Characteristics of Fresh Fruit Bunch Yield and the Physicochemical Qualities of Palm Oil

during Storage in North Sumatra, Indonesia

Mohammad Basyuni

1,*, Nofrizal Amri

1, Lollie Agustina Pancawaraswati Putri

2,

Indra Syahputra

3, and Deni Arifiyanto

31

Department of Forestry, Faculty of Forestry, University of Sumatera Utara, Jl. Tri Dharma Ujung No. 1 Kampus USU Medan 20155, North Sumatra Indonesia 2

Faculty of Agriculture, University of Sumatera Utara, Medan 20155, North Sumatra, Indonesia 3

Laboratory of Biomolecular of PT Socfin Indonesia, Martebing, Dolok Masihul, Tebing Tinggi 20991, North Sumatra, Indonesia

Received May 10, 2017; Accepted July 7, 2017

ABSTRACT

This study examines the fresh fruit bunch (FFB) yield and the effect of fruit storage on the quality of palm oil in Bangun Bandar Estate, Dolok Masihul, North Sumatra, with special reference to the physicochemical parameters. The quality of palm oil is mostly determined by the color, free fatty acids (FFAs), moisture, impurities, carotene content, and deterioration of bleachability index (DOBI). The palm fruits were stored in a refrigerator for 0, 7, 14, 21, and 28 days after harvesting before analyzing their carotenoid content, DOBI, FFAs, moisture, and impurities. The results showed that the potency of the crude palm oil (CPO) types, dura, pisifera, and tenera, were 23.5, 26.2, and 23.6%, respectively. The carotenoid content and DOBI of the palm oil types, dura, pisifera, and tenera, were decreased significantly by lengthy storage of the fruit. By contrast, lengthy storage of the fruit significantly increased the FFA, moisture, and impurity contents of these palm oil types, indicating that this reduced the quality of the palm oil. Oil processed from FFB has excellent quality with a high carotene content and DOBI, and a low concentration of FFA, moisture, and impurities. The present study contributes to palm oil stability and nutritional value.

Keywords:carotenoid; free fatty acid; North Sumatra; nutritional value; oil quality

ABSTRAK

Penelitian ini menguji hasil tandan buah segar (TBS), kualitas buah dan pengaruh penyimpanan buah sawit terhadap kualitas minyak sawit di Kebun Bangun Bandar, Dolok Masihul, Sumatera Utara dengan referensi khusus untuk parameter fisikokimia. Kualitas minyak sawit sebagian besar ditentukan oleh warna, asam lemak bebas (ALB), kelembaban, kadar kotoran, kandungan karotenoid dan indeks derajat kepucatan (DOBI). Buah disimpan di lemari es pada 0, 7, 14, 21 dan 28 hari setelah pemanenan sebelum pemrosesan untuk menentukan konten ALB, kelembaban, kadar kotoran, karotenoid dan DOBI. Hasil penelitian menunjukkan bahwa potensi jenis CPO dari dura, pisifera, tenera masing-masing adalah 23,5, 26,2, dan 23,6%. Konsentrasi karotenoid dan DOBI minyak sawit dari dura, pisifera, dan tenera menurun secara signifikan terhadap lama penyimpanan buah. Sebaliknya, lama penyimpanan buah meningkatkan secara signifikan pada parameter-parameter ALB, kadar air, dan kadar kotoran dari jenis minyak sawit dura, pisifera, dan tenera. Penyimpanan buah yang lama mengindikasikan buruknya kualitas minyak kelapa sawit. Minyak yang diproses dari TBS mempunyai kualitas yang baik dengan nilai kandungan yang tinggi dari karotenoid dan DOBI, dan rendahnya konsentrasi ALB, kelembaban dan kandungan kotoran minyak. Penelitian ini memberikan kontribusi kepada stabilitas kelapa minyak dan nilai gizi.

Kata Kunci:karotenoid; asam lemak bebas; Sumatera Utara; nutrisi; kualitas minyak

INTRODUCTION

The oil palm (Elaeis guineensis Jacq, Arecaceae) originated from West Africa. Indonesia is currently the largest producer and exporter of palm oil worldwide. Oil palm (E. guineensis) has three fruit types (Fig. 1), namely dura (thick-shelled), pisifera (shell-less), and tenera (thin-shelled)–a cross betweenduraandpisifera.

