Double Shear Connection of Shorea Compression Member Using Combined Double-Sided Adhesive Tapes and Lag Screws

Adrian P. Dharma and Bambang Suryoatmono, Parahyangan Catholic University

ABSTRACT

The use of double-sided adhesive tapes to resist shear force in a connection of wood compression member has the advantage of less construction time than the use of mechanical fastener such as lag screw because it is not necessary to make holes in connection with double-sided adhesive tapes. However, connection with mechanical fastener is more ductile compared to connection with double-sided adhesive tapes. To resist the same force, a connection with combined double adhesive tapes and lag screws needs shorter connection length compared to a connection with lag screws only. In this paper, three types of compression member connections are studied, namely connection with double adhesive tapes only (type 1), connection with lag screws only (type 2), and connection with combined double adhesive tapes and lag screws (type 3). The performance of each type of connections in terms of strength, initial stiffness, and ductility are studied experimentally. The thickness, width, and length of double adhesive tape are 1.1 mm, 20 mm, and 300 mm, respectively. The diameter of lag screw is 9.53 mm (3/8 in.). Four specimens for each connection type were laterally loaded on universal testing machine (UTM) until failure occurred. Load-deflection curve of each specimen were recorded. The average strength of the first, second, and third types of connections are 15.60 kN, 27.71 kN, and 31.22 kN, respectively. The average initial stiffness of the first, second, and third types of connections are 1.58 kN/mm, 4.32 kN/mm, and 4.33 kN/mm, respectively. The average ductility of the first, second, and third types of connections are 1.41, 5.60, and 4.63, respectively. It can be concluded that connection that utilizes combined double-sided adhesive tapes and lag screws has the highest performance in terms of strength and initial stiffness. Although the ductility of wooden connection that utilizes combined double-sided adhesive tapes and lag screws is lower than that of wooden connection that utilizes lag screw, it is much higher (3.3 times) than that of wooden connection that utilizes double-sided adhesive tape only.

INTRODUCTION

Nowadays, construction project is increasing rapidly. In response to that, the world needs less time and efficient method of construction. There are many factors that affect construction time. In wood structures one of those factors is construction time to join two or more structural members. Until now, a connection usually uses dowel type mechanical fastener such as nail, bolt, screw, and lag screw. Those type of fastener penetrates wooden member in certain depth to withstand the load. Threaded dowel type fasteners such as screw, bolt, and lag screw need holes prepared with drilling process to penetrate wooden members. Unthreaded dowel type fastener penetrates wood member through hammering process. Both drilling process and hammering process need construction time. Beside of dowel type connection, there is adhesive type connection, such as glue or adhesive tape. This type of connection needs no holes to connect two or more wooden members. It relies on adhesive force to withstand the load. Therefore, this type of connection needs less construction time than dowel type fastener. Another advantage of adhesive type connection is that corrosion is not a problem.

A few researches on wooden connection using double-sided adhesive tape have been done in the past decade. Fukuta et al (2013) performed double-shear testing to investigate the mechanical performance of joints formed using double-sided adhesive tape and compared the performance with nailed connections. The conclusion is that the former had greater shear strength than the latter. Fukuta et al (2013) utilized not only double-side adhesive tape but also wooden dowel in the connections. To increase ductility and strength, the wooden dowel can be replaced by more ductile metal dowel (mechanical fastener) such as nail, screw, lag screw, or bolt (Forest Product Laboratory 2010).

More recent study on static shear strength of five types of connections, namely 145 μm thick adhesive tape, 1040 μm thick adhesive tape, combined 145 μm thick adhesive tape and 10 mm diameter wood dowel, combined 1040 μm thick adhesive tape and 10 mm diameter wood dowel, and nails only, showed that connection type with the highest strength and the lowest ductility was the one with combined 145 μm thick adhesive tape and 10 mm

diameter wood dowel. Connection with the lowest strength and highest ductility is the one with nails only (Otawa et al 2015, Otawa et al 2016).

