Recent Decisions in

Technologies for

Sustainable Development

Recent Decisions in

Technologies for Sustainable

Development

Selected, peer reviewed papers from the

3

rdInternational Conference on

Sustainable Technology Development

(ICSTD 2014),

October 30-31, 2014, Bali, Indonesia

Edited by

A. Ghurri, N.P.G. Suardana, N. N. Pujianiki,

I. N. Arya Thanaya, A.A. Diah Parami Dewi,

I. N. Budiarsa, I. W. Widhiada,

Copyright 2015 Trans Tech Publications Ltd, Switzerland

All rights reserved. No part of the contents of this publication may be reproduced or transmitted in any form or by any means without the written permission of the

publisher.

Trans Tech Publications Ltd Churerstrasse 20

CH-8808 Pfaffikon Switzerland

http://www.ttp.net

Volume 776 of

Applied Mechanics and Materials ISSN print 1660-9336

ISSN cd 1660-9336 ISSN web 1662-7482

Full text available online at http://www.scientific.net

Distributed worldwide by and in the Americas by

Trans Tech Publications Ltd Trans Tech Publications Inc. Churerstrasse 20 PO Box 699, May Street CH-8808 Pfaffikon Enfield, NH 03748

Switzerland USA

Preface

This volume was selected from papers presented at the 3rd International Conference on

Sustainable Technology Development (ICSTD Bali 2014), which have been held in Udayana

University Bali during October 30-31, 2014. The conference was organized by Faculty of Engineering,

University of Udayana Bali Indonesia. This conference covered wide range of engineering issues

toward the achievement of sustainablility.

In order to meet high standard of Applied Mechanics and Materials, the organization committee

has made their efforts to do the following things. Firstly, all submitted papers have been reviewed by 2

anonymous expert reviewers, poor quality papers have been rejected after reviewing. Secondly,

periodically review meetings have been held around the reviewers about three times for exchanging

reviewing suggestions. Finally, the conference organization had several preliminary sessions before the

conference. Through efforts of the scientific committee and Editors team, the volume will be the best

collected papers.

We would like to thank the Faculty of Engineering, University of Udayana, the member of

organizing and scientific committees, and also to TTP publisher.

Editors

Ainul Ghurri

N.P.G. Suardana

Ni Nyoman Pujianiki

I Nyoman Arya Thanaya

A.A. Diah Parami Dewi

I Nyoman Budiarsa

I Wayan Widhiada

I Putu Agung Bayupati

Table of Contents

PrefaceChapter 1: Technologies of Sustainable Development in Civil

Engineering, Transportation and Urban Planning

Sustainable Development of Concrete Using GGBS: Effect of Curing Temperatures on the Strength Development of Concrete

G. Turu'allo 3

Properties of Sand Sheet Asphalt Mixture Incorporating Waste Plastic

I.N.A. Thanaya, I.G.R. Purbanto and I.G. Wikarga 9

Asphalt Pavement Temperature Profile for Tropical Climate in Indonesia

I.M.A. Ariawan, B.S. Subagio and B.H. Setiadji 17

The Development of Slurry Seal Design with Ordinary Portland Cement Replacement by Low Calcium Fly Ash

A. Setyawan, D. Sarwono and M.S. Adnan 24

The Structural Properties Assessment of Thin Hot Mixture Asphalt for Pavement Preservation

A. Setyawan, A.H. Mustafa Elshawesh and S. As'ad 30

Mechanical Strength of Hydraulic Binder Made by Blending Type I Portland Cement and Pozzolan

I.M.A.K. Salain 36

Laboratory Tests on Failure of Retaining Walls Caused by Sinusoidal Load

A.M. Hidayati, R.W. Sri Prabandiyani and I.W. Redana 41

Deformation Behavior of Concrete due to the Influence of the Steel Ring Width Variations as the External Confinement

E. Safitri, I. Imran, Nuroji and S. Asa'ad 47

Evaluation of High Grade Recycled Coarse Aggregate Concrete Quality Using Non-Destructive Testing Technique

N.N. Kencanawati, J. Fajrin, B. Anshari, Akmaluddin and M. Shigeishi 53

Experimental and Theoretical Investigation of Bolted Bamboo Joints without Void Filled Material

