Production of Crude Enzyme Cellulases from Cassava Waste by Trichoderma viride

I Wayan Arnata 1, Dwi Setyaningsih2, Nur Richana3

1

Agroindustrial Technology, Udayana University, Bali, Indonesia 2

Agroindustrial Technology, Bogor Agricultural University, Bogor, Indonesia 3

Research Institute for Food Crops Biotechnology, Bogor, Indonesia

Correspondence author: [email protected]

Abstract

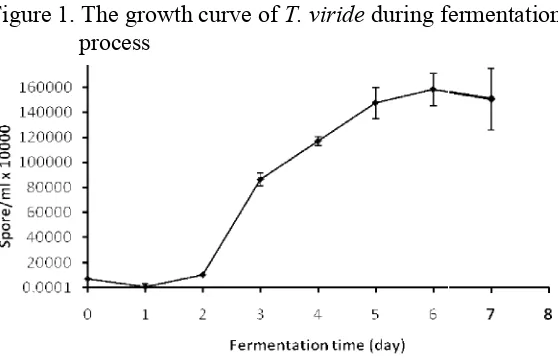

Cellulases are a complex enzymes system, commercially produced by filamentous fungi and bacteria. It has wide applicability in food and beverage industry for effective saccharification process. In this study, the crude enzyme cellulase was produced from cassava waste by Trichoderma viride. The experiments was carried out in two phases. The first phase was the cultivation of Trichoderma viride to determine the stationary phase of maximum spore yield. The second phase was the determination of the produce time needed that gave maximum crude enzyme activity. Enzyme assay was conducted by measuring the FPase and CMCase activities. The results showed that the stationary phase of maximum spore yield occurred after 6 days of cultivation Trichoderma viride with maximum spore number of 1.6 x 109 spores mL-1. Optimum activity of the crude enzyme obtained after 7 days of fermentation with the FPase activities of 4.77±0.72 UmL-1and the CMCase activities of 5.05± 0.42 UmL-1.

Key words : cassava waste, cellulase, Trichoderma viride.

INTRODUCTION

Cellulose being an abundant and renewable resource, are the largest fraction of the plant cell wall of agricultural residues such as straw from wheat, corn, rice soy and cotton, sugarcane bagasse, and cassava waste. In Indonesia, cassava waste was called “onggok”. Onggok is one of the agro-industrial by products that it was obtained from processing of cassava tubers for tapioca production. Onggok generally in solid formed and discarded to the environment without any treatment, so that it would coused problems to environmental polution, espesially in arounded of factory areas (Arnata et al. 2011).

The dry of onggok has a composition of starch 56-60%, cellulose 15-18%, hemicellulose 4-5%, lignin 2-3%, protein 1.5-2.0%, pentosans 2%, and reducing sugars 0.4-0.5% (Wongskeo et al. 2012), while, Susijahadi et al. (1997); Yuwono and Sutopo (2008) reported that onggok was contained high carbohydrates such as 10 % crude fiber and 50-70 % starch. Utilization of “onggok” for material in bioprocesses product is one way to given value added in cassava tuber, in the other hand, it was helped to solve pollution problem. The “onggok” can be used as substrate in ethanol production (Susijahadi et al. 1997) and lactic acid production (Yuwono and Sutopo, 2008). Various product of starch derived such as maltose, maltodextrine and glucose syrup was also made from onggok. In the fermentation process, onggok was used as substrate for fermentation of citic acid and fumaric acid (Panday et al., 2000), amyloglucosidase enzyme (Arnata et al. 2011)

commercially produced by filamentous fungi under solid-state and submerged cultivation. It has wide applicability in textile, food and beverage industry for effective saccharification process (Chellapandi and Jani, 2008) . Commercial cellulase generally obtained from filamentous fungi (Stoilova et al.2005). One of filamentous fungi that it known able to produce cellulose is Trichoderma viride. The production of cellulase is highly influenced by several factor i.a. component of the growth medium, especially carbon sources and time of fermentation process. In this study was conducted to determine the effect of time of fermentation process with T. viride as an inoculum and onggok as an inducer on crude enzyme cellulose.

MATERIALS AND METHODS Raw material

The “onggok” (by-product tapioca factory) was obtained from Bogor West Java. It was sun dried and milled to uniform size (40 mesh). T. viride was obtained from microbiology laboratorium PAU IPB. Onggok was analysed to determine chemical compotition before it is used to fermentation process. Analysed that is moisture, fat, proteine, carbohydrate and crude fiber contents.

Inoculum culture Trichoderma viride

The strains T. viride were used in this work. Stock cultures were maintained on potato dextrose agar (PDA) and cultivation for 5 days at 30 oC. Properly sporulated cultured were used for inoculation.

