Optimising product recycling chains by control theory

U. Kleineidam

*

, A.J.D. Lambert, J. Blansjaar, J.J. Kok, R.J.J. van Heijningen

Eindhoven University of Technology, Faculty of Technology Management, P.O. Box 513, NL-5600 MB Eindhoven, Netherlands

Received 15 March 1999; accepted 24 September 1999 Abstract

In this paper, a modelling method is described for production chains including recycling. It consists of elementary models of standard production operations, connected by market modules. The models are analysed using methods from control theory. These methods allow us to investigate essential properties of the chain concerning its dynamical behaviour, particularly with respect to stability and controllability. These properties are prerequisites for e!ective chain management, as in the evaluation of recycling policy. A case study on paper recycling was carried out to demonstrate the applicability of this method to practice. ( 2000 Elsevier Science B.V. All rights reserved.

Keywords: Recycling; Control theory; Product chain; Sustainability; Optimisation

1. Introduction

Modelling of material and energy #ows has

appeared to be a useful tool in economy, parti-cularly in the study of the behaviour of systems such as product life-cycle chains. A commonly

ap-plied method for chain modelling is the

prod-uct}process chain[1]. This is a chain consisting of alternate transformation processes and product

#ows between these processes. For environmental

purposes, the full material life-cycle within the

tech-nosystem, from `cradle to gravea, is frequently

modelled. In the simplest case it is linear, i.e. it excludes cycles. These linear chains are typically considered in gross energy requirement (GER) and

life-cycle assessment (LCA) studies [2}4]. In these

studies the environmental impact caused by a prod-uct is determined by adding the impacts of all the

*Corresponding author.

processes in the life-cycle of a product in a standard way. In common practice, however, the situation is growing more and more complex because of the increasing importance of the recycling of materials. Traditionally, the emphasis only was on the recycl-ing of process waste, i.e. the waste that is generated as an unintended by-product of production pro-cesses. Nowadays, there is a growing interest for post-consumer or product waste that originates from discarded products. This concern is closely

related to the economic bene"ts that can be

achieved by the enterprises in the chain, the concept of product responsibility and the intention to de-crease both resource consumption and waste quantity. Such a policy is often speci"ed by

catch-words such as closing the chain, although a fully

closed chain is neither obtainable nor desirable [5]. This idea, that stems from the study of the often

surprisingly e$cient functioning of the many

close-ly interwoven processes in nature, is studied in the

interdisciplinary "eld that is named according to

its biological counterparts: industrial ecology, industrial metabolism or industrial symbiosis. For realistic modelling the inclusion of recycle loops is indispensable.

The product}process chain model, in which

phys-ical #ows play an essential role, is controlled by

variousinformation#ows (orsignals). Each unit in

the model, typically a production enterprise, is a partially autonomous decision unit. There are, however, signals to the enterprise from other pro-duction units within the chain, usually based on

transactions (horizontal control). Moreover, the

authorities want to control the chain in such a way

that it acts as a whole in an optimal way (vertical

control). From the point of view of authorities, enterprises, and consumers, a proper policy should be implemented to obtain optimal results. Each

actor has di!erent purposes and is, moreover, able

to make the right decisions based on an optimal adaptation to its surroundings. This implies a com-plicated multi-level hierarchical decision structure and impedes a clear insight into the consequences of decision making, and the choice of optimal decisions.

Many studies in this "eld are restricted to

de-scriptive chain modelling (see for example [6] for a wide range of products from aluminium to packaging products). In fewer cases, the possibility is included of adaptation of internal variables of a mathematical model to external parameters. This holds for optimisation models in which systems operation or technology choice are incorporated. Such models are usually based on mathematical programming (MP-)techniques, such as static and dynamic linear programming, where the optimisa-tion criterion is expressed by an objective funcoptimisa-tion. So far, little attention has been paid to methods for model analysis that are available in systems and control theory. These are widely applied in mech-anical, physical and chemical systems, varying from relatively simple systems like robot arms, up to complex systems such as process industries and power plants. Although analogies between

com-pletely di!erent kinds of systems are abundant in

modelling, this has rarely been applied in studies on the meso, i.e. product chain, level.

A property of product chains, which can be

ana-lysed by control theory, is the controllability. It

embraces questions concerning, for instance, the

possibility for a system to reach a de"nite state

starting from some initial state or concerning the possibility to control a system in such a way that its state follows a de"nite trajectory over time. This is relevant to environmental policy, because environ-mental policy is concerned with reaching some tar-get, for example, a decrease of materials use by 10%, within a de"nite period of time, e.g. 5 years.