G.M. Oka, A. Triwiyono, A. Awaludin and S. Siswosukarto 59

The Significant Importance to Measure Road Safety

S.A. Caroline 66

Accessibility to Location of Activities in Denpasar City, Bali-Indonesia

P.A. Suthanaya 74

Travel Time Estimation Based on Spot Speed with Instantaneous and Time Slice Model

A.M.H. Mahmudah, A. Budiarto and S.J. Legowo 80

Port Location Selection Model: Case Study of Tourism Sector in Bali

R.M.N. Budiartha, T. Achmadi and D. Manfaat 87

Determining Passenger Car Equivalent for Motorcycle at Mid-Block of Sesetan Road

I.G.R. Purbanto 95

Readiness Criteria: Indonesias’ New Initiative to Ensure Sustainable Development Program

A. Merthayasa 101

Conceptual Framework of Bidding Strategy in Order to Improve Construction Project Performance

I.N.Y. Astana, H.A. Rusdi and M.A. Wibowo 108

The Conceptual Framework of Design Change Effects in Some Project Delivery Systems

A.A.G.A. Yana, H.A. Rusdi and M.A. Wibowo 114

An Identification of Construction Project Overheads for Sustainable Cost Management and Controlling Practices (CMCPs)

N.M. Jaya and A. Frederika 121

Risk Analyses for Riau Regional Water Supply Projects (SPAM), Indonesia

b Recent Decisions in Technologies for Sustainable Development

Modeling Discharge of the Bangga Watershed under Climate Change

I.W. Sutapa, M. Bisri, Rispiningtati and L. Montarcih 133

Water Resources Management of Subak Irrigation System in Bali

I.N. Norken, I.K. Suputra and I.G.N.K. Arsana 139

Study of the Evolution of Sanur Beach Nourishment Project for Beach Enhancement

I.G.B.S. Dharma and S.S. Efendi 145

Numerical Simulation of Breaking Waves in a Wave Group by SPH

N.N. Pujianiki 151

The Study on Bore Piles Foundation of the Reinforced Concrete Arch Bridge Beams of Tukad Pekerisan and Tukad Penet

I.N. Sutarja and I.W. Wayan Redana 157

The Importance of the Physical Boundary Line onBali Coastal Tourist Resorts

A. Rajendra, N. Temple and R. Nicholls 163

Comparative Analysis of Traditional House at Taman Mini Indonesia Indah with Modern House

S. Purnawan, I.W. Sukania and L. Widodo 169

Chapter 2: Materials and Technologies for a Sustainable Development

The Property and Applicability to Auto Industry of Natural Fiber Reinforced Composites

R.H. Hu, Z.G. Ma, S. Zheng, C.L. Zheng and A.J. Jiang 179

Fracture Parameters of Short Carbon Fiber Reinforced Polycarbonate Composite Fabricated by Injection Molding Process

M.G. Hwang, G.H. Kim, H.J. Park, Y.G. Lee, C.M. Yang, J.K. Lim and H.Y. Kang 186

Effect of Polar Extract of Cocoa Peels Inhibitor on Mechanical Properties and Microstructure of Mild Steel Exposed in Hydrocloric Acid

Gunawarman, Y. Yetri, Emriadi, N. Jamarun, Ken-Cho, M. Nakai and M. Niinomi 193

Hardness Distribution and Effective Case Depth of Low Carbon Steel after Pack Carburizing Process under Different Carburizer

D.N.K.P. Negara, I.D.M.K. Muku, I.K.G. Sugita, I.M. Astika, I.W. Mustika and D.G.R. Prasetya 201

The Effect of Solidification on Acoustical of Tin Bronze 20Sn Alloy

I.K.G. Sugita and I.G.N. Priambadi 208

Morphological Analyses and Crystalline Structures of Anodic TiO2 Thin Film on Ti6Al4V

Alloy Using Phosphate and Calcium Containing Electrolyte under Different Voltage and Calcium Molarity

I.N.G. Antara, K.I.M. Gatot, I.M. Budiana and D.K. Choi 215

Determination of Optimal Clinker Factor in Cement Production by Chemical Grinding Aids Addition

