Author Index

A

Achmad Munir

C4-1 (Pp.298-302);

C4-2 (Pp.303-306)

Aciek Ida Wuryandari

B1-1 (Pp.97-102)

Adang Suwandi Achmad

A1-1 (Pp.21-25);

SS1 (Pp.1-6);

SS2 (Pp.7-10);

SS3 (Pp.11-15);

SS4 (Pp.16-20);

B2-2 (Pp.137-142)

Addin Suwastono

B4-3 (Pp.188-192)

Ade Ramdan

B3-3 (Pp.158-162)

Adi Soeprijanto

B1-2 (Pp.103-108)

Adi Sucipto

C3-1 (Pp.272-277)

Adit Kurniawan

A2-5 (Pp.68-72)

Agung Nuza Dwiputra

D5-2 (Pp.365-370)

Agus Bejo

B4-3 (Pp.188-192);

C2-2 (Pp.264-267)

Ahmad Zainudin

A2-2 (Pp.51-56)

Akbari Indra Basuki

B1-1 (Pp.97-102)

Andri Fachrur Rozie

B3-3 (Pp.158-162)

Andriyan Bayu Suksmono

C5-2 (Pp.320-325)

Andriyan Suksmono

C1-3 (Pp.236-241)

Andryan Bagoes Noegroho

A2-2 (Pp.51-56)

Angga Pratama Putra

D5-3 (Pp.371-375)

Angga Putra

A2-4 (Pp.63-67)

Annisa Maulidary Muthiah

C5-3 (Pp.326-330)

Ardhi Maarik

B3-4 (Pp.163-167)

Arief Darmawan

B4-3 (Pp.188-192)

Arif Sasongko

B1-3 (Pp.109-114)

Arwin Datumaya Wahyudi Sumari

SS1 (Pp.1-6);

SS2 (Pp.7-10)

Astri Maria

A2-3 (Pp.57-62)

B

Bagas Mardiasyah Prakoso

A2-2 (Pp.51-56)

Bagas Prima Anugerah

D5-1 (Pp.360-364)

Baharuddin Aziz

A3-1 (Pp.73-78)

Bambang Anggoro

SS3 (Pp.11-15);

B2-2 (Pp.137-142)

Barokatun Hasanah

C4-1 (Pp.298-302)

Bijay Kumar Sahoo

B5-4 (Pp.219-224)

Bima Sahbani

B4-4 (Pp.193-198)

C

Camallil Omar

A3-2 (Pp.79-84)

Catherine Olivia Sereati

SS2 (Pp.7-10)

Chembian WT

C3-2 (Pp.278-282)

D

Danny M Gandana

B5-3 (Pp.214-218)

Dedy Rahman Wijaya

C5-5 (Pp.337-342)

Djohar Syamsi

B1-1 (Pp.97-102);

B3-3 (Pp.158-162)

Donny Danudirdjo

C1-3 (Pp.236-241);

C5-2 (Pp.320-325)

Dwi Nugroho Hari Wicaksono

A1-3 (Pp.30-34)

E

Efy Yosrita

A1-2 (Pp.26-29)

Eko Tjipto Rahardjo

D4-1 (Pp.343-346)

Elvayandri

A3-1 (Pp.73-78)

Enggar Fransiska Dwi Widyatama

C5-3 (Pp.326-330)

Enny Zulaika

C5-5 (Pp.337-342)

F

Fadhli Dzil Ikram

C5-1 (Pp.315-319)

Faisal Ardhy

E1-2 (Pp.386-393)

Fajar Adiatmoko

B1-2 (Pp.103-108)

Farkhad Ihsan Hariadi

A1-1 (Pp.21-25);

B4-1 (Pp.179-183);

Febry Ramos Sinaga

D5-4 (Pp.376-379)

Fitri Yuli Zulkifli

D4-1 (Pp.343-346)