It is evident that the e!ectiveness of an

environ-mental policy strongly depends on the possibility of obtaining the proposed targets. In this paper, the application of systems and control theory is elabor-ated on some problems that are relelabor-ated to product chains. Both physical and economic aspects are incorporated, with an emphasis on the environ-mental policy. The resulting model is tested on an existing chain, viz. the Dutch paper chain. This

chain was selected because it includes an e!ective

recycling system. Moreover, it is well documented by rather extended time series of statistical data.

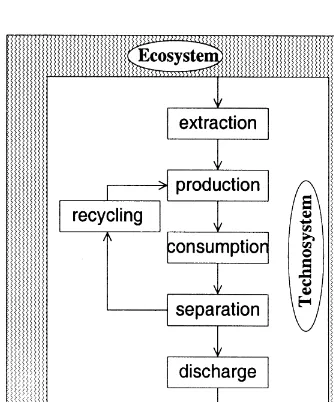

2. The product chain as a system

In industrial ecology (see, e.g. [1]) the physical world is subdivided into ecosystem and technosys-tem. The technosystem involves the settings that are designed and controlled by people. There is a mutual exchange of physical, i.e. material and

energy,#ows between these two systems. In a

sim-pli"ed presentation of the technosystem, #ows of matter and energy are successively extracted,

trans-formed into products, consumed, and "nally

discharged. This is the linear chain that is depicted

in the process}product scheme of Fig. 1. In the real

world modi"cations of the linear chain are

impor-tant. A fundamental extension is the inclusion of loops that represent recycling and reuse of process residues and discarded products. Usually, however, the process and product wastes are only partially recyclable due to technical and economic reasons.

There will always be some remaining#ows that are

discharged to the ecosystem. This is depicted in Fig. 2.

Although the aggregate #ows within the total

Fig. 1. The process}product scheme of a linear chain.

Fig. 2. The process}product scheme of a chain with recycling.

consequently, the#ows and the processes should be

disaggregated. When focusing on such a partial

#ow, for example paper and paper products,

ambi-guity arises in setting appropriate system bound-aries. Moreover there is an exchange of physical

#ows between di!erent production chains, which

cannot be included in the study up to the same extent. In the paper example paper is made of pulp, which in turn is made of wood. Clay and other paper chemicals are added, and so on.

Geographical system boundaries also play a role. In general, not the global system but rather the production system of a particular country or region is studied. This requires the de"nition of import and export. With further detail, disaggregation of production systems may also be needed. Paper production, for example, involves a sequence of

di!erent production steps, which may vary

accord-ing to the kind of paper product that is produced.

Di!erentiation between paper products is also

required with respect to the di!erent characteristics

these products have in the consumption and recycl-ing phases.

Disaggregation and recycling transforms the chains of Figs. 1 and 2 into complicated networks that consist of many strongly interconnected chains. Within these networks, basic modules can be discerned. In the following, the essential features of a basic module will be described and a model of such a module will be presented.

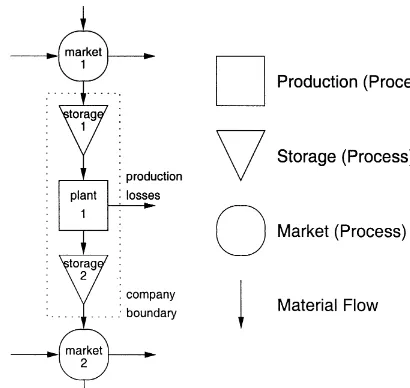

3. A generalised company model

As was stated before, a process}product chain is

considered to be a network of basic units, each represented by a generalised company model.

A characteristic of the product}process chain

de-scription is the succession of product #ows and

processes. Although the description deals with

physical #ows, these are controlled by economic

mechanisms. They are incorporated within the model by the introduction of markets. Transactions of products between the parts of the chain are

described by a market model * a market is the

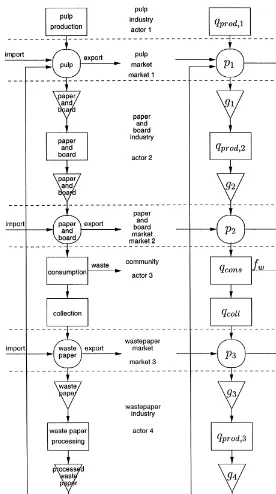

interface between companies. Fig. 3 shows a

simpli-"ed#owchart of a company including two storage facilities, accompanied by two markets that refer to

the input and the output#ows of the system. The

boundary of the company subsystem is indicated

by the dashed line. As a company's basic activity is

the transformation of material#ows; it is

represent-ed as a process (square). Storage is representrepresent-ed by

Fig. 3. A company#owchart.

materials or semi-manufactured products and

orig-inate from a market; leaving#ows are products that

are directed towards another market.

