Mode I Fracture Toughness of Interply Hybrid Epoxy Composite

Reinforced with Carbon-Basalt Fibers

I.D.G Ary Subagia1,a*, Leonard D. Tijing2,b* and KT. Adi Atmika1,c

1

Mechanical Engineering, Faculty of Udayana University (UNUD), Bukit Jimbaran Badung Bali – Indonesia 80361.

2

School of Civil and Environmental Engineering, University of Technology, Sydney (UTS), P.O. Box 123, Broadway, NSW 2007, Australia.

a

[email protected], [email protected], ctutadi2001.yahoo.com

Keywords: Strength, toughness, basalt, carbon, hybrid composite, mode I fracture toughness.

Abstract. In this study, the fracture strength of hybrid composite epoxy matrix reinforced with woven

carbon-basalt fibers were investigated within the framework of Mode I fracture toughness. The present work aimed to determine the strength and toughness properties of hybrid composite influenced by the basalt fiber contents on the carbon fiber reinforced plastics composite (CFRP) based on mode I fracture toughness. A vacuum assisted resin transfer molding technique was conducted to manufacture the composite. Compact tension specimen form with a single-edge notched was subjected to realizing fracture toughness behavior of the interply hybrid composite. Fracture toughness, KIC, of plane-stresses has been calculated from the critical load and crack length based on the two-dimensional analysis according to ASTM D 5045 standard. We used scanning electron microscopy to examine the fracture surface, and micro-fracture of matrix cracking as well as the fiber breakage of interply carbon/basalt/epoxy hybrid composite. The result showed that the toughness of hybrid composite with increasing basalt fiber contents also increased, as shown by the decrease of the crack propagation of the notch. De-bonding and fiber pull-out have dominated the failure behavior of the hybrid composites. Generally, basalt fabric shows potential to improve toughness of a brittle composite material due to its deformability.

Introduction

Composite materials have shown good potential to replace traditional materials in most of engineering products in the last two decades. This is largely because of their good mechanical properties, good stiffness and high strength [1]. In addition, composite materials have good corrosion resistance, low thermal conductivity, high strength to weight ratio and are light [2]. However, one of their weaknesses is their brittle behavior. Brittle manner of materials is really dangerous due to sudden failure without any warning. Fracture toughness of a material is its sensibility towards cracks. Cracks occurring on a structure or engineering component will decrease the material strength. The fracture toughness value depends on the specimen thickness. It will be decreased by a surface shear mode. Many researchers have agreed that the hybridization approach is a good attempt to improve the fracture toughness of a material [3, 4].

eco-friendly expectation. In the present study, incorporation of both carbon fibers and organic fibers as composite reinforcements has been conducted. One potential fiber for hybridization with carbon fiber is basalt fiber [10-12].

Basalt fibers are a new kind of an organic fiber that has a great potential to replace synthetic fiber (glass fiber) as polymer material reinforcement. Basalt fiber is made from volcanic rock which is produced through a melting process at high temperatures around 1300˚C-1700˚C [13]. Basalt fibers have been promoted as a reinforcement due to its good properties and characteristics such as high tensile and modulus of elasticity [11, 14], eco-friendly, non-combustible [15] and inexpensive [13, 16]. Based from their properties, basalt may have good potential to be applied to engineering products.

In order to improving fracture toughness of composite materials, hybridization of carbon fiber and basalt fibers have been manufactured based on the vacuum assisted resin transfer molding (VARTM) technique. The present work aimed to determine the strength and toughness properties of hybrid composite influenced by the basalt fiber contents of 40 wt% on the carbon fiber reinforced plastics composite (CFRP) based on mode I fracture toughness. Compact tension (CT) specimen tests have

been carried out in accordance with ASTM D 5045 [17]. Fracture toughness (KIC) of the hybrid

composite was tested under mode I fracture toughness test, and the fracture characteristics were analyzed using scanning electron microscope (SEM).