Fig 1.Palm oilElaeis guineensishas three fruit forms, a. dura (thick-shelled), b. pisifera (shell-less), c. tenera (thin-shelled), a hybrid betweenduraandpisifera

PKO. Targets for the quality of oil and the oil extraction rate are the main concerns of each miller. The milling equipment and the fresh fruit bunch (FFB) characteristics play an important role in producing good quality oil. The quality of the crude oil is important as it can greatly affect the efficiency of the refining process and the quality of the final product [2].

The yield of the palm oil depends on a number of components, including the FFB and fruit quality [3]. Delays in processing the FFBs are sometimes unavoidable, primarily due to fluctuation in supply. Fruit storage before processing is a standard practice that acts as a buffer against uncertainty, but this practice is detrimental to the quality of the CPO [4]. CPO obtained from the mesocarp consists mainly of glycerides and small quantities of non-glyceride components. Non-glyceride characteristics include free fatty acids (FFA), moisture, trace metals and impurities and minor qualities, such as the carotene content and the DOBI [5]. The storage time of damaged oil palm fruits poses a major problem, as lipase enzymes may be activated, directly reducing the oil quality. Lengthy storage of fruits led to a considerable increase in the FFAs, which could affect the quality of the oil, as well as microorganism contamination and oxidation [6-8]. Carotenes confer special features on the CPO due to their biological and nutritional properties, as well as improving the stability of the oil [9]. The storage time of the chopped oil palm fruit spikelets was determined prior to oil processing. The aim of this study was to examine the fresh fruit bunch (FFB) yield and the effect of storage of palm fruits (chopped

FFB) on the physicochemical qualities of the palm oil, in terms of the carotene content, the DOBI, and the FFA, moisture, and impurity contents. The correlation between the lengthy storage of fruit and the oil palm quality criteria is discussed.

EXPERIMENTAL SECTION

Materials

Ripe fresh fruit bunches and orange-red palm oil (E. guineensis) of dura, pisifera andtenera types from sixteen-year-old palms were obtained from PT Socfin Indonesia, Bangun Bandar Estate, North Sumatra, Indonesia. The fruits were picked from the spikelets and 30–50 loose fruits were stored in a refrigerator for 0, 7, 14, 21 and 28 days before processing. Samples were preheated at 105 °C before use. All chemicals used are analytical grade (Merck).

Instrumentation

The instrumentation used included a Precisa XB-220A analytical balance (Dietikon), an oven (Memmert), an Agilent Technologies Cary 60 UV-vis spectrophotometer (Crawford Scientific Ltd), a moisture analyzer MX-50 (A & D Company Ltd), a Soxhlet extraction apparatus (Sigma Aldrich, USA), a digital burette (Titrex 2000), and an autoclave Hiclave HVE-50 (Hirayama).

Procedure

Oil extraction

A fresh fruit bunch (FFB) from three types of oil palm, dura, pisifera and tenera, was used for each extraction and cut into spikelets before analyzing as described previously [10]. The FFB characteristics and the quality of palm oil are generally characterized by the average bunch weight (kg), the average loose fruit (ALF), the total loose fruit (TLF), the weight of loose fruits (WLF), the percentage of fruit to bunch ratio (%F/B), the percentage of mesocarp to fruit ratio (%M/F), the percentage of oil to mesocarp ratio (%O/M), the percentage of palm kernel oil to fruit (%PKO/F), the moisture content (%), the crude palm oil (CPO), and the palm kernel oil (PKO).

Determination of total carotene

content was determined by diluting a 1 mL aliquot of a fraction of each of the three varieties withn-hexane to an appropriate dilution. The solution was transferred into a 1 cm quartz cuvette and the absorbance was measured at 446 nm. The cuvette error was measured at the same wavelength. The carotene content was calculated using the equation 1.

383

Carotene (ppm) 25 as ab

100W

(1)

where as = absorbance of the sample, ab = cuvette error, W = weight of sample (g).

Deterioration of bleachability index (DOBI)

The deterioration of palm oil was determined by the DOBI method, as previously reported, [12] with a few modifications. About 0.2 g oil was weighed into 50 mL n-hexane (99%). The oil solution was placed in a 1 cm cuvette and the absorbance readings were 446 and 269 nm, obtained from a UV-vis spectrophotometer. The DOBI value involved spectrophotometric measurements of the ratio of absorbance at 446 nm to that at 269 nm.

