Chapter18 - Statistical Applications in Quality Mgt

Teks penuh

Gambar

Dokumen terkait

One of the most common causes of indoor allergy symptoms is the house dust mite. It´s estimated that up to 85% of asthma cases˙eczema and hay fever too˙are caused by the fecal

In fact, many small business owners don’t understand the process or complain that conducting a market analysis is too complicated or too expensive and wonder why or if it is

Operation Process chart (OPC), Process Flow chart, charts Assembly, and the scheduling method is IE the basic tools needed in the planning and production control in SMEs (Kunday

Motivation Process Based on the chart above, if character education is carried out with certain principles and a strong commitment from the teacher and the community, it will affect

24 | P a g e 2.3.1 Company’s Project Lifecycle Process In this study the emphasis is on major capital projects within CCP and the causes of project delays and its effects,

If it is complete and the pupil is spared, the patient Table I: The more common systemic diseases with ocular involvement Disease More common ocular manifestations Diabetes

readiness of human resources in using computer technology is one of the important factors in terms of public services.Therefore we need a computer technology transfer process that is

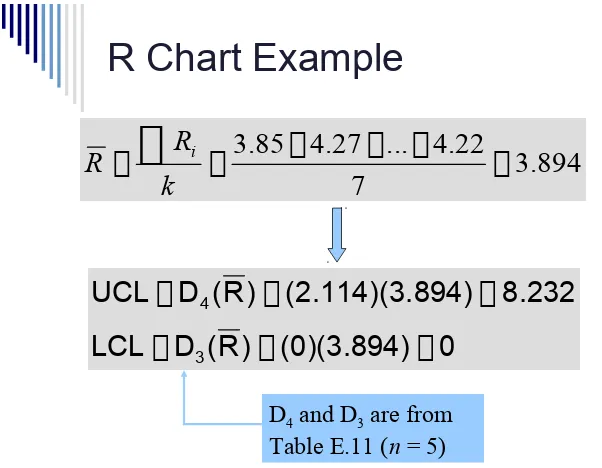

The method used in this study is the Statistical Quality Control SQC method, where this method is used to control defects from the initial process to the final process in the company