Proceedings of the IConSSE FSM SWCU (2015), pp. BC.118–121 ISBN: 978-602-1047-21-7

SWUP BC.118

Mocaf characterization using thermogravimetric analysis (TGA)

Iip Sugihartaa§,John Hendrib,Suripto Dwi Yuwonob,Wasinton Simanjuntakb

aGraduated Student, Department of Chemistry, Faculty of Mathematic and Natural Sciences,

University of Lampung, Lampung, Indonesia

bDepartment of Chemistry, Faculty of Mathematic and Natural Sciences,

University of Lampung, Lampung, Indonesia

Abstract

Mocaf (modified cassava flour) can substitute wheat flour used by food induistry, because of the characteristics of mocaf are almost similar to those of wheat flour. Mocaf manufacture in this study is done by modifying the cassava mush through a fermentation process using the bacteria Lactobacillus plantarum. Mocaf was

characterized and compared with wheat flour, cassava flour, and tapioca flour, in terms of amylose and amylopectin contents, and mass reduction using TGA measurement. The greater the amylose content in starch, then smaller the mass reduction. By looking at the content of amylose and mass reduction, then mocaf (42.62 and 86.91 %) approaching wheat flour (45.22 and 85.72 %), suggesting that mocaf the potential to be used as a substitute for wheat flour.

Keywords Amylopectin, amylose, mocaf, thermogravimetric analysis (TGA)

1.

Introduction

One of the main foods in Indonesia is carbohydrate flour produced from a variety of sources such as wheat, rice, maize, cassava, sweet potato, sago and breadfruit, widely used for production of staple food, snacks, appetizers and desserts (Subagio et al., 2008). Up to present, wheat flour is still the most widely used by food industry, causing heavy reliance on international markets since wheat is not cultivated in Indonesia. On the other hand, cassava is a very common plant cultivated, but the properties of cassava flour are not fully compatible with wheat flour.

Mocaf (modified cassava flour) is obtained from cassava with lactic acid fermentation process. Mocaf has unique characteristics and can be developed as an raw material for food industrial. manufacture of mocaf almost the same as cassava flour, only manufacture of mocaf have an extra special treatment in the form of a fermentation process which is an important part for getting the best quality mocaf (Subagio et al., 2008).

In previous study the fermentation process for production of mocaf was carried out using lactic acid bacteria. During the fermentation, the viscosity of mocaf changed and reached the peak value of 1130 BU (Brabender Units) and the whiteness to 73.9 to 86.4% (Misgiyarta et al., 2009). Mocaf inoculum composed of the combinations of two types of lactic acid bacteria such asLactobacillus plantarumand a combination ofLactobacillus lactis,

were found to work more effectively in which the fermentation process for one day time was found to produce mocaf with whiteness between 91.36 to 94.55% (Enny & Yuliasri, 2012). The fermentation process using Lactobacillus casei inoculum carried by Darmawan et al.

I. Sugiharta, J. Hendri, S.D. Yuwono, W. Simanjuntak

SWUP BC.119

(2013), the inoculum concentration and thickness variation of cassava chips, best mocaf produced is at a concentration of 5 %V inoculum and cassava chip thickness of 2 mm, mocaf produced has a protein content of 3.68 % and amounted to 1.63 % solubiliti. The process of making mocaf made from cassava chips using Lactobacillus plantaruminoculum produces

the best mocaf on fermentation for 5 days by looking at the levels of protein and fat by 8.5 and 2.8% (Lina et al., 2012).

Several parameters commonly used to define the characteristics of mocaf, are degree of whiteness, viscosity using a Brabender, protein content, fat content, swelling power, solubility and HCN levels (Subagio et al., 2012; Misgiyarta et al., 2009; Lina et al., 2012; Darmawan et al., 2013). In this research, the characteristic of mocaf measured were amylose and amylopectin contents, and the mass loss using Thermogravimetric Analysis (TGA).

2.

