities. They want to own that product for free and do not want to pay for the intellectual property for our researcher”. This situation may appear because of unclear contractual agreements between the two sides.

RQ2. What mechanism of intervention assists the industry toward greater collaboration?

Proposed mechanism of innovation adoption assistance

20

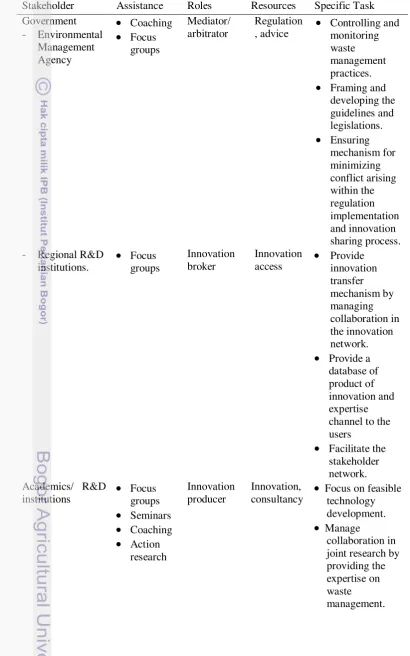

Table 2 The intervention of assistance mechanism in innovation adoption of waste management practices in Lampung Province

Stakeholder Assistance Roles Resources Specific Task

Distribute the Lampung Province, the government plays an important role as a “middle person”. The government’s role is divided into two parts: Mediator/arbitrator and innovation broker. The Environmental Management Agency acts as mediator/ arbitrator. Its role includes ensuring all tapioca plants follow the environmental regulations, and providing fair punishment for any contraventions. Regional R&D institutions play a role as innovation brokers by facilitating technology transfer mechanism to other stakeholders.

Academics have their part as innovation producers. This is related to the three basic pillars of academics: education, research and development, and community services. Therefore, academics and R&D institutions have a focus to produce new innovations based on waste management problems in the field. They ensure that the products of innovation are applicable to tapioca plants since tapioca plants are users of innovation. However, academics and tapioca plants can work together regarding the achievement of innovation. Academics provide the knowledge and expertise, whilst the tapioca plants offer financial support to solve their waste management problems.

RQ3. What forms of collaboration reveal more immediate influences on innovation practices in waste management?

Collaboration Form of Innovation Adoption

22

or R&D institutions. Each stakeholder has its role description that is listed in the regulations or legislation, especially for Government, academics,or R&D institutions. However, problems can emerge during the information sharing process.

According to Regulation of Lampung Governor No. 33/ 2010, the Environmental Monitoring Agency has a role in coordinating, facilitating, mentoring, and reviewing environmental management in Lampung Province. These roles include providing technical assistance and consultancy about environmental issues for the industry and society. However, it is found that a coordinating role has not worked in the field. Another organization that has involvement in the innovation adoption process is the Regional R&D institution. The Regional R&D institution has a role in developing technical policies for research and development; and providing advice to the local government based on scientific studies. Nevertheless, the presence of this institution is not perceived well by another stakeholder. For this reason, the tapioca firms had difficulties getting information about innovation.

“There is a poor role from the Regional R&D institution to coordinate and manage the innovation in this province. They do not even have a database conducting research and development activities. These situations raise a problem in the overlap of innovation products. It is often found that R&D institutions and academics organize almost similar research, especially for the most demanding topics such as alternative energy sources from tapioca waste water. It indicates lack of information sharing among stakeholders.

“It happened with us. A few years ago we arranged research about biogas in Pesawaran district, then we got information that the R&D institution from the Ministry of Energy and Mineral Resources did the same research in another tapioca plant.” (Aca2)

Based on the description of the role of stakeholders, the collaboration form among stakeholders can be arranged as seen in Figure 4.

Figure 4 The collaboration form of innovation adoption in waste management

The Proposed Stage of Action Learning in Innovation Adoption of Waste Management Practices

As regards accelerating the innovation adoption process, some of the interviewees mentioned some factors that may enhance stakeholder collaboration: 1. Regular meetings among stakeholders.