Free fatty acid (FFA) content

The FFA content was measured using the titration method described previously [7]. Two (2) g of oil pre-heated to about 50 °C weighed in a beaker. Aliquots of ethanol (50 uL) were added to the oil to dissolve the fatty acids and the ethanol-oil mixture was titrated with 0.1 N NaOH using phenolphthalein indicator. NaOH was required to produce a permanent pink color and the FFA content was determined from the formula,

M V N

where: M = relative molecular mass of palmitic acid, V = volume of NaOH used, N = normality (concentration) of NaOH used, W = weight of oil used.

Moisture content

Oil extracts (5 g) from three types of palm oil were weighed and used to measure the moisture content using a moisture analyzer, MX-50 (A & D Company Ltd) at 115 °C.

Impurity content

The impurity content was measured as previously reported [8]. Gooch crucibles were lined with filter paper, washed with n-hexane, and dried at 105 °C for 30 min, then allowed to cool and weighed (W1). An Erlenmeyer

flask (250 mL) was weighed (W2) and 2 g oil extract was

added before reweighing (W3); n-hexane (20 mL) was

added to the oil extract and the flask was swirled and heated to homogenize the mixtures. The mixtures were poured into the crucibles and allowed to drain. The flask was rinsed with hexane and poured into the crucibles to remove any particles present in the flasks. The crucibles

were then removed after all the solution had drained and dried at 105ºC for 30 min. After cooling, the crucible and oil were reweighed (W4). Impurities in the oil extract were expressed as a percentage using the following formula [8].

4 1

3 2

W W (dry weight of oil)

%Impurity 100%

W W (fresh weight of oil)

(3)

where: W1 = weight of crucible + filter paper, W2 =

weight of flask, W3= weight of flask + oil, and W4= dry

weight of crucible + oil.

Statistical analysis

The data were analyzed by one-way analysis of variance (ANOVA), followed by Dunnett’s test for comparison of storage treatments (7, 14, 21, and 28 d), carotene, the DOBI, and the FFA, moisture and impurity contents against the control (0 d). Evaluation of the FFB yield, the fruit diameter and the fruit length was carried out using Duncan's multiple range test (DMRT). All of the statistical analyses were performed using the SAS 9.1 statistical software program (SAS Institute Inc.). To determine the relationships between the time of storage and the oil-palm quality parameters for the three palm types, a correlation matrix was performed using SPSS version 17.0 (SPSS for Windows, SPSS Inc.).

RESULT AND DISCUSSION

FFB and Its Characteristics

Table 1.Characteristics fresh fruit bunch yield of palm oil of dura, pisifera and tenera varieties in North Sumatra

Variety BW (kg) ALF TLF WLF (g) F/B (%) M/F (%) O/M (%)

Dura 21.3±1.3a 12.8±0.5a 10.0±0.3a 140.5±3.7b 67.7±1.3a 66.6±0.1c 49.1±0.2c

Pisifera 19.0±3.4a nd nd 241.0±1.2a 49.3±7.5b 100±0.0a 61.1±2.1a

Tenera 11.2±1.6b 7.6±0.6a 11.6±1.4a 104.5±11.1a 66.5±0.2a 80.4±3.5b 55.6±1.3b Table continued:

Variety PKO/F (%) M (%) CPO (%) PKO (%)

Dura 8.0±0.1a 37.6±0.2a 23.5±0.3a 4.9±0.1b

Pisifera nd 12.2±0.6c 26.2±4.4a nd

Tenera 7.4±1.7a 30.1±1.2b 23.6±1.3a 25.5±1.3a

BW (bunch weight), ALF (average loose fruits), TLF (total loose fruits), WLF (weight of loose fruits), F/B (fruit to bunch), M/F (mesocarp to fruit), O/M (oil to mesocarp), PKO/F (palm kernel oil to fruit), M (moisture), CPO (crude palm oil), PKO (palm kernel oil). Nd= not determined. Data are expressed as the mean ± SE (n=6–12)

Fig 2.Fruit diameter (a) and length (b) from three type of oil palm. Data are expressed as the mean ± SE (n= 6–8)

processing machines. Dura's fruit diameter and fruit length was distinguishable from pisifera and tenera, which are significantly different (Fig. 2a and 2b).