Cellulase Production

Fermentation process to cellulase production was conducted in batch system at 250 mL erlenmeyer flask with work volume 100 ml. The composition of medium for cellulase production by T. viride was 14 ml (NH4) 2SO410%, 15 ml 1M KH2PO4, 3 ml of 10% urea, 3 ml CaCl2 10%, 3 ml MgSO4. 7H2O 10%, 1 ml of trace elements stock and 2 ml Tween 80, then made 1 liter. Trace elements composed of 495 ml of distilled water, 5 ml of concentrated HCl, 2.5 g FeSO4, 0.89 g MnCl2. 4H2O, 1.76 g ZnSO4.H2O, 1.25 g Co (NO3) 2. 6H2O. For the production of cellulase added 5-10 g cassava wate/”onggok” and 0.5 to 1.0 g polipepton to 1 liter of medium. The production process is carried out at a temperature of 30°C and pH 4.0. The ability to produce cellulase enzyme was observed by measuring activity of FPase and CMCase every 24 hours for 7 days. Enzyme activity curves were made and used to see the achievement of maximum activity timeT. virideto produce cellulase.

Isolation of cellulase

Samples were collected from each periodic time of fermentation were added 1% tween 80 and agitated thoroughly on orbital shaker at 100 rpm for 30 min. The crude enzyme was filtered through Whatman # 42 filter paper. The filtrates were centrifuged at 10000 rpm for 30 min at 4oC to remove the suspended particles.

Analysis methods

The cultivation number of spores were average number of spores spores decreased significantly spores are white with

quickly from the first day showing relatively slow and spores from white number of spores with Growth curveT. viride

In this study Media. Modifications using cassava waste. crude fiber is mainly

microbial growth. In addition, enzyme. Crude fiber

concentration of cassava (2004), crude fiber content and cellulose 2.61%. 8.65 ± 0.10 % moisture, 2.69 ± 0.04 % crude fiber hemicellulose and 13,44 cellulose content 0,56 % fat (wb)

was found to have by dry sugars and 3.13% protein.

In Figure 2 shows activity until the fourth day and the maximal activity or a week. It is also shown fermentation was decreased Maximal activity of 4.77

Figure 1. The

RESULTS AND DISCUSSION

ultivation of T. viride was carried out for 7 days were formed every day. At the beginning of number of spores 7.08 x 107/ml. At the end of the first da

significantly due to spore germination. The next day with an average number of 1.02 x 108/ml. T. viride from the first day until the third day. After the third da

relatively slow phase of spore formation. The color change from white to green was formed after cultivation for 6 days

with an average of 1.58 x 109/ml spores occurred virideis presented in Figure 1.

the production of cellulase enzyme using Modifications done by replacing the pure cellulose as an

. Cassava can be used as an material inducement is mainly fraction of cellulose that could be used as a

In addition, cellulose is also a compound

Crude fiber content of cassava on average 6.58 ± 0.08 cassava waste used in this study was 10 g/L. According

content of cassava was 9.7%, consisting of 1.3%

Arnata et al. (2011) also reported that the contents of onggok were 0.10 % moisture, 2.55 ± 0.14 % ash, 6.54 ± 0.02 % fat, 1.81

0.04 % crude fiber and 62.54 ± 0.00 % starch. Crude fiber 13,44 cellulose. Padonou et al. (2005) was reported that 0,56 % fat (wb), while according to Pothiraj and Eyini (2007)

to have by dry weight 55.8% starch, 14.5% cellulose, 1.21% sugars and 3.13% protein.

2 shows that at the initial time of fermentation was until the fourth day. After that, CMCase enzyme activity

maximal activity of 5.05 ± 0.42 U/ml was obtained after fermentation shown on the amount of FPase activity, which

decreased until the third day and on the next day 4.77 ± 0.72 U / ml was also obtained after fermentation Figure 1. The growth curve of T. virideduring fermentation

process

days by calculating the beginning of inoculation are the the first day, the number of The next day, began to form

viride produces spores fter the third day, T. viride started

hange of the mycelium for 6 days. The maximum occurred on the sixth day.

a modified Andreoti as an induction of cellulase inducement because it contains as a carbon source for of synthesis cellulase ± 0.08% (w/w). The According Richana et al. 1.3% lignin, 5.8% xylan the contents of onggok were 0.02 % fat, 1.81 ± 0.03 % proteine, starch. Crude fiber content 69.98 % (2005) was reported that cassava flour and Eyini (2007) Cassava waste 14.5% cellulose, 1.21% free reducing

The increased

T. viride have to degradation produce glucose to be used synthesis of extracellular time before sporulation phase. The condition is followed by decrease in of cellulase enzymes

The increased caused by the change of Enari (1983) mentioned whereas for cellulase enzyme, the pH should be the enzyme would occur production is directly related cassava. The pattern of

enzymes is presented

The stationary cultivation T. viride activity of the crude enz activities of 4.77±0.72 U m/L

Arnata I W, Setyaningsih Amyloglucosidase From Seminar of Indonesian in Food Safety, Bali: 236

Chellapandi P, Jani HM. Streptomyces Isolates 39:122-127

Enari, TM. 1983. Microbial Cellulose.