2. Revive the regional R&D agency. 3. Define the role of stakeholders.

4. Commitment for long-term projects from stakeholders. 5. Power from the government for regulation implementation.

24

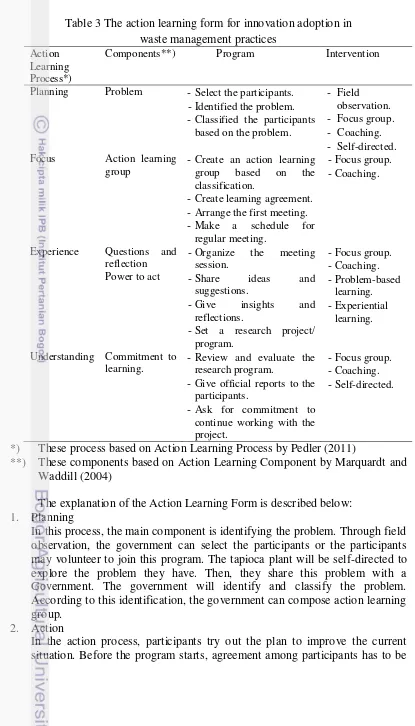

Table 3 The action learning form for innovation adoption in waste management practices

-Classified the participants

based on the problem.

*) These process based on Action Learning Process by Pedler (2011)

**) These components based on Action Learning Component by Marquardt and Waddill (2004)

The explanation of the Action Learning Form is described below: 1. Planning

In this process, the main component is identifying the problem. Through field observation, the government can select the participants or the participants may volunteer to join this program. The tapioca plant will be self-directed to explore the problem they have. Then, they share this problem with a Government. The government will identify and classify the problem. According to this identification, the government can compose action learning group.

2. Action

made. This agreement is important to ensure the sustainability of the project. Thus, an action learning group meeting can be arranged.

3. Experience

In this stage, the government acts as a moderator for the project. A moderator explores the problem and extracts insights from participants. Together with other stakeholders (government and academics), the project can be started. A project should involve the new knowledge that is important for waste management practices.

4. Understanding

26

5

CONCLUSION

Conclusion

The initial findings found that stakeholders have concerns about waste management practices in the tapioca industry. Pressures from government regulation, market demand, and the need for alternative energy sources lead the tapioca plants to implement innovative waste management practices. This positive trend also has support from academics and R&D institutions that produce innovation products to solve environmental issues. However, this research reveals that an undefined role of stakeholders, a lack of coordination among stakeholders, and financial problems are a burden for the innovation adoption process.

It is clear from the research that the stakeholders should build strong collaboration, based on the fact that innovation is an inter-disciplinary process. Therefore, this research offers action learning approach to enhancing innovation in waste management. Through action learning, each stakeholder can learn from other experience and work together to solve a problem in waste management. The most important issue underlined in the action learning implementation is the role definition of stakeholders and the trust building among stakeholders. It requires for the progress of an action learning project because action learning is a sustainable learning process. This study has sought to highlight the requirement of middleman who play the role as facilitator and coordinator for cross-sharing information among stakeholders. According to the observation, Government is the best stakeholder to take this role.

Limitation

The scope of this study is limited to tapioca industry in Lampung Province, particularly to stakeholders that involved in innovation adoption of waste management practices. This study used eight respondents to represent stakeholders in tapioca industry. The limited number of respondents may lead to the subjectiveness of the research. Nevertheless, this research offers collaboration form of action learning regarding innovation adoption of waste management. It may help the stakeholders to arrange the future joint engagement. Although the proposed action learning structure give advice for the arrangement of collaboration work, it is rather simple and involved only three stakeholder components in tapioca industry.

Implication for Further Research

This research observed the collaborative action of stakeholders in a purpose enhancing the innovation of waste management. The research acknowledges that, based on the empirical findings, the results may be generalizable to other agricultural industries in other provinces in Indonesia, but may not be applicable to other countries, due to the organisational context and type of waste that generates.

28

REFERENCES

Chavalparit O, Ongwandee M. 2009. Clean technology for the tapioca starch industry in Thailand. Journal of Cleaner Production. 17(2): 105-110. Frambach RT, Schillewaert N. 2002. Organizational innovation adoption: A

multi-level framework of determinants and opportunities for future research. Journal of Business Research. 55(2): 163-176.

Hanss D, Bohm G. 2011. Sustainability seen from the perspective of consumers. International Journal of Consumer Studies. 36(2012): 678-687.

Indonesian Bureau of Statistics. 2014. Production of plantation crops by province and crops. Viewed on 20 February 2015. Available at <http://www.bps.go.id/tnmn_pgn.php>.