The fruit quality criteria, i.e., the mesocarp to fruit ratio (M/F), the oil to mesocarp ratio (O/M), and the palm kernel oil to fruit ratio (PKO/F), are relatively proportional to the mesocarp and kernel. Palm oil and kernel oil are derived from the flesh of the fruit (mesocarp) and the kernel, respectively. The oil content in the mesocarp is highest in pisifera; on the other hand, the highest oil content in the kernel was found intenera(Table 1).The pisifera fruit does not have a shell, but it is difficult to produce the fruit because this variety produces abortive fruit, even though it contains the highest CPO content (Table 1). Pisifera has female flowers that are sterile when grown in conditions of high and regular water availability, such as in North Sumatra [13]. This situation creates the problem of limited pollen production for breeding, which can be overcome by defoliation as a means of controlling the pollen production [13].

The tenera variety has a thin shell and the female flowers are fertile. Thetenera seed is considered to be superior because it is a cross of the parentdura(female palms) withpisifera(male palms). As a result,tenerais a derivative that overcomes the limitations of both the parent types. Tenera is therefore the most planted variety around the world, including in Bangun Bandar, North Sumatra. It has been reported recently thattenera

was obvious from dura and pisifera based on composition of the carbon chain-length of polypernol and dolichol detected and chemotaxonomically significant [14]. The oil palm fruit has a unique and superior characteristic, compared with other vegetable oil crops, in that it can produce two types of oil from the same fruit. The flesh of the fruit produces CPO and the palm kernel produces palm kernel oil.

Effect of Storage Time on Palm Oil Quality

The chemical and physical (physicochemical) properties have been determined to assess the quality of CPO. The most important criteria are the carotene content, the deterioration of bleachability index (DOBI), the free fatty acid (FFA) content, the moisture content, and the impurity content.

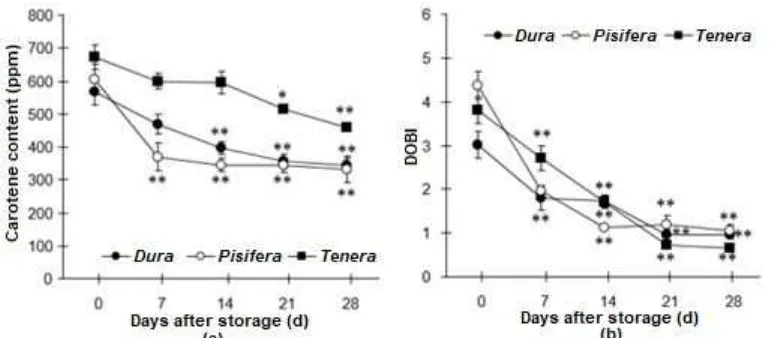

Carotene content and DOBI

Fig 3.Effect of oil palm fruit storage on the content of carotene (a) and DOBI (b). Data are expressed as the mean ± SE (n= 6-8)

feed CPO has been shown to contain carotene at 632 ppm [11]. The carotene criterion determined by the specification and quality requirements for Lotox CPO was 600–700 ppm [2]. From the data obtained, the carotene content of dura ranged from 343–568 ppm, which was the value at day 0 (568.42 ppm) and is thus only suitable as a standard; after 7 to 28 days’ storage, the carotene content decreased to < 500 ppm. Similarly, the carotene content of pisifera at day 0 was 605.98 ppm, and this decreased to almost half the initial value after 28 days’ storage (Fig. 3a).

In the case of tenera,after up to 21 days’ storage, the carotene content was > 500 ppm; this fell slightly below 500 ppm after 28 days. This result suggests that the relatively constant carotene content in this commercial variety may be due to the biological properties of this molecule [9]. It has been reported that increasing the short-term storage (from 30 to 120 min) of teneraresulted in a decrease in the carotene content [7]. The degradation of the carotene content may be caused by damaged fruit, a longer storage time and excessive thermal processing during the drying process [7]. Furthermore, carotene imparts a characteristic orange-red color to CPO and contributes to the stability and nutritional properties of palm oil. Our results, in conjunction with previous reports, indicated that CPO is considered to be the richest natural plant source of carotenes.