FX Arinto Setiawan

C1-5 (Pp.248-252)

G

Goutam Mohanty

B5-4 (Pp.219-224)

Grasia Meliolla

B4-1 (Pp.179-183)

H

Habibullah Akbar

C3-5 (Pp.293-297)

Hajiar Yuliana

A2-5 (Pp.68-72)

Hamdan Prakoso

C3-3 (Pp.283-286)

Harjito Bambang

B2-3 (Pp.143-147)

Haruna Aimi

C2-1 (Pp.258-263)

Helmy Fitriawan

D5-4 (Pp.376-379)

Hendro Widodo

B1-2 (Pp.103-108)

Heri Prasetyo

B2-3 (Pp.143-147)

Hilman Syaeful Alam

B5-2 (Pp.208-213)

Hiroshi Ochi

A2-3 (Pp.57-62)

I Iskandar

C4-2 (Pp.303-306)

I Wayan Sudiarta

A3-3 (Pp.85-87)

Igi Ardiyanto

C1-6 (Pp.253-257)

Ii Munadhif

B1-2 (Pp.103-108)

Ilman Himawan Kusumah

A3-4 (Pp.88-91)

Iskandar

D4-3 (Pp.355-359)

Ismail Ariffin

A3-2 (Pp.79-84)

J

Jamil Akhtar

B1-4 (Pp.115-120);

B5-4 (Pp.219-224)

Joko Suryana

A2-1 (Pp.46-50)

Juhana Jaafar

A1-5 (Pp.41-45)

K

Karel Octavianus

B2-2 (Pp.137-142)

Karel Octavianus Bachri

SS3 (Pp.11-15)

Kenji Suyama

C1-2 (Pp.230-235);

C2-1 (Pp.258-263);

Kenta Omiya

C3-4 (Pp.287-292)

Khilda Afifah

B1-6 (Pp.127-131)

Khoirul Anwar

D4-2 (Pp.347-354)

Kiewlamphone Souvanlit

C2-2 (Pp.264-267)

Kurnia Adi Nugroho

B4-1 (Pp.179-183)

L

Lilik Subiyanto

B1-2 (Pp.103-108)

LP Deshmukh

B1-4 (Pp.115-120)

B3-6 (Pp.174-178)

M

Mahendra Drajat Adhinata

B1-3 (Pp.109-114)

Marcelinus Henry Menori

B2-1 (Pp.132-136)

Mareli Telaumbanua

C1-5 (Pp.248-252)

Mario Tressa Juzar

C1-1 (Pp.225-229)

Mat Syai’in

C5-4 (Pp.331-336);

B1-2 (Pp.103-108)

Maulana Yusuf Fathany

B1-6 (Pp.127-131)

Mochamad Fahri

B3-1 (Pp.148-152)

Mochamad Hariadi

B3-1 (Pp.148-152)

Mochamad Irwan Nari

A3-4 (Pp.88-91)

Mochammad Alif Ramadhan

B3-5 (Pp.168-173)

Moh Amanta KS Lubis

D4-1 (Pp.343-346)

Moh Hasbi Assidiqi

B1-5 (Pp.121-126)

Mohamad Nasyir Tamara

A1-3 (Pp.30-34)

Mohammad Nuh

A1-4 (Pp.35-40)

Monang Kevin Napitupulu

B4-4 (Pp.193-198)

MS Kasbe

B1-4 (Pp.115-120)

MS Kasbe

B3-6 (Pp.174-178)

Muhamad Amin Abdul Wahab

A3-2 (Pp.79-84)

Muhamad Komarudin

D5-4 (Pp.376-379)

Muhammad Amin Sulthoni

D5-1 (Pp.360-364)

Muhammad Ammar Wibisono

C4-2 (Pp.303-306)

Muhammad Arief Ma'Ruf Nasution

D5-2 (Pp.365-370)

Muhammad Arsyad

A2-2 (Pp.51-56)