T. Eryanto and E. Amrina 223

Wear of Carbon Steel (0.65%C) in Rolling-Sliding Contact with Creep Ratio

M. Widiyarta, T.G.T. Nindhia and H. Mudiastrawan 229

Hardness Prediction Based on P-h Curves and Inverse Material Parameters Estimation

I.N. Budiarsa 233

The Influence of Austenisation Temperature and Holding Time on Mechanical Properties, Scale Thickness, and Microstructure in Alloy Steel

A. Aziz, M. Hidayat and I. Hardiyanti 239

Hardness, Density and Porosity of Al/(SiCw+Al2O3p) Composite by Powder Metallurgy

Process without and with Sintering

K. Suarsana and R. Soenoko 246

Development of Fiberglass Woven Roving Composite as an Alternative Material for the Hull of Fishing Boat

Winarto, W. Eddy, R. Liza and H. Syamsul 253

Tensile Strength of Banana Fiber Reinforced Epoxy Composites Materials

A.P. Irawan and I.W. Sukania 260

Green Composites Based on Recycled Plastic Reinforced Local Sisal Fibers

N.P.G. Suardana, N.M. Suaniti and I.P. Lokantara 264

Cement Bonded Sol-Gel TiO2 Powder Photocatalysis for Phenol Removal

Applied Mechanics and Materials Vol. 776 c

Review on Zn-Based Alloys as Potential Biodegradable Medical Devices Materials

M.S. Dambatta, D. Kurniawan, S. Izman, B. Yahaya and H. Hermawan 277

Bone Implant Materials from Eggshell Waste

I. Sopyan 282

Boiling Phenomenon of Tabulate Biomaterial Wick Heat Pipe

W.N. Septiadi and N. Putra 289

Fluidization Characteristic of Sewage Sludge Particles

I.N.S. Winaya, R.S. Hartati and I.N.G. Sujana 294

Design of Fluidized Bed Co-Gasifier of Coal and Wastes Fuels

I.N.S. Winaya, R.S. Hartati, I.P. Lokantara, I.G. Subawa and I.M.A. Putrawan 300

Chapter 3: Advanced Decisions in Mechanical Engineering

Magnetic Camera and its Applications in Aging Aircraft, Express Train and Pipelines for Green Technology

J.Y. Lee and J.M. Kim 309

Buckling Analysis on Pechiko Field of Fixed Offshore Platform in Makassar Strait

M.Z.M. Alie, Y.R. Palentek and D.G. Sesa 313

Simulation of a Differential-Drive Wheeled Mobile Lego Robot Mindstorms NXT

I.W. Widhiada, C.G.I. Partha and Y.A.P. Wayan Reza 319

Design and Simulation of Five Fingers Gripper for Dexterous Pick-Up Various of Components

I.W. Widhiada, E. Pitowarno, C.G.I. Partha and Y.A.P. Wayan Reza 325

Tar Balls Collector for Mechanical Recovery in Combating Oil Spill on the Marine Environment

C.P. Mahandari, M. Yamin and D.S.A. Asandi 331

Three Wheel Bike as Physical Therapy Equipment for Post-Stroke Patient

I.M.L. Batan, Rodika and M. Riva'i 337

Geometric Progression Application in Design Transmission Gear Ratio

A.A.I.A.S. Komaladewi, I.G.A.K. Suriadi and I.K.A. Atmika 343

Role of Risk Management in Effective Maintenance

H.A. Yuniarto and P.F. Paristiawati 349

Redesign Combustion Air Shelter of the Furnace to Improve the Performance in Melting Bronze for Manufacturing Gamelan

I.G.N. Priambadi, I.K.G. Sugita, A.A.I.A.S. Komaladewi, K. Astawa and I.W.B. Adnyana 355

Model of Carbon Dioxide (CO2) Emission from Motorcycle to the Manufactures, Engine

Displacement, Service Life and Travel Speed

A.M. Mulyadi and S. Gunarta 361

Experimental Study of Heat Transfer Characteristics of Condensed Flow on the Vertical Wave Plates

W.H. Piarah and Z. Djafar 371

Forces Analysis on a Spherical Shaped Delivery Valve of Hydram Pump

M. Suarda 377

The Influence of Distance Variation between Rings with Sloping Position on the Cylinder Surface to Drag Coefficient

S.P.G.G. Tista, A. Ghurri and H. Wijaksana 384

Auto PID Tuning of Speed Control of DC Motor Using Particle Swarm Optimization Based on FPGA