Table 1. Basalt fabrics (EcoB4-F210) compounds

Items SiO2 Al2O3 Fe2O3 MgO CaO Na2O K2O TiO2 P2O5 MnO CrO

% 52.8 17.5 10.3 4.63 8.59 3.34 1.46 1.38 0.28 0.16 0.06

Experimental procedure

Materials

In the present study, two kinds of fabrics for reinforcement had been employed [15]. Plain carbon fabrics (C120-3K) are the main reinforcements, manufactured by Hyundai Fiber Co. Ltd. (Korea). We used a plain basalt fabric (EcoB4-F210) that was fabricated by Seco-Tech (Korea). Basalt fabric components are shown in Table 1. Additionally, epoxy resin (HTC-667C), a thermoseting polymer, was used as matrix bought from Jet. Korea Industrial Corporation. The hardener used was a modified aliphatic amine.

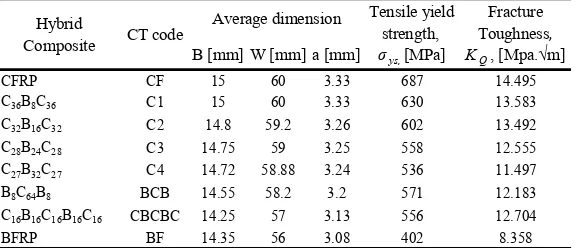

Table 2. Variation of interply hybrid composite panel

B [mm] W [mm] a [mm]

CFRP CF 15 60 3.33 687 14.495

C36B8C36 C1 15 60 3.33 630 13.583

C32B16C32 C2 14.8 59.2 3.26 602 13.492

C28B24C28 C3 14.75 59 3.25 558 12.555

C27B32C27 C4 14.72 58.88 3.24 536 11.497

B8C64B8 BCB 14.55 58.2 3.2 571 12.183

C16B16C16B16C16 CBCBC 14.25 57 3.13 556 12.704

BFRP BF 14.35 56 3.08 402 8.358

Hybrid

Composite CT code

Average dimension Tensile yield strength, σys,[MPa]

Fracture Toughness, KQ, [Mpa.√m]

Fabrication of hybrid composite

pre-notch plus razor notch), is equal with the specimen thickness, B. In this case, the specimen is used accordance to standard: 2 < w/B < 4. Then, the applied PQ was 5% of the secant line which is, P5 = PQ.

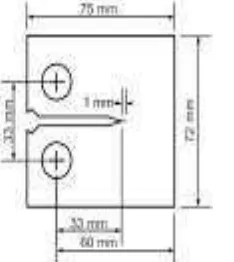

Figure 1. Compact tension specimen geometry.

Test setup and Mode I Fracture toughness analysis

In the present study, the CT specimen of hybrid interply composites was determined based on the mode I fracture toughness using a universal testing machine (Unitec-M, R&B). Two tonnes load cell was used with cross head speed of 1 mm/min. Crack propagation of the specimen is measured using the clip-on gage of 0.25 mm (Epsilon Technology Corp. Jackson, WY USA). According to ASTM D 5045 standard, the fracture toughness was measured five times for each variety of hybrid composite.

Theoretically, fracture toughness of plain strain condition is strongly dependent on the specimen thickness. The plastics zone at the crack tip has to be appreciably less than the specimen thickness, B, as shown in Eq. 1 [17]: Here, the width of specimen followed the recommended size, which is:

2

In this work, the toughness for CT specimen is calculated following Eq. 3:

1

Here, PQ is critical load that was measured by projecting a line whose slope is 5% less than the original

slope of curve, and f (δ) is the geometry function that depends on the crack size of specimen width

ratio.

Result and Discussion

Mode I fracture toughness behavior hybrid composite

basalt fiber reinforced plastic (BFRP) (Fig. 2b). At point "B" (inset of Fig. 2b), only quasi-elastic deformation occurred ahead of the notch as marked by a bright color in the figure. At this point, the crack started, but pop-in behavior did not occur. This result indicates that CFRP has semi-stable crack growth failure compared with BFRP composite.

A

pp

lie

d

L

oa

d,

P

(K

gf

)

Figure 2. Load-displacement curves of the compact tension specimens: a. carbon fabric, b. basalt fabric.