Nanna Suryana

C3-5 (Pp.293-297)

Naoki Shinohara

C1-2 (Pp.230-235)

Nasril

B5-3 (Pp.214-218)

Ndaru Anggit Wicaksono

D5-1 (Pp.360-364)

Nevi Faradina

D4-3 (Pp.355-359)

Ngoc-Bao Nguyen

C1-4 (Pp.242-247)

Nico Surantha

A2-3 (Pp.57-62)

Nicodimus Retdian

B4-2 (Pp.184-187)

NN Maldar

B1-4 (Pp.115-120)

Noorman Rinanto

B1-2 (Pp.103-108);

B3-5 (Pp.168-173);

C5-4 (Pp.331-336)

Novi Prihatiningrum

B1-3 (Pp.109-114)

O

Octarina Nur Samijayani

C5-3 (Pp.326-330)

Oka Mahendra

B3-3 (Pp.158-162)

Oktanto Dedi Winarko

C5-3 (Pp.326-330)

Panji Ramadhan

B4-4 (Pp.193-198)

Pristy Ar Nurisysyifak

A2-2 (Pp.51-56)

R

Rachmad Vidya Wicaksana Putra

B1-6 (Pp.127-131)

Radhian Ferel Armansyah

C5-1 (Pp.315-319)

Rahmadina Alamsyah

B5-3 (Pp.214-218)

Raja Fathurrahim Akmaludin

A3-3 (Pp.85-87)

Rakhmat Arianto

A1-2 (Pp.26-29)

Rengga Yanuar Putra

B3-2 (Pp.153-157)

Retno Tri Wahyuni

A3-5 (Pp.92-96)

Ricky Disastra

B1-3 (Pp.109-114)

Ridi Ferdiana

C3-3 (Pp.283-286)

Riko Hasiando Goknipasu Nainggolan

D5-2 (Pp.365-370)

Rinaldi Munir

B2-1 (Pp.132-136)

Rinaldi Munir

C1-1 (Pp.225-229)

Risanuri Hidayat

C2-2 (Pp.264-267)

Riyanarto Sarno

C5-5 (Pp.337-342)

Rizqia Cahyaningtiyas

A1-2 (Pp.26-29)

Rubita Sudirman

A1-5 (Pp.41-45)

Rubita Sudirman

A3-2 (Pp.79-84)

Rudy Hartanto

C3-3 (Pp.283-286)

Ryan Adhitya

B1-2 (Pp.103-108);

C5-4 (Pp.331-336)

Ryan Yudha Adhitya

B3-2 (Pp.153-157);

B3-5 (Pp.168-173)

S

Salih Ergun

B4-5 (Pp.199-202)

Samudra Arrachman

B1-2 (Pp.103-108)

Sarwono Sutikno

SS4 (Pp.16-20)

Seetharaman Krishnamoorthy

C3-2 (Pp.278-282)

Sena Sukmananda Suprapto

A3-4 (Pp.88-91)

Septafiansyah Dwi Putra

SS4 (Pp.16-20)

S-Erlyane Rosli

A1-5 (Pp.41-45)

Son Kuswadi

A1-3 (Pp.30-34);

B1-5 (Pp.121-126)

Sri Ratna Sulistiyanti

C1-5 (Pp.248-252)

Sri Wahjuni

B3-4 (Pp.163-167)

Sryang Sarena

B1-2 (Pp.103-108)

Sryang Tera Sarena

C5-4 (Pp.331-336)

SS Mule

B1-4 (Pp.115-120);

B3-6 (Pp.174-178);

S-Syakiylla S-Daud

A1-5 (Pp.41-45)

Suci Rahmatia

C5-3 (Pp.326-330)

Sunu Wibirama

C1-6 (Pp.253-257)

Supeno Mardi Susiki

B3-1 (Pp.148-152)

Surya Ramadhan

A1-1 (Pp.21-25)

