Cotton: a flow cycle to exploit

Maria Proto *, Stefania Supino, Ornella Malandrino

Uni6ersita` degli Studi di Salerno,Facolta di Economia,Dipartimento di Studi e Ricerche Aziendali,Via Ponte don Melillo, Cattedra di Merceologia,84084Fisciano,SA,Italy

Accepted 8 October 1999

Abstract

The relation between agricultural resources, industrial activities and the environment has complex aspects because of many dynamic interrelationships. Among the sectors that are showing a certain environmental sensibility, there is the textile one, and particularly the cotton sector. Cotton is one of the most important non-food crops in the world. Its products are destined to different industries: textiles, food, chemicals and so on. In Italy, cotton cultivation encounters economic problems that makes its development quite difficult. In this paper, the development opportuni-ties in agricultural and manufacturing processes are analysed in view of new trends that are characterised by sustainable life-cycle assessments. © 2000 Elsevier Science B.V. All rights reserved.

Keywords:Cotton; Flow cycle; Non food crops; Life cycle assessments

1. Introduction

Cotton, included in the genus ‘Gossypium’1, is

economically the most important vegetable fibre. Botanically, the cotton fibres are the protective

covering of the seeds in a cotton plant. The cotton fibre, in its pure form, and also in blends, is the principal clothing fibre of the world, accounting for about 50% of total world fibre production (Shariq, 1995).

Cotton fibre production depends on many fac-tors, including soil productivity, climate2, cost of

production, market conditions, government pro-grams, etc.

This paper analyses the biomass balance related to the cotton crop, and aims at underlining how it is possible to obtain a large variety of different products utilised in various fields from this inter-esting renewable resource.

* Corresponding author. Tel.: +39-89-963146; fax: + 39-89-963505.

1The most important species included in theGossypiumare

hirsutum,barbadense,arboreumandherbaceum. It is very easy to distinguish each type by using a microscope or chemical staining. The average cotton plant is a herbaceous shrub with a normal height of 4.5 – 6.0 m (Villavecchia Eigenmann, 1973).

2The most favourable growing conditions for this plant is a

warm climate (21 – 30°C mean temperature).

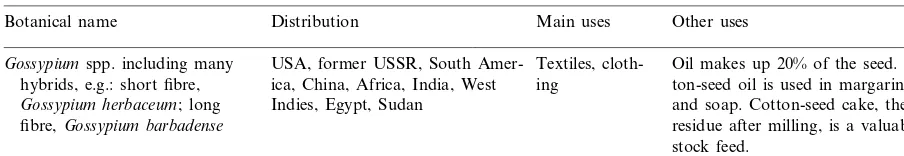

Table 1

Distribution and main uses of cotton

Other uses

Botanical name Distribution Main uses

Oil makes up 20% of the seed.

Cot-Gossypiumspp. including many USA, former USSR, South Amer- Textiles,

cloth-ing ton-seed oil is used in margarine hybrids, e.g.: short fibre, ica, China, Africa, India, West

Gossypium herbaceum; long Indies, Egypt, Sudan and soap. Cotton-seed cake, the residue after milling, is a valuable fibre,Gossypium barbadense

stock feed.

2. Cultivation and production report

The use of cotton dates back to a remote period. It has been used as a fibre in spinning and weaving for over 5000 years. It was originally used in India, later spread to China and Central Asia, and then reached Italy (Sicily), Spain and Africa (Sarno, 1987). As trade flowed from the East into Europe, cotton products became a valu-able commodity. In Great Britain, the textile in-dustry began to develop quite rapidly after 1500, with most of the technological advances in spin-ning and weaving originating in that country. As regards Italy, the diffusion of cotton cultivation dates back to about 1850 when the Italian textile industries, like those in other European countries, had a crisis scarcity of the raw material.

During the following decades, the history of the culture of cotton in Italy suffered various prob-lems. After periods of crises, improvements and downfalls, cotton production has almost com-pletely disappeared.