These #owcharts are graphical representations

from which mathematical models can be derived providing insight into the functioning of the chain. As dynamic processes such as storage and dynamic markets play an important role, dynamic models are needed. Such a model is represented here as a set of di!erential equations.

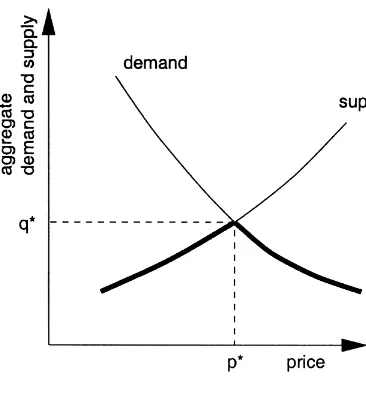

3.1. The market model

Here a market is considered to be a virtual place

in which a trade-o! between demand and supply

takes place. As a whole it is governed by some price mechanism. Although in economic science markets are crucial, the development of quantitative market

models has proven to be extremely di$cult [7}9].

In standard economic theory there is a demand curve that decreases with increasing price, and a supply curve that increases with increasing price. The intersection of these two curves is the market equilibrium. However, the shape of the curves is

a result of di!erent mechanisms (substitution,

change of real income, etc.) that cannot be analysed individually. As an extra complication, the dynam-ics of the system plays a role. Change in supply is

often not instantaneously possible, but requires preparations, such as investments in capital goods, or the recruitment of an appropriately skilled labour force. On the other hand, in the case that demand and supply are in disequilibrium on a mar-ket, the price adjustment will not occur instan-taneously but rather in a dynamic way. A normally functioning market is in equilibrium, but the point of equilibrium will gradually change, because the economy as a whole is not in equilibrium.

For the purpose of a chain model we assume

a strongly simpli"ed market model, which also

de-scribes non-equilibrium situations. To this purpose we observe that two quantities are measurable: the

tradet(in kg/yr), which represents the real product

#ow that enters or leaves the system, and theprice

p(in$/kg). Each of these quantities may vary over

time according to the time scale that is chosen.

It is assumed that there are di!erent producers

(indicated by the indexi) and consumers (indicated

by the indexj). The total supply and demand are

denoted bys

505andd505, respectively. The amount of traded products then reads as follows:

t"min(s505,d505). (1)

In Fig. 4, an example of demand and supply curves is depicted. In caset"s

505(d505there is scarcity, in the caset"s

505'd505there is excess. Competition

mechanisms between di!erent producers and

con-sumers are not modelled so that distribution pro-ceeds proportionally. This means that in case of

excess a producerisupplies the share

d

In case of scarcity a consumerjbuys the share

s505

d505di. (3)

When the production of some producer surpasses t

ithe remaining production is stored. This will only

be possible up to some extent however because storage is associated with costs, and the storage capacity is restricted.

Fig. 4. Supply and demand curves.

into account by dealing with an adjusting mecha-nism that may establish an equilibrium situation. There are two basic theories to describe such a mechanism: the Marshallian theory of quantity

adjustment that assumes a di!erence between

hypothetical prices as a driving force for adjusting

product #ows, and the Walrasian theory of price

adjustment that assumes a di!erence between

hypothetical product #ows as a driving force for

adjusting prices [10]. As in our description

hypo-thetical product#ows, viz. supply and demand, are

at the centre, the Walrasian description is adopted here. Its basic dynamics are described by the following:

p5"c(d

505!s505). (4)

Here cis a proportionality constant, measured in

$/kg2.

3.2. The company model

The company is represented by a stock of re-sources, a transformation process, and a stock of

"nished products, see Fig. 3. Production is adjusted

according to the di!erence between the actual

amount of "nished products and a prede"ned

norm. Let us, for the sake of simplicity, assume that

there is only one producer and one consumer. In this case the subscriptsi,jand tot are omitted. It is assumed that the producer produces to stock, so that the production equals

q"c

1(gs!g) with q*0. (5)

Here g

s is the desired stock, gis the actual stock

and c

1 a proportionality constant expressed in

yr~1. For the stock of"nished products the follow-ing equation holds, because of mass conservation:

g5"q!t. (6)

As a matter of fact, all storage processes are

described by di!erential equations similar to (6).