Performance in terms of strength, initial stiffness, and ductility of double shear connection using double-sided adhesive tape is studied experimentally in this paper. Compressive axial loading was applied to the wood members using universal testing machine (UTM) so the connection was loaded laterally. The first connection type utilizes double-sided adhesive tapes, the second connection type formed utilizes lag screws, and the third type utilizes combined double-sided adhesive tapes and lag screws. All three connection types use identical material and the members are of the same dimensions so the results can be compared to each other. Summary of the specimens are shown in Table 1.

Table 1: Specimens summary

Specimen Type Connecting Material Number of specimens 1 Double-sided adhesive tape (1.1 mm thick) 4

2 Lag screw (9.53 mm diameter) 4

3 Combined double-sided adhesive tape (1.1 mm thick) and lag screw (9.53 mm diameter)

4

MATERIALS AND METHODS

Specimen Preparation

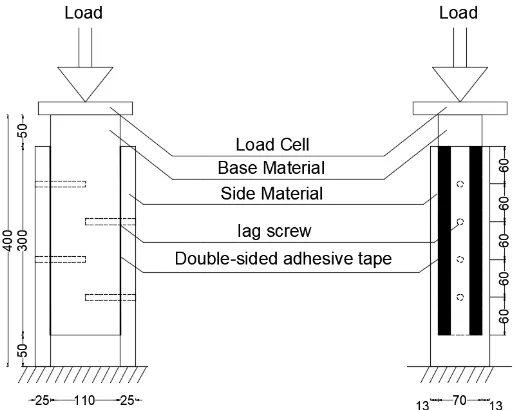

In this study, double-shear connections were prepared. Fig.1 shows the specimens dimensions. Base material (main member) was air-dried Meranti wood (Shorea sp) with dimension of 70 mm × 110 mm × 350 mm, average specific gravity for first, second, and third connection types are 0.70, 0.76, and 0.77, respectively, and average moisture content for first, second, and third connections types are 16.50%, 16.00%, and 16.50%, respectively. Side materials (side members) were air-dried Meranti wood (Shorea sp) with dimension of 25 mm × 95 mm × 350 mm, average specific gravity for all type of connections is 0.69, and average moisture content for first, second, and third connections are 16.50%, 16.25%, and 15.75%, respectively. The connectors for base and side materials are two acrylic double-sided adhesive tapes, each of which has dimensions of 1.1 mm x 20 mm x 300 mm. Metal dowel fasteners used in this study are lag screws with 9.53 mm of diameter.

Compression Test of Double Shear Connection

Compression test was performed to determine the performance of each type of connections. Before being loaded, each specimen was placed between two rigid steel plates on top and bottom (see Fig. 2). The loading is displacement controlled with a rate of 2.4 mm/minute. Linear Variable Differential Transformer (LVDT) was attached to measure slip displacement of the connection. Axial load of the main member during the test, and hence lateral load to the connection, was recorded directly in the computer connected to the UTM. Therefore, load-displacement curve could be obtained for each specimen. Fig. 3 shows the average load-displacement curve of four specimens for each connection type.