H. Tayara, D.J. Lee and K.T. Chong 390

Mobile Robot Motion Planning to Avoid Obstacle Using Modified Ant Colony Optimization

N. Habib, A. Soeprijanto, D. Purwanto and M.H. Purnomo 396

Mobile Robot Motion Control Using Laguerre-Based Model Predictive Control

M. Chipofya, D.J. Lee and K.T. Chong 403

d Recent Decisions in Technologies for Sustainable Development

Experimental Investigation of Micro-Hydro Waterwheel Models to Determine Optimal Efficiency

L. Jasa, A. Priyadi and M.H. Purnomo 413

Understanding Peak Average Power Ratio in VFFT-OFDM Systems

N.M.A.E.D. Wirastuti 419

Fusing Multiple Inexpensive GPS Heading Data via Fuzzified Ad-Hoc Weighing

F.P. Vista IV, D.J. Lee and K.T. Chong 425

Tree Data Structure Implementation in Android Base System of E-Ulambebantenan

A.A.K.O. Sudana and A.A.G. Brampramana Putra 431

Design and Implementation of Web-Based Geographic Information Systems on Mapping Hindu’s Temple

N. Piarsa and K. Adi Purnawan 437

Improving Biogas Quality through Circulated Water Scrubbing Method

H.S. Tira, Y.A. Padang, Mirmanto and Hendriono 443

Study on Solar Generating Apparatus for Solving Problem of Shadow

J.W. Chang, S.S. Kim, J.K. Lim and J.J. Lee 449

An Experimental Study on the Thickness of Stainless Steel as an Electrode in Alkaline Fuel Cell

M. Sucipta, I.M. Suardamana, I.K.G. Sugita, M. Suarda and K. Astawa 455

Transient Thermal Efficiency of Natural Hybrid Dryer System on Chimney Height Variation of Exhaust Moist Air

CHAPTER 4:

An Experimental Study on the Thickness of Stainless Steel as an

Electrode in Alkaline Fuel Cell

Made Sucipta

1,2,a, I Made Suardamana

2,b, I Ketut Gede Sugita

1,2,c,

Made Suarda

1,d, and Ketut Astawa

1,e1Department of Mechanical Engineering, Faculty of Engineering, University of Udayana, Kampus

Bukit Jimbaran, Badung, Indonesia

2Department of Mechanical Engineering, Program of Postgraduate, University of Udayana,

Kampus Jl. P.B. Sudirman, Denpasar, Indonesia

am.sucipta@gmail.com, bm.suardamana@gmail.com, csgita_03@yahoo.com, dsuarda@yahoo.com, eawatsa@yahoo.com

Keywords: thickness, stainless steel, electrode, alkaline fuel cell

Abstract. An alkaline fuel cell (AFC) is a device that converts the chemical energy of a fuel directly into electrical energy and heat. Efforts to improve the performance of the AFC is continuously conducted, and one of the work that has been investigated in this study was to examine the effect of the use of stainless steel as an electrode in the AFC. More specifically, this study focuses on to the influence of the thickness of the stainless steel plates used as an electrode. During the experiments, the design of the AFC with a particular dimension has been prepared with the flow of hydrogen enters at the anode and the flow of oxygen enters at the cathode at a certain pressure. Potassium hydroxide (KOH) is used as an electrolyte with a particular concentration dissolved in the water. The experiment results showed that the variation in the thickness of the stainless steel plates used as an electrode significantly affect the performance of the AFC. Similar results were also obtained for the effect of KOH concentration in the electrolyte also provide significant impact on the performance of the AFC, especially from the electrical voltage and current obtained during the experiment.

Introduction

World energy demand is projected to increase in parallel with the growth of world population. Energy becomes important in human life, this is because of almost all human activities require energy. Utilization of fossil fuels is still dominant today and its projection for the next decade. Moreover, the efforts to meet the energy needs and to reduce the impact of the fossil fuels on the environment, in addition to the possible depletion of its resources, bring an increase attention to the attractive renewable energy resources.