Today, the world production of raw cotton — a renewable resource from which it is possible to obtain textiles, pulp and paper, but also different products in the field of chemical, pharmaceutical, cosmetics, food, zootechnics, etc., that are

ob-tained from cotton-seed oil — is about 53×106

tons, and the most important producers are the USA, the former USSR, South America, China and India, which together contribute to almost 80% of total production. Other important produc-ers are East Africa, Egypt and the Sudan (Table 1) (Shariq, 1995).

The most important world raw cotton

produc-ing countries (total amount about 20×106

tons) are reported in Table 2.

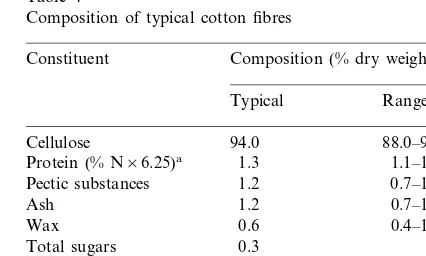

In Table 3, the percentage of the world produc-tion of cotton fibres, reduced to half during our century, is confronted with wool and chemical fibres (artificial and synthetic). The chemical com-position (%) of dry weight of cotton fibres is shown in Table 4.

A renewed interest in this crop is manifested by Italy and the EU — today the importers of 338 000 and 952 000 tons, respectively (Rapporto sull’industria Cotoniera e Liniera, 1998) — be-cause cotton crop can be seen as a useful renew-able resources from which to obtain fibres and other derived products3.

The best known by-product of the cotton plant is lint; that is the hairs that grow on the seed coat yeld. Another very valuable product is in the form of oil, which makes up 20% of the seed. Cotton-seed oil is used for cooking, margarine and soap, but also for chemical and pharmaceutical uses. Cotton-seed cake, the residue after milling, is a valuable animal feed (Villet, 1994).

3. Problems and perspectives on cotton crop

The relation between agricultural resources, in-dustrial activities and the environment has