Susi Juniastuti

B3-1 (Pp.148-152)

Swizya Satira Nolika

C5-1 (Pp.315-319)

Syaiful Alam

D5-4 (Pp.376-379)

Syamsiar Kautsar

B1-2 (Pp.103-108)

Syamsiar Kautsar

B3-2 (Pp.153-157);

Syifaul Fuada

A2-4 (Pp.63-67);

B1-6 (Pp.127-131);

D5-3 (Pp.371-375)

T

Takeshi Shima

B4-2 (Pp.184-187)

Tatag Budiardi

B3-4 (Pp.163-167)

Taufik Ibnu Salim

B5-2 (Pp.208-213)

TH Mujawar

B1-4 (Pp.115-120)

B3-6 (Pp.174-178)

Thanh Duc Ngo

C1-4 (Pp.242-247)

Thoriq Satriya

C1-6 (Pp.253-257)

Tien Do

C1-4 (Pp.242-247)

Tiper Uniplaita

C1-3 (Pp.236-241)

Titin Yulianti

C1-5 (Pp.248-252)

Trio Adiono

A2-4 (Pp.63-67);

B1-6 (Pp.127-131);

C5-1 (Pp.315-319);

SS2 (Pp.7-10)

Triya Haiyunnisa

B5-2 (Pp.208-213)

Tuppak Bobby Vorlen Sagala

A2-1 (Pp.46-50)

Tutun Juhana

C4-3 (Pp.307-310)

V

Vu-Hoang Nguyen

C1-4 (Pp.242-247)

W

Wahyul Amin Syafei

C4-4 (Pp.311-314)

Y

Yoanes Bandung

C3-1 (Pp.272-277);

E1-1 (Pp.380-385)

Yuhei Nagao

A2-3 (Pp.57-62)

Yulian Aska

A2-4 (Pp.63-67);

D5-3 (Pp.371-375)

Yusmar Palapa Wijaya

A3-5 (Pp.92-96)

Z

Meat Quality Classification Based on Color Intensity

Measurement Method

Titin Yulianti1,a, Afri Yudamson1,b, Hery Dian

Septama1,c, Sri Ratna Sulistiyanti 1,d, F.X.Arinto

Setiawan1,e

1Department of Electrical Engineering,

University of Lampung, Bandar Lampung, Indonesia

b[email protected], c[email protected], d[email protected], e[email protected],

Mareli Telaumbanua2,f

2Department of Agriculture Engineering,

University of Lampung, Bandar Lampung, Indonesia

Abstract— The fresh and defective beef identification by consumers is subjectively through visual observation. However, identifying beef quality manually has disadvantage, there is human visual limitations, differences in human perception in assessing the quality of an object, and ability of each individual knowledge are different. Therefore, we need a technological device that can be applied to identify the quality of beef that can be used by people. The aim of this research is measuring the percentage of color intensity average from R, G, and B channel. The fresh and defective beef is identified using feature of the beef image. That feature is percentages of intensity average value from R (red), G (green), and B (blue) channel. The optimal feature is gotten based on the percentage values. The feature is gotten by using image processing method. The percentage of R channel intensity average value isdefined, which can be used to classify the fresh and defective beef. The percentage of R channel intensity is consecutively decrease on every 4 hours. It is shown on each beef sample. The R channel of the fresh image has higher percentage of intensity average value than the defective beef. The fresh beef has 56.38% to 66.33% of the R channel intensity average. whereas the defective beef has 37.76% to 51.71% of the R channel intensity.

Keywords—percentage of intensity average, beef quality classification, image pocessing.

I. INTRODUCTION

Data from National Survey of Social Economic in Indonesia (SUSENAS) year 2014 showed that Indonesian consumption of beef is only 2.08 kg / capita / year. This number is lower than beef consumption in other developed countries. In general, the Indonesian people consume beef mostly at celebrations and religious holidays [1].