When companies and markets are combined to a chain or network, markets are nodes for which

the entering#ows equal the leaving#ows because

markets have no storage capacity.

In the model, discontinuities in the functions or in their derivatives occur frequently. Examples are (1), see Fig. 4, and cases in which a splitting of

product #ows takes place. When, for example,

waste is generated, the decision for recycling or

"nal processing might be taken on the basis of the processing costs. In standard modelling techniques like linear programming these discontinuities do

not cause essential di$culties; in control theory,

however, they are usually smoothened.

As an example, for the recycling percentage, the Heaviside function is replaced by the smoothening function, see Fig. 5:

f(p)"1

2(1#tanh(c2(p!p&1))). (7)

Herep

&1is the"nal processing price andf(p) is the

recycling percentage, p is the price for recycling,

c

2 is a constant of proportionality, expressed in

kg/$. In the model incineration is taken as the"nal

processing technology. Thus, directly in#uencing

the incineration price is a method for controlling the recycling percentage.

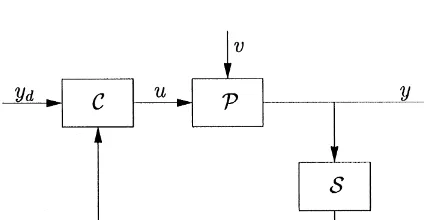

3.3. Chain dynamics

Information#ows (signals) rather than physical

#ows are essential to control theory. The abstract

elements of a simpli"ed control system are given in

Fig. 6. It consists of a processPthat is

Fig. 5. The recycling percentage as a function of the pricepof a product.

Fig. 6. The abstract elements of a control system.

external disturbances, which are denoted byv. The

output signal from the process isy. It is measured

by a sensorS, which produces the measured signal

y

.. The measured signal is compared with the

desired signal y

$ by a controllerC that produces

the control signalu. This signal is fed to the process. The process dynamics are described by the follow-ing evolution equations:

x5"f(x,u,v), (8)

y"g(x,u,v). (9)

For a generalised production system the state

vector is composed of the stocks in the di!erent

storage facilities and the market prices. Eq. (8)

is called the state equation, and it describes the complete chain dynamics. Eq. (9) expresses the out-put as a function of state, inout-put, and disturbances. The set of equations is a standard way of describing a system in control theory, be it physical, chemical, or economic.

4. A chain model:The Dutch paper chain

In this section, a model of a chain is described on the basis of a combination of generalised producers. Several transformation processes are linked, among which a consumption process. One recycle loop is present.

4.1. The chain model

The model that is presented in Fig. 7 is based on the present situation in the Netherlands. Actually, used paper contributes for a considerable part to the raw materials supply, which further consists of primary pulp. Another secondary resource, process waste, is not described by the model, as it is

incorp-orated implicitly in the producer's characteristics.

For the sake of simplicity, existing control mecha-nisms as determined by the Dutch Paper Fibre Convenant (including a takeback obligation for used paper and the determination of a guaranteed price), are omitted in the model. Fig. 7 shows the

#ows of paper, cardboard and their waste as they

currently are encountered in the Dutch paper chain: the paper industry buys a mix of primary pulp and processed wastepaper (secondary pulp) at their respective markets. Subsequently, the paper and board industry supplies the virgin paper it has produced to the paper and board market (market 2). The paper and board market also experiences supply from foreign suppliers. Part of the bulk paper and board is bought by the paper and board product industry, which converts these raw materials into products of paper and board (printed paper, cardboard packaging boxes, and so on).

Currently, wastes from the sector (o$ces, shops,

Fig. 7. The#owchart of the paper chain.

large and many-branched network of wastepaper

collection, largely kept up by non-pro"t

associ-ations. There is no market between paper and board consumption and its collection. The

col-lected#ows form a supply to the wastepaper

Fig. 8. Model outcomes with estimated parameters.

supply waste paper to the market or decide to incinerate it.

4.2. Paper chain modelling

The dynamic variables involved in the presented

model are included in the system's state vectorx.