Fr

ac

tu

re

T

ou

gh

ne

ss

, K

Q

, [

M

Pa

√m

]

(a) (b)

Figure 3. Mode I fracture toughness results: a) effect of the amount of basalt fabrics inserted into the carbon fabric, and; b) effect of the lamination sequences mode between the basalt fabrics with carbon fabrics.

Figure 3 shows the average fracture toughness behavior of interply hybrid epoxy composite reinforced with plain woven carbon fabrics and basalt fabrics. We can see from the results that an opposite trends has occurred for fracture toughness of interply hybrid composites. Here, the fracture toughness of each hybridization variation of carbon fabrics increased with increasing the amount of basalt fabrics content , which may be due to the deformability of basalt fabrics. This result indicates that basalt fiber can potentially improve the fracture toughness of CFRP. Similar results have been reported [20]. In the present work, increasing the amount of plain woven basalt content (40 wt%) has given influence on the deformable toughness of the composites increasing up to 20.68%. The interply hybrid epoxy composite with sequence laminate mode between the carbon fabrics and basalt fabrics showed some effect on the fracture toughness of the composites compared with CFRP and CBC mode (B1) (see Fig.3b). From the result, it can be seen that the sequence laminate mode CBCBC showed the

best result and is therefore a potential configuration for improving the fracture toughness (KIC) of

composite materials.

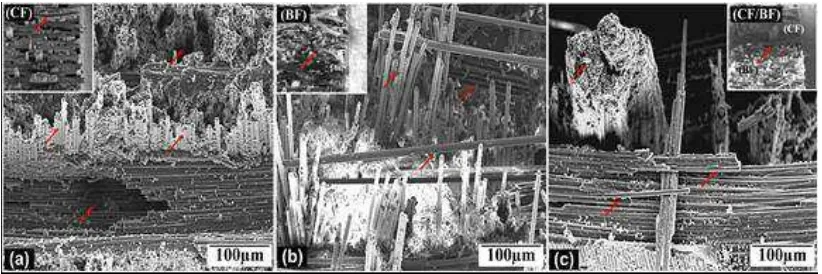

Failure behavior of interply hybrid composite under mode I

nature. This was different with the failure mode of the epoxy composite reinforced with plain woven basalt fibers (Fig. 4b). This difference could be due to the good deformability of basalt fabrics. Generally, the failure of interply epoxy hybrid composite reinforced with plain woven carbon and basalt fabrics were dominated by failure via pull-out, de-lamination and de-bonding form. For BFRP, the basalt yarn failure is by individual fiber rupture [21]. Figures 4a, b and c show the failure shape of the CT specimen of CFRP, BFRP and interply hybrid composite of carbon fabric with 40 wt% basalt fabrics, respectively.

Figure 4. Fracture surfaces of interply hybrid composites showing region of failure along transversely as well as longitudinally arranged fiber bundles, and sites of brittle matrix fracture; a) CFRP, b) BFRP and, c) 40wt% of basalt fabrics hybrid with carbon fabrics.

Conclusions

In this study, we successfully investigated the fracture toughness and failure characteristics of interply hybrid epoxy composites reinforced with carbon fabrics and basalt fabrics under mode I fracture toughness test. The specimen was manufactured using VARTM process. CT specimen test was carried out. From this investigation, the results showed that the strength fracture toughness, KIC, decreased with the increase of basalt fibres contents (40 wt%) in the CFRP. The toughness of hybrid composite with increasing basalt fibre contents also increased, as shown by the decrease of the crack propagation of the notch. De-bonding and fiber pull outs dominated the failure behaviour of the hybrid composites. This is an indication of instances of shear deformations, which occurred locally in such structures. Here, due to the deformability of basalt fibres hybridization with carbon fibres shows potential to improve the fracture toughness of hybrid composites under the mode-I test.

Acknowledgements

The authors would like to thank Udayana University, Bali, Indonesia for the support of this study and in realizing this paper.

References

[1] Reza Eslami Farsani, Seyed Mohammad Reza Khalili, Vahid Daghighi and Reza Fazaeli, Creep Behavior of Basalt and Glass Fiber Reinforced Epoxy Composites. Journal of Mechanical Research and Application, 3 (1) (2011) 29-36.