Figure 2: Experimental setup

RESULTS AND DISCUSSION

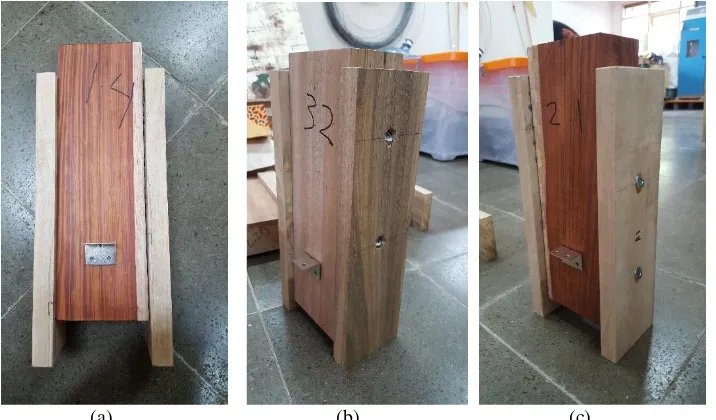

Fig. 4 shows failure modes of each type of connections. As seen in Fig. 4(a), connection with double-sided tapes failed in a brittle manner. The tapes failed to join the main and side members. Fig. 4(b) and 4(c) show that type 2 and type 3 connections failed in ductile manner. Large deformation could be obtained because the head of lag screws pressed the side members and the members experienced compression perpendicular to the grain. If wood is subjected to compression perpendicular to the grain, it tends to undergo large deformation (Forest Product Laboratory 2010). In connection with combined double-sided adhesive tapes and lag screws (type 3), although the tapes had failed, the connection could resist more loads and displacement due to the presence of lag screws. From the load-slip displacement curve, strength, initial stiffness, and ductility of each connection type can be obtained. Strength is defined as the maximum load in the load-displacement curve. Strength of type 1, 2, and 3 connections are 15.60 kN, 27.71 kN, and 31.22 kN, respectively (Table 2). Clearly the strength of the double shear connection with combined double-sided adhesive tapes and lag screws is the highest.

(a) (b) (c)

Figure 4: Failure modes of connections type (a) 1, (b) 2, and (c) 3

Table 2: Average values of experimental results

Specimen Type Strength [kN] Initial Stiffness [kN/mm] Ductility

1 15.60 1.58 1.41

2 27.71 4.32 5.60

3 31.22 4.33 4.63

Initial stiffness of each connection is measured by the slope of load-displacement curve at zero displacement. Region with constant slope means linear load-displacement relationship. It is the elastic region. Initial stiffness for first, second, and third type of connections are 1.58 kN/mm, 4.32 kN/mm, and 4.33 kN/mm, respectively (Table 2). This means, in the elastic region, the connection with double-sided adhesive tapes is very flexible compared to the other two types of connections.

Ductility of a connection is defined as the ratio of maximum displacement and the displacement at the end of elastic region. Ductility shows the ability of the connection to deforms beyond the elastic limit. Ductility for first, second, and third types of connections are 1.41, 5.60, and 4.63, respectively (Table 2). The low ductility value in the connection with double-sided adhesive tapes confirms that the connection failed in brittle manner.

CONCLUSION

ductility. The second type of connection that uses lag screws have the highest ductility. The third type of connection that utilizes combined double-sided tapes and lag screws have the largest strength. It is recommended to conduct further research to investigate the effect of other parameters such as lag screw dimensions, double-sided tape dimensions, wood specific gravity, and moisture content, on the performance of double shear connections.

ACKNOWLEDGEMENTS

The authors wish to acknowledge the Faculty of Engineering, Parahyangan Catholic University for the financial support and the Structural Laboratory facility.

REFERENCES

American Wood Council. 2014. National Design Specification for Wood Construction 2015 Edition. American Forest & Paper Association. Leesburg, VA

Brockman W., Ludwig P., Klingen\ J., Schrӧder B. 2008. Adhesive Bonding Materials, Application and Technology. Lambsheim.

Forest Products Laboratory, 2010. Wood Handbook-Wood as Engineering Materials. General Technical Report FPL-GTR-190. Madison, Wisconsin.

Fukuta S., Nomura M., Nishizawa M., Yamasaki M., Sasaki Y. 2013. Composition of wooden joint by double-faced tape and wood dowel. Wood Industry 68:55-59. In Japanese.

Ogawa K., Sasaki Y., Yamasaki M., Fukuta S. 2015. Theoretical estimation of mechanical properties of

plywoodsheathed shear wall with combined use of adhesive tape and wood dowels. Wood and Fiber Science 47, 4:421-430