According to Fig. 7, this vector consists of seven

elements: the prices p

1 through p3 (prices of

pri-mary and secondary pulp, and paper) and the

stocksg

1 through g4 (primary pulp, paper, waste

paper, and secondary pulp). In the model, control

takes place by economic instruments. It is e!

ec-tuated here by in#uencing the prices: by setting the

incineration price or by imposing taxes on primary pulp and on paper, respectively. So the input vector

uconsists of three components. Disturbancesvare

imposed on the system by external supply and demand. These are present for pulp, paper, and

waste paper, so that the disturbance vectorvhas six

components here. When the control aims to mini-mise the environmental impact, the output vector

ymight consist of components that represent the

material and product #ows. Combining all the

company and market models and using the nota-tion introduced above leads to a model in the usual state space notation (8) and (9).

5. Model evaluation

5.1. Parameter adjustment

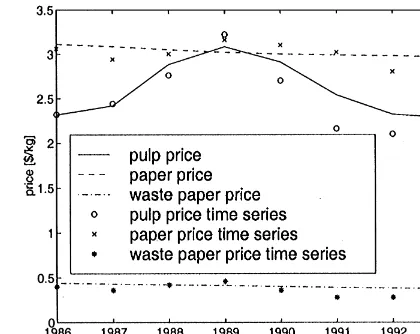

Apart from variables, parameters are encoun-tered in the model that is described here, for example the proportionality constants in (4), (5)

and (7). Several standard parameter identi"cation

techniques exist in control theory, see for example [11]. Here we adjust the parameters by minimising

the squared di!erence between the model outcomes

and available time series. The available time series, which were collected by National Statistics, are given by the prices of pulp, paper, and waste paper. Unfortunately the amount of available data is rather limited here, and the accuracy of these data is somewhat uncertain. Therefore the result of the adjustment must be considered as a rough estimate of the appropriate parameter values. Fig. 8 shows

the course of the yearly averaged prices of the

di!erent products in the paper chain as they

were observed in the period from 1986 to 1993. The model outcomes with a particular parameter set are represented by lines. As can be seen from the"gure they closely approximate the chain be-haviour.

5.2. Stability analysis

An essential characteristic of dynamic systems, which can be analysed by control theory, is its

stability. A system is said to be stable if its state

evolves into a certain constant value. Stability of the controlled system is an absolute requirement since its absence causes signals to grow beyond any limit, eventually destroying and breaking down the system. As an example, an unlimited growth of some price will bring the economic rela-tions in the product chain to an end, a situation which is certainly undesirable for any of the chain actors.

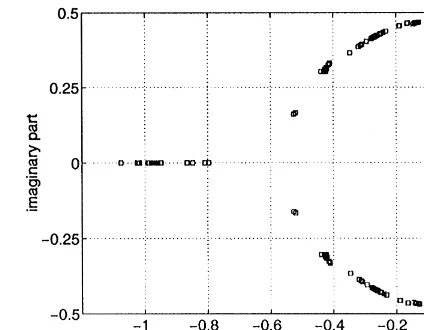

Decisive stability analysis for systems like this, in which discontinuities and non-linearities are en-countered, is a complex task, but two methods are

indicative with respect to stability. Simulationcan

be carried out with the known parameters in-cluded in the system. Results of this calculation are shown in Fig. 9, which represents the state

variablesx

Fig. 9. The stable chain.

Fig. 10. Eigenvalues of the system matrix.

simulation horizon. The simulation indicates stab-ility, albeit for a particular set of initial values.

The second method is based on linearisation

around the points of the system trajectory (x

0(t),u0(t),v0(t)). Via the decomposition around

this reference trajectory (where *x"x!x

0, *u"u!u

0,*v"v!v0), (8)}(9) is linearised. As a result of this transformation (8)}(9) can be written as follows:

*x5"A*x#B*u#E*v,

*y"C*x#D*u#F*v, (10)

withA,B,C,D,E,Fmatrices of appropriate dimen-sions. These relations are valid in a neighbourhood of the reference trajectory. For the linearised system linear control systems analysis can be applied. According to standard linear control theory a

system is stable if the eigenvalues of the matrixA

lie in the left complex half-plane. For the

pro-duct chain system the eigenvalues ofAare depicted

in Fig. 10 for some selected points of the same trajectory as in Fig. 9. As the state vector has seven

components, the matrix A, at each point of the

trajectory, has seven eigenvalues, some of which can coincide. It is shown here that the linearised model is indeed stable because the eigenvalues of the system matrix lie in the left complex half-plane.