Jabbour AB, Jabbour C, Govindan K, Kannan D, Arantes AF. 2014. Mixed methodology to analyze the relationship between maturity of environmental management and the adoption of green supply chain management in Brazil. Resources, Conservation and Recycling. 92: 255-267.

Johnson M. 2010. Barriers to innovation adoption: a study of e-markets. Industrial Management & Data Systems. 110 (2): 157-174.

Laukkanen T, Sinkkonen S, Kivijärvi M, Laukkanen P. 2007. Innovation resistance among mature consumers. Journal of Consumer Marketing. 24(7): 419-427.

Li Y, Vanhaverbeke W. 2009. The effects of inter-industry and country difference in supplier relationships on pioneering innovations. Technovation. 29(12): 843-858.

Mai HNP. 2006. Integrated treatment of tapioca processing industrial wastewater based on environmental bio-technology. Wageningen University.

Mansourighasri A, Muhamad N, Sulong A. 2012. Processing titanium foams using tapioca starch as a space holder. Journal of Materials Processing Technology. 212(1): 83-89.

Marquardt M, Waddill D. 2004. The power of learning in action learning: a conceptual analysis of how the five schools of adult learning theories are incorporated within the practice of action learning. Action Learning: Research and Practice. 1(2): 185-202.

Ministry of Environment and Forestry. 2014. Indonesian Environmental Compliance Public Diclosure Program: Ministry of Environment and Forestry Decree No. 180/2014. Viewed on 13 March 2015. Available at <http://proper.menlh.go.id/portal/filebox/141202070812Kepmen%20LHK% 20Nomor%20180%20Tahun%202014%20tentang%20Peringkat%20PROP ER%202014.pdf>.

Mohammadi K, Sohrabi K. 2012. Bacterial biofertilizers for sustainable crop production: a review. Asian Research Publishing Network. 7(5): 307-316. Mol A, Dieu TTM. 2006. Analysing and governing environmental flows: the case

of Tra Co tapioca village, Vietnam. NJAS-Wageningen Journal of Life Sciences. 53( 3): 301-317.

Ogbo FC. 2010. Conversion of cassava wastes for biofertilizer production using phosphate solubilizing fungi. Bioresource Technology. 101(11): 4120-4124. Olsson A, Wadell C, Odenrick P, Bergendahl MN. 2010. An action learning

method for increased innovation capability in organisations. Action Learning: Research and Practice. 7(2): 167-179.

Pedler M. 2011. Action learning in practice. Gower Publishing, Ltd.

Ram S, Sheth JN. 1989. Consumer resistance to innovations: the marketing problem and its solutions. Journal of Consumer Marketing. 6(2): 5-14. Ramsey E, Ibbotson P, Mccole P. 2008. Factors that impact technology

innovation adoption among Irish professional service sector SMEs. International journal of innovation management. 12(4): 629-654.

Rennings K, Rammer C. 2011. The impact of regulation-driven environmental innovation on innovation success and firm performance. Industry and Innovation. 18(3): 255-283.

Revans R. 2011. ABC of action learning. Gower Publishing, Ltd. Rogers EM. 2010. Diffusion of innovations. Simon and Schuster.

Setyawaty R, Setiadi T, Katayama-Hirayama K, Kaneko H, Hirayama K et al. 2012. Polyhydroxyalkanoate (PHA) production from tapioca industrial wastewater treatment: Operating conditions and influence on PHA content. Sustainable Environment Resources. 22(2): 123-127.

30

Sriroth K, Chollakup R, Chotineeranat S, Piyachomkwan K, Oates CG. 2000. Processing of cassava waste for improved biomass utilization. Bioresource Technology. 71(1): 63-69.

Suzuki M, Kehdy BO, Jain S. 2010. Identifying barriers for the implementation and the operation of biogas power generation projects in South-east Asia: an analysis of clean development mechanism project in Thailand. Economics and Management Series. EMS-2010-20. International University of Japan.

Thanwised P, Wirojanagud W, Reungsang A. 2012. Effect of hydraulic retention time on hydrogen production and chemical oxygen demand removal from tapioca wastewater using anaerobic mixed cultures in anaerobic baffled reactor (ABR). International journal of hydrogen energy. 37(20): 15503-15510.

Trehan K, Pedler M. 2009. Animating critical action learning: Process-based leadership and management development. Action Learning: Research and Practice. 6(1): 35-49.