Similarly, for the DOBI, as the storage time was increased, this value also decreased, as depicted in Fig. 3b. The DOBI is basically the ratio of the carotene content to the content of secondary oxidation products. A DOBI > 3.3 indicates an excellent CPO grade, whereas values from 3.0–3.2 indicate good CPO. From the data obtained, for all three varieties, the DOBI meets the requirement for excellent CPO at day 0, when it is harvested (control). However, after 7 days’ storage

(except in tenera), a DOBI below 2 testifies an oil with very poor quality, which is more difficult to refine [2]. It has been reported that after short-term storage of the palm fruits (30 min to 120 min), the chopped fruits produced a lower quality of palm oil [7]. The combined low carotene and DOBI values after 7 days’ storage indicated that the samples would be difficult to bleach.

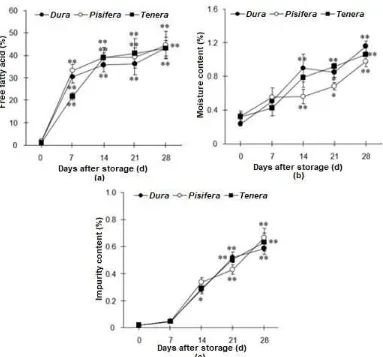

Free fatty acid content

Storage of the fruits before processing into crude oil significantly increased the FFA contents of all varieties examined, as shown in Fig. 4a. According to Indonesian and Malaysian standards, [16-17] for special-quality CPO, the FFA content should be no more than 2.5% and for standard-quality CPO, no more than 5%. The FFA content of the three types of oil palm meets the standard only for freshly harvested FFB (day 0); after 7 days of storage, the FFA content ranged from 21.67–44.45%, which was unacceptable according to the standard. Our result was in agreement with a previous report [8], in which the FFA content increased from 6.02 to 32.37% after 6 to 26 days of storage of the fruits. The FFA content reaches an unacceptable level by 72 h after harvesting [4]. The increase in the FFA content with increasing fruit storage may be due to the lipolytic enzymes released from the mesocarps of the broken fruit. This rapid acceleration of lipolytic enzyme activity simultaneously increases the FFA content [7].

Fig 4. Effect of oil palm fruit storage on the free fatty acids (a), moisture (b), impurities (c). Data are expressed as the mean ± SE (n= 6–8)

to processing have high FFA contents (Fig. 4a). Basically, fatty acids are present in oils as part of triacylglycerol molecules. The presence of FFAs as non-glyceride moieties in palm oil is an indicator that the oil quality is impaired. Importantly, this process is attributed to an active lipase present in the mesocarp of the oil palm fruit, which is responsible for the hydrolysis of tryacylglycerols [19].

Moisture content and impurity content

Increasing the duration of storage of palm fruit significantly increased the content of moisture for all types (Fig. 4b). The increased moisture may be due to the outer layer of the fruit being damaged; the mesocarp was exposed to the environment when the fruit was chopped [7]. Several studies reported that the longer the oil is stored, the higher the microbial activity [7-8]; microbes such as Pseudomonas and Lactococcus were identified in palm oil and oil palm fruits [8].

Freshly harvested FFBs gave the lowest moisture contents (0.24–0.33%, Fig. 4b); after 7 days’ storage, the moisture content was above the standard levels (0.5% maximum). This could possibly be due to the storage period of palm fruits. It is clear, therefore, that the moisture content is influenced by the length of storage of the oil or the type of fruits used to produce the oil.

Table 2.Correlation matrix between oil palm quality parameter and storage induratype

Parameter Storage (d) CC (ppm) DOBI FFA (%) MC (%) IC (%)

Storage (d) 1

CC (%) -0.716** 1

DOBI -0.805** 0.671** 1

FFA (%) 0.808** -0.763** -0.766** 1

MC (%) 0.725** -0.501 -0.565* 0.650** 1

IC (%) 0.895** -0.563* -0.680** 0.597* 0.571* 1

**P< 0.01, *P< 0.05 are indicated statistically significant.

CC, carotene content, DOBI, deterioration of bleachability index, FFA, free fatty acid, MC, moisture content, IC, impurity content.