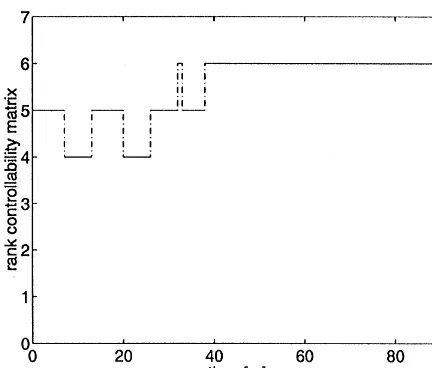

5.3. Controllability analysis

In complex systems, the question of the selection of the inputs that are used for system control is relevant. In a typical plant, for example, many possibilities for process control exist, but sensitive-ness of the output to various inputs can be signi"cantly di!erent. The same might be true for production chains. The relevant question here is whether or not the system is controllable by the selected inputs. A system is said to becontrollableif, for a given initial situation, each value of the state

xcan be reached at a chosen time¹by an

appro-priate choice of the input u. In standard linear

control theory (see, e.g. [12]) controllability can be assessed by examining the rank of the so-called

controllability matrixC"[B AB2An~1B] with

AandBfrom (10), see the Appendix for an

illustra-tive example. For controllability the rank ofCmust

be of the same magnitude as the number of

elements in the state vectorx. Fig. 11 shows the

rank of the product chain controllability matrix for the given trajectory. As the rank of this matrix

varies between two and "ve, the value of the full

Fig. 11. Rank of the controllability matrix.

6. Conclusions

The study of chain dynamics is relevant for appropriate control of product chains, which is of considerable economic, societal, and

environ-mental interest. Control theory o!ers the tools to

analyse system models with respect to essential properties, such as stability and controllability. These tools have long been used to deal with this kind of problem mainly for dynamical mechanical, electrical and chemical systems, and appear to be particularly suited for the analysis of product chains, because product chains show analogues to technical systems. Starting out with a standard production system description, chains can be com-posed.

For the example of the paper chain, some results of stability and controllability analysis are shown. It is made clear that controllability analysis can

help us to "nd strategies to identify the ways to

in#uence product chains. On the basis of the

pre-sented model of the paper chain, it can be con-cluded that the chain is not controllable by the incineration price and taxes on pulp and paper. Additional instruments such as regulatory instru-ments and convenants between government and industry should be taken into consideration.

A principle restriction of the model is that a lin-ear approximation is applied. Further analysis with

inclusion of the non-linear structure of the models is therefore necessary to obtain more general results.

Appendix

As an example to illustrate the controllability of a system, consider the simple two-dimensional linear system de"ned by the following:

x5"

C

1 01 1Dx#

C

1

0

D

u"Ax#Bu. (A.1)For this system the controllability matrix is given by

C"[B AB]"

C

1 10 1D

and has full rank: two. On the other hand if the

input matrixBis changed to

B"

C

01

D

, then C"C

0 0

1 1Dwith rank

C"1.

The"rst system is controllable whereas the second is not. This is intuitively clear because in the second

example only the second component of x5 can be

in#uenced by the inputubutx

2, in turn, does not in#uencex

1because the upper right element ofAis

0. Thusx

1cannot be altered into any desired value.

References

[1] R.U. Ayres, Industrial metabolism, in: J.H. Ausubel, H.E. Sladovich (Eds.), Technology and Environment, National Academy Press, Washington, DC, 1989, pp. 23}49. [2] IFIAS, Report of the International Federation of Institutes

for Advanced Study, Workshop no. 6 on Energy Analysis, Guldsmedshyttan (S), 1973.

[3] J.B. GuineHe, H.A. Udo de Haes, G. Huppes, Quantitative life cycle assessment of products, Part one: Goal de"nition and inventory, Journal of Cleaner Production 1 (1) (1993) 3}13.

[5] T.E. Graedel, B.R. Allenby, Industrial Ecology, Prentice-Hall, Englewood Cli!s, NJ, 1995.

[6] R.U. Ayres, L.W. Ayres, Industrial Ecology: Towards Closing the Materials Cycle, Edward Elgar, Cheltenham, 1996.

[7] K.J. Arrow, F.H. Hahn, General Competitive Analysis, Holden-Day, San Francisco, CA, 1971.

[8] G. SchwoKdiauer (Ed.), Equilibrium and Disequilibrium in Economic Theory, Reidel, Dordrecht, 1978.

[9] C.R. Plott, G. George, Marshallian vs. Walrasian stability in an experimental market, The Economic Journal 102 (1992) 437}460.

[10] A. Takayama, Mathematical Economics, Cambridge Uni-versity Press, Cambridge, 1985.

[11] J.P. Norton, An Introduction to Identi"cation, Academic Press, London, 1986.