Un-Habitat & Programme, UNHS. 2010. Solid waste management in the world's cities: water and sanitation in the world's cities 2010. Earthscan.

APPENDICES

Appendix 1. Glossary of Specific Terms

No. Terms Definition

1. Innovation adoption The process through which an individual or other decision-making unit passes from first knowledge of an innovation, to forming an attitude toward the innovation, to a decision to adopt or reject, to implementation of the new idea, and to confirmation of the decision (Rogers 2010).

2. Action learning A process underpinned by a belief in individual potential: a way of learning from our actions, and from what happens to us, and around us, by taking the time to question, understand and reflect, to gain insights, and consider how to act in future (Weinstein 2012).

The essence of action learning based on Revans (2011) is “there can be no learning without action and no action without learning”. 3. Environmental

innovation

32

Appendix 2. The List of Interview Questions

I want to thank you for taking the time to meet with me today. My name is Nur Aini Oktiningrum Adinda and I would like to talk to you about your experiences participating in waste management in tapioca processing industry.

The interview should take less than hour. I will be taping the session because I don’t want to miss any of your comments. Although I will be taking some notes during the session, I can’t possibly write fast enough to get it all down. Because we are on tape, please be sure to speak up so that we do not miss your comments.

All responses will be kept confidential. This means that your interview responses will only be shared with research team members and we will ensure that any information we include in our report does not identify you as the respondent. Remember, you do not have to talk about anything you do not want to and you may end the interview at any time.

Are there any questions about what I have just explained? Are you willing to participate in this interview?

Interviewee Witness Date :

RQ1. What problems does a tapioca industry have in adopting innovative waste management practices in Lampung Province?

a) How waste is usually managed?

b) Why do they improve the current waste management? c) What factors inhibit the innovation adoption?

RQ2. What intervention mechanism would assists the industry to move towards greater collaboration?

a) What form of co-operative formal and informal network exist among actors?

RQ3. What forms of collaboration have the greatest influences on innovative practices in waste management?

a) What factors inhibit cross-actors information sharing? b) What factors enhance collaborative operations ?

I will analyse the information you gave me for my research. I will be happy to send you a copy to review at that time, if you interested.

Appendix 3. Transcript of Interview

RQ1. What problems does a tapioca industry have in adopting innovative waste?

a. How waste is usually managed?

Code Detailed

Cattle feed 4 Usually, cassava peels are

34

b. Why do they improve the current waste management?

Code Detailed (tapioca industry) improve their waste management is because they have to comply with government regulations, if not their business license can be

Preventive Alternative energy 4 “The coal and fuel price

in a market are very high now,

Clean technology 2 “Water recycling is

c. What factors inhibit the innovation adoption?

Usage barrier Interest with new

innovation.

investment for new technology

in waste management is they do not have any idea about

36

RQ2. What intervention mechanism would assists the industry to move towards greater collaboration?

Government Mediator/ arbitrator 5 “ we have to monitoring

and controlling waste

management in industry..we have to make sure they are

following the regulation..”

(Gov2).

Innovation broker 2 “We have Regional

Research Council in Lampung Province, which involved all

expertise in this Province”

(Aca2).

Academics/ R&D institutions

Innovation producer 4 “The role of university

has mentioned in Tri Dharma,

which include education,

research and development, and

community service” (Aca2). research with university in

RQ3. What forms of collaboration have the greatest influences on innovative practices in waste management?

a. What factors inhibit cross-actors information sharing?

Code Detailed

R&D institution to coordinate and manage innovation from other institution. At least they have database about innovation

result in Lampung Province”

Agreement Lack of agreement

among stakeholders.

6 “Every stakeholder has

their own interest and purpose, which sometimes overlap each

other” (Aca1).

among tapioca firms is so strict. It makes them do not want to

share their experience to

38

AUTOBIOGRAPHY

Nur Aini Oktiningrum Adinda was born on 01st October 1984 in Surabaya, Indonesia. She completed his elementary education in 1997 and joined SMPN 1 Surabaya for junior education. She later joined SMAN 5 Surabaya and finished in 2003. She graduated from Institut Teknologi Sepuluh Nopember (ITS) Surabaya major in Environmental Engineering in 2008.

She has been working in Ministry of Industry as a researcher since 2009. As a researcher in Ministry of Industry, she tries to solve the problem in environmental issue by conducting research in laboratory.