Materials and methods

2.1 Materials

Materials used in this study were white cassava tubers, sodium citrate,Lactobacillus plantaruminoculum, skim milk powder, HCl, NaOH, H2SO4, amylose potato, distilled water,

tapioca flour (sagu tani), and wheat four (segitiga biru). Inoculum ofLactobacillus plantarum

strains was obtained from the Center for the Study of Food and Nutrition, University of Gadjah Mada. Cassava tubers used were those harvested three days before used for the experiments.

2.2 Methods

Preparation of mocaf consists of three main processes of raw material preparation, fermentation, and flouring. As a raw material, 500 g of cassava was cleaned and shredded, then mixed with 15 mL of inoculum and 500 ml of water. The fermentation process was carried out for 48 hours and pH 4 at 28 °C. Flouring process was performed after the fermented cassava pulp was dried, and then ground into flour passes through 80 mesh sieve. The mocaf was characterized and compared with wheat flour, cassava flour, and tapioca flour, in terms of amylose and amylopectin contents, and mass reduction using TGA measurement.

2.3 Characterization of mocaf, wheat flour, tapioca, and cassava flour

Measurements of starch content used Luff Schoorl method (AOAC International, 1997), amylose content used iodometry method (Yuan et al., 2007) and the levels of amylopectin is calculated by deducting starch content with amylose content. The thermal analysis of all samples were carried out with TGA (SSI TG/DTA 7300) thermal analyser in a platinum measuring cell, with the use of Muse Jobs programme for data handling. Measurements were performed in a nitrogen atmosphere (gas flow 50 cm3min-1) with the heating rate 15oC min-1. The samples (about 5 mg) were heated up to 650oC, starting from room temperature. All measurements were repeated at least three times.

3.

Results and discussion

Mocaf characterization using thermogravimetric analysis (TGA)

SWUP BC.120

fermentation process, because amylose and amylopectin undergo changes during the fermentation process. Changes of amylose and amylopectin content occurs because bond termination by amylase enzyme produced by the bacteriumLactobacillus plantarum(Giraud,

1991). Comparison of the composition of amylopectin and amylose in the starch will affect the level of viscosity, solubility and degree of starch gelatinization (Flach, 2003).

Table 1.Content of amylose and amylopectin based on the weight of the starch.

Sample Starch (mg)

Amylosa (mg)

Amylopektin (mg)

Amylosa (%)

Amylopektin (%)

Tapioca 97.87 21.08 76.79 21.54 78.46

Cassava flour 55.13 21.18 33.94 38.43 61.57

Mocaf 50.91 21.69 29.21 42.62 57.38

Wheat flour 42.75 19.33 23.41 45.22 54.78

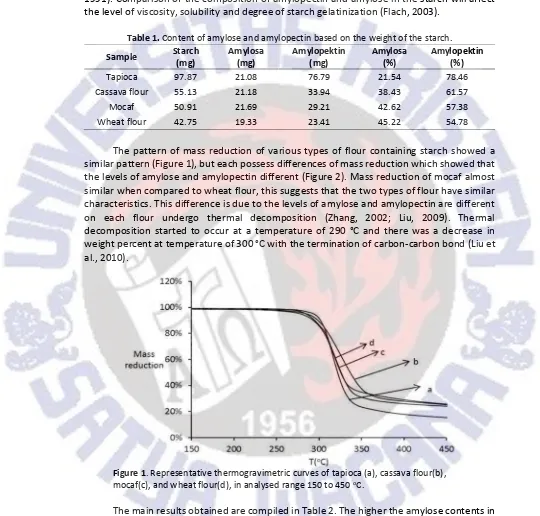

The pattern of mass reduction of various types of flour containing starch showed a similar pattern (Figure 1), but each possess differences of mass reduction which showed that the levels of amylose and amylopectin different (Figure 2). Mass reduction of mocaf almost similar when compared to wheat flour, this suggests that the two types of flour have similar characteristics. This difference is due to the levels of amylose and amylopectin are different on each flour undergo thermal decomposition (Zhang, 2002; Liu, 2009). Thermal decomposition started to occur at a temperature of 290 °C and there was a decrease in weight percent at temperature of 300 °C with the termination of carbon-carbon bond (Liu et al., 2010).