One device of the power generation unit to facilitate the using of renewable energy is the fuel cell. In principle, fuel cells are the device to directly convert fuel chemical energy into electricity but complete conversion of fuel chemical energy into electricity is not possible. Inefficient part of energy conversion means the heat generation. Alkaline fuel cell (AFC) is one type of fuel cell has been developed for decades [1]. In case of the low-temperature fuel cells, such as AFC, fuel is restricted and, in most practical applications, it is hydrogen. Thus in the AFC, hydrogen is reacted with oxygen that would generate electricity, water and heat. The reaction of hydrogen and oxygen in the AFC is in the absence of combustion processe, so that it could be used to reduce environmental pollution. Strictly speaking, an AFC is a zero emission device, excluding water produced in the electrochemical reaction. One major component of the AFC is the electrolyte that serves as a medium to conduct electrically charged particle and the electrode that serves as a electrical conductor [2,3].

Applied Mechanics and Materials Vol 776 (2015) pp 455-460 Submitted: 2015-02-19

© (2015) Trans Tech Publications, Switzerland Accepted: 2015-04-10

Alkaline fuel cell is one of the most developed fuel cell technologies. In the early development of the AFC using platinum plates as an electrodes and as an electrolyte using potassium hydroxide (KOH). However, the use of platinum plate will make this device become an expensive device, thus some researchers is already leading to how to be able to obtain the appropriate potential material and at a low cost as a substitute for platinum plate.

Stainless steel is one of the materials that can potentially be used as an electrodes in the AFC. From the previous experiment results showed that stainlees steel was used as the electrode had been able to produce a quiet good electrical voltage and the material does not experience a significant reaction with the electrolyte [4,5,6]. However, more studies on the use of stainless steel is still being developed. Electrodes as a medium for the transfer of ions becomes an important part in the design of the AFC, it is necessary to consider the resistance of the movement of the ions, and one factor that should be considered in the next study is the thickness of the stainless steel plates used as an electrodes in the AFC. Therefore, based on these hypothesis, it has been examined the effect of variations in the thickness of the stainless steel plates used as an electrode on the performance of the AFC.

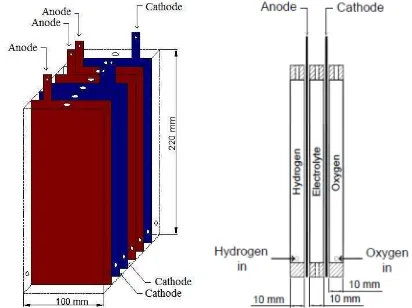

Method

It has been developed an laboratory-scale AFC module using of stainless steel plate series 304 that are arranged in series of three pairs of electrodes. A stainless steel plate that is used as an electrodes is a pure stainless steel plate without any initial process in order to improve its performance. AFC module container was designed by using an acrylic material with a knock-down system to facilitate a simplicity to do the experiments in this research. The arrangement of the series for three pairs of electrodes are arranged such that for the oxygen flow regime, the boundary channel is facing chatode-to-chatode side, while for the hydrogen flow regime, the boundary channel is facing anode-to-anode side, except for those regime close to the side wall of the AFC module container is one side is facing by the anode or cathode side, while other is facing by acrylic container wall, as shown in Figure 1. This AFC module is designed with an area of each electrode is 100 mm x 220 mm. But, the edges of the electrode is also used as a handle for container AFC module, therefore, the effective area of each electrode becomes equal to 90 mm x 200 mm.

The distance between anode and cathode side, which also indicates the volume of electrolyte space of the AFC module is kept at 10 mm. Similarly that to the channel cross-sectional area of hydrogen and oxygen are designed with the same width of 10 mm times the effective length of stainless steel plate, i.e. 90 mm, as illustrated in Figure 1, but this figure only shows for a pair of electrode arrangement.

In simple description of the working principle of this AFC module can also be explained from Figure 1, that is the electrolyte flows on between the cathode and anode side, while the hydrogen and the oxygen flow on the other side. Hydrogen and oxygen mass flow rate is maintained by using the regulators at a pressure of 1 kg/cm2 and 0.5 kg/cm2 respectively. Theoretically, the chemical

reaction occurs at the anode and cathode can be described as in Eq. 1 and 2 below.