com-plex aspects because of many dynamic

interrelationships. The cotton textile sector is

3Chemists recognise several different types of cellulose,

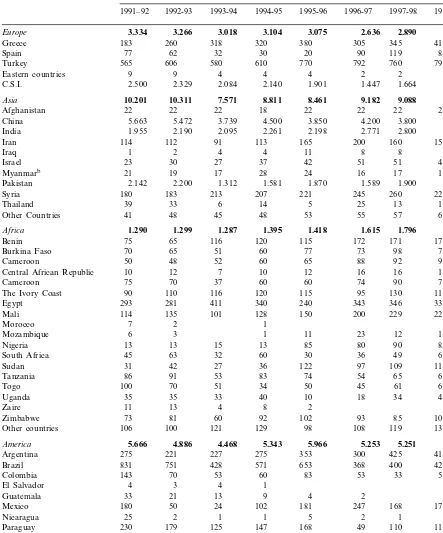

Table 2

Main producers of cotton in the world

Producers/countries Thousands of tons

1992-93 1993-94 1994-95 1995-96 1996-97

1991–92 1997-98 1998-99a

Europe 3.334 3.266 3.018 3.104 3.075 2.636 2.890 3.033

260 318 320 380

183 305

Greece 345 415

77

Spain 62 32 30 20 90 119 89

606 580 610 770 792

Turkey 565 760 799

9 4 4 4

9 2

Eastern countries 2 2

2.329 2.084 2.140 1.901

C.S.I. 2.500 1.447 1.664 1.728

10.311 7.571 8.811

Asia 10.201 8.461 9.182 9.088 9.114

Afghanistan 22 22 22 18 22 22 22 22

5.472 3.739 4.500 3.850

5.663 4.200

China 3.800 4.000

1.955

India 2.190 2.095 2.261 2.198 2.771 2.800 2.711

Iran 114 112 91 113 165 200 160 151

2 4 4 11

Myanmarb 17 18

2.142

Pakistan 2.200 1.312 1.581 1.870 1.589 1.900 1.859

183 213 207 221

180 245

Syria 260 227

39

Thailand 33 6 14 5 25 13 10

41

Other Countries 48 45 48 53 55 57 60

1.299 1.287 1.395

Africa 1.290 1.418 1.615 1.796 1.801

Benin 75 65 116 120 115 172 171 171

65 51 60

Burkina Faso 70 77 73 98 78

48 52 60 65

50 88

Cameroon 92 96

10

Central African Republic 12 7 10 12 16 16 17

70 37 60

Cameroon 75 60 74 90 73

110 116 120 115

90 95

The Ivory Coast 130 115

281 411 340 240

Egypt 293 343 346 338

135 101 128 150

114 200

South Africa 45 36 49 63

42 27 36 122

31 97

Sudan 109 111

91 53 83 74

Tanzania 86 54 65 67

70 51 34 50

Zimbabwe 81 60 92 102 93 85 108

Other countries 106 100 121 129 98 108 119 131

4.886 4.468 5.343

America 5.666 5.966 5.253 5.251 5.278

Argentina 275 221 227 275 353 300 425 419

751 428 571

Brazil 831 653 368 400 425

70 53 60 83

Table 2 (Continued)

Thousands of tons Producers/countries

1992-93 1993-94 1994-95 1995-96

1991–92 1996-97 1997-98 1998-99a

24 18

Venezuela 25 22 16 22 18 20

33 15 24 25

35 26

Other countries 43 49

359

Oceania 339 329 329 310 614 622 577

20.101 16.671 18.982 19.230 19.300 19.647

World total 20.850 19.803

aEstimated dates. bEx Burma.

Table 3

World production of cotton wool and chemical fibresa

Thousand of tons/(%) Years

% Wool % Chemical fibres %

Cotton Total %

81 730 19

1900 3.162 1 3.893 100

1920 4.629 85 816 15 15 5.460 100

76 1.134 12 1.132

6.907 12

1940 9.173 100

10.113

1960 68 1.463 10 3.358 22 14.934 100

54 1.659

1970 11.784 7 8.397 39 21.840 100

47 1.599 5 14.182

13.844 48

1980 29.625 100

18.997

1990 47 1.927 5 19.151 48 40.075 100

19.962

1995 45 1.485 3 22.104 52 43.551 100

44 1.456 3 23.209

18.960 53

1996 43.625 100

42 1.450

1997 19.580 3 26.763 55 47.793 100

aRapporto sull’industria Cotoniera e Liniera, 1998.

demonstrating a certain environmental awareness in its production cycle.

To determine the environmental impact con-nected to a product, it is necessary to estimate inputs and outputs of its productivity cycle. To-day, the Life Cycle Analysis (LCA), with a ‘cra-dle-to-grave’ approach, is increasing, but it is still often incomplete and approximate (Proto et al., 1996). The first step of this flow cycle includes agricultural activities, where many important challenges are turned towards the reduction of pesticides used to control insects, disease and weeds, and defoliants to facilitate harvest. In most areas, cotton production consumes more pesti-cides than any other agricultural crop (Bacheler, 1996).

Cotton fresh from the bale has the appearance of ‘cotton wool’ mixed with pieces of dead leaf and other debris. Hand-picked cotton is, however,

cleaner than machine-picked cotton. Samples from different sources vary greatly in cleanliness, staple length and colour.

Table 4

Composition of typical cotton fibres

Constituent Composition (% dry weight)

Typical Range

aStandard method of estimating percentage of protein from

Fig. 1. Cotton crop: global balance of biomass (moist weight) (1 ha). For the source, see Proto et al., (1996a).

Cotton picking is highly labour-intensive, and on a large scale is often carried out by machinery. In many parts of the world, however, picking is carried out by hand. Since cotton must be picked at weekly intervals to prevent discoloration of the lint in the field, it is a very laborious task: small-holders average only 9 kg per day.

The first stage in processing the cotton bales into fibre suitable for spinning is the removal of the cotton seeds by ginning. The mechanical ginning process, invented by Ely Whitney in 1793, is the principle applied today to remove foreign matter and moisture, and to separate cottonseed from raw seed cotton. To obtain lint cotton, various impuri-ties must be removed before the manufacturing process. These are than transformed and later employed as high added-value products.