The potential of cattle breeding development for meat demand in Indonesia is very large. The availability of land, labour, and the capacity of natural resources is abundant. Moreover, the government support, making cattle breeding sector in Indonesia become potential.

However, Indonesia still not be able to fulfill beef stock for nationaldemand. Therefore, Indonesia is depending on import to overcome the situation.

The location of cattle farm in Indonesia is also not evenly distributed in each province. This resulted in a lack of availability meat and an increase price of meat in an area with a great level of meat consumption. The cattle production centers in Indonesia are in East Java province that is equal to 21.09% of beef production throughout Indonesia, while the province of Lampung produce only 2.44% of national beef production.

Based on Information System for Agriculture in 2015, the development of beef prices at the consumer level from 1983 to 2015 has fluctuated and tended to increase. During these periods, the price of beef at the consumer level rose by 13.21% per year. Beef prices last five-year period (2011-2015) tend to increase Rp.69.641 to Rp.104.326 [1].

The high price of beef cause to a few unfair traders take action to mix the fresh beef with defective beef to obtain greater profits. Thus, the problem of defective beef sales in the market are still happening. The inspection and investigation conducted by government has not been able to guarantee that traders did not sells defective beef. Therefore, consumers need the ability to identify beef quality, before buying it.

Until now, fresh and defective beef identification method by consumers is subjectively through visual observation [2]. However, identifying beef manually has disadvantage, there is human visual limitations, differences of human perception on assessing the quality of an object, and ability of each individual knowledge are different [2-4]. Therefore, we need a technological device that can be applied to identify the quality of beef that can be used by people. The first step in research that starts from develop of a method for identifying fresh beef and defective ones. The method is used based on image processing, because the image of meat are able to represent its quality [2].

The beef image can be extracted by using computer analysis features. Through analysis process and classification

2016 International Symposium on Electronics and Smart Devices (ISESD) November 29-30, 2016

using computational algorithms, the meat quality information can be obtained.

This work is focused on identify of beef quality and clasify it as fresh and defective. The aim of this study is measuring the percentage of color intensity average from R, G, and B channel. The optimal feature is gotten based on the percentage values.

II. RELATED WORKS

The fresh and defective meat identification can be performed by laboratory tests. However, the access is limited only by food quality associated institutions. Guzek et al [5] studied the appropriate way to analyze and develop method to identify meat quality outside the laboratory. The results of this study is a method of meat identification using infrared spectroscopy near distance and computer-based image analysis. The research related to the identification of meat has been conducted by several researchers. Nai chian et al [2] classified the meat freshness degree using texture and the change of color space and histogram. Red Green Blue (RGB) and Hue Sturation Intensity (HSI) color space were used in the research. Mean value and mean interval value of color space were used in classification. The other research investigated that the color change in foal meat can vary after thawing out in relation to slaughtering age of the horses and to the post thawing time [6]. The color and multispectral image texture features were used on beef tenderness prediction [7].

Yuristiawan [8] developed an aplication for local beef freshness level detection using feature extraction of color statistical approach.

III. MATERIAL AND METHOD

A. Data Preparation

The tenderloin beef that commonly used for steak is used as the sample. Furthermore, the beef is sliced crosswise as five pieces and placed on the plate. The smartphone’s camera with resolution of 5MP is used to capture the beef images. Since the resolution is commonly used on smartphone and as the minimum resolution of smartphone’s camera today. We assume when using camera with resolution of 5MP can identify the beef quality, it is mean with higher resolution the beef quality can be identified easier. The images are taken every 4 hours consecutively in 24 hours. Since there are 5 samples of beef, the number of data are 30 images.

B. Approach

In this research , fresh and defective beef is identified using feature of the beef image. That feature is percentages of intensity average value from R (red), G (green), and B (blue) channel. The feature is gotten by using image processing method. The steps of the image processing is shown in Fig.1.