Anode : H2 + 2OH- 2H2O + 2e- (1)

Cathode : ½ O2 + 2e- + 2H2O 2OH- (2)

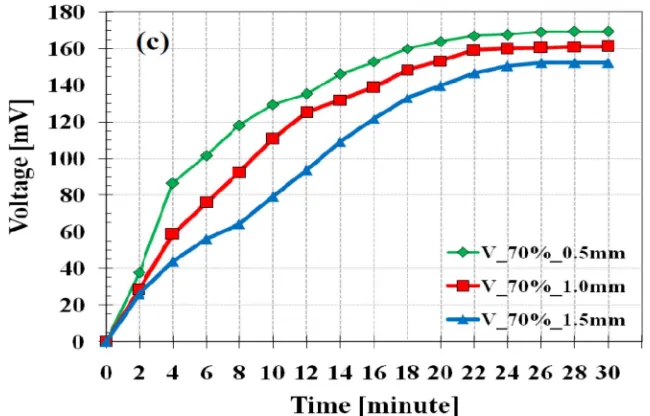

Electrolytes used in this study is KOH with the variation of the concentration of 30%, 50% and 70% based on the mass in water. While for the stainless steel plates that were tested varied for the plate thickness of 0.5 mm, 1.0 mm and 1.5 mm. Data collection procedures in this research was carried out for 30 minutes with an interval of about 2 minutes. The time interval was chosen because based on the previous studies showed that is in the time interval for the previous experiments have been observed a trend towards generated electrical voltage approaches a stable value. Furthermore, to obtain the generated electrical current, it was conducted by providing the electrical load when the voltage stability has been reached.

Figure 1. Schematic diagaram of arrangement of three pairs of anode and cathode in the AFC module and its main dimension

Results and Discussions

After the AFC module and others experiment equipment have been carefully prepared, the next step is the preparation of the solution of KOH in water used as the electrolyte with a concentration of 30%. Then in the subsequent studies KOH solution with a concentration of 50% and 70% are also prepared as described in the previous section. From this initial step of the experiments, it was obtained that the electrolyte temperature increased with an increasing concentration of KOH in the water. The results of these observations showed a similar trends to the results which is obtained in the previous studies. For example, the temperature of the electrolyte at a concentration of 30% KOH is about 75oC, whereas for a concentration of 50% and 70%, the temperature of the electrolyte

is about 88oC and 115oC respectively.

The experiment results showed that the thicker stainless steel plates used as an electrodes will be diminish the performance of the AFC module. This result indicates that the thicker of the stainless steel plate used can cause barriers to the diffusion of ions inside the material become larger, so that the reaction occurs at the anode and the cathode sides becomes slower. As shown in Figure 2 (a), it appears that for the electrolyte concentration of 30% KOH in water used as an electrolyte, the generated electrical voltage which is obtained on the stainless steel plate thickness of 0.5 mm is about 105.3 mV. Other result obtained with the same concentration of electrolyte, for the thickness of 1.5 mm of stainless steel plate it is obtained the electrical voltage that can be generated is about 90.2 mV.

As we can see from Figure 2 (b) and 2 (c), it can be concluded that for all of the KOH concentration in the electrolyte tested showed that the thiner stainless steel plate will result in the better performance of the AFC module. From Figure 2 also can be identified that the higher concentration of the KOH in the electrolyte will be resulted in higher electrical voltage can be generated as well. At the concentration of 70% KOH in the electrolyte, for stainless steel plate

thickness of 0.5 mm, it is obtained that generated electrical voltage will be 169.2 mV. This result indicates the highest electrical voltage can be achieved in this research.

From Figure 2, it can also be seen that at the lower concentration of KOH in the electrolyte, the electrical voltage stability will be more quickly achieved than at the higher concentration of KOH in the electrolyte. However, a longer time to achieve stable electrical voltage generated at higher KOH concentration in the electrolyte can be compensated with the higher electrical voltage that can be generated. These results can be caused due to the influence of the electrolyte temperature used in the experiments. It can be correlated that the higher temperature of the electrolyte, the higher electrical voltage could be generated.

As shown in Figure 2, it is interesting to note that the magnitude of the increase of the electrical voltage generated in the experiments will begin to decrease with the increase of KOH concentration in the electrolyte. When the KOH concentration in the electrolyte is increased from 30% to 50%, the generated electrical voltage can be increased by about 45.8%, but the increase in the generated electrical voltage when the KOH concentration in the electrolyte was increased from 50% to 70% is only reached 10.2% . These results indicate that there is a certain concentration of KOH that can be dissolved in water for use as an electrolyte. Increasing the concentration of KOH in the electrolyte higher than 70% may cause the performance of the AFC will be decreased, but this would need further research.