Once the cotton is grown, ginned and manufac-tured, the textile processing necessary to provide the colourful fabrics desired requires the use of numerous environmentally dangerous materials. In fact, the dying and finishing processes consume huge amounts of energy and water, mixed with various chemical substances.

Scientists are engaged in the process of identify-ing and isolatidentify-ing useful genes from various sources

and evaluating them in the possibility of improving cotton. Most current genetic-engineering attempts are targeted at conferring agronomic traits such as insect herbicide and stress tolerance.

Transgenic varieties resistant to both insects and herbicides are expected to be available within the next few years (Bacheler, 1996).

An American researcher (Maliyakal, 1994) de-veloped the first naturally coloured cotton, consid-erably reducing the environmental impact. Today, the production of organic cotton is about 5000 tons.

However, in the light of the high environmental impact of the cotton cycle, it is necessary not only to improve photosynthetic efficiency of the crop and to introduce new genetic engineering but also to utilise all the by-products obtained from pro-cessed cotton. In order to analyse the most impor-tant substances deriving from the cotton cycle that may be employed in a large variety of industrial sectors4, the global biomass balance of these

re-sources is reported (Fig. 1).

4Cotton cultivation has declined since the appearance of

Fig. 2. Traditional and innovative uses of cotton plant.

may be obtained through the diffusion, on large quantities of cotton products, of the European

Ecolabel, introduced in Regulation 880/92.

To-day, the European Commission has placed the environmental criteria on the elaboration of a life-cycle analysis for bed linen and T-shirt only. It is obvious, therefore, that one of the cotton sector’s prime future aims is to achieve certifica-tion of its environmental quality.

References

Bacheler, J.S., 1996. Cotton insect scouting guide, Center for IPM, April 1996, http://ipmwww.ncsu.edu/cotton/insect/

scout –insect.htlm.

Maliyakal, E.J., 1994a. Cotton futures. Chemtech 24 (10), 27 – 30.

Proto, M., Malandrino, O., Supino, S., 1996. Environmental quality management: tools for sustainable development, Proceedings of Fifth International Commodity Science Conference ‘Quality for European Integration’, Poznan, 19 – 21 September 1996, 151-154.

Proto, M., Malandrino, O., Supino, S., 1996a. ‘Il cotone: una filiera da non sottovalutare’, Atti del XVII Congresso Nazionale di Merceologia Merceologia e cicli produttivi nel settore agroindustriale alle soglie del 21° secolo, Lecce, 3 – 5 October, 1996a, 230 – 238.

Proto, M., Malandrino, O., Supino, S., 1996b. Disponibilita` e impieghi di cellulosa in Italia: realta` e prospettive, Atti del XVII Congresso Nazionale di Merceologia ‘Merceologia e cicli produttivi nel settore aggroindustriale alle soglie del 21° secolo, Lecce, 3 – 5 October, 1996b, 239 – 248. .Rapporto sull’Industria Cotoniera del Lino e delle Fibre

Affini, September – October 1998.

Sarno, R., 1987. Situazioni e prospettive tecnico-economiche della coltivazione del cotone in Sicilia, Economia e Credito 1, 55 – 81.

Shariq, K., 1995. ‘Cotton’, Chemical Economics Handbook, 540.3000 A 540.3000 S, SRI International.

Villavecchia Eigenmann, 1973. Nuovo Dizionario di Merce-ologia e Chimica Applicata, Hoepli Editore, 3, 1137 – 1145. Villet, R.H., 1994. Increasing the value of agricultural

feed-stocks. Chemtech 24 (9), 44 – 48.

The most important uses of these materials are reported in Fig. 2.

Until more attention is placed on the relative problems concerning the environmental quality of products and processes, it is essential to identify suitable ways of creating correct eco-management policies and outlining appropriate instruments in order to solve the current difficulties.

These derive principally from the scarce har-monisation of instruments suggested up to now (life-cycle analysis, environmental balances, ecola-bels, etc.). Their results are not comparable and, above all, are not very ‘transparent’, particularly for the final consumer.

In the textile sector, the diffusion of ‘ecological private labels’, only disorientate and complicate the market, rather than facilitate commercial ex-changes. On the contrary, opposite contributions