[2] Kedar S Pandya, Ch. Veerraju and N.K. Naik, Hybrid composites made of carbon and glass woven fabrics under quasi-static loading. Materials and Design, 32 (2011) 4094–4099.

[4] Liu Q and Hughes M, The fracture behaviour and toughness of woven flax fibre reinforced epoxy composites. Composites Part A-Applied Science and Manufacturing, 39 (2008) 1644-1652. [5] P.S. Shivakumar Gouda, S.K. Kudari, Prabhuswamy S and Dayananda Jawali, Fracture toughness of glass-carbon (0/90)S fiber reinforced polymer composite – an experimental and numerical study. Journal of Minerals & Materials Characterization & Engineering, 10 (8) (2011) 671-682.

[6] Jin Zhang, Khunlavit Chaisombat, Shuai He and Chun H. Wang, Hybrid composite laminates reinforced with glass/carbon woven fabrics for lightweight load bearing structures. Materials and Design, 36 (2012) 75–80.

[7] Taketa I, Ustarroz J, Gorbatikh L, Lomov S. V and Verpoest I, Interply hybrid composites with carbon fiber reinforced polypropylene and self-reinforced polypropylene. Composites Part A-Applied Science and Manufacturing, 41 (2010) 927-932.

[8] Ahmed K.S and Vijayarangan S, Elastic property evaluation of jute-glass fibre hybrid composite using experimental and CLT approach. Indian J Eng. Mater Sci, 13 (2006) 435-42.

[9] I.D.G Ary Subagia, Leonard D Tijing, Yonjig Kim, Cheol Sang Kim, Felipe P Vista Iv and Ho Kyong Shon, Mechanical performance of multiscale basalt fiber–epoxy laminates containing tourmaline micro/nano particles. Composites Part B: Engineering, 58 (2014) 611-617.

[10] Enrico Quagliarini, Francesco Monni, Stefano Lenci and Federica Bondioli, Tensile characterization of basalt fiber rods and ropes: A first contribution. Construction and Building Materials, 34 (2012) 372–380.

[11] T. Czigány, J. Vad and And K. Pölöskei, Basalt fiber as a reinforcement of polymer composits. Periodica Polytechnica Ser.Mech.Eng, 49 (1) (2005) 3–14.

[12] Dalinkevich A.A, Gumargalieva K.Z, Marakhovsky S.S and Soukhanov A.V, Modern basalt fibrous materials and basalt fiber-based polymeric composites. Journal of Natural Fibers, 6 (2009) 248-271.

[13] Kunal Singha, A short review on basalt fiber. International Journal of Textile Science, 1 (4) (2012) 19-28.

[14] V. Lopresto, C. Leone and I. De Iorio, Mechanical characterisation of basalt fibre reinforced plastic. Composites Part B: Engineering, 42 (2011) 717–723.

[15] I.D.G Ary Subagia, Yonjig Kim, Leonard D Tijing, Cheol Sang Kim and Ho Kyong Shon, Effect of stacking sequence on the flexural properties of hybrid composites reinforced with carbon and basalt fibers. Composites Part B: Engineering, 58 (2014) 251-258.

[16] V. Fiore, G. Di Bella and A. Valenza, Glass–basalt/epoxy hybrid composites for marine applications. Materials and Design, 32 (2011) 2091–2099.

[17] Astm-D-5045-99, Standard test method for plane-strain fracture toughness and strain energy release rate of plastic maerials. ASTM International, West conshohocken, (2007) PA 19428-2959, United State.

[18] Bender D, Schuster J and Heider D, Flow rate control during vacuum-assisted resin transfer molding (VARTM) processing. Composites Science and Technology, 66 (2006) 2265-2271.

[19] Nina Kuentzer, Pavel Simacek, Suresh G Advani and Shawn Walsh, Correlation of void distribution to VARTM manufacturing techniques. Composites Part A: Applied Science and Manufacturing, 38 (2007) 802–813.

[20] K. Mohamed Kaleemulla and B. Siddeswarappa, Plane strain fracture behaviour of fabric reinforced hybrid composites under varied notch configurations. Journal of Minerals & Materials Characterization & Engineering, 8, No.6 (2009) 495-508.