Figure 1. Representative thermogravimetric curves of tapioca (a), cassava flour(b),

mocaf(c), and wheat flour(d), in analysed range 150 to 450oC.

I. Sugiharta, J. Hendri, S.D. Yuwono, W. Simanjuntak

SWUP BC.121

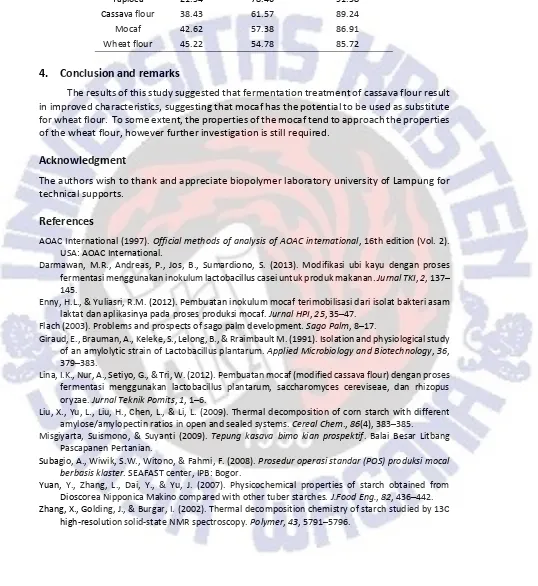

Table 2.content of amylose, amylopectin and mass reduction. Sample Amylose (%) Amylopektin (%) Mass reduction (%)

Tapioca 21.54 78.46 91.58

Cassava flour 38.43 61.57 89.24

Mocaf 42.62 57.38 86.91

Wheat flour 45.22 54.78 85.72

4.

Conclusion and remarks

The results of this study suggested that fermentation treatment of cassava flour result in improved characteristics, suggesting that mocaf has the potential to be used as substitute for wheat flour. To some extent, the properties of the mocaf tend to approach the properties of the wheat flour, however further investigation is still required.

Acknowledgment

The authors wish to thank and appreciate biopolymer laboratory university of Lampung for technical supports.

References

AOAC International (1997).Official methods of analysis of AOAC international, 16th edition (Vol. 2).

USA: AOAC International.

Darmawan, M.R., Andreas, P., Jos, B., Sumardiono, S. (2013). Modifikasi ubi kayu dengan proses fermentasi menggunakan inokulum lactobacillus casei untuk produk makanan.Jurnal TKI,2, 137

145.

Enny, H.L., & Yuliasri, R.M. (2012). Pembuatan inokulum mocaf terimobilisasi dari isolat bakteri asam laktat dan aplikasinya pada proses produksi mocaf.Jurnal HPI,25, 35 47.

Flach (2003). Problems and prospects of sago palm development.Sago Palm, 8 17.

Giraud, E., Brauman, A., Keleke, S., Lelong, B., & Rraimbault M. (1991). Isolation and physiological study of an amylolytic strain of Lactobacillus plantarum.Applied Microbiology and Biotechnology,36,

379 383.

Lina, I.K., Nur, A., Setiyo, G., & Tri, W. (2012). Pembuatan mocaf (modified cassava flour) dengan proses fermentasi menggunakan lactobacillus plantarum, saccharomyces cereviseae, dan rhizopus oryzae.Jurnal Teknik Pomits,1, 1 6.

Liu, X., Yu, L., Liu, H., Chen, L., & Li, L. (2009). Thermal decomposition of corn starch with different amylose/amylopectin ratios in open and sealed systems.Cereal Chem.,86(4), 383 385.

Misgiyarta, Suismono, & Suyanti (2009). Tepung kasava bimo kian prospektif. Balai Besar Litbang

Pascapanen Pertanian.

Subagio, A., Wiwik, S.W., Witono, & Fahmi, F. (2008).Prosedur operasi standar (POS) produksi mocal berbasis klaster. SEAFAST center, IPB: Bogor.

Yuan, Y., Zhang, L., Dai, Y., & Yu, J. (2007). Physicochemical properties of starch obtained from Dioscorea Nipponica Makino compared with other tuber starches.J.Food Eng.,82, 436 442.