Fig. 1 Flowchart of approach image processing

The first step is image preprocessing by cropping the image to get the RoI (Region of Interest) and eliminating the image label and the background. In this research the RoI of image is the beef as the object. The example of the cropped image is shown in Fig 2.

Fig. 2 Example of beef images after 4 hours (first row) and beef images after 16 hours (second row) that have been cropped

Measuring Intensity average value of R, G, and B channel

Start

RGB Image

Since the image is in RGB color, the channels can be extracted. The measurement of the separate color intensity average is done in each channel by using the equations below.

1 1

Then the percentage of the separate color intensity average of each channel is measured by using equation (4), (5), and (6).

%R R therefore the optimal feature is obtained.

IV. RESULT AND DISCUSSION

During beef observation by taken image of beef consecutively every 4 hours, the beef its self has decomposed. The decomposed process can be observed visually based on the beef color of image. However, the color change is subjective and has not been measurable yet. It means that identifying of beef freshness is depend on observer experience. The freshness level of beef can be identified by using image processing method conducted in this research.

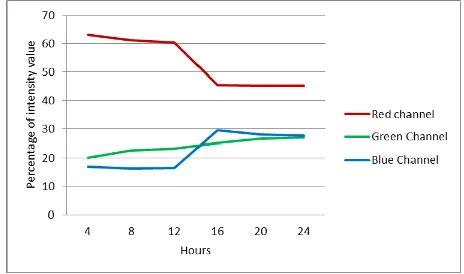

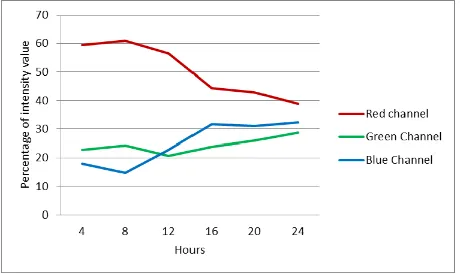

The result of this research is shown in graph. Fig.3- Fig.7 show the alteration percentages of intensity value of R, G, and B channel consecutively every 4 hours on each beef sample.

Fig. 3 The alteration of percentages of intensity value consecutively every 4 hours on beef sample 1

Fig. 4 The alteration of percentages of intensity value consecutively every 4 hours on beef sample 2

Fig. 5 The alteration of percentages of intensity valueconsecutively every 4 hours on beef sample 3

Fig. 6 The alteration of percentages of intensity value consecutively every 4 hours on beef sample 4

Fig. 7 The alteration of percentages of intensity value consecutively every 4 hours on beef sample 5

The results show that the RGB channel intensity has a common pattern. The percentage of R channel intensity value are consecutively decrease every 4 hours and more significantly decrease among 12 and 16 hours. Whereas the percentage of B channel intensity value mostly increase every 4 hours and more significantly increase among 12 and 16 hours. However, the percentage of G channel intensity value did not show alteration significantly. Therefore we assumed that we can clasify the meat quality by using the color intensity measurements. The results show that first 12 hours may clasified as fresh meat and after 12 hours as defective meat.

The minimum, maximum, and average value of the percentages of intensity average are tabulated in Table 1.

TABLE I. THE COMPARISON OF PERCENTAGES OF INTENSITY AVERAGE VALUE

Beef Fresh Defective

%R Min 56.38 37.76 percentages of B channel intensity average value on the fresh beef is mostly lower than the defective beef. However, the percentages of G channel intensity average value on the fresh and defective beef are fluctuating.

The minimum value of the percentage on R channel of fresh beef is 56.38%, therefore the maximum value of percentage on R channel of defective beef is 51.71%. It is mean that it is can be used as the feature to identify the fresh and defective beef. The fresh beef has percentage of R channel intensity average value range from 56.38% to 66.33%, whereas

the percentage value range for defective beef is 37.76% to 51.71%.

On the B channel, the minimum percentage value of fresh beef is 18.05% while the maximum value of the defective beef is 22.96%. The two values are closely intersect, thus it can’t be used as the feature.

Then, the maximum value of the percentage on G channel of fresh beef and the minimum value of percentage on G channel of defective beef have same value, 22.85%.

It means that the proposed method is successfully obtain the optimal feature. The percentage of R channel intensity average value is defined, which can be used to separate the fresh and defective beef.

V. CONCLUSION

The measurements of the color intensity average on the R, G, and B channel of the beef image is presented in this paper. The percentage of R channel intensity is consecutively decrease on every 4 hours and more significantly decrease among 12 and 16 hours.. It is shown on each beef sample. The percentage of color intensity average of each channel is also measured. The R channel of the fresh image has higher percentage of intensity average value than the defective beef. The fresh beef has 56.38% to 66.33% of the R channel intensity average. whereas the defective beef has 37.76% to 51.71% of the R channel intensity. Therefore, the percentage of the color intensity average of the Red channel on beef image can be used as the feature to identify the fresh and defective beef.

VI. FUTURE WORKS

The R, G, and B channel pattern in this paper for beef quality classification may be used to classified another meat that have closely characteristics with beef i.e red color. The others should observed as future works to find the R, G, and B channel pattern.

ACKNOWLEDGMENT

The authors would like to thank Integrated Control System (ICS) Riset Group of Electrical Engineering, University of Lampung and also thank to LPPM for providing financial support through DIPA PNBP Faculty of Engineering.

REFERENCES

[1] R. Suryani, "Agricultural Commodities Outlook: beef livestock subsector (in bahasa : Outlook komoditas pertanian subsektor peternakan daging sapi)." Sekretariat Jenderal, Kementerian Pertanian, Indonesia2015.

[2] V. N. Chian, F. S. A. Saad, M.F.Ibrahim, S. Sudin, A. Zakaria, and A. Y. M. Shakaff, "Meat Color Recognition and Classification Based on Color using NIR/VIS Camera," presented at the 8 th MUCET, Melaka, Malaysia, 2014.

[3] R. C. Gonzales and R. E. Woods, Digital Image Processing, 3rd

ed. Upper Saddle River, New Jersey: Prentice Hall, 2008.

[4] T. Yulianti, "No-reference Retinal Image Quality Assessment Method Development Based on Feature Extraction (in bahasa: Pengembangan Metode Penilaian Kualitas Citra Retina Tanpa Menggunakan Citra Referensi Berbasis Ekstraksi Fitur)," Electrical Engineering, Universitas Gadjah Mada, Yogyakarta, Indonesia, 2015.

[5] D. Guzek, D. Glabska, E. Pogorzelska, G. Pogorzelski, and A. Wierzbicka, "Instrumental Texture Measurement of Meat in A Laboratory Research and on A Production Line," Advances in

Sience and Technology Journal, vol. 7, September 2013.

[6] P. D. Palo, A. Maggiolino, P. Centoducati, and A. Tateo, "Colour Changes in Meat of Foals as Affected by Slaughtering Age and Post-thawing Time," Asian-Aust. J. Anim. Sci., vol. 25,

pp. 1775-1779, December 2012.

[7] X. Sun, K. J. Chen, K. R. Maddock-Carlin, V. L. Anderson, A. N. Lepper, C. A. Schwartz, et al., "Predicting beef tenderness

using color and multispectral image texture feature," Meat

Science Journal, vol. 92, pp. 386-393, December 2012.

[8] D. Yuristiawan, F. Z. Rahmanti, and H. A. Santoso, "Application for Beef freshness level detection using color extraction features with statistics Approach (in bahasa : Aplikasi Pendeteksi Tingkat Kesegaran Daging Sapi Lokal enggunakan Ekstraksi Fitur Warna dengan Pendekatan Statistika," Riptek,

vol. 9, pp. 9-11, 2015.