Figure 2. Change of generated electrical voltage for three variation of concentration KOH in the electrolyte; (a) KOH 30%, (b) KOH 50%, (c) KOH 70%

Figure 3. Distribution of generated electrical current in AFC module after loaded for three variation of thickness of stainless steel plate as an electrode

Figure 4. Distribution of generated electrical voltage in AFC module after loaded for three variation of thickness of stainless steel plate as an electrode

As described in the previous section, when the generated electrical voltage achieve the stable value, then the AFC module was loaded by connecting a electrical resistor to determine the generated electrical current. The experiment result indicates that the influence of the thickness of the stainless steel plate appears that the thicker stainless steel plates used as an electrode, than the generated electrical current will be decreased. It was obtained for the smallest electrical current is about 0.59 mA can be generated at the stainless steel plate thickness of 1.5 mm and the concentration of KOH in the electrolyte of 30%. While the highest electrical current is obtained at 0.5 mm of the thickness of stainless steel plate and the concentration of KOH in the electrolyte at 70% that is 0.93 mA. These results of this study also have been shown in Figure 3.

The effect of the concentration of KOH in the electrolyte to the generated electrical current can also be observed from Figure 3. For each thickness of the stainless steel plate used, it can be observed the influence of the concentration of KOH in the electrolyte, that is the higher concentration of KOH in the electrolyte will be resulted in the higher the generated electric current.

When the electric current is generated after the AFC module is loaded then the stability of the electrical voltage become disappear. It leads to the decline rapidly of electrical voltage reaches a certain level. These results happen for each thickness of the stainless steel plate and for each concentration of KOH in the electrolyte. As shown in Figure 4, the generated electrical voltage could be decreased approximately 29% to 47% of that which is obtained when the voltage reaches the initial stability. It can be explained also, the thicker stainless steel plates used as the electrode will result in the greater decrease of electrical voltage. Similar result is also obtained to the effect of increasing concentrations of KOH in the electrolyte that tend to show a similar results as those for thickness variation of the stainless steel plate.

Summary

Based on the experiment results that has been discussed previously, we can conclude that the thickness of the stainless steel plates used as an electrode have a significant impact on the performance of the AFC. The thicker of stainless steel plate used will result in the decrease of the performance of the AFC module, i.e. it can be seen from the drop in the generated electrical voltage and current. In addition, the concentration of KOH in water used as an electrolyte is also resulted in a significant influence on the performance of the AFC, although to some extent on the percentage of increment of the concentration of KOH in the electrolyte, the effect began to decline at higher concentrations, however this result needs to be studied further.

Acknowledgement

The present study has been fully supported by the LPPM University of Udayana for the research grant “Hibah Bersaing” scheme with the contract number: 104.45/UN14.2/PNL.01.03.00/2014.

References

[1] EG&G Technical Services, Inc., Fuel Cell Handbook, sixth ed., U.S. Department of Energy Office of Fossil Energy National Energy Technology Laboratory, West Virginia, 2002.

[2] J. Larminie, A. Dick, Fuel Cell Systems Explained, second ed., John Wiley & Sons, Inc., New York, 2003.

[3] R. O’Hayre, et. al., Fuel Cell Fundamentals, second ed., John Wiley & Sons, Inc., New York, 2009.

[4] S.A. Bagas, Design of Alkaline Fuel Cell (AFC) with an Electrode of Stainless Steel, Aluminum, Iron, and Zinc. Final Project ITS, Surabaya. (2010).

[5] I.M. Suardamana, Design of a Simple Alkaline Fuel Cell by Using of Stainless Steel as an Electrode. Journal of Energy and Manufacture Vol. 6 No. 1 (2014).

[6] M. Sucipta, et. al., Effect of the Concentration of Potassium Hydroxide (KOH) in Electrolyte to the Performance of Alkaline Fuel Cell. Proceeding of National Seminar of Mechanical and Industry 8 (SNMI 8), Jakarta, November, 14. (2013).