Biotechnology Applied Science Published, New York. Figure 2. The change of pH and

increased activity of the enzyme cellulase (CMCase and to degradation of the cellulose fraction contained to be used for cell metabolism. Suhartono (19 extracellular enzymes in the greatest number, normally sporulation, ie, at the end of the exponential phase The condition is expected because in the transition of

ease in the number of carbon sources in the medium, started to increase.

he increased activity of the enzyme in the fermentation process the change of pH from pH 4.0 to 3.28 at the beginning

mentioned that the optimal pH for growth of Trichoderma cellulase production approaching 3.0 . During the

should be maintained in the range from 3.0 to 4.0 would occur if the pH is below 2.0. Decrease in pH that is directly related to the consumption of carbohydrates

The pattern of change in pH during fermentation for the production of is presented in Figure 2.

CONCLUSION

The stationary phase of maximum spore yield occurred with maximum spore number of 1.5 x 109 the crude enzyme obtained after 7 days of fermentation

72 U m/L and CMC-ase activities of 5.05±0.42 U m/L

REFERENCES

W, Setyaningsih D, Richana N. 2011. Production of Amyloglucosidase From “Onggok” by Aspergillus niger. Proceeding Seminar of Indonesian Society for Microbiology ang IUMS-IMS

, Bali: 236-240.

HM. 2008. Production Of Endoglucanase By The Isolates in Submerged Fermentation. Journal

Enari, TM. 1983. Microbial Cellulose. In W.M. Fogarty (ed.) Microbial Enz Biotechnology Applied Science Published, New York.

Figure 2. The change of pH and cellulase activity during fermentation process

and FPase) showed that contained in the substarat to (1989) reported that the normally occurred in the exponential phase and early stationary of exponential phase in the medium, so the synthesis

fermentation process thought to be beginning of the seventh day. Trichoderma about 4.0, the production of the from 3.0 to 4.0 due to inactivation of

that occurs in cellulase carbohydrates contained in the production of cellulase

ield occurred after 6 days of 9

spores m/L. Optimum of fermentation with the FP-ase

42 U m/L.

Production of Crude Enzyme niger. Proceeding International IMS Outrech Program

Endoglucanase By The Native Strains of Journal of Microbiology

Pandey, A., C.R. Soccol, P. Nigarm, V.T. Soccol, L.P.S. Vandenberghe and R. Mohan, 2000. Biotechnological potential of agro-industries residue II. Cassava bagasse. Bioresour. Technol., 74: 81-87.

Pothiraj C., Balaji P. Eyini M. 2006. Enhanced Production Of Cellulases By Various Fungal Cultures in Solid State Fermentation of Cassava Waste. African Journal of Biotechnology Vol. 5 (20): 1882-1885.

Pothiraj C, Eyini M. 2007. Enzyme Activities and Substrate Degradation by Fungal Isolates on Cassava Waste During Solid State Fermentation. Mycobiology 35(4): 196-204.

Richana N, Lestina P, Irawadi TT. 2004. Karakterisasi Lignoselulosa dari Limbah Tanaman Pangan dan Pemanfaatannya Untuk Pertumbuhan Bakteri RXA III-5 Penghasil xilanase. Penelitian pertanian Tanaman Pangan23 (3) : 171-176.

Stoilova IS, Gargova SA, Krastanov AI. 2005. Production of Enzymes by Mixed Culture From Micelial Fungi in Solid State Fermentation. J. Biotechnol and 19 : 103-107.

Suhartono MT. 1989. Enzim dan Bioteknologi. Departemen Pendidikan dan Kebudayaan Direktorat Pendidikan Tinggi Antar Universitas Bioteknologi. IPB. Bogor.

Susijahadi, Neran, Kurniawan MF. 1997. Fermentation Control With Settings Sugar Concentration Cassava Starch Hydrolysis to Produce Alcohol. Proceedings of the seminar of Food Technology, Jember : 45-54.

Yuwono D. Sutopo H. 2008. Production of Lactic Acid from Onggok and Tofu Liquid Waste with Concentrate Maguro Waste Supplement by Streptococcus bovis. Australian Journal of Basic and Applied Sciences, 2(4): 939-942.