Table 3.Correlation matrix between oil palm quality parameter and storage inpisiferatype

Parameter Storage (d) CC (ppm) DOBI FFA (%) MC (%) IC (%)

Storage (d) 1

CC (%) -0.673** 1

DOBI -0.720** 0.681** 1

FFA (%) 0.722** -0.797** -0.795** 1

MC (%) 0.821** -0.478 -0.534* 0.456 1

IC (%) 0.895** -0.501* -0.482 0.564* 0.752** 1

**P< 0.01, *P< 0.05 are indicated statistically significant.

CC, carotene content, DOBI, deterioration of bleachability index, FFA, free fatty acid, MC, moisture content, IC, impurity content.

Table 4.Correlation matrix between oil palm quality parameter and storage inteneratype

Parameter Storage (d) CC (ppm) DOBI FFA (%) MC (%) IC (%)

Storage (d) 1

CC (%) -0.655** 1

DOBI -0.883** 0.446 1

FFA (%) 0.862** -0.611** -0.781** 1

MC (%) 0.776** -0.562* -0.675** 0.702** 1

IC (%) 0.894** -0.558* -0.755** 0.681** 0.619** 1

**P< 0.01, *P< 0.05 are indicated statistically significant.

CC, carotene content, DOBI, deterioration of bleachability index, FFA, free fatty acid, MC, moisture content, IC, impurity content.

Correlation between Fruit Storage and Palm Oil Quality

In order to obtain more insight into the important aspects of the quality of CPO, a correlation matrix between the length of fruit storage and the palm oil criteria was performed. Tables 2–4 summarize the significant negative correlations between the length of storage with carotene content and with the DOBI for all the varieties studied. These results were in accordance with those reported [7,9,11], suggesting that increasing the length of storage will reduce minor components in the CPO, especially the carotene content and the DOBI. It is the accepted view that the nutritionally important minor components of palm oil, such as carotenes, improve the stability of the oil [6].

The length of storage of the fruits before processing into crude oils was of significance and correlated positively with the FFA, the MC and the IC in dura(0.808, 0.725, 0.895),pisifera(0.722, 0.821, 0.895) and tenera (0.862, 0.776, 0.894), respectively. The longer the fruits are stored, the higher the FFA and therefore the greater the deterioration and microbial

activity. After harvesting, the enzymes in the FFB start to attack the mesocarp, making the flesh soft over time with the decomposition of crude oil and the production of FFAs [4]. The microbial attack will lead to hydrolysis of the crude oil and will therefore rapidly increase the FFA content [8]. It has been reported that high water activity in the palm fruit also supported more microorganisms. Furthermore, water activity is positively correlated with the moisture content of the samples [8]. Thus, higher moisture is required for microbial growth.

CONCLUSION

Dura type dominated the criteria for the characteristic FFB yield of palm oil and fruit quality traits. The tenera type, as a hybrid between dura (female palms) and pisifera (male palms) had only two high-value parameters, namely the total loose fruits and the palm kernel oil. The quality of palm oil is greatly influenced by the fruit storage, as a part of the processing procedure. The chopped FFB should be processed as soon as possible in order to obtain an excellent quality of palm oil. Increasing the length of storage of the palm fruit significantly decreased the carotene content and the DOBI; on the other hand, it significantly increased the FFA, moisture and impurity contents of the crude oil. Oil processed from the fresh fruits has excellent oil quality (control) with a high carotene content and DOBI, as well as low concentrations of FFA, moisture and impurities.

ACKNOWLEDGEMENT

A part of this study was supported by Grant-in Aids for PUPT (Penelitian Unggulan Perguruan Tinggi) 2014 (No. 4808/UN5.1.R/KEU/2014 to MB) and Riset Pengembangan Ilmu Pengetahuan dan Teknologi (IPTEK) 2016 (No. 017/SP2H/LT/DRPM/II/2016 to MB) from the Directorate for Research and Community Service, Ministry of Research, Technology and Higher Education, Republic of Indonesia.

REFERENCES

[1] Wening, S., Croxford, A.E., Ford, C.S., Thomas, W.T.B., Forster, B.P., Okyere-Boateng, G., Nelson, S.P.C., Caligari, P.D.S., and Wilkinson, M.J., 2012, Ranking the value of germplasm: New oil palm (Elaeis guineensis) breeding stocks as a case study,Ann. Appl. Biol., 160 (2), 145–156.

[2] Gibon, V., Ayala, J.V., Dijckmans, P., Maes, J., and De Greyt, W., 2009, Future prospects for palm oil refining and modifications,OCL, 16 (4), 193–200. [3] Barcelos, E., Rios S.A., Cunha, R.N.V., Lopes, R.,

Motoike S.Y., Babiychuk, E., Skirycz, A., and Kushnir, S., 2015, Oil palm natural diversity and the potential for yield improvement, Front. Plant Sci., 6:190, doi:10.3389/fpls.2015.00190.

[4] Kumaradevan, D., Chuah, K.H., Moey, L.K., Mohan, V., and Wan, W.T., 2015, Optimizing the operational parameters of a spherical sterilizer or the treatment of oil palm fresh fruit bunch, IOP Conf. Ser. Mat. Sci. Eng., 88 (1), 012031.

[5] Kasemsumran, S., Thanapase, W., Punsuvon, V., and Ozaki, Y., 2012, A feasibility study on nondestructive determination of oil content in palm

fruits by visible–near infrared spectroscopy, J. Near Infrared Spectrosc., 20 (6), 687–694.

[6] Tan, C.H., Ghazali, H.M., Kuntom, A., Tan, C.P., and Ariffin, A.A., 2009, Extraction and physicochemical properties of low free fatty acid crude palm oil,Food Chem., 113 (2), 645–650. [7] Ali, F.S., Shamsudin, R., and Yunus, R., 2015,

The effect of storage time of chopped oil palm fruit bunches on the palm oil quality,Agric. Agric. Sci. Procedia, 2, 165–172.

[8] Tagoe, S.M.A., Dickinson, M.J., and Apetorgbor, M.M., 2012, Factors influencing quality of palm oil produced at the cottage industry level in Ghana, Int. Food Res. J., 19 (1), 271–278.

[9] Prada, F., Ayala-Diaz, I.M., Delgado, W., Ruiz-Romero, R., and Ruiz-Romero, H.M., 2011, Effect of fruit ripening on content and chemical composition of oil from three cultivars (Elaeis guineensisJacq.) grown in Colombia,J. Agric. Food Chem., 59 (18), 10136–10142.

[10] Simarani, K., Hassan, M.A., Abd-Aziz, S., Wakisaka, M., and Shirai, Y., 2009, Effect of palm oil mill sterilization process on the physicochemical characteristics and enzymatic hydrolysis of empty fruit bunch,Asian J. Biotechnol., 1 (2), 57–66. [11] Baharin, B.S., Latip, R.A., Che Man, Y.B., and

Abdul Rahman, R., 2001, The effect of carotene extraction system on crude palm oil quality, carotene composition, and carotene stability during storage, J. Am. Oil Chem. Soc., 78 (8), 851–855.

[12] Juliano, P., Swiergon, P., Lee, K.H., Gee, P.T., Clarke, P.T., and Augustin, M.A., 2013, Effects of pilot plant-scale ultrasound on palm oil separation and oil quality, J. Am. Oil Chem. Soc., 90 (8), 1253–1260.

[13] Adam, H., Collin, M., Richaud, F., Beulé, T., Cros, D., Omoré, A., Nodichao, L., Nouy, B., and Tregear, J.W., 2011, Environmental regulation of sex determination in oil palm: Current knowledge and insights from other species,Ann. Bot., 108 (8), 1529–1537.

[14] Arfiyanto, D., Basyuni, M., Sumardi, Putri, L.A., Siregar, E.S., Risnasari, I., and Syahputra, I., 2017,Identification and cluster analysis of oil palm (Elaeis guineensis) fruit type using two-dimensional thin layer chromatography, Proceeding The 2nd International Conference on Science, Technology and Interdisciplinary Research (IC-STAR) 2016, Lembaga Penelitian dan Pengabdian kepada Masyarakat (LPPM), Universitas Lampung, 102.

propane-1,2-diol esters in relation to palm oil minor components,Food Chem., 135 (2), 799–805. [16] TAMSI-DMSI, 2010, Facts of Indonesian Oil Palm,

Indonesia Palm Oil Advocacy Team-Indonesian Palm Oil Board, Jakarta, 35.

[17] Malaysian Standard MS 814, 1983,Specification for Crude Palm Oil, Standards Research Institute of Malaysia, Kuala